127728026-binder-del-alumno.pdf

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View 127728026-binder-del-alumno.pdf as PDF for free.

More details

- Words: 4,534

- Pages: 227

Loading documents preview...

Subject

Content

Tab

Boomer 281/282 DC15

Introduction

1-4

Safety

5-22

Component location

23-34

Valves location

35-50

Daily checks

51-72

Operators platform

73-82

Traction

83-96

24V

97-106

Positioning

107-134

Electrical system

135-152

Air & Water system

153-162

Drilling

163-194

Telescopic feed

195-198

Cut hole

199-204

Swellex

205-223

Options

Training

Introduction

1 of 223 1

2 of 223

Introduction Teacher name: ____________________ Training hours 08,00 – 16,00 Tea / coffee brakes to be discussed 10,00 / 14,00 Lunch time to be discussed 12,00 Smoke brakes to be negotiated No smoking in Lecture room No Phone calls during lecture No computers during lecture Written check questions after each section Written exam after training Practical 3 of 223 2

4 of 223

Safety

1

5 of 223

6 of 223

Safety Knowledge target for this section You will after this section know safety features: Signs and symbols (warnings), Risk area of the rig, warning signals, emergency stops, fire fighting equipment

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

7 of 223

Safety References in documentation Safety Manual

3

8 of 223

Safety Content (Boomer 280-Series) Always read the safety instructions Location of Ansul and Fire extinguishers Emergency stop ”Beacon” Risk areas

4

9 of 223

Safety Fire fighting - ANSUL System A – Activator B – Nozzles C – Fire Extinguisher D – Propellant cartridge

5

10 of 223

Safety Fire fighting - ANSUL Activators

6

11 of 223

Safety ANSUL Activators

Check fire (option)

Ansul

7

12 of 223

Safety Fire extinguisher

8

13 of 223

Safety Emergency Stop

Emergency stop button

Indicator light

9

14 of 223

Safety Audio and visual alarms Horn button

Strobe

10

15 of 223

Safety Risk Areas during tramming and drilling

11

16 of 223

Safety Warning The manuals contain warnings. The warnings are in boxes and contain a safety message preceded by a warning symbol and a signal Different degrees of warnings – Danger – Warning – Caution

12

17 of 223

Safety Signs

13

18 of 223

Safety Signs

14

19 of 223

Safety Rig Stability

15

20 of 223

Safety Knowledge target for this section Be aware of: – The different signs and symbols (warnings) – Risk area of the rig when tramming – What kinds of warning signals the rig is equipped with – Functionality of the emergency stops – Different fire fighting equipment

16

21 of 223

22 of 223

Component location B281/B282-DC15

1

23 of 223

24 of 223

Component Location Knowledge target for this section Get a general knowledge of where the major component on the rig is located

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

25 of 223

Component Location References in documentation Operators Instructions – Component Locations

3

26 of 223

Component Location Main Components Protection roof Feed

Rock Drill

Electrical Cabinet Cable reel

Boom Rear Jacks Front Jacks

4

27 of 223

Component Location Right Rear Diesel engine air filter Ansul cartridge and powder container

Water reel

El.motor and pumps for boom 2 Rear Jacks 5

28 of 223

Component Location Right Rear

6

Hydraulic oil – Electric filling pump

29 of 223

Component Location Left Electrical cabinet Cable reel

ECL Lubrication tank

El. motor and pumps for boom 1

7

30 of 223

Component Location Behind Water Reel Water pump

Water inlet strainer

8

31 of 223

Component Location Inside Water Reel ISO switch Battery

Main fuse

9

32 of 223

Component Location Knowledge target for this section Be aware of: – The major components on the rig eg. Boom, cable reel, Pumps

If the rig is available: – Have walked around the rig and seen the components

10

33 of 223

34 of 223

Valves Location B282-DC15

1

35 of 223

36 of 223

Valves Location Knowledge target for this section Be aware of the different adjustment valves on the drill rig

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

37 of 223

Valves Locations References in documentation Maintenance Instructions – Component Locations

3

38 of 223

Valves Location VB 1 block

CT4

CT5 CT2 CT1 CT3/ Y156

4

39 of 223

Valves Location Valve V10 and V11 Percussion Pressure

V11 Percussion Pressure full drilling V10 Percussion Pressure Collaring

5

40 of 223

Valves Location V3a Rotation Speed V3a

6

41 of 223

Valves Location V3a Rotation Speed (Reaming)

V3a

7

42 of 223

Valves Location Vdp Damper Pressure

Vdp

8

43 of 223

Valves Location Vfm Maximum Feed Pressure

Vfm

9

44 of 223

Valves Location Vfl-Collaring / Vfh-full drilling pressure Vfh Vfl

10

45 of 223

Valves Location RPCF Regular/Reaming V1a (Regular)

11

V1b(Reaming)

46 of 223

Valves Location Vaj Anti jamming, feed return movement

Vaj

12

47 of 223

Valves Location V8/V17 Telescopic feed pressure difference and max feed return V17 V8

13

48 of 223

Valves Location V6 Feed pressure full drilling (Reaming)

V6

14

49 of 223

Valves Location Knowledge target for this section Be aware of: – Where the adjustment valves are located and their function

If the rig is available: – Have walked around the rig and seen the components

15

50 of 223

Daily checks

Inspections points

1

51 of 223

52 of 223

Daily Checks Knowledge target for this section Be aware of the daily checks, understand the importance of cleaning between shifts

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

53 of 223

Daily Checks References in documentation Maintenance schedules rig – Every 10 Percussion hour – Every 10 Diesel hour

Maintenance instructions rock drill Operation manual diesel engine – Maintenance Schedule

3

54 of 223

Daily Checks Purpose of daily checks Detect faults at an early stage Prevent costly secondary damage Prevent breakdowns Prevent personal injury

4

55 of 223

Daily Checks Cleaning – Between shifts To be able to see wear To be able to see damages

5

56 of 223

Daily Checks What to check for Check safety devices Check hoses and cables Check oil levels Check the lubrication points Keep your eyes open for possible leakage and wear Pay attention to any faults in the function of the controls

6

57 of 223

Inspections Points Emergency stop devices Control objects – Emergency stop devices

Action – Check the function of all the emergency stops on the rig

7

58 of 223

Inspections Points Fire extinguishers

0

0

OK

OK

Control objects – Fire extinguishers

Action – Make sure the indicator is in the green zone

1250 0098 88

– Check that none of the seals are broken and that service has been carried out within the prescribed time – Check that the fire extinguisher and its holder are not damaged

