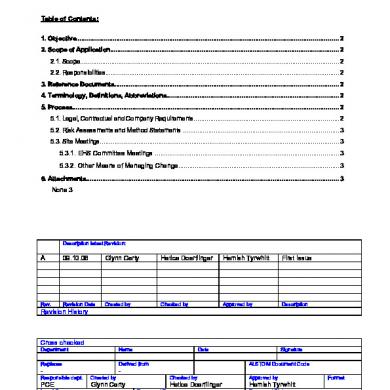

170072 Sl 4m Change Management Briefing En

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View 170072 Sl 4m Change Management Briefing En as PDF for free.

More details

- Words: 6,278

- Pages: 42

Loading documents preview...

4M CHANGE MANAGEMENT

4M Change Management Overview 4 M – Rollout @ GS in 2015 / 2016 What is 4M

Objective of 4M

• 4M is a method for planning and tracking of changes in the production process in accordance with defined responsibilities

• Visualisation and exchange of information about all intentional and incidental changes

• 4M is used in the shop floor

• Systematic tracking of changes

• the changes are classified into the 4M´s: Man, Machine, Material, Method

• Monitoring of the change control method and result confirmation

Procedure and status Plants group I: BaP; BhP; BuP1; EhP; FeP-Ru; MuP; NuP1; RBCB; RBEF; TbP; WaP Plants group II: AdP; CaP; ChP; DaeP; AmaP; UAES; HcP; TlP; SlpP; BljP; GanP

2

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Schedule

4M Change Management Big Picture Situation: Incidents, sorting actions , recursions • Instructions not followed • Changes not validated / not sufficiently validated • Responsibilities not clear / not clearly defined

Action: 4M is structuring specifications • • • •

Focus: minor changes (changes w/o formal ECR process) and implementation of ECR Strength: Communication and Visualization Clearly defined responsibilities Integrations in existing process landscape and tools

Result: standardized, validated procedure what, how, who, when • No “wild” changes in the shop floor • Validation of effectiveness • Traceability 3

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management 4M as part of daily management / daily routine Daily routine 4M: Review

Process Confirmation of last / shortly implemented changes

Actual

Which changes are running / planned for today

Preview

Which (additional) changes are planned for the upcoming days

Implementation of ECR on shop floor

Change / Maintenance St. 130

Change of gauges

New employee

Softwarechange St. 10

Change of process parameters

New PQI / Instruction

Participants: Team leader, QMM, supporting function e.g. TEF, MOE-Planner Advantages: • Regular and systematic information exchange • All concerned functions are participating in daily routine • Preventive Approach: Problem avoidance instead of problem solving 4

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management 4M as part of daily management / shop floor routine Daily Management •

Focus: Deviation Management Strength: • Detect deviations • Measures to return to standard

5

4M Change Management •

Focus: Change Management Strength: • Avoid deviations • Method to implement changes w/o negative impact on the production porcess

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Supporting Documents Rules and Standards: 4M Change Matrix • Overview (existing) specification for implementing and validation of changes • Clear responsibilities • …

Outlook: 4M Intentional Change Management Schedule • Visualization: Which changes are planned? • Communication: One document instead of loads of e-mails, verbal information, … • Common understanding (shift overlapping)

Systematic implementation: 4M Change Point Record Sheet • Documentation of actual changes • What is changing / has changed • Who is therefore responsible • Effectiveness validation

Advantages: • Well-defined procedure for implementation changes in the shop floor No firefighting • 4M templates are available; plant specific modifications are explicitly allowed 6

Internal | GS/QMM2 - Steff | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Management Briefing “How to” – Central Theme 4M Change Matrix: Listing of intended and incidental changes with control and documentation method purpose:

Specification of intentional / incidental change point with control method and responsibilities

procedure:

see the following matrix

legend:

4M

○ ◎ ● △ Category

intentional change

preparation approval implementation confirmation Change Point

intentional change

Method

incidental change

7

control method

documentation method

Fitter

SAP

SAP

replacement of measuring and testing equipment

inspection of measuring and testing equipment

PM-Info

●*3

additional measuring and testing equipment MAE regular maintenance (TPM) relocation of MAE exchange of workpiece carrier exchange of tooling, fixture

test instruction TPM instruction ECR TPM instruction TPM instruction

KEB-Production TMP check sheet Serial Release TMP check sheet TMP check sheet

●

● ●△

● ●

○●△◎ ○●△◎

Change over

maintenance and restart check sheet

maintenance and restart check sheet

maintenance and restart check sheet ECR

maintenance and restart check sheet Oracle DB (SAP)

restart

maintenance and restart check sheet

maintenance and restart check sheet

●△

damage of workpiece carrier damage of tooling, fixture

TPM instruction TPM instruction

E-Mail to Planner E-Mail to Planner

●△ ●△

machine breakdown, error without TEF support

maintenance and restart check sheet

maintenance and restart check sheet

●△

machine breakdown, error with TEF support maschine stop with andon cord / high scarp rate

malfunction message escalation model

SAP Shift book

restart after breakdown / andon cord

Quality release form

Quality release form / Change Point record sheet

Change of tool after tool break / crash

Quality release form

SPC mesurement

Process Engineering Change according to CDQ Change of process specification Change of test specification

ECR process data sheet test instruction maintenance and restart check sheet

Change of maintenance and restart specification deviation from production process

