เครื่องที่ใช้ควรเป็น Triple Action Press: Hydroforming

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View เครื่องที่ใช้ควรเป็น Triple Action Press: Hydroforming as PDF for free.

More details

- Words: 360

- Pages: 8

Loading documents preview...

PRESS

15

เครื่องที่ใช้ ควรเป็ น Triple action press

Advanced Forming Processes

HYDROFORMING

16

Advanced Forming Processes

The Process - in four steps to the finished hydroformed part 1. Close die The starting tube ‐ a straight or pre‐bent tubular section ‐ is placed into a die which has the contour of the component to be produced.

2. Fill with water The die is closed and held closed by means of a hydraulic press and kept under pressure. Hydraulically actuated sealing punches close off the tube ends and fill the tube with the fluid medium, thus building up internal pressure. 17

Advanced Forming Processes

3. Move horizontal cylinders, regulate water pressure, move counter holder In the actual forming process the material is expanded. At the same time the sealing punches compress the tube ends. This causes the material to flow into the contour of the die. A precise control of the internal pressure and of the axial cylinder movement enables that the material takes on the form of the internal die contour and the component gets its final shape. 4. Open press, unload component After hydroforming the hydraulic press opens the die for unloading the component

18

Advanced Forming Processes

Tube Hydroforming a

b

c

d

e Faxial

Faxial P

19

Advanced Forming Processes

20

Advanced Forming Processes

f

Open Model

Complete

21

Advanced Forming Processes

Hydroformed Side Rails on a Truck Chassis

Hydroformed Exhaust Parts Hydroformed Cam Shafts have Lower Rotational Inertia and Require Less Machining 22

Advanced Forming Processes

23

Advanced Forming Processes

ELECTROMAGNETIC FORMING EMF

24

Advanced Forming Processes

Electro-Magnetic Forming

Operating principle of electromagnetic metal forming process 25

Advanced Forming Processes

Basic Methods of EMF

Compression forming

Expansion forming 26

Advanced Forming Processes

Basic Methods of EMF

Contour forming 27

Advanced Forming Processes

Electro magnetic actuator

Improve stamping operation

28

• Improved Formability —at high velocity.

• Active control of springback

• Improved strain distribution

• Distortions at local features are minimized

• Reduction in wrinkling

• Local coining

Advanced Forming Processes

A demonstration of the ability to add character lines without distortion and/or wrinkling with full-size aluminum hood.

29

Advanced Forming Processes

30

Advanced Forming Processes

15

เครื่องที่ใช้ ควรเป็ น Triple action press

Advanced Forming Processes

HYDROFORMING

16

Advanced Forming Processes

The Process - in four steps to the finished hydroformed part 1. Close die The starting tube ‐ a straight or pre‐bent tubular section ‐ is placed into a die which has the contour of the component to be produced.

2. Fill with water The die is closed and held closed by means of a hydraulic press and kept under pressure. Hydraulically actuated sealing punches close off the tube ends and fill the tube with the fluid medium, thus building up internal pressure. 17

Advanced Forming Processes

3. Move horizontal cylinders, regulate water pressure, move counter holder In the actual forming process the material is expanded. At the same time the sealing punches compress the tube ends. This causes the material to flow into the contour of the die. A precise control of the internal pressure and of the axial cylinder movement enables that the material takes on the form of the internal die contour and the component gets its final shape. 4. Open press, unload component After hydroforming the hydraulic press opens the die for unloading the component

18

Advanced Forming Processes

Tube Hydroforming a

b

c

d

e Faxial

Faxial P

19

Advanced Forming Processes

20

Advanced Forming Processes

f

Open Model

Complete

21

Advanced Forming Processes

Hydroformed Side Rails on a Truck Chassis

Hydroformed Exhaust Parts Hydroformed Cam Shafts have Lower Rotational Inertia and Require Less Machining 22

Advanced Forming Processes

23

Advanced Forming Processes

ELECTROMAGNETIC FORMING EMF

24

Advanced Forming Processes

Electro-Magnetic Forming

Operating principle of electromagnetic metal forming process 25

Advanced Forming Processes

Basic Methods of EMF

Compression forming

Expansion forming 26

Advanced Forming Processes

Basic Methods of EMF

Contour forming 27

Advanced Forming Processes

Electro magnetic actuator

Improve stamping operation

28

• Improved Formability —at high velocity.

• Active control of springback

• Improved strain distribution

• Distortions at local features are minimized

• Reduction in wrinkling

• Local coining

Advanced Forming Processes

A demonstration of the ability to add character lines without distortion and/or wrinkling with full-size aluminum hood.

29

Advanced Forming Processes

30

Advanced Forming Processes

Related Documents

Triple Talaq

January 2021 1

Triple Eliminasi.pptx

February 2021 0

Hoja-triple-renglon.pdf

February 2021 0

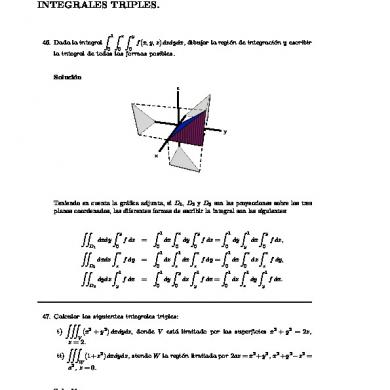

Problemas Resueltos Integral Triple

January 2021 1

Integral Doble Y Triple

February 2021 1

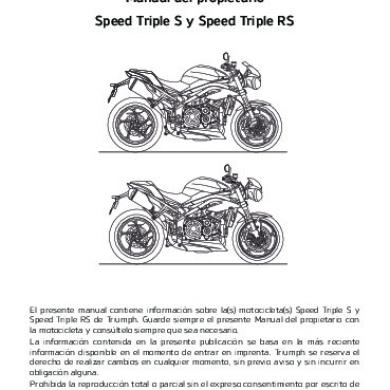

Speed Triple S And Speed Triple Rs Owners Handbook Spanish.pdf

February 2021 0More Documents from "Jairo Ribera Pessoa"

Mfg Tooling -09 Progressive Dies.pdf

February 2021 1

Automotive Applications Stamping

February 2021 0

Using Limiting Draw

February 2021 0

Stock Strip Layout: Percentage Utilization = 56.5%

February 2021 0