8

59 of 223

Inspection Points Check/Service points on feed

9

CHECK POINTS

SERVICE POINTS

•Hoses, tension and wear •Hose drum •Damages & oil leaks •Tension of ropes •Cradle and Feed retainers •Wear strips & Slides •Drill Steel Bushings •Centre drill steel support •Limit switch function •Rock drill attachment

•Tightening of bolts •Grease all lub. Points •Torque the tension bushing on feed cylinder •Wear strips & Slides •Ropes •Drill steel bushings •Bearings, pulley wheel & hose drum

60 of 223

Inspection Points Feed Control objects – Guide rails and slide pieces

Action – Check for wear on slide pieces and slide rails. Adjust if necessary

10

61 of 223

Inspection Points During Drilling Hyd. oil temp Water pressure Hydraulic pressures – Feed – Rotation – Percussion Lubrication pressure Return filters Hour meter Leakages Broken or damaged hoses

11

62 of 223

Inspection Points Check/Service points on the boom

12

CHECK POINTS

SERVICE POINTS

•Hoses, tension and wear •Damages & oil leaks •Drill Steel Bushings

•Tightening of bolts •Grease all lub. Points

63 of 223

Inspection Points Rock Drill Lubrication Air Lubrication oil Front Bushing Flushing seals Drill Collaring Accumulators Pressure and flow Pressure and frequency Check clearance No leaks Always on the shank

13

64 of 223

Inspections points Rock Drill Control objects – Rock drill accumulator charge pressure

Action – Press in the pin on the test valve. If the accumulator is charged, the pin will stick out by 4.5 mm and give a firm resistance when pressed in

14

65 of 223

Inspections points Rock drill cradle Control objects – Machine cradle

Action – If necessary, adjust the cradle to the correct height and centre directly on the beam

Clearance 5-7 mm

15

66 of 223

Inspections points Hydraulic system Control objects – Hydraulic oil level

Action – Top up if necessary

16

67 of 223

Inspections points Compressor Control objects – Oil reservoir

Action – Check the oil level in the oil reservoir (See instruction on how to check)

17

68 of 223

Inspections points Water system Control objects – Water inlet strainer

Action – Clean by opening blue valve

18

69 of 223

Inspections points Fire fighting system ANSUL Control objects – Nozzles/Hoses – Powder container

Action – Check that nozzles are clean and the protective caps are fitted and tight – Check that there is no damage to the powder container

19

70 of 223

Inspections points Diesel Engine oil level Control objects – Engine oil level

Action

Oil stick

– Top up if necessary

Oil fill

20

71 of 223

Daily checks Knowledge target for this section Be aware of: – The daily checks, what to check

Know: – The importance of performing daily checks – The importance of cleaning the rig between shifts

21

72 of 223

Operators platform B280-DC15

1

73 of 223

74 of 223

Operators platform Knowledge target for this section Know the functionality of the controls for driving, brake test, driving

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

75 of 223

Daily inspections References in documentation Operators Manual – Controls

3

76 of 223

Operators platform Drivers seat Instrument panel Levers for roof Levers for jacks Levers for diesel positioning

4

77 of 223

Operators platform Drilling and Positioning panel

5

78 of 223

Operators platform Instrument panel

T2 – Ignition key T4 – Parking brake T5 – Drilling lights T6 – Tramming lights T8 – Lamp test T10 – Gear lever T12 – Horn T16 – Park brake test button P1 – Hour meter for engine P2 – Fuel gauge 6

79 of 223

H11 – Parking brake H12 – Brake pressure H13 – Engine temp H14 – Hydraulic oil level H15 – Transmission H16 – Engine lubrication oil pressure H17 – Suction filter H18 – Battery charging H20 – Preheat indicator

Operators platform Brake test – Parking brake 1. Make sure that the parking brake is applied 2. Start the diesel engine and engage 2nd gear 3. Gradually increase engine rpm to maximum 4. Check the rig for movement. If the rig moves the brakes must be adjusted without delay – Note Do not continue this check for longer than 4 seconds at most

7

80 of 223

Operators platform Brake test – Service brakes 1. Start the diesel engine 2. Depress the brake pedal and hold it down 3. Release the parking brake 4. Engage 2nd gear 5. Gradually increase engine rpm to maximum 6. Check the rig for movement. If the rig moves the brakes must be adjusted without delay – Note Do not continue this check for longer than 4 seconds at most

8

81 of 223

Operators platform Knowledge target for this section Know the functionality of the controls for driving – – – –

Instrument panel Drill panel Boom panel Levers for jacks/roof

Know how to: – Perform parking brake test – Perform service brake test – Start the rig

Know the basics of driving the rig – Driving forward/backward – Turning – Gear selecting

9

82 of 223

Traction B282 DC15

1

83 of 223

84 of 223

Traction Knowledge target for this section Understand the hydraulics for brake and steering

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

85 of 223

Daily inspections References in documentation Diagrams and Drawings – Hydraulics

3

86 of 223

Components

5 6

4

2 3

1 4

87 of 223

Starting the system

5

88 of 223

Applying the brakes

6

89 of 223

Releasing the brakes

7

90 of 223

Park brake

8

91 of 223

Releasing Park brake

9

92 of 223

Activating Park brake

10

93 of 223

Steering

11

94 of 223

Traction Knowledge target for this section Be aware of: – The components in the brake and steering circuit – How the circuit is started hydraulically – How the brake and steering circuit works

12

95 of 223

96 of 223

Boomer

24V

1

97 of 223

98 of 223

Boomer 24V Knowledge target for this section Know how the 24 V system is built up

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

99 of 223

Daily inspections References in documentation Diagrams and Drawings – Electrics

3

100 of 223

Boomer 24V Main Switch Main switch

4

101 of 223

Power on

5

102 of 223

Ignition sequence

6

103 of 223

Interlock brake valve circuit

7

104 of 223

Cable reel 3 laps left

8

105 of 223

Boomer 24V Knowledge target for this section Be aware of: – What happens in the 24V circuit when the main switch is turned on – What happens in the circuit when the ignition key is turned – How the interlock brake valve circuit works – What happens when there are only three laps left on the cable reel

9

106 of 223

Positioning

1

107 of 223

108 of 223

Positioning Knowledge target for this section Controls for positioning, hydraulics for positioning

