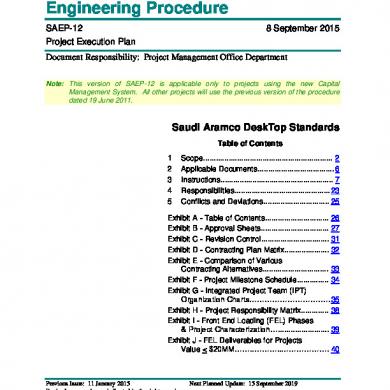

Best Practice: Saudi Aramco Desktop Standards

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Best Practice: Saudi Aramco Desktop Standards as PDF for free.

More details

- Words: 12,420

- Pages: 36

Loading documents preview...

Best Practice SABP-A-028 12 September 2009 Optimizing Design and Operation of Reverse Osmosis Plants Document Responsibility: Materials Engineering and Corrosion Control Division

Saudi Aramco DeskTop Standards Table of Contents 1 2 3 4

5 6

Introduction..................................................................... 3 Scope and Purpose........................................................ 3 Conflicts and Deviations................................................. 3 References..................................................................... 3 4.1 Saudi Aramco References.................................... 3 4.2 Industry Codes and Standards.............................. 4 Definitions and Abbreviations......................................... 4 Important Design Parameters......................................... 9 6.1 Membrane Performance........................................ 9 6.2 Water Analysis...................................................... 9 6.3 Recovery............................................................. 10 6.4 Membrane Design Configuration........................ 10 6.4.1 Concentrate Staging............................... 10 6.4.2 Permeate Staging................................... 11 6.5 Membrane Flux................................................... 12 6.6 Feed Water Flow................................................. 12 6.7 Feed Water Salinity............................................. 13 6.8 Feed Water Pressure.......................................... 13 6.9 Feed Water Temperature.................................... 14 6.10 Minimum Brine Flow............................................ 14 6.11 Concentration Polarization (Beta factor)............. 14 6.12 Fouling Tendency During System Shut Down.... 15 6.13 Suspended Solids............................................... 15 6.14 SDI Test.............................................................. 16

Previous Issue: New Next Planned Update: TBD Page 1 of 36 Primary contact: Isaias, Nicos Philippou on 966-3-8760249 Copyright©Saudi Aramco 2009. All rights reserved.

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Table of Contents (cont'd)

7 8 9 10 11

12 13 14

15

6.15 Preventing Biological Growth on Membranes..... 16 6.15.1 Storage.................................................... 16 6.15.2 Membrane Shipping................................ 16 6.15.3 System Shut Down.................................. 16 6.16 Membrane Fouling.............................................. 17 6.17 Fouling................................................................ 17 6.18 Membrane Fouling/Scaling................................. 17 6.19 Antiscalant Injection............................................ 18 6.20 Dispersant Injection............................................. 18 6.21 Acid Injection....................................................... 18 6.22 Reduce Recovery................................................ 18 6.23 Correcting Fouling............................................... 18 6.23.1 Check and Fix the Pretreatment............. 18 6.23.2 Change the Operating Conditions........... 19 How to design an RO System...................................... 19 Reverse Osmosis Plant Start Up.................................. 23 Reverse Osmosis Plant Shut Down............................. 24 Preservation of RO Membranes................................... 24 RO System Data Collection and Monitoring................. 24 11.1 Silt Density Index (SDI)....................................... 25 11.2 RO System Pressure Drop................................. 25 11.3 Salt Rejection...................................................... 25 11.4 Normalized Permeate Flow................................. 25 Common RO System Failures/Problems...................... 27 Reverse Osmosis Membrane Cleaning........................ 28 Chemical Water Treatment for Reverse Osmosis........ 29 14.1 Coagulants/Flocculents....................................... 29 14.2 Chlorine............................................................... 29 14.3 Sodium Meta-Bisulfite, Bisulfite, Sulfite............... 30 14.4 Biocides.............................................................. 31 14.5 Scale Inhibitors................................................... 32 Troubleshooting............................................................ 32 15.1 Profiling an RO Array.......................................... 32 15.2 Probing................................................................ 33 15.3 Replacing O-Rings.............................................. 34 15.4 Shimming............................................................ 34 15.5 Replacing RO Membrane Elements................... 34 15.6 Membrane Autopsies…………………………..… 35 Page 2 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

1

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Introduction Reverse Osmosis (RO) technology is evolved into a widely used process for both seawater and brackish water desalination. Well designed and properly operated systems give a trouble-free performance over long periods of time. On the other hand, mistakes made during the design or operation of RO systems can lead to ongoing problems and reduced membrane performance and membrane useful life. The membrane system, which includes the membrane elements housed in pressure vessels and a high pressure pump constitutes the heart of the RO plant. The system also includes a pretreatment section to achieve the required feed water quality, a clean in place (CIP) section to facilitate membrane cleaning, and a post-treatment section to achieve the required product quality. The RO performance is typically characterized by the permeate flow and permeate quality. These parameters should always be referenced to the feed water analysis, feed pressure and system recovery. The goal of a good RO design for a certain required permeate flow is to minimize feed pressure and membrane costs, while maximizing permeate quality and recovery. This Saudi Aramco Best Practice (SABP) outlines some of the common mistakes made during the design and operation of the RO systems and provides guidelines for best RO design and operational performance.

2

Scope and Purpose This SABP provides guidelines that will improve the performance of RO systems by avoiding mistakes in their design and operation. It is based on current industry experience as well as direct experience from Saudi Aramco RO desalination plants such as Tanajib, Abqaiq, Uthmaniyah, Shedgum, Hawiyah, Berri, Dhahran and others. This SABP is meant for internal use only.

3

Conflicts and Deviations If there is a conflict between this SABP and other standards and specifications, please contact the Coordinator of ME&CCD/CSD.

4

References 4.1

Saudi Aramco References Saudi Aramco Engineering Procedure SAEP-348

Chemical Cleaning, Disinfection, Post Treatment

Page 3 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

and Storage of Reverse Osmosis Membranes Saudi Aramco Materials System Specifications 32-SAMSS-033

Reverse Osmosis Systems

Saudi Aramco Sanitary Code SASC-S-01 4.2

Water

Industry Codes and Standards American Society of Mechanical Engineers ASME SEC VIII

Pressure Vessels

ASME SEC X

Fiber-Reinforced Plastic Pressure Vessels

American Water Works Association

5

AWWA B100

Filtering Materials

ASTM D4189 - 07

Standard Method for Silt Density Index (SDI) of Water

Definitions Antiscalant: Chemical added to increase the solubility of sparingly soluble salts. In RO systems CaCO3, CaSO4, SrSO4, BaSO4 and CaF are the most common scales of concern. Anti-Telescoping Device (ATD): A plastic device placed on the ends of a membrane element, which provides structural support to the membrane envelopes preventing unraveling and extension. Array: The physical arrangement of the pressure vessels, e.g., a 6:3 array configuration is a 2-stage configuration with a total of 9 vessels. The 1st stage has 6 pressure vessels and the 2nd stage has 3 pressure vessels. The reject of each stage is the feed stream for the next successive stage. Brackish Water: Technically, is defined as water of total dissolved solids (TDS) levels from 1,500 mg/l up to 10,000 mg/l. Brine Seal: Plastic or rubber devices that seal the outside of one end of a spiral wound membrane element against the wall of the RO housing. These devices prevent bypassing of feed water around the element and force the feed water through the element. RO Membrane Compaction: It is the physical compression of the membrane. This compression results in a decrease in flux. The rate of compaction is directly Page 4 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