E-Mail to Planner

Restart Checklist

Responsibilities Operator

planned maintenance (additional to TPM)

MAE modification

incidental change

Quality release form

--> planning of the change --> approval for implementation --> Implementation of the change --> result confirmation

replacement of MAE components (e.g. repair work) Machine

Control Method

Teamleader Shift Supervisor Supervisor

△

Planner

Senior Manager

○●△

◎

○●

○△ ○ ○●

◎ ◎ ◎

… ◎

●

○△ ○

Test instruction / SPC TPM instruction

△

◎ ● ◎

●

Documentation Method

◎

SAP / Shop floor documentation

●

△ △ ●△

◎

●

○●△

◎

SAP KEB-Production KEB-Production

● ●

◎ ◎

○●△ ○●△ ○●△

◎ ◎ ◎

KEB-Production

●

◎

○●△

◎

Outlook

TEF

○◎*2 ◎ ◎

○△

QMM

◎

△

●

Director

● ◎

●△

Restart Checklist Change Point record sheet

◎

●△

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

TPM check sheet …

Responsibilities

4M Change Management - Management Briefing “How to” – Central Theme Example for Quality Release form: Werkstatt Grund:

laufende Nummer (optional) geplanter Umbau

Uhrzeit:

Datum:

Beschädigung / Crash / BA

Reparatur, Tausch

Linie:

Störung / Stillstand / hoher AS

Station:

Teil A: Durch Einsteller/Maschinenführer

IST-Situation: Problem, Ursache

Beurteilung Auswirkung auf bereits gefertigte Teile: (auch Vorgängerfertigung) Auswirkung auf gefertigte Teile?

Nein

Ja

Möglich

(bei "Ja" und "möglich" müssen Teile gesperrt und rückverlesen werden)

Begründung bei NEIN: Teile gesperrt?

Nein

Ja

Typ:

Anzahl:

Teile rückverlesen?

Nein

Ja

Typ:

Anzahl:

(z.B. 100% Sichtprüfung auf Beschädigung)

Ergebnis Rückverlesen:

Teil B: Durch Einsteller/Maschinenführer

☐ Block / sorting / scarp / rework? ☐ How many parts blocked / sorted and result of sorting ☐ Short description of action or change effectuated

Aktion / Änderung erfolgreich? Ja

Nein

☐ Validation of action / change by responsible for action / change

Noch nicht abschätzbar

Weiteres Vorgehen:

Bei Unterstützung Service-MA Name und Abteilung für Rückfragen angeben:

☐ Validation of quality of the produced parts after change

Q-Wiederfreigabeprüfung nach Neustart Fertigung: Beurteilung der nach Aktion / Änderung gefertigten Teile durch: Prüfung nach PA

Dummyprüfung

Zusatzprüfung

Art der Zusatzprüfung: (z.B. Abzugskraft, Schliff, ...)

Typ:

Anzahl:

Ergebnis:

Wiederfreigabe erfolgt am: Datum:

Uhrzeit:

☐ Additional test / serial test including results and quantity

Einsteller / Anlagenführer

i.O.

Teil C:

☐ What do we have to do with the already produces parts?

☐ Action / Change Point

Aktion / Änderung (z.B. Reparatur, Tausch, Justierung, ...)

Meister oder Pl.

☐ Short description of problem / cause ☐ Planned action or breakdown / high scrap rate etc.

Rückverlesen nach:

8

☐ What happened?

n.i.O.

Kenntnisnahme (spätestens am Folgetag): Datum: Uhrzeit:

W.-Meister oder Meister oder Planer:

i.O.

n.i.O.

Aufnahme in Teilelebenslauf:

Ja

Nein Bei ja Info an Planer zum Eintrag in Lebenslauf

Prüfen ob Vorgang LL relevant:

Ja

Nein Bei ja Info an WaP LL Koordinator über Planer

☐ Validation by Supervisor latest in morning meeting ☐ Transfer in 4M Matrix / Input for LL / Input for CIP projects

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Management Briefing “How to” – Central Theme Example for Restart / Machine Release from:

☐ Definition of interventions on the machine / stations ☐ Maintenance actions / Regular Maintenance ☐ Repairs and Replacement of different organs of the machine / station

☐ Adjustment on the machine / stations ☐ Process parameters / high adjustment / …

☐ Definition of which inspections / test have to be done after intervention ☐ Allocation of test numbers from table below

☐ Definition of different inspections / test to be done ☐ Definition of what, how, how many ☐ Definition of responsibility for inspection / test (e.g. Technician, MFE) ☐ Numeration for allocation the interventions in table above

☐ Validation by Supervisor 9

☐ Validation by different sections if necessary (e.g. MFT, TEF, MOE, Planner, …) Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Management Briefing “How to” – Central Theme 4M Change Point Record Sheet: Listing of all effectuated intended and incidental changes Change Point describtion and implementation consecutive NO

start date

added by

4M

station

Change Point describtion

1

13.01.2015

Miller

machine

testing

replacement of proximity switch No. 251-A

2

15.01.2015

Buck

man

3

15.01.2015

Buck

material

assembly

4

19.01.2015

Miller

method

testing

5

23.01.2015

Miller

machine

assembly

visual inspection new operator old: holding plate …05 254 new: ..05 257 new process specification St3: 25mA --> 19mA planned maintenance St. 3-6

Change Point Decryption Classified in the 4M – Man, Machine, Material, Method Concerned station / machine / area Who added