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

109 of 223

Positioning References in documentation Diagrams and Drawings – Hydraulics

Operators Instructions – Controls

3

110 of 223

Positioning Positioning panel Feed look out Feed rotation

Boom extension Feed extension Boom positioning

Anti parallel button

4

111 of 223

Positioning Overview of boom cylinders

5

K – Feed rotation

Z - Lock – out

FE – Feed ext

B – Boom ext

A1 – Boom cyl. rear left

A2 – Boom cyl. rear right

E1 – Boom cyl. front left

E2 – Boom cyl. front right

E1 FE

E2

B

Z K A1

112 of 223

A2

Positioning Levers for jacks and roof Left roof cyl

Right front jack Right slide

Right roof cyl

Rear jacks Left slide Left front jack

6

113 of 223

Positioning Levers for reels and diesel positioning 1/2 Diesel positioning Cable reel Hose reel

7

114 of 223

Positioning Levers for reels and diesel positioning 2/2 Cable reel override button Warning light for 3 laps left

8

115 of 223

Positioning Rear Controls for Reels Water reel Cable reel

9

116 of 223

Positioning Components

10

117 of 223

Positioning Diagram legend Red – pressure Blue – tank/return Green – pilot pressure (40bar) Yellow – other pilotpressure

11

118 of 223

Positioning Raising the Boom 1/2

12

119 of 223

Positioning Raising the Boom 2/2

13

120 of 223

Positioning Lowering the boom 1/2

1250 0060 05

14

121 of 223

Positioning Lowering the boom 2/2

15

122 of 223

Positioning Moving the boom to the right 1/2

1250 0060 05

16

123 of 223

Positioning Moving the boom to the right 2/2

17

124 of 223

Positioning Moving the boom to the left 1/2

1250 0060 05

18

125 of 223

Positioning Moving the boom to the left 2/2

19

126 of 223

Positioning Using the anti-parallel system feed swing 1/2

1250 0065 20

20

127 of 223

Positioning Using the anti-parallel system feed swing 2/2

21

128 of 223

Positioning Using the anti-parallel system feed lift 1/2

1250 0065 20

22

129 of 223

Positioning Using the anti-parallel system feed lift 2/2

23

130 of 223

Positioning Movement of the feed

24

131 of 223

Positioning Jacks

25

132 of 223

Positioning Roof

26

133 of 223

Positioning Knowledge target for this section Be aware of: – The controls for positioning, which lever does what and where are they located

Be able to describe the following – How the positioning works hydraulically – Which are the main components – Boom positioning valves / functions

27

134 of 223

Electrical system

1

135 of 223

136 of 223

Electrical System Knowledge target for this section Be aware of the components in the electrical system

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

137 of 223

Positioning References in documentation Diagrams and Drawings – Electrics

Operators Instructions – Electrics system

3

138 of 223

Electrical System Warning lights on A-cabinet

4

Phase sequence fault

Low hyd. Oil level

High hyd. Oil temp

Motor overload

Return oil filter indicator

Power on

139 of 223

Electrical System Switches on A-cabinet Diode test Emergency stop

Lamp test

Motor switch, motor nr 2 Motor switch, motor nr 1

5

140 of 223

Electrical System Main Switch

6

141 of 223

Electrical System The right side of the A-Cabinet V33 Diode bridge for check lights

T50 Internal Transformer

7

142 of 223

K29

Electrical System The right side of the A-Cabinet

K64 Start relay pump1

K164

K74

Emergency stop power supply relay

Start relay pump1

K163

K28

24V Power Supply changer

Low hydraulic oil level relay

K31 24V Power supply changer

K128 Emergency stop relay

K30 Compressor timer relay

8

143 of 223

Electrical System The right side of the A-Cabinet K132 Water Pump relay K127 Compressor relay

9

144 of 223

Electrical System The right side of the A-Cabinet F131

F18

F20

Water Pump Fuse

Fuse 3 phase outlet

Back-Up Fuse

F19 F126 Compressor Fuse

10

145 of 223

Control Transformer Fuse

Electrical System The right side of the A-Cabinet

F22 F17

F66

Battery Charger

F77

F91

Fuse Control 110V AC Pump1 Fuse descriptions

F76 Fuse Control 110V AC Pump1

11

146 of 223

F48

F67

F49

Headlight 24V AC

Control 24V DC

Working light 220V AC

Electrical System The right side of the A-Cabinet S13 Select Measuring

12

147 of 223

P12

K10

Voltmeter/ Ampmeter

Earth-fault relay

Electrical System The right side of the A-Cabinet P66 Hour meter Rock Drill 1

P76 Hour meter Rock Drill 1

ECL Rock Drill Lubrication

K26 Phase rotation F6 Fuse relay

K133 Water pump time relay

K32

13

148 of 223

Electrical System ECL System

Diod to indicate lubrication time T2 Lubrication Dosage T1 Lubrication pulse time

Indicates that power is on

14

149 of 223

Electrical System The Left side of the A-Cabinet U158 Battery charger

U180 Rectifier

X1 3 Phase outlet

15

150 of 223

Electrical System Knowledge target for this section Be aware of: – The different components in the electrical system – Where the components are located

If the rig is available: – Have walked around the rig and seen the components

16

151 of 223

152 of 223

Air & Water system B281/282-DC15

1

153 of 223

154 of 223

Air & Water Knowledge target for this section Understand the air and water system

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

155 of 223

Positioning References in documentation Diagrams and Drawings – Air

3

156 of 223

Air & water schedule Valves for rock drill lubrication (Y106, Y107) Compressor

Watermist Water pump and flow guard B141

Watermist

4

157 of 223

Air & water schedule Y106 Y107

5

158 of 223

Air & water schedule

B141

6

159 of 223

Air blowing

Air 7

160 of 223

Water (Flushing)

Water 8

161 of 223

Air & Water Knowledge target for this section Be aware of: – How the air and water circuits work

9

162 of 223

Drilling B281/282-DC15

1

163 of 223

164 of 223

Drilling Knowledge target for this section Controls and gauges for drilling, drilling circuits, components

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

165 of 223

Drilling Drilling Panel 1/2

Percussion pressure Feed pressure

Rotation pressure Pump on

ECL Collaring Full drilling

3

166 of 223

Drilling Drilling Panel 2/2

Pump off Water

Percussion Feed movement

Rotation

Hole size (option)

4

167 of 223

Drilling Manometers Return oil filter

Air

Water

Damper rock drill 2

Damper rock drill 1

5

168 of 223

Drilling Check points during drilling Hyd. oil temp Water pressure Hydraulic pressures – Feed – Rotation – Percussion Lubrication pressure Return filters Hour meter Leakages Broken or damaged hoses

6

169 of 223

Drilling Power packs DCS 12 1-boom

P1

P2

DCS 12 2-boom, DCS 15/18 all rigs

P1 P2

P3

P1 – Main pump (positioning and percussion). (damper only on 1 boom) P2 – Rotation pump P3 – Damper pump (only 2-boom), water pump (only 1-boom) 7