proportional to increase in temperature and pressure. Membrane compaction occurs naturally over time requiring a greater feed pressure. Concentration Polarization: Refers to the concentration gradient of salts on the high pressure side of the membrane surface. The salt concentration in this boundary layer exceeds the concentration of the bulk water. This phenomenon impacts the performance of the process by increasing the osmotic pressure at the membrane’s surface, reducing flux, increasing salt passage and increasing the probability of scale formation. Increasing the velocity (turbulence) of the brine stream or reducing recovery helps to reduce concentration polarization. Conversion or Recovery: The percentage of the feed water which is converted into permeate. Cross Flow: The running of the feed water stream in parallel to the membrane surface so that it continuously removes contaminants from the membrane surface. Elements: Often referred to as a module, elements are the physical devices that house the membrane. Spiral wound systems can have up to six elements per pressure vessel. Hollow fiber RO systems usually have only one element per pressure vessel. Feed Channel Spacer: Found in spiral wound elements, feed channel spacers are a netting material placed between the flat sheets of the membrane envelopes to promote turbulence in the feed / concentrate stream. RO Feed Stream: Flow into the first stage of an RO system. The feed stream is separated into permeate or product stream and a concentrated or brine stream. Feed stream = Permeate stream + Concentrate stream. Flux or Water Flux: Typically expressed as volume per area per unit of time, flux is used to express the rate at which water permeates a membrane. Typical units are gallons per square foot per day (GFD) or liters per square meter per hour (l/m2/hr). The flux of a membrane is directly proportional to temperature and pressure. As a rule of thumb, flux decreases 1.5% per 1oF. Salt flux is the amount of TDS passed through a given area of membrane per unit of time. Salt flux is a function of concentration gradient and not driving pressure. Therefore, with increasing driving pressure, the concentration of salts in the permeate decreases due to constant salt leakage (e.g., milligrams) and increased water flux (e.g., liters). The net effect of increased drive pressure is to dilute a constant amount of salt with more pure water. Note: 1 GFD = 1.66 l/m2/hr

Hollow Fiber Element: One of four possible membrane configurations (others are spiral wound, plate and frame, and tubular). Hollow fiber elements are made of extruded cellulose acetate or polyamide material. Pressurized feed water passes across

Page 5 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

the outside of the fibers. Pure water permeates the fibers and is collected at the end of the element. Hollow fibers were among the first RO systems. The hollow fiber element does not allow for turbulent flow or uniform flow across the fiber surface making these elements more prone to fouling and scaling. Once hollow fiber elements are fouled they are more difficult to clean due to the inability to get the cleaning solution to the fouled area. Hollow fiber elements are mostly found in seawater desalination applications and limited brackish water applications where fouling potential is minimal. Hydrolysis: Chemical breakdown of a membrane from exposure to low or high pH, bio-activity and temperature. Normally associated with CA membranes where the acetyl groups are replaced by hydroxyl groups. Hydrolysis increases salt leakage (i.e., greater conductivity of the permeate) and a lower feed pressure requirement. Oxidants and temperature can cause hydrolysis in TFC elements. Langelier Saturation Index (LSI): is a measurement of CaCO3 scaling potential and is used as a key performance indicator in the management of RO systems. A positive Langelier Saturation Index indicates that CaCO3 can precipitate. A negative LSI indicates that the water is corrosive. RO Membranes: An RO membrane is a semipermeable material, that is, a material through which water passes relatively quickly, while other substances cannot (or do so relatively slowly). Membranes provide the barrier layer or interface for cross flow separation. Membranes are thin, porous material constructed of organic polymer (e.g., cellulose acetate, polyamide and charged polysulfone). RO membranes will typically reject contaminants with molecular weights greater than 200. Nanofiltration (NF) Membranes: Similar to Reverse Osmosis membranes but are not as effective at removing dissolved solids. NF membranes are commonly referred to as membrane softeners because they will usually reject the double-positively charged hardness ions (i.e., calcium & magnesium) fairly well, but they show very low rejection for the single-positive and negative charged ions (e.g., sodium & potassium, chloride). NF membranes can also reject double-negative ions such as sulfate. NF membranes are most commonly used in the drinking water industry where the dissolved solids must be reduced to below 500 mg/L (Safe Drinking Water Act). The choice between NF and RO in these applications comes down to economics. NF membranes require less pumping pressure than RO membranes. Net Driving Pressure: NDP, the difference between the feed pressure and the osmotic pressure. It is the measure of the actual driving pressure available to force the water through the membrane. As net driving pressure increases, the flux increases proportionally (given all other factors remain constant).

Page 6 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Normalized Permeate Flow: NPF is a calculation that allows the comparison of a measured permeate flow rate to a standard (or start up) condition. Permeate flow is a function of Net Driving Pressure (NDP), temperature and membrane condition. By normalizing measured permeate flow for observed NDP and temperature, a measure is obtained that can be used to compare the condition of the membrane to original start up conditions. A decrease in NPF of 10-15% indicates that membrane cleaning is required. O-Rings: Used to seal the permeate water tube inter-connectors of adjacent elements to prevent the intrusion of high pressure feedwater (poor quality) into the low pressure permeate water (good quality). A damaged O-ring will result in higher salt concentration of the permeate in that section of the system. Osmotic Pressure: Is the pressure required to prevent the flow of water across a semipermeable membrane separating two solutions having different ionic strengths. For RO systems it is osmotic pressure that has to be overcome in order to produce permeate. A “rule of thumb” is for every 100 mg/L of TDS difference between feed and permeate, 1 psi of osmotic pressure exists. Permeate: Often referred to as “product,” permeate is the portion of the feedwater stream water which passes through the membrane. Permeate = Feedwater – Concentrate

Polyamide Membranes: Introduced in the early 1970’s this asymmetric polymer is used in the construction of thin film composite (TFC) spiral wound membrane. Polyamide membranes are the most typical membrane construction material due to less pressure requirements and more flexible operating conditions. Polyamide membranes are oxidant (chlorine, chloramine, bromine, ozone etc.) intolerant. Pressure Vessel: This is a tubular device, which contains the membrane elements. For spiral wound elements the pressure vessel often is referred to as the pressure tube or housing and can contain up to eight membrane elements (usually six). In hollow fiber systems the pressure vessel is often referred to as the “permeator.” Product Channel Spacer: this is also known as a permeate water carrier or permeate spacer. In the construction of a membrane element, the product channel spacer is placed between two layers of the flat sheet membrane. This spacer is a knit fabric called Tricot and is used to prevent the membrane from closing off on itself under the high pressure of operation. Permeate water will flow in a spiral path across the product channel spacer into the product collection tube. Product Collection Tube: Collects the permeate water and directs to a product water header. The product collection tube is in the center of a spiral wound membrane element with the “membrane-product channel spacer - membrane- feed water channel spacer” sandwich wrapped around it. Page 7 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Product Stream: Same as permeate. Often referred to as “product” permeate is the portion of the feed water stream water which passes through the membrane. Recovery: Recovery is the percentage of the feed water, which is converted into permeate (sometimes referred to as conversion). Salt Passage: The quantity of salt, as a percentage, which passes through the membrane into to the permeate stream. Salt passage is a function of temperature, velocity and concentration gradient (i.e., concentration of salt in the brine versus the permeate). Note: Salt Passage = 1 - Salt Rejection % Salt passage = [(TDS of product) / (TDS of feed)] x 100

Salt Rejection: The quantity of salt removed from the feed water stream as a percentage. Note: Salt Rejection = 1 - Salt Passage % Salt Rejection = [(TDS of feed – TDS of product) / (TDS of feed)] x 100