170 of 223

Drilling Hydraulic diagram legend Red – pressure Blue – tank/return Green – pilot pressure (50bar) Yellow – other pilot pressure

8

171 of 223

Drilling Main Components 1/2 Rotation Unit

Rock Drill

Feed

RPCF Valve Low/High Feed Pressure Regulator Feed Pressure Control Valve

Button for loosening of drill bit

Antijamming valve

Rotation Lever

9

Percussion Lever

Feed Movement Lever

172 of 223

Drilling Main Components 2/2 Limit switch

VB1

Main pump

ECL Pump

Flow regulation for damper

Rotation pump Damper pump

Flow regulation for rotation

10

173 of 223

Drilling Main pump start – The first 8 seconds To tank

Step 1

Percussion/Rotation

Power the water pump

Rotation 11

174 of 223

Drilling Main pump start – After 8 seconds Step 2

12

175 of 223

Drilling Rotation 1/2

13

176 of 223

Drilling Rotation 2/2

14

177 of 223

Drilling Feed forward 1/2

15

178 of 223

Drilling Feed forward 2/2

16

179 of 223

Drilling Feed Reverse

17

180 of 223

Drilling Drill Sequence – Collaring 1/2

40-50 bar

230 bar

18

181 of 223

Drilling Drill Sequence – Collaring 2/2

V11

19

182 of 223

Drilling Drill Sequence – Full Drilling 1/2 image description

65-100 bar

20

183 of 223

Drilling Drill Sequence – Full Drilling 1/2

V12

21

184 of 223

Drilling Limit Switch (Black Jack) 1/2

22

185 of 223

Drilling Limit Switch (Black Jack) 2/2

23

186 of 223

Drilling Drilling Protection Systems RPCF (Rotation Pressure Control Feed) FPCI (Feed Pressure Control Impact) Anti Jamming (Feed reverse with full system pressure)

24

187 of 223

Drilling Drilling Protection System 1 – RPCF 1/2 50-60 bar

50 bar

Pressure limit set to appr. 20 bar above normal rotation Pressure

25

188 of 223

Drilling Drilling Protection System 1 – RPCF 2/2

Pressure increases

Pressure increases

26

189 of 223

Drilling Drilling Protection System 2 – FPCI (Anti jamming) 1/2

Pressure increases

Pressure increases

27

190 of 223

Drilling Drilling Protection System 2 – FPCI (Anti jamming) 2/2

28

191 of 223

Drilling Loosening the drill bit 1/2

29

192 of 223

Drilling Loosening the drill bit 2/2

30

193 of 223

Drilling Knowledge target for this section Be aware of: – The different controls for drilling – The checkpoints during drilling – Powerpack setup – Hydraulic circuits for drilling – Drilling protection RPCF, Anti-Jamming and FPCI

31

194 of 223

Telescopic feed

1250 0064 09

1

195 of 223

196 of 223

Telescopic Feed 31 33

2

197 of 223

198 of 223

Cut hole

1

199 of 223

200 of 223

Cut hole Knowledge target for this section Understand the function of the cut hole option

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

201 of 223

Components

Control valve for small hole/cut hole feed pressure

V1b

V6

V3A

Cut hole lever

3

202 of 223

Cut hole ~60 bar

4

203 of 223

Cut hole Knowledge target for this section Be aware of: – How the Cut hole option does and how it works

5

204 of 223

Swellex

Boomer

205 of 223

206 of 223

Swellex Content Manufacturing General description Installation procedure Technical features Range of products Accesories

207 of 223

Swellex Manufacturing

208 of 223

Swellex Expansion principles SWELLEX before expansion

Face Plate

Inlet Hole SWELLEX Installed In the hole

B A >> B

High water

Expanded SWELLEX in the hole

SWELLEX after expansion

Pressure 300 bar After expansion air pressure force water out of the inlet hole

209 of 223

Swellex Immediate full column support

210 of 223

Swellex Installation methods Manual bolting Semi-mechanized bolting Boomer + Service platform Fully Mechanized BOLTEC

211 of 223

Swellex Installation sequence

1

Drilling

2

Insertion

3

Expansion

4

Pumps automatically stops

Atlas Copco

Atlas Copco

212 of 223

Swellex

0,5 m

Features in the hole

Allows major shear movements Swellex bridges gaps in the rock

Swellex follows all the irregularituis in the hole In hard rock, 50 cm inflated profile develop 100KN friction

Swellex Net washer for screening

213 of 223

Swellex Range

Mn12 Swellex

Mn24 Swellex

Mn16 Swellex

TOP BOLT

Coated Swellex

BOTTOM BOLT

3m

Connectable Swellex

INTERMEDIATE BOLTS 214 of 223

Swellex Dimensions Standard&Super Mn12 Swellex

Mn24 Swellex 36 mm

25,5 mm 3 mm

2 mm

215 of 223

Swellex Recommended hole diameters

Initial Profile

Min Hole diameter

Mn12 Swellex

26 mm

32 mm

39 mm

Mn24 Swellex

36 mm

43 mm

52 mm

Mn16 Swellex

36 mm

43 mm

52 mm

216 of 223

Max hole diameter

Swellex Equipement

PSP 240 / 300 HYDRAULIC pump with manometer

Pull test equipment

Special adapter for Swellex lower bushing

217 of 223

Swellex Face plate Adjustable faceplate for optimal load distribution, even in case of angled hole direction

218 of 223

Swellex Net washer

219 of 223

Swellex

Strainer

Swellex pump H1

(100µ = 0,1mm = 0.003936996 Inch)

Valve Pressure regulator

Pump unit 220 of 223

Swellex Swellex pump H1 Water Connection

Manometer water pressure

Swellex arm water Oil pressure in

Drain

Oil pressure return 221 of 223

Swellex Swellex pump H1 - Specification

Water pressure, water consumption and water temperature - Water pressure in 2-20 bar - Max. water pressure 350 bar - Max. water consumption 17 L/min - Max water temperature 70°C Hydraulic pressure and flow rates - Min. hydraulic pressure 120 bar - Max. hydraulic pressure 210 bar - Flow 40 L/min

222 of 223

Swellex Swellex pump H1 – Setting pressure 300 Bar Bolt – Setting 300 bar to 305 bar

240 Bar Bolt – Setting 240 bar to 245 bar

223 of 223

Content

Tab

Boomer 281/282 DC15

Introduction

1-4

Safety

5-22

Component location

23-34

Valves location

35-50

Daily checks

51-72

Operators platform

73-82

Traction

83-96

24V

97-106

Positioning

107-134

Electrical system

135-152

Air & Water system

153-162

Drilling

163-194

Telescopic feed

195-198

Cut hole

199-204

Swellex

205-223

Options

Training

Introduction

1 of 223 1

2 of 223

Introduction Teacher name: ____________________ Training hours 08,00 – 16,00 Tea / coffee brakes to be discussed 10,00 / 14,00 Lunch time to be discussed 12,00 Smoke brakes to be negotiated No smoking in Lecture room No Phone calls during lecture No computers during lecture Written check questions after each section Written exam after training Practical 3 of 223 2

4 of 223

Safety

1

5 of 223

6 of 223

Safety Knowledge target for this section You will after this section know safety features: Signs and symbols (warnings), Risk area of the rig, warning signals, emergency stops, fire fighting equipment

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

7 of 223

Safety References in documentation Safety Manual

3

8 of 223

Safety Content (Boomer 280-Series) Always read the safety instructions Location of Ansul and Fire extinguishers Emergency stop ”Beacon” Risk areas

4

9 of 223

Safety Fire fighting - ANSUL System A – Activator B – Nozzles C – Fire Extinguisher D – Propellant cartridge

5

10 of 223

Safety Fire fighting - ANSUL Activators

6

11 of 223

Safety ANSUL Activators

Check fire (option)

Ansul

7

12 of 223

Safety Fire extinguisher

8

13 of 223

Safety Emergency Stop

Emergency stop button

Indicator light

9

14 of 223

Safety Audio and visual alarms Horn button

Strobe

10

15 of 223

Safety Risk Areas during tramming and drilling

11

16 of 223

Safety Warning The manuals contain warnings. The warnings are in boxes and contain a safety message preceded by a warning symbol and a signal Different degrees of warnings – Danger – Warning – Caution

12

17 of 223

Safety Signs

13

18 of 223

Safety Signs

14

19 of 223

Safety Rig Stability

15

20 of 223

Safety Knowledge target for this section Be aware of: – The different signs and symbols (warnings) – Risk area of the rig when tramming – What kinds of warning signals the rig is equipped with – Functionality of the emergency stops – Different fire fighting equipment

16

21 of 223

22 of 223

Component location B281/B282-DC15

1

23 of 223

24 of 223

Component Location Knowledge target for this section Get a general knowledge of where the major component on the rig is located

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

25 of 223

Component Location References in documentation Operators Instructions – Component Locations

3

26 of 223

Component Location Main Components Protection roof Feed

Rock Drill

Electrical Cabinet Cable reel

Boom Rear Jacks Front Jacks

4

27 of 223

Component Location Right Rear Diesel engine air filter Ansul cartridge and powder container

Water reel

El.motor and pumps for boom 2 Rear Jacks 5

28 of 223

Component Location Right Rear

6

Hydraulic oil – Electric filling pump

29 of 223

Component Location Left Electrical cabinet Cable reel

ECL Lubrication tank

El. motor and pumps for boom 1

7

30 of 223

Component Location Behind Water Reel Water pump

Water inlet strainer

8

31 of 223

Component Location Inside Water Reel ISO switch Battery

Main fuse

9

32 of 223

Component Location Knowledge target for this section Be aware of: – The major components on the rig eg. Boom, cable reel, Pumps

If the rig is available: – Have walked around the rig and seen the components

10

33 of 223

34 of 223

Valves Location B282-DC15

1

35 of 223

36 of 223

Valves Location Knowledge target for this section Be aware of the different adjustment valves on the drill rig

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

37 of 223

Valves Locations References in documentation Maintenance Instructions – Component Locations

3

38 of 223

Valves Location VB 1 block

CT4

CT5 CT2 CT1 CT3/ Y156

4

39 of 223

Valves Location Valve V10 and V11 Percussion Pressure

V11 Percussion Pressure full drilling V10 Percussion Pressure Collaring

5

40 of 223

Valves Location V3a Rotation Speed V3a

6

41 of 223

Valves Location V3a Rotation Speed (Reaming)

V3a

7

42 of 223

Valves Location Vdp Damper Pressure

Vdp

8

43 of 223

Valves Location Vfm Maximum Feed Pressure

Vfm

9

44 of 223

Valves Location Vfl-Collaring / Vfh-full drilling pressure Vfh Vfl

10

45 of 223

Valves Location RPCF Regular/Reaming V1a (Regular)

11

V1b(Reaming)

46 of 223

Valves Location Vaj Anti jamming, feed return movement

Vaj

12

47 of 223

Valves Location V8/V17 Telescopic feed pressure difference and max feed return V17 V8

13

48 of 223

Valves Location V6 Feed pressure full drilling (Reaming)

V6

14

49 of 223

Valves Location Knowledge target for this section Be aware of: – Where the adjustment valves are located and their function

If the rig is available: – Have walked around the rig and seen the components

15

50 of 223

Daily checks

Inspections points

1

51 of 223

52 of 223

Daily Checks Knowledge target for this section Be aware of the daily checks, understand the importance of cleaning between shifts

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

53 of 223

Daily Checks References in documentation Maintenance schedules rig – Every 10 Percussion hour – Every 10 Diesel hour

Maintenance instructions rock drill Operation manual diesel engine – Maintenance Schedule

3

54 of 223

Daily Checks Purpose of daily checks Detect faults at an early stage Prevent costly secondary damage Prevent breakdowns Prevent personal injury

4

55 of 223

Daily Checks Cleaning – Between shifts To be able to see wear To be able to see damages

5

56 of 223

Daily Checks What to check for Check safety devices Check hoses and cables Check oil levels Check the lubrication points Keep your eyes open for possible leakage and wear Pay attention to any faults in the function of the controls

6

57 of 223

Inspections Points Emergency stop devices Control objects – Emergency stop devices

Action – Check the function of all the emergency stops on the rig

7

58 of 223

Inspections Points Fire extinguishers

0

0

OK

OK

Control objects – Fire extinguishers

Action – Make sure the indicator is in the green zone

1250 0098 88

– Check that none of the seals are broken and that service has been carried out within the prescribed time – Check that the fire extinguisher and its holder are not damaged

8

59 of 223

Inspection Points Check/Service points on feed

9

CHECK POINTS

SERVICE POINTS

•Hoses, tension and wear •Hose drum •Damages & oil leaks •Tension of ropes •Cradle and Feed retainers •Wear strips & Slides •Drill Steel Bushings •Centre drill steel support •Limit switch function •Rock drill attachment

•Tightening of bolts •Grease all lub. Points •Torque the tension bushing on feed cylinder •Wear strips & Slides •Ropes •Drill steel bushings •Bearings, pulley wheel & hose drum