Silt Density Index (SDI): Silt Density Index is an empirical test used to characterize the fouling potential of a feed water stream. The test is based on measuring the rate of plugging a 45 micron filter using a constant 30 psig feed pressure for specified period of time. SDI15 refers to a silt density index test, which is run for 15 minutes. Typically spiral wound systems require an SDI < 5 and hollow fiber systems require an SDI < 3. Most deep well waters have an SDI of 3 and most surface water have SDI’s greater than 6. Spiral Wound Element: A membrane configuration, which is comprised of “flat sheet membrane-permeate channel spacer - flat sheet membrane - feed channel spacer” combinations rolled up around a product collection tube. Staging - “Reject Staging”: refers to a configuration where the reject from one group of RO pressure vessels becomes the feed stream of a second group of RO pressure vessels. Reject staging is used to increase the recovery of water. A one stage system typically could recover 50 - 60% of the feed water stream with 2 and 3 stage systems operating at 75 - 80% and greater than 85% respectively. “Product Staging”: referred to as “multiple pass”, is a configuration where the product of the first group of RO pressure vessels becomes the feed water stream for a second group. Product staging is used to increase the quality of the product water. Telescoping: Longitudinal unraveling of spiral wound elements, which results in the RO membrane leaves extending beyond the spacing material between the leaves. It can Page 8 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

be caused by hydraulic surges, excessive differential pressures or by temperature extremes. It is physically damaging to the construction of the membrane element. Most manufactures install anti-telescoping devices (ATD’s) on their elements. Thin Film Composite (TFC): Is an RO membrane composed of and manufactured as three layers bonded together. The two base layers of the asymmetric design have a thin skin (3rd) layer of polyamide deposited on the surface. The thin film is the salt rejecting layer where the two base layers provide a porous structure support. Ultrafiltration: A membrane separation technique used to remove colloidal, very fine particles and macromolecules from a water stream. Pore sizes in an Ultrafiltration (UF) system range from 0.001 to 0.1 micron. UF membrane systems are characterized by the molecular weight cut-off points (e.g., 3,000, 10,000, 20,000, and 80,000 Daltons). Unlike RO systems, UF does not remove dissolved salts from water. Ultrapure Water: Term used to characterize electronic grade process water. Essentially, ultrapure water is free of particles, colloids, organic and inorganic contaminants. 6

Important Design Parameters 6.1

Membrane Performance There is one simple but extremely important fact in keeping the membranes at their peak performance: "Keep The Membrane Surface Clean" All impurities in water are removed at the membrane surface. The dynamics of this separation step must ensure that concentrated materials are not accumulating at the membrane surface. If concentrations are allowed to build up near the membrane surface (boundary layer), fouling of the membrane surface as well as precipitation of low solubility substances will follow resulting in a decline in membrane performance.

6.2

Water Analysis A good and reliable raw water analysis is of paramount importance for the design of RO systems. Understanding the water analysis and the potential problems that can arise from the sparingly soluble salts are crucial for the design and operational success of the RO system. RO systems which are designed and constructed with unreliable or incomplete water analysis they are bound to fail. These types of mistakes are difficult to fix once the plant is put into operation. The required water analysis for the design of an RO system is given in 32-SAMSS-033 “Technical Data Sheet Water Analysis.” Page 9 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Ba2+ and Sr2+ must be analyzed at the 1 μg/L (ppb) and 1 mg/L (ppm) level of detection, respectively. It is also important that the temperature be given as a range (temperature for winter and summer) rather than an absolute value. Temperature variation can impact the scaling potential of an RO system, especially when silica and bicarbonate levels in the feed water are high. Measurements of pH, alkalinity, and gasses must be taken at the point of sampling or pressurized samples need to be taken if these analyses are to be done in the laboratory. Analysis of suspended solids in the presence of soluble iron, or hydrogen sulphide should also take place at the point of sampling or if the analysis is to be done in the laboratory pressurized samples should be taken. 6.3

Recovery Recovery is a very important parameter in the design and operation of RO systems. Membrane recovery is defined as the ratio of permeate flow to feed flow. (1) Operating membranes at higher than the design recovery will result in fouling and scaling of the membrane surface.

6.4

Membrane Design Configuration Membranes assembly units consists of pressure vessels placed on RO blocks or racks, which support the pressure vessels together with the interconnecting piping, and feed permeate manifolds. The membranes are installed inside the pressure vessels. Depending whether maximum water recovery or maximum water quality is the objective, different membrane staging configurations are used. If maximum water recovery is the aim “concentrate staging” is used, whereas, if maximum water quality is the aim, “permeate staging” is used. 6.4.1

Concentrate Staging Figure 1, shows a typical two-stage RO concentrate staging membrane configuration. The system is divided into two groups of pressure vessels called concentrate stages. In each stage pressure vessels are connected in parallel with respect to the direction of the feed concentrate flow.

Page 10 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

st

1 Stage 6 x 6 Array

PG

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

1st + 2nd Stage Permeate

1st Stage Permeate

2nd Stage 3 x 6 Array 2nd Stage Permeate

PG

Final Reject

Figure 1 – A Two-Stage Reverse Osmosis System (A Typical Drinking Water Plant) In this particular case the first stage consists of 6 pressure vessels connected in parallel with each pressure vessel containing 6 membrane elements inside (6 x 6 membrane array). The second stage consists of 3 vessels connected in parallel with each pressure vessel containing 6 membrane elements inside (3 x 6 membrane array). The decreasing number of parallel pressure vessels from stage to stage compensates for the decreasing volume of feed flow, which is continuously being partially converted to permeate. The reject from the first stage is used as the feed to the second stage. The permeate water of all vessels from each stage is combined into a common permeate manifold. The reject from the second stage is the final reject, which is sent to waste. A 2-stage concentrate staging configuration is suitable for brackish RO systems where the water is of relatively low salinity and the objective is to obtain high recovery (usually 75% recovery). If seawater is to be desalinated then a single stage is normally adopted. 6.4.2

Permeate Staging For some applications, the single pass RO system may not be capable of producing permeate water of the required quality. Such a situation may be encountered in a brackish RO application when the quality of

Page 11 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

permeate required is to supply make-up water for boilers. In this case the permeate staging is adopted.

1st Pass

Feed

2nd Pass Permeate

Reject Reject Recycle

Figure 2 – A Two-Pass Reverse Osmosis System (Typical Plant for Boiler Make Up) Figure 2 shows a typical permeate staging. To achieve additional reduction in permeate salinity, the permeate water produced in the first pass is desalted further in the second pass. The reject from the second pass is of very good quality (better quality than the feed to first pass) and therefore is recycled to the suction of the feed pump. 6.5

Membrane Flux Membrane flux is the rate at which water permeates the membrane, i.e., the volume of permeate produced per membrane area per unit time. It has units of gallons per square foot per day (GFD). (2) All membranes have one common limitation. They can only produce a maximum flow of a certain maximum permeate flow for a given water. This limit is controlled by the quality of feed water and not by the make of the membrane. For example, a maximum permeate flow for brackish water treated by conventional filtration and of SDI 4.0 is 14 gallons per square foot per day (GFD). If the membranes are run at fluxes higher than this value, fouling will take place.

6.6

Feed Water Flow A minimum feed flow must be maintained throughout the membrane. Feed velocity helps to reduce build up of concentrated materials at the membrane Page 12 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

surface. When several membranes are being used, the arrangement of these membranes is crucial in maintaining proper flow velocities (see example, Figure 3). This arrangement must be checked against other related factors such as higher pumping costs, recycle flow, etc. Example:

50 GPM Feed Flow

2

1

50 GPM Feed Flow

3

1 3 2

Figure 3 – Higher Feed Flow Helps to Reduce Membrane Fouling 6.7

Feed Water Salinity Sometimes the RO system may experience fluctuation of feed water composition during operation. This may be due to seasonal fluctuation of feed water salinity supplies or due to intermittent operation of a number of water sources of different salinity. Changes in feed water composition will affect the required feed pressure and permeate water salinity. If the change in feed water composition involves changes in sparingly soluble salts higher than in the design, then the recovery may have to be reduced to avoid the precipitation of scale in the concentrate stream.