60 of 223

Inspection Points Feed Control objects – Guide rails and slide pieces

Action – Check for wear on slide pieces and slide rails. Adjust if necessary

10

61 of 223

Inspection Points During Drilling Hyd. oil temp Water pressure Hydraulic pressures – Feed – Rotation – Percussion Lubrication pressure Return filters Hour meter Leakages Broken or damaged hoses

11

62 of 223

Inspection Points Check/Service points on the boom

12

CHECK POINTS

SERVICE POINTS

•Hoses, tension and wear •Damages & oil leaks •Drill Steel Bushings

•Tightening of bolts •Grease all lub. Points

63 of 223

Inspection Points Rock Drill Lubrication Air Lubrication oil Front Bushing Flushing seals Drill Collaring Accumulators Pressure and flow Pressure and frequency Check clearance No leaks Always on the shank

13

64 of 223

Inspections points Rock Drill Control objects – Rock drill accumulator charge pressure

Action – Press in the pin on the test valve. If the accumulator is charged, the pin will stick out by 4.5 mm and give a firm resistance when pressed in

14

65 of 223

Inspections points Rock drill cradle Control objects – Machine cradle

Action – If necessary, adjust the cradle to the correct height and centre directly on the beam

Clearance 5-7 mm

15

66 of 223

Inspections points Hydraulic system Control objects – Hydraulic oil level

Action – Top up if necessary

16

67 of 223

Inspections points Compressor Control objects – Oil reservoir

Action – Check the oil level in the oil reservoir (See instruction on how to check)

17

68 of 223

Inspections points Water system Control objects – Water inlet strainer

Action – Clean by opening blue valve

18

69 of 223

Inspections points Fire fighting system ANSUL Control objects – Nozzles/Hoses – Powder container

Action – Check that nozzles are clean and the protective caps are fitted and tight – Check that there is no damage to the powder container

19

70 of 223

Inspections points Diesel Engine oil level Control objects – Engine oil level

Action

Oil stick

– Top up if necessary

Oil fill

20

71 of 223

Daily checks Knowledge target for this section Be aware of: – The daily checks, what to check

Know: – The importance of performing daily checks – The importance of cleaning the rig between shifts

21

72 of 223

Operators platform B280-DC15

1

73 of 223

74 of 223

Operators platform Knowledge target for this section Know the functionality of the controls for driving, brake test, driving

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

75 of 223

Daily inspections References in documentation Operators Manual – Controls

3

76 of 223

Operators platform Drivers seat Instrument panel Levers for roof Levers for jacks Levers for diesel positioning

4

77 of 223

Operators platform Drilling and Positioning panel

5

78 of 223

Operators platform Instrument panel

T2 – Ignition key T4 – Parking brake T5 – Drilling lights T6 – Tramming lights T8 – Lamp test T10 – Gear lever T12 – Horn T16 – Park brake test button P1 – Hour meter for engine P2 – Fuel gauge 6

79 of 223

H11 – Parking brake H12 – Brake pressure H13 – Engine temp H14 – Hydraulic oil level H15 – Transmission H16 – Engine lubrication oil pressure H17 – Suction filter H18 – Battery charging H20 – Preheat indicator

Operators platform Brake test – Parking brake 1. Make sure that the parking brake is applied 2. Start the diesel engine and engage 2nd gear 3. Gradually increase engine rpm to maximum 4. Check the rig for movement. If the rig moves the brakes must be adjusted without delay – Note Do not continue this check for longer than 4 seconds at most

7

80 of 223

Operators platform Brake test – Service brakes 1. Start the diesel engine 2. Depress the brake pedal and hold it down 3. Release the parking brake 4. Engage 2nd gear 5. Gradually increase engine rpm to maximum 6. Check the rig for movement. If the rig moves the brakes must be adjusted without delay – Note Do not continue this check for longer than 4 seconds at most

8

81 of 223

Operators platform Knowledge target for this section Know the functionality of the controls for driving – – – –

Instrument panel Drill panel Boom panel Levers for jacks/roof

Know how to: – Perform parking brake test – Perform service brake test – Start the rig

Know the basics of driving the rig – Driving forward/backward – Turning – Gear selecting

9

82 of 223

Traction B282 DC15

1

83 of 223

84 of 223

Traction Knowledge target for this section Understand the hydraulics for brake and steering

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

85 of 223

Daily inspections References in documentation Diagrams and Drawings – Hydraulics

3

86 of 223

Components

5 6

4

2 3

1 4

87 of 223

Starting the system

5

88 of 223

Applying the brakes

6

89 of 223

Releasing the brakes

7

90 of 223

Park brake

8

91 of 223

Releasing Park brake

9

92 of 223

Activating Park brake

10

93 of 223

Steering

11

94 of 223

Traction Knowledge target for this section Be aware of: – The components in the brake and steering circuit – How the circuit is started hydraulically – How the brake and steering circuit works

12

95 of 223

96 of 223

Boomer

24V

1

97 of 223

98 of 223

Boomer 24V Knowledge target for this section Know how the 24 V system is built up

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

99 of 223

Daily inspections References in documentation Diagrams and Drawings – Electrics

3

100 of 223

Boomer 24V Main Switch Main switch

4

101 of 223

Power on

5

102 of 223

Ignition sequence

6

103 of 223

Interlock brake valve circuit

7

104 of 223

Cable reel 3 laps left

8

105 of 223

Boomer 24V Knowledge target for this section Be aware of: – What happens in the 24V circuit when the main switch is turned on – What happens in the circuit when the ignition key is turned – How the interlock brake valve circuit works – What happens when there are only three laps left on the cable reel

9

106 of 223

Positioning

1

107 of 223

108 of 223

Positioning Knowledge target for this section Controls for positioning, hydraulics for positioning

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

109 of 223

Positioning References in documentation Diagrams and Drawings – Hydraulics

Operators Instructions – Controls

3

110 of 223

Positioning Positioning panel Feed look out Feed rotation

Boom extension Feed extension Boom positioning

Anti parallel button

4

111 of 223

Positioning Overview of boom cylinders

5

K – Feed rotation

Z - Lock – out

FE – Feed ext

B – Boom ext

A1 – Boom cyl. rear left

A2 – Boom cyl. rear right

E1 – Boom cyl. front left

E2 – Boom cyl. front right

E1 FE

E2

B

Z K A1

112 of 223

A2

Positioning Levers for jacks and roof Left roof cyl

Right front jack Right slide

Right roof cyl

Rear jacks Left slide Left front jack

6

113 of 223

Positioning Levers for reels and diesel positioning 1/2 Diesel positioning Cable reel Hose reel

7

114 of 223

Positioning Levers for reels and diesel positioning 2/2 Cable reel override button Warning light for 3 laps left

8

115 of 223

Positioning Rear Controls for Reels Water reel Cable reel

9

116 of 223

Positioning Components

10

117 of 223

Positioning Diagram legend Red – pressure Blue – tank/return Green – pilot pressure (40bar) Yellow – other pilotpressure

11

118 of 223

Positioning Raising the Boom 1/2

12

119 of 223

Positioning Raising the Boom 2/2

13

120 of 223

Positioning Lowering the boom 1/2

1250 0060 05

14

121 of 223

Positioning Lowering the boom 2/2

15

122 of 223

Positioning Moving the boom to the right 1/2

1250 0060 05

16

123 of 223

Positioning Moving the boom to the right 2/2

17

124 of 223

Positioning Moving the boom to the left 1/2

1250 0060 05

18

125 of 223

Positioning Moving the boom to the left 2/2

19

126 of 223

Positioning Using the anti-parallel system feed swing 1/2

1250 0065 20

20

127 of 223

Positioning Using the anti-parallel system feed swing 2/2

21

128 of 223

Positioning Using the anti-parallel system feed lift 1/2

1250 0065 20

22

129 of 223

Positioning Using the anti-parallel system feed lift 2/2

23

130 of 223

Positioning Movement of the feed

24

131 of 223

Positioning Jacks

25

132 of 223

Positioning Roof

26

133 of 223

Positioning Knowledge target for this section Be aware of: – The controls for positioning, which lever does what and where are they located

Be able to describe the following – How the positioning works hydraulically – Which are the main components – Boom positioning valves / functions

27

134 of 223

Electrical system

1

135 of 223

136 of 223

Electrical System Knowledge target for this section Be aware of the components in the electrical system

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

137 of 223

Positioning References in documentation Diagrams and Drawings – Electrics

Operators Instructions – Electrics system

3

138 of 223

Electrical System Warning lights on A-cabinet

4

Phase sequence fault

Low hyd. Oil level

High hyd. Oil temp

Motor overload

Return oil filter indicator

Power on

139 of 223

Electrical System Switches on A-cabinet Diode test Emergency stop

Lamp test

Motor switch, motor nr 2 Motor switch, motor nr 1

5

140 of 223

Electrical System Main Switch

6

141 of 223

Electrical System The right side of the A-Cabinet V33 Diode bridge for check lights

T50 Internal Transformer

7

142 of 223

K29

Electrical System The right side of the A-Cabinet

K64 Start relay pump1

K164

K74

Emergency stop power supply relay

Start relay pump1

K163

K28

24V Power Supply changer

Low hydraulic oil level relay

K31 24V Power supply changer

K128 Emergency stop relay

K30 Compressor timer relay

8

143 of 223

Electrical System The right side of the A-Cabinet K132 Water Pump relay K127 Compressor relay

9

144 of 223

Electrical System The right side of the A-Cabinet F131

F18

F20

Water Pump Fuse

Fuse 3 phase outlet

Back-Up Fuse

F19 F126 Compressor Fuse

10

145 of 223

Control Transformer Fuse

Electrical System The right side of the A-Cabinet

F22 F17

F66

Battery Charger

F77

F91

Fuse Control 110V AC Pump1 Fuse descriptions

F76 Fuse Control 110V AC Pump1

11

146 of 223

F48

F67

F49

Headlight 24V AC

Control 24V DC

Working light 220V AC

Electrical System The right side of the A-Cabinet S13 Select Measuring

12

147 of 223

P12

K10

Voltmeter/ Ampmeter

Earth-fault relay

Electrical System The right side of the A-Cabinet P66 Hour meter Rock Drill 1

P76 Hour meter Rock Drill 1

ECL Rock Drill Lubrication

K26 Phase rotation F6 Fuse relay

K133 Water pump time relay

K32

13

148 of 223

Electrical System ECL System

Diod to indicate lubrication time T2 Lubrication Dosage T1 Lubrication pulse time

Indicates that power is on

14

149 of 223

Electrical System The Left side of the A-Cabinet U158 Battery charger

U180 Rectifier

X1 3 Phase outlet

15

150 of 223

Electrical System Knowledge target for this section Be aware of: – The different components in the electrical system – Where the components are located

If the rig is available: – Have walked around the rig and seen the components

16

151 of 223

152 of 223

Air & Water system B281/282-DC15

1

153 of 223

154 of 223

Air & Water Knowledge target for this section Understand the air and water system

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

155 of 223

Positioning References in documentation Diagrams and Drawings – Air

3

156 of 223

Air & water schedule Valves for rock drill lubrication (Y106, Y107) Compressor

Watermist Water pump and flow guard B141

Watermist

4

157 of 223

Air & water schedule Y106 Y107

5

158 of 223

Air & water schedule

B141

6

159 of 223

Air blowing

Air 7

160 of 223

Water (Flushing)

Water 8

161 of 223

Air & Water Knowledge target for this section Be aware of: – How the air and water circuits work

9

162 of 223

Drilling B281/282-DC15

1

163 of 223

164 of 223

Drilling Knowledge target for this section Controls and gauges for drilling, drilling circuits, components

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

165 of 223

Drilling Drilling Panel 1/2

Percussion pressure Feed pressure

Rotation pressure Pump on

ECL Collaring Full drilling

3

166 of 223

Drilling Drilling Panel 2/2

Pump off Water

Percussion Feed movement

Rotation

Hole size (option)

4

167 of 223

Drilling Manometers Return oil filter

Air

Water

Damper rock drill 2

Damper rock drill 1

5

168 of 223

Drilling Check points during drilling Hyd. oil temp Water pressure Hydraulic pressures – Feed – Rotation – Percussion Lubrication pressure Return filters Hour meter Leakages Broken or damaged hoses

6

169 of 223

Drilling Power packs DCS 12 1-boom

P1

P2

DCS 12 2-boom, DCS 15/18 all rigs

P1 P2

P3

P1 – Main pump (positioning and percussion). (damper only on 1 boom) P2 – Rotation pump P3 – Damper pump (only 2-boom), water pump (only 1-boom) 7

170 of 223

Drilling Hydraulic diagram legend Red – pressure Blue – tank/return Green – pilot pressure (50bar) Yellow – other pilot pressure