6.8

Feed Water Pressure RO systems using spiral wound membrane elements operate at constant flux i.e. produce constant permeate flow. Over operating time the feed pressure may be adjusted to compensate for changes in feed water temperature, salinity, and permeate decline due to fouling or membrane compaction. For the purpose of specifying the high pressure pump it is usually assumed that the membrane flux will decline by about 20% over three years and therefore the pump should be Page 13 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

designed accordingly to compensate for this flux decline. Since Saudi Aramco RO plants use centrifugal pumps it is better to use an oversize pump and regulate the feed pressure by throttling (partially closing the feed valve). Alternatively, electric motors with variable speed drives can be used, which enable adjustment of flow and feed pressure of the pump. 6.9

Feed Water Temperature Change in the feed water temperature affects the rate of diffusion through the membrane. The rate of change in permeate flux is about 3% per degree Celsius. Since RO systems are designed to operate at constant output, the feed pressure should be adjusted to compensate for water flux changes due to change in temperature. The salt diffusion (salt passage) through the membrane also changes approximately at the same rate as the water flux. Since the permeate flux is maintained constant the permeate salinity changes according to temperature fluctuations.

6.10

Minimum Brine Flow There should be a minimum brine flow to flash the concentrated stream which contains foulants and scalants away from the membrane surface. This minimum brine flow depends on the feed water quality in relation to sparingly soluble salts and SDI. The typical minimum brine flow per vessel for RO permeate (second pass) is 8-10 gpm whereas, for any other water sources, e.g., brackish well softened is 12-14 gpm brackish well not softened is 12-16 gpm, for seawater without Microfiltration or Ultrafiltration treatment is 12-16 gpm for seawater with Microfiltration or Ultrafiltration treatment is 12-14 gpm, etc.

6.11

Concentration Polarization (Beta Factor) The Concentration Polarization Factor (CPF) or Beta Factor can be defined as the ratio of salt concentration at the membrane surface (Cs) to bulk concentration (Cb). CPF = Cs/Cb The value of the Concentration Polarization Factor of 1.2, which is the recommended Hydranautics limit, corresponds to 18% permeate recovery for a 40" long membrane element. As water flows through the membrane and salts are rejected by the membrane, a boundary layer is formed near the membrane surface in which the salt concentration exceeds the salt concentration in the bulk solution. This increase of salt concentration is called concentration polarization. The effect of concentration

Page 14 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

polarization is to reduce the normalized permeate flow rate and the normalized salt rejection. The effects of concentration polarization are as follows: 1)

Greater osmotic pressure at the membrane surface than in the bulk feed solution (Δπ).

2)

Reduced net driving force across the membrane (ΔP-Δπ). Where ΔP is the feed pressure.

3)

Reduced water flow across membrane (Qw).

4)

Increased salt flow across membrane (Qs).

5)

Increased probability of exceeding solubility of sparingly soluble salts at the membrane surface, and the distinct possibility of precipitation causing membrane scaling.

An increase in permeate flux will increase the delivery rate of ions to the membrane surface and increase Cs. An increase of feed flow increases turbulence and reduces the thickness of the high concentration layer near the membrane surface. Therefore, the Beta Factor is directly proportional to permeate flow (Qp), and inversely proportional to average feed flow (QFavg). CPF = Kp * exp(Qp/ QFavg) Where Kp is a proportionality constant depending on system geometry. 6.12

Fouling Tendency during System Shut-Down The fouling tendency of feed water when flowing through membranes is quite different than that of stagnant water at shut down. Certain suspended solids may settle on membrane surface during stagnant periods. These constitute ideal conditions for anaerobic bacteria such as Sulfate Reducing Bacteria (SRBs) to grow. Also silica is found to crystallize during shut down. A proper flush cycle can eliminate these problems.

6.13

Suspended Solids Suspended solids and colloidal materials in feed water are one of the biggest problems in reverse osmosis systems. Even though most systems have some pretreatment including 5 micron prefilters, these fine particles are responsible for fouling of reverse osmosis membranes. In order to have some measure of the degree of this fouling problem, a concept called Silt density index (SDI) is used. Here, a 0.45 micron filter is exposed to the feed water under pressure and filtration rates are calculated.

Page 15 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

An SDI of less than 5 is considered acceptable for the reverse osmosis systems but the lower the value the better. This means that at values of SDI of less than 5, the membranes should foul at a very low rate. Even though the concept works most of the time, there are exceptions when a lower SDI (less than 3) is desirable due to the nature of the suspended solids in that feedwater. 6.14

SDI Test This is a very important test in reverse osmosis systems and should be carried out correctly. Silt density index (SDI) is an empirical test used to characterize the fouling potential of a feedwater stream. The test is based on measuring the rate of plugging a 0.45 micron filter using a constant 30 psig feed pressure for specified period of time. SDI15 refers to a silt density index test which is run for 15 minutes. Full details of the test are given in ASTM D4189 - 07 “Standard Test Method for Silt Density Index (SDI) of Water.”

6.15

Preventing Biological Growth on Membranes To prevent biological growth on membranes, care should be taken for storage Shipping, and System Shut-Down. 6.15.1 Storage Store the membranes in a cool area out of direct sunlight. Membrane storage temperature limits are 22°F-113°F (-5.5°C to 45°C). Preserve in a solution of 2% sodium bisulfite and 20% glycerine if freezing conditions are anticipated. This will not prevent freezing below 32°F, but the crystals are soft and the membrane is not damaged. Keep new elements in their original packaging. Examine the preservative solutions in preserved elements every 3 months. The pH of the preservative solutions should not drop below 3. Storage time for preserved elements is 6 months to 1 year. Storage time for dry (new) elements is unlimited. 6.15.2 Membrane Shipping Preserve the element in the plastic bag using the recommended procedure. Make sure the plastic bag does not leak and the element is properly identified. Make sure the preservative solution is correctly labeled. Protect the element package from physical damage. Page 16 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

6.15.3 System Shut-Down - Clean the membranes in the system using the appropriate cleaning procedure. - Circulate the preservative solution. - Shut down the system and close valves to prevent air entering the system. - Check preservative once a month. 6.16

Membrane Fouling All membranes lose their performance with time. One of the major causes for the loss of performance is due to substances that deposit on the membrane surface. Although the term fouling is used for deposition of any materials on the membrane, the coating of the membrane surface can be due to the following: - Fouling - Scaling

6.17

Fouling Fouling of membranes is due to the suspended or emulsified materials that may be present in the feed water to the reverse osmosis system. Examples of such materials are: silica, oil, clay, iron, sulfur and humic acids. These substances can be present in a very fine or colloidal form. Even the typical 5 micron cartridge filters used upstream of a reverse osmosis system may not completely remove these foulants.

6.18

Membrane Fouling/Scaling The concentration of all materials in the feed water – dissolved and suspended - is highest near the membrane surface. As the permeate passes through the membrane, all impurities are left behind near the membrane surface. The layer of water next to the membrane surface (boundary layer) gets increasingly concentrated in dissolved and suspended materials. These concentrations reach a certain steady level depending on the feed velocity; element recovery and membrane permeate flux (gallons per square foot of permeate produced per day). It is important to follow the membrane manufacturer’s recommendations on minimum feed flow, maximum element recovery, minimum brine flow and maximum element flux. These recommendations are based on element size and quality of feed water being treated. The concentrations of the dissolved and suspended solids in the boundary layer control the performance of the membrane. Higher concentrations mean higher osmotic pressure, higher tendency of Page 17 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

suspended solids to coagulate and coat the membrane surface, and higher likelihood of scaling to take place. Maintaining proper operating conditions for the membrane is the key preventative step to minimize membrane fouling. 6.19

Antiscalant Injection One of the options to avoid carbonate and sulfate scales is the use of antiscalants. These are injected directly into the feed water usually upstream of the cartridge filter. Dosage of antiscalant depends on the feed water analysis but usually is between 2 to 5 ppm. In simplified terms, the antiscalants delay the scale formation process. This delay is sufficient to avoid precipitation of carbonate salts and sulfate salts on the membrane surface. As this delay is for a finite period, scaling can take place in systems on shut down. For this reason, it is a good practice to flush the membranes with permeate water or feed water at shut down to displace the concentrated solution in the membrane by permeate or feed water.

6.20

Dispersant Injection For suspended or colloidal materials, a dispersant can be injected in the feed water. The usual dosage for a dispersant is 10 ppm. Dispersants keep fine suspended solids from coagulating and coming down on the membrane surface. Proper use of dispersants can minimize fouling due to problem particulates that are difficult to prefilter.

6.21

Acid Injection Adjusting the pH of the feed water by acid injection is another way to control calcium carbonate scaling. The net effect of lowering the feed pH with acid injection is to convert bicarbonate alkalinity to carbon dioxide and thereby prevent the formation of calcium carbonate scale.

6.22

Reduce Recovery Recovery can be reduced by increasing the feed flow. Another way to reduce recovery is to decrease the operating pressure. Lower operating pressure produces a lower amount of permeate. If the feed flow can be maintained near the original value, then a lower recovery is obtained. The effect of lower recovery is to reduce the overall concentration of all substances in the reverse osmosis system, thus achieving more favorable boundary layer conditions.

6.23

Correcting Fouling 6.23.1 Check and Fix the Pre-Treatment Membrane fouling can result from a number of pretreatment Page 18 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

deficiencies or equipment failure. Some common examples of these are given below. Check and fix these items as appropriate.

Activated carbon fines

Water hardness

Pre-filter breakdown

Pre-filter is too coarse

Pump impeller sheds fines

Chorine breakthrough

6.23.2 Change the Operating Conditions Fouling can also be caused by improper system design and maintenance. The fouling can be minimized by implementing one or more of the below steps. 1. Reduce recovery 2. Reduce operating pressure (thus reducing membrane flux) 3. Improve pretreatment system (media filtration, coagulant and flocculent dose, mixing, pH adjustment etc.) 4. Change cartridge filters more frequently (ensure that cartridge filters do not bypass) 5. Sanitize the system regularly 7

How to Design an RO System Step 1: Consider Feed Source, Feed Quality, Feed/Product Flow and Required Product Quality Step 2: Select the Flow Configuration and Number of Passes Step 3: Select Membrane Element Type Step 4: Select Average Membrane Flux (Design Flux) Step 5: Calculate the Number of Membrane Elements Needed Step 6: Calculate the Number of Pressure Vessels Needed Step 7: Select the Number of Stages Step 8: Select the Staging Ratio (Array Ratio) Page 19 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Step 9: Balance the Permeate Flow Rate Step 10: Example Example: Given Conditions:

Feed source: Well water, SDI<2

Required permeate Flow = 200 gpm (1090 m3/d)

6-element pressure vessels to be used

Steps: 1. Well water with SDI<2, total permeate flow = 200 gpm (1090 m3/d) 2. Select plug flow 3. Hydranautics CPA2 [membrane with active membrane area of 365 ft2 (33.9 m2) 4. Recommended average flux for well water feed with SDI <2 = 14.6 gfd (24.3 L/m/h). 5. Total number of elements =(200 gpm)(1440 gpd)/14.6 gfd)(365 ft2) = 54 6. Total number of pressure vessels = 54/6 = 9 7. Number of stages for 6-element vessels and 75% recovery = 2 8. Staging ratio selected: 2:1. Appropriate stage ratio (Array) = 6:3 9. The chosen system must then be analyzed using the Reverse Osmosis Integrated Membrane Solutions Design Software (IMSDesign) computer program. This computer program software calculates the feed pressure required and the permeate quality of the RO system as well as the operating data of all individual elements. It is then easy to optimize the system design by changing the number and type of elements and their arrangement.

Page 20 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

First Stage 6 x 6 Array

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

FinalPermeate (200 gpm) (TDS 73 mg/l) Permeate (162.9 gpm)

PG

103.8 gpm 266.7 gpm (TDS 2800 mg/l)

Second Stage 3 x 6 Array Permeate (37.1 gpm)

PG Note: Membrane area of CPA2 = 365 ft2 Reject (66.7 gpm)

Figure 4 – Schematic Diagram of How to Design RO System Calculations Example: Figure – shows the details of the example used for the step 10 in “how to design an RO system”. It assumes that the TDS of the well water is 2800 m/l. The flows of permeates and rejects of the first and second stage were obtained using the IMSDesign Hydranatics software as well as the final permeate of 73 mg/l in TDS. On the basis of Figure 2 the following calculations may be carried out. 1. % Recovery of 1st stage = [ QP /( QP + QR )] x 100 = [162.9 gpm / (162.9 gpm + 103.8 gpm)] x 100 = 61.1 % 2. % Recovery of 2nd stage = (QP / QP + QR ) x 100 = (37.1 gpm / 37.1 gpm + 66.7 gpm) x 100 = 35.7 % 3. % Overall System Recovery = [QP /( QP + QR )] x 100 = [200 gpm /(200 gpm + 66.7 gpm)] x 100 = 75.0 % 4. 1st Stage Flux = QP /A = 162.9 gpm x 60 x 24 / 6 x 6 x 365 ft2 = 17.85 GPD/ft2 5. 2nd Stage Flux = QP /A = 37.1 gpm x 60 x 24 / 6 x 6 x 365 ft2 = 8.13 GPD/ft2 6. Average RO Flux = QP /A = 200 gpm x 60 x 24 / 9 x 6 x 365 ft2 = 14.6 GPD/ft2 7. % Overall System Salt Passage (% SP) = [Permeate TDS / Feed TDS ] x 100 = [73 mg/l / 2800 mg/l ] x 100 = 2.6 %

Page 21 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

8. % Overall System Salt Rejection (% SR) = 100 - % SP = 100 – 2.6 % = 97.4 % Where: QP = Flow rate of permeate QR = Flow rate of reject A = Membrane surface area (surface area of Hydranautics membrane CPA2 = 365 ft2) Important Points to Note in this Design 1)

The 1st stage recovery is 61.1%, which is higher than the 2nd stage recovery. This is what a good design requires, because the TDS in the 1st stage is low and the system can operate at higher recovery without scaling.

2)

The 2nd stage recovery of 35.7 % is lower than the 1st stage recovery. This is what a good design requires since the TDS in the 2nd stage is higher than in the 1st stage and the 2nd stage needs to operate at lower recovery to avoid scaling.

3)

Despite the difference in recoveries between the 1st and 2nd stages of the RO system, the overall system recovery is 75% as per design.

4)

The 1st stage flux is 17.85 GPD/ft2 which is high. However, this is acceptable because the TDS in the 1st stage is low and the membrane can still operate without scaling.

5)

The 2nd stage flux is only 8.13 GPD/ft2 because the TDS in the second stage is high and operation at higher flux will cause scaling.