8

171 of 223

Drilling Main Components 1/2 Rotation Unit

Rock Drill

Feed

RPCF Valve Low/High Feed Pressure Regulator Feed Pressure Control Valve

Button for loosening of drill bit

Antijamming valve

Rotation Lever

9

Percussion Lever

Feed Movement Lever

172 of 223

Drilling Main Components 2/2 Limit switch

VB1

Main pump

ECL Pump

Flow regulation for damper

Rotation pump Damper pump

Flow regulation for rotation

10

173 of 223

Drilling Main pump start – The first 8 seconds To tank

Step 1

Percussion/Rotation

Power the water pump

Rotation 11

174 of 223

Drilling Main pump start – After 8 seconds Step 2

12

175 of 223

Drilling Rotation 1/2

13

176 of 223

Drilling Rotation 2/2

14

177 of 223

Drilling Feed forward 1/2

15

178 of 223

Drilling Feed forward 2/2

16

179 of 223

Drilling Feed Reverse

17

180 of 223

Drilling Drill Sequence – Collaring 1/2

40-50 bar

230 bar

18

181 of 223

Drilling Drill Sequence – Collaring 2/2

V11

19

182 of 223

Drilling Drill Sequence – Full Drilling 1/2 image description

65-100 bar

20

183 of 223

Drilling Drill Sequence – Full Drilling 1/2

V12

21

184 of 223

Drilling Limit Switch (Black Jack) 1/2

22

185 of 223

Drilling Limit Switch (Black Jack) 2/2

23

186 of 223

Drilling Drilling Protection Systems RPCF (Rotation Pressure Control Feed) FPCI (Feed Pressure Control Impact) Anti Jamming (Feed reverse with full system pressure)

24

187 of 223

Drilling Drilling Protection System 1 – RPCF 1/2 50-60 bar

50 bar

Pressure limit set to appr. 20 bar above normal rotation Pressure

25

188 of 223

Drilling Drilling Protection System 1 – RPCF 2/2

Pressure increases

Pressure increases

26

189 of 223

Drilling Drilling Protection System 2 – FPCI (Anti jamming) 1/2

Pressure increases

Pressure increases

27

190 of 223

Drilling Drilling Protection System 2 – FPCI (Anti jamming) 2/2

28

191 of 223

Drilling Loosening the drill bit 1/2

29

192 of 223

Drilling Loosening the drill bit 2/2

30

193 of 223

Drilling Knowledge target for this section Be aware of: – The different controls for drilling – The checkpoints during drilling – Powerpack setup – Hydraulic circuits for drilling – Drilling protection RPCF, Anti-Jamming and FPCI

31

194 of 223

Telescopic feed

1250 0064 09

1

195 of 223

196 of 223

Telescopic Feed 31 33

2

197 of 223

198 of 223

Cut hole

1

199 of 223

200 of 223

Cut hole Knowledge target for this section Understand the function of the cut hole option

Content Safety Component Location Daily Checks Driving

2

Positioning Drilling Options

201 of 223

Components

Control valve for small hole/cut hole feed pressure

V1b

V6

V3A

Cut hole lever

3

202 of 223

Cut hole ~60 bar

4

203 of 223

Cut hole Knowledge target for this section Be aware of: – How the Cut hole option does and how it works

5

204 of 223

Swellex

Boomer

205 of 223

206 of 223

Swellex Content Manufacturing General description Installation procedure Technical features Range of products Accesories

207 of 223

Swellex Manufacturing

208 of 223

Swellex Expansion principles SWELLEX before expansion

Face Plate

Inlet Hole SWELLEX Installed In the hole

B A >> B

High water

Expanded SWELLEX in the hole

SWELLEX after expansion

Pressure 300 bar After expansion air pressure force water out of the inlet hole

209 of 223

Swellex Immediate full column support

210 of 223

Swellex Installation methods Manual bolting Semi-mechanized bolting Boomer + Service platform Fully Mechanized BOLTEC

211 of 223

Swellex Installation sequence

1

Drilling

2

Insertion

3

Expansion

4

Pumps automatically stops

Atlas Copco

Atlas Copco

212 of 223

Swellex

0,5 m

Features in the hole

Allows major shear movements Swellex bridges gaps in the rock

Swellex follows all the irregularituis in the hole In hard rock, 50 cm inflated profile develop 100KN friction

Swellex Net washer for screening

213 of 223

Swellex Range

Mn12 Swellex

Mn24 Swellex

Mn16 Swellex

TOP BOLT

Coated Swellex

BOTTOM BOLT

3m

Connectable Swellex

INTERMEDIATE BOLTS 214 of 223

Swellex Dimensions Standard&Super Mn12 Swellex

Mn24 Swellex 36 mm

25,5 mm 3 mm

2 mm

215 of 223

Swellex Recommended hole diameters

Initial Profile

Min Hole diameter

Mn12 Swellex

26 mm

32 mm

39 mm

Mn24 Swellex

36 mm

43 mm

52 mm

Mn16 Swellex

36 mm

43 mm

52 mm

216 of 223

Max hole diameter

Swellex Equipement

PSP 240 / 300 HYDRAULIC pump with manometer

Pull test equipment

Special adapter for Swellex lower bushing

217 of 223

Swellex Face plate Adjustable faceplate for optimal load distribution, even in case of angled hole direction

218 of 223

Swellex Net washer

219 of 223

Swellex

Strainer

Swellex pump H1

(100µ = 0,1mm = 0.003936996 Inch)

Valve Pressure regulator

Pump unit 220 of 223

Swellex Swellex pump H1 Water Connection

Manometer water pressure

Swellex arm water Oil pressure in

Drain

Oil pressure return 221 of 223

Swellex Swellex pump H1 - Specification

Water pressure, water consumption and water temperature - Water pressure in 2-20 bar - Max. water pressure 350 bar - Max. water consumption 17 L/min - Max water temperature 70°C Hydraulic pressure and flow rates - Min. hydraulic pressure 120 bar - Max. hydraulic pressure 210 bar - Flow 40 L/min

222 of 223

Swellex Swellex pump H1 – Setting pressure 300 Bar Bolt – Setting 300 bar to 305 bar

240 Bar Bolt – Setting 240 bar to 245 bar

223 of 223

More Documents from "Cesar Quintanilla"

127728026-binder-del-alumno.pdf

January 2021 0

Para Caminos 2.docx

January 2021 3

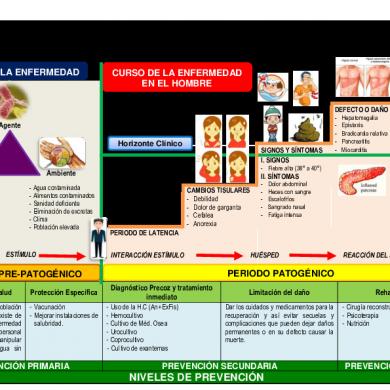

Tifoidea Esquema

January 2021 2

Bombeo En Pavimentos

February 2021 0