6)

Despite the difference in fluxes between 1st and 2nd stages of the RO system, the average RO system flux is 14.6 GPD/ft2 as per design.

Design Limits For any RO design, recommended design limits should be adopted. The table below shows such recommended design limits. Feedwater Parameters

RO Brackish Well Brackish Well Seawater Surface Permeate Softened not Softened Conventional

SDI15

Maximum

1

2

3

4

Turbidity NTU

Typical

0.1

0.1

0.1

0.1

Particle Count 2µm particles/ml System Average Flux (GFD)

Typical

100

100

100

100

Conservative Typical Aggressive

18 21 24

14 16 20

14 16 18

7 8 10

Page 22 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

Feedwater Parameters Lead Element Flux (GFD) % Flux Decline (per year) % Salt Passage Increase/per year Feed GPM (Maximum per Vessel) 8-inch Reject GPM (minimum per vessel) 8-inch DeltaP (psi) 6 M Vessel Membrane Element Saturation Limits with Antiscalant (LSI &SDSI)

8

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

RO Brackish Well Brackish Well Seawater Surface Permeate Softened not Softened Conventional Conservative Typical Aggressive Conservative Typical Aggressive Conservative Typical Conservative Typical Maximum Conservative Typical Typical Maximum Maximum Typical Aggressive

29 30 35 7 5 3 7 5 75 75 75 10 7.1 25 40 10 < 1.8 < 2.5

24 27 29 10 7 5 15 10 70 75 75 12 9.6 25 40 10 < 1.8 2.5

21 24 27 10 7 7 15 10 65 75 75 12 9.6 25 40 10 < 1.8 2.5

17 20 24 10 7 7 15 10 60 75 75 15 10.3 25 40 10 < 1.8 2.5

Reverse Osmosis Plant Start Up Startup - Before starting up a reverse osmosis plant system, verified that all pretreatment systems are working according to their specifications. Take water samples for analysis to ensure that specifications are met. In the case of polyamide (thin film composite) membranes free chlorine must be 0.0 ppm. The Silt Density Index (SDI) should be according to the RO design guidelines (typically < 5.0 and preferably <3.0). If the water analysis (ions, temperature, pH) has changed significantly, run a new scale projection analysis on the system. On startup, the inlet valve should open prior to the initiation of the high-pressure pump, to completely fill the system with low pressure water (<100 psi [< 7 Bars]). An alternative is to open the recycle valve for the pump and then gradually open the feed control valve to introduce the feed water at low pressure. This “soft start” will prevent hydraulic shock at startup. Pre-treatment chemical addition should begin at this time (making sure the chemicals are not over-injected). The high-pressure pump should then be started and the system slowly bought on-line, up to the design permeates flow. If starting up after a period of shutdown, flush the RO permeate to drain for 30 minutes to remove residual preservation chemicals. Produced water permeate can be used only when it meets the quality requirement of downstream processes.

Page 23 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

9

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Reverse Osmosis Plant Shut Down As salts in the feed water have concentrated up and exceeded their solubility during operation, they should be rinsed out (>15 minutes) prior to any shutdown. Rinsing of the membranes with permeate water on shut down will also aid the flushing of colloids and bacteria from the membrane surface. Flow rate during flushing should be based on the recommended cleaning instruction flow rates (refer to SAEP-348). This is normally 30 – 40 gpm [6.8 – 9.1 m3 /hr] per pressure vessel. Flushing time should be long enough for the conductivity out to equal the conductivity in. This is typically 15 - 20 minutes. If the permeate flush is unavailable, feed water can be used by allowing low-pressure water to replace the water within the system by delaying the inlet valve closing. Scale inhibitor should be turned OFF during the permeate flush. If the water temperature in the membranes exceeds 115°F, flush water should be continuously passed through the system to prevent membrane degradation.

10

Preservation of RO Membranes It is recommended to preserve membrane systems when the unit is out of production. Failure to preserve membranes may result in the development of biofilm on the membrane surface, causing operation problems such as increased pressure drops and lower normalized permeate flow to occur. Also note that prior to any shutdown, RO membranes need to be cleaned (dependent on the operation parameters). The system then MUST be flushed with RO permeate before the preservation solution can be pumped into the RO (at low pressure). For membrane preservation see SAEP-348.

11

RO Plant Systems - Data Collection & Monitoring Data collection is critical for monitoring the performance of the membrane system. Without it, there will be no idea if the system is fouling, suffering from scale formation, or if the membranes are deteriorating. When operating data is recorded, it should be compared to previously established alert and alarm levels. These levels should be associated with well-defined response procedures corresponding to the potential problem. The alert and alarm levels are set for a 15% change from normalized start up data.

Page 24 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

11.1

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Silt Density Index (SDI) The SDI is an on-site measurement of the suspended solids concentration in the feed water. It should be used to monitor the performance of the pre-treatment equipment. SDI measurements should be made pre and post multimedia filters and post cartridge filters. An SDI < 5.0 for the RO feedwater should be maintained at all times preferably SDI<3.0. Pre-treatment should be controlled efficiently using the designed flow rates and differential pressure limits for back-washing of the multi-media filters and replacing of the cartridge filters to give an SDI before the membranes of < 3.0.

11.2

RO System Pressure Drop The difference between the inlet to the initial membrane elements and the concentrate stream pressure coming off the tail end elements is what pushes the water across the membrane surface of all the elements. This is called the pressure drop (DP) or the hydraulic differential pressure. As long as the flows are constant, the DP will not change unless something physically blocks the passage of flow between the membrane envelopes of the elements (fouling). Therefore, it is important to monitor the DP across each stage of the system. An increase in DP can then be isolated as lead end, tail end or both to indicate possible cause.

11.3

Salt Rejection Since the RO systems are used to remove (or concentrate) dissolved salts, measuring salt rejection is a direct way to monitor the performance. Salt rejection is the percentage of the feed water TDS that has been removed in the permeate water. The simple way to monitor the salt rejection is to measure permeate water conductivity. The permeate water conductivity should be measured for each pressure vessel on a daily basis. This will then help determine if a high salt passage problem is universal (indicating membrane damage), isolated to a certain stage (possible fouling) or isolated to an individual pressure vessel (indicating O-ring problems). Probing of individual pressure vessels can be carried out to isolate a salt rejection problem to an individual membrane element.

11.4

Normalized Permeate Flow The permeate (product water) flow of the RO system is related to water temperature and the net driving pressure. Permeate flow should therefore be

Page 25 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

standardized for the effects of these variables to allow better monitoring of how well water is permeating through the membranes. The formula used to calculate Normalized Permeate flow is: Qnorm = Qi * (NDPstart / NDPi) * (TCstart/TCi) Where Qnorm = Normalized permeate flow Qi = Permeate flow at point i NDPstart = Net Driving Pressure at startup or reference condition NDPi = Net Driving Pressure at point i. TCstart = Temperature Correction Factor at startup or reference condition TCi = Temperature Correction Factor at point i. The membrane manufacturer provides the temperature correction factors (at a constant net pressure) to allow normalization for temperature effects. The net driving pressure is the applied pressure minus the permeate backpressure minus the osmotic pressure. This driving pressure is proportional to the permeate flow rate. We can multiply by a ratio of the startup driving pressure to the current driving pressure to obtain the permeate flow rate if we were at startup pressure conditions. The calculated permeate flow rate can then be multiplied by the membrane temperature correction factor to give the normalized permeate flow. To save time and give accurate measurements, either the membrane manufacturers or our ROCIsoft software should be used to normalize all permeate flow readings. A decline indicates that fouling or scale formation is reducing permeate flow through the membranes. An increase indicates that fouling/scaling has been removed or that membrane deterioration is occurring. It is recommended that normalized permeate flow is monitored for each stage. This will help identify and isolate problems more accurately.

Page 26 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

12

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Common Reverse Osmosis Systems Failures/Problems Failure/Problem

Effect

Recommended Monitoring Practice

Antiscalant

Scale formation on membranes, usually in the back-end stages, high salt passage, high differential pressure in final stage

Ineffective sanitization procedures

Sanitize sand filters and GAC filters. Check Biofouled pipe-work, cartridge filters and microbiological analysis, chlorine dosing, membranes - high differential pressure contamination in chemical dosing tanks

High iron content

Iron loading on cartridge filters. Iron fouling of membranes – high differential pressure, low permeate flow

High organic content

Humic substances and organic fouling on Feed water composition, review flocculation membrane – low permeate flow, high procedures, feed water color, TOC feed pressure

Colloidal breakthrough

Colloidal particles foul micron filters and membranes – high differential pressure, low permeate flow

Granular activated carbon Carbon fines foul micro filters and filters membranes

Check dosing equipment and monitor changes in water quality

Pipe-work corrosion, ferric breakthrough from media beds, failure of media filters, or iron source between media filters and cartridge filters

Silt Density Index (SDI), condition of cartridge filters, eliminate media fines Check washing procedure to remove fines from GAC filters

Overdosing of flocculent

Cationic flocculent fouls membrane – low permeate flow, high feed pressure.

Check flocculent dosing levels

Overdosing of chlorine

Membrane damage – high salt passage and increased flux

Dosing equipment, Redox meters, bisulfite dosing levels and positioning of dosing point, chlorine test kit

Permeate tube “O” ring failure

High salt passage

Check individual vessels’ conductivity, probe suspect vessels to check individual membrane product conductivity

Ineffective biocide

High bacterial/fungal counts in water samples. Biofouling of membranes – high differential pressure

Biocide adsorption on GAC, check contact times and dose rate, select broad-spectrum biocide, Select biocide for organic content

Sand/Multi-media filter breakthrough

Colloidal and bacterial fouling of micron filters and membranes

Check wash procedures to remove fines

Acid dosing

Scale formation – CaCO3 only

pH monitor/controller

Seasonal algae blooms (sea water)

High microbiological loading, biofilm, severe cartridge filter fouling

Microbiological counts in water samples, evidence of biofilms, check algae counts

Poor performance on start up after shutdown

Fouling/scaling of membranes

Check membrane flush procedures on shut down and preservation procedures on extended shutdowns

Page 27 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

13

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Reverse Osmosis Membrane Cleaning RO membrane cleaning is an important part of any reverse osmosis maintenance program. Effective cleaning usually requires some knowledge of the type of foulant and the cleaning options available. Foulants on the membrane surface can cause flux loss (permeate flow), an increase in differential pressure, higher product water conductivity, a need for increased feed pressure to maintain output or a combination of these effects. Even with all the preventative care given to a reverse osmosis system, some fouling of the membranes will take place. Cleaning of the membranes can improve membrane performance. Membranes can be cleaned using only Cleaning Solutions approved by the membrane manufacturer. What to do before cleaning? Perform all daily monitoring and use the results to perform data normalization as outlined by the membrane manufactures. The data normalization programs consist of Excel spreadsheet on which the operating parameters and operating data are inserted. These data normalization programs are given free of charge by the membrane manufacturers or can be downloaded from the membrane manufacturers’ websites. Hydranautics membranes: Use the RODataXL software for tracking the RO system performance. This is an RO normalization program. This program allows easy input of operational data and graphs of operational and normalized parameters are automatically updated. Toray membranes: Use the TorayTrack software for tracking the RO system performance. This is for the data collection, normalization and management of Reverse Osmosis (RO) membranes in plants of any size. The graphs and output of the software will provide operators with crucial information guiding their maintenance and operation plans and optimizing membrane performance for maximum membrane cost effectiveness. Dow Filmect membranes: Use the FTNORM - Software to Normalize Membrane Operating Data. This is a spreadsheet-based program. The program is Microsoft® Excel 97® based and provides for automatic standardization of operating data. Charts are created showing standardized permeate flow, standardized salt passage / salt rejection and differential pressure. One spreadsheet should be used for each train in the system. When to clean? It is essential to clean membranes at an early stage of fouling. It is often difficult to clean excessively fouled membranes and irreversible damage may occur during the cleaning process. Cleaning is recommended when one or more of the following parameters change by 10 – 15% after data normalization:

Page 28 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Decrease in normalized permeate flow

Increase in product conductivity or salt passage

Increase in feed pressure to maintain normalized permeate flow

Increase in differential pressure

If any of the above performance parameters deteriorates by more than 30%, it may be impossible to recover plant performance by routine cleaning practices. What to clean? Find out the kind of impurities from simple examination of the SDI filter pad. Autopsy a couple of membranes taken from strategic points within the RO system. One lead element membrane taken from the first stage of the RO system to establish the foulants present and one membrane element taken from the tail end of the second stage to establish the type of scaling. How to clean? Once you decide what to clean, follow the appropriate chemical cleaning procedures as outlined in SAEP-348. 14

Chemical Water Treatment for Reverse Osmosis 14.1

Coagulants/Flocculents Coagulants/flocculents can be used to improve filtration and aid the removal of fine colloids, reducing SDI values of RO feedwater. The coagulant should always be dosed prior to the multimedia/sand filters and as far back in the system as possible for good mixing and coagulation. Cationic flocculents can foul RO membranes. It is therefore important that the dosage is accurately controlled. Over-dosing, particularly of organic flocculents, can cause the coagulant to break-through the filters and end up in the RO plant. Organic flocculent reaction with anionic polymer antiscalants can also occur, resulting in membrane fouling. It is therefore important to ensure a flocculent compatible antiscalant is used when using cationic flocculents in the pre-treatment.

14.2

Chlorine Chlorine (Na/Ca hypochlorite, bleach or gas) can be dosed to control biological fouling of the pre-treatment system. If biological contamination is an issue, chlorine can be dosed prior to the pre-treatment system to give a free chlorine residual of 0.2 – 1.00 ppm depending on severity of contamination. Chlorine will destroy polyamide thin film composite membranes. It is essential that ALL chlorine be removed from the feed water prior to entering the membranes (CA membranes can tolerate up to 1ppm free chlorine). Even trace Page 29 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

amounts of free chlorine can cause oxidation damage, especially in the presence of metals such as iron. Chlorine can be removed by bisulfite/metabisulfite addition or by the use of carbon filters. 14.3

Sodium Meta-Bisulfite, Bisulfite, Sulfite Sodium Bisulfite, Sodium Meta-Bisulfite or Sodium Sulfite can all be used to de-chlorinate the RO feed water. De-chlorination is essential with polyamide type membranes. Sodium Metabisulfite (SMBS = Na2S2O5) is a 100% active solid and dissolves in water to form sodium bisulfite. It is 100% active. The fumes from mixing with water can be irritating. Na2S2O5 + H2O

2NaHSO3

De-chlorination reaction with bleach (HOCl): HOCl + NaHSO3

NaCl + H2SO4

Sodium Bisulfite (SBS = NaHSO3) is liquid and usually sold as a 40% active. De-chlorination reaction with bleach (HOCl): HOCl + NaHSO3

NaCl + H2SO4

Sodium Sulfite (SS = Na2SO3) is a liquid, usually with a maximum active of 20%. De-chlorination reaction with bleach (HOCl): HOCl + Na2SO3

HCl + Na2SO4

A 40% sodium bisulfite solution (either as supplied or made up with metabisulfite) will probably be the most stable solution to use. Important points to note:

The SBS solution should be dosed as close to the RO system as possible (to keep as much of the pre-treatment as possible in contact with chlorine – e.g., cartridge filters). However,

If the free chlorine level is high, the SBS should be dosed prior to the antiscalant injection point (or antiscalant dosage adjusted to compensate for chlorine attack). Some antiscalants are attacked by free chlorine.

The antiscalant and SBS dosing point should be far enough apart to prevent Page 30 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

neat product mixing (SBS and antiscalant can often be mixed when diluted correctly, but pH differences of the neat products can cause problems). 14.4

Biocides RO Biocides - Non-oxidizing, non-ionic biocides can be used either on line or as part of a cleaning program to control biofouling in RO membranes. When used as an on-line treatment, the biocide should be dosed prior to the RO system to control bio-growth in the membranes. Application frequency will depend on biological loading and biofilm growth rate. The program should be used to control differential pressures in the RO plant to reduce cleaning frequency. Application rates and frequency of application (biocide program costs vs. effectiveness) vs. reduction in cleaning frequency, down time, membrane life (operating costs without biocide program) should be balanced to determine the most cost effective biocide dosing frequency. Dosing biocide further back in the pre-treatment will help control bio-growth but will greatly increase demand and application costs. The main goal of an effective biocide program is to control biofouling in the membranes to an acceptable and cost effective level compared to cleaning program costs. The two products widely used are 2,2-dibromo-3-nitrilopropionamide (DBNPA) and isothiazolone. These products are fully compatible with polyamide (PA) and cellulose acetate (CA) membranes. DBNPA DBNPA (2,2dibromo-3-nitrilopropionamide) is fast biocide acting and readily decomposes to harmless by-products on discharge. On-line, it is dosed just prior to the RO system to control biofouling in the membranes. Dose rate is typically 100 ppm for 1 hour. Frequency of application depends on degree of biological contamination in the feed water and rate of biofilm growth in the membranes. Typically, frequency of application can vary from every other day to once a month. The half-life of DBNPA is reduced with the increase of pH. In high pH feed waters (>8.5) the dose rate and contact time should be doubled. DBNPA biocide should not be dosed with stainless steel injection quills as corrosion of the injection assembly will occur. Isothiazolone Isothiazolone has a longer contact time than DBNPA. Dose rate is typically 50 – 100 ppm for 4 hours contact. Isothiazolone is more effective than DBNPA in waters with high organic loading. Isothiazolone can also be used at low dose rates on a continuous basis (10 – 20 ppm). Page 31 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Hydrogen Peroxide Silver Blend ROCbio Silver, an innovative blend of hydrogen peroxide and silver, is an eco-friendly, multi-component oxidizing biocide utilizing a stable combination of Hydrogen Peroxide (H2O2) and Silver(Ag) ions to form a highly effective sanitizing solution. This synergistic combination is so effective it creates a biocide twenty times more powerful than that of hydrogen peroxide alone. 14.5

Scale Inhibitors RO Scale inhibitors or antiscalants can be dosed before or after the system cartridge filters. If iron is present in the feed water, the antiscalant can be dosed post to prevent “pick-up” of iron (or in the case of polymer antiscalants deactivation by iron – in this case use a phosphonate based product with good iron sequestering properties). The dose point should be after the sodium bi-sulfite injection to ensure chlorine is removed (especially with high levels of free chlorine). Dose point should be sufficiently down-stream of the SBS injection point to avoid “neat” product mixing.

15

Troubleshooting The performance of an RO system is determined by the quality and quantity of product water that delivers. Permeate flow and salt rejections are therefore important parameters for the RO system evaluation. In certain situations changes in the element’s differential pressure (ΔP) can be used as another parameter for RO system evaluation. A problem exists when these factors are outside the range of expected values. Although performance may still satisfy the end-user, any unexpected change in these parameters should be investigated and corrective action taken immediately to prevent further deterioration of the system. Many factors affect product flow, salt rejection and element ΔP. Some of these items involve changes in operating conditions. These changes can be taken into account by normalizing to a fixed set of conditions. Performance variations unexplained by operating conditions involve troubleshooting. 15.1

Profiling an RO Array When problems arise with an RO system, the ability to isolate the problem to a particular location within the system provides valuable information as to the nature of the problem. This will determine the remedial action such as cleaning, O-ring replacement or membrane element replacing. Online investigation is done while the system is in operation. It involves analyzing performance trends in normalized product flow salt rejection and correlating these trends with symptoms of known problems. The information for the online investigation is obtained from the plant operating data log and basic plant design package. The frequency, Page 32 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

accuracy and completeness of the operating log are vital for successful troubleshooting. Also, critical is the accuracy of the instrumentation. It cannot be over-emphasized that before troubleshooting any plant problem, the good working order and proper calibration of meters and gauges must first be assured. 15.2

Probing Once profiling has isolated a salt rejection problem to a particular pressure vessel, or set of vessels, probing can be used to further isolate the problem. Probing involves inserting flexible tubing through one of the vessel permeate connections as a means of diverting the permeate from a specific area within the elements. This water is then tested for conductivity with a portable meter. Probing must be performed while the RO is operating. The tubing is worked through various fittings to the other end of the vessel. It is then gradually pulled back as diverted water samples are tested. The end of the vessel should be sampled and then every 20 inches through the whole of the vessel. Sufficient time (30 seconds) should be allowed between samples to ensure that water from the new sampling location has completely displaced the water within the tubing. Figure 5 shows how the probing procedure is applied. From the conductivity readings obtained a graph is plotted. Curve A represents the expected graph if none of the membrane elements or o-rings are malfunctioning. Curve B indicates the source of the high salt passage problem.

Curve B

Curve A

Figure 5 – Location of High Salt Passage (Probing)

Page 33 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

15.3

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants

Replacing O-Rings Movement of the spiral wound membrane elements within their pressure vessel can commonly cause abrasion and breaking of the O-rings that seal the interconnector to the element permeate tube. A sudden increase in permeate conductivity, not accompanied with a noticeable increase in permeate flow rate could indicate a broken or missing O-ring. Profiling and then probing to determine if only individual pressure vessels/membrane elements are causing the increased conductivity will indicate if O-ring damage is the problem. To replace the O-ring, the RO should be shut down and allowed to drain by opening the sample valves. The end-cap is then removed. Usually, O-ring damage is visible. The O-ring is replaced by hand, wetting with lubricant (glycerin- use sparingly) if necessary.

15.4

Shimming It is normal to have some movement of the membrane elements within their pressure vessel housings. This occurs because the pressure drop across the elements can cause them to compress. Fouling or high flow rates can result in significant movement, mostly when the system starts up. When it shuts down, the elements will then relax. This movement will cause rubbing against the inter-connector O-rings, particularly in the lead end elements. With time, this can cause them to abrade and possibly break. In case of severe pressure drops, O-rings can be completely dislodged and blow out of their slots. The potential for this movement should be minimized by making certain that the elements fit tightly within their pressure vessel. Any slop should be taken up with shims. Shims are slices of plastic piping that have an inside diameter that just fits over the outside of an end connector, usually the end connector between the lead end element and the vessel end cap. Enough should be installed so that replacing the end cap in its vessel should be met with some resistance.

15.5

Replacing RO Membrane Elements Occasionally, it is necessary to replace RO membrane elements. This will be determined if necessary following trouble shooting and other remedial actions. As with replacing O-rings, the system should be shut down and drained. Prior to installation, the new element serial numbers should be recorded indicating their Page 34 of 36

Document Responsibility: Materials and Corrosion Control Issue Date: 12 September 2009 Next Planned Update: TBD

SABP-A-028 Optimizing Design and Operation of Reverse Osmosis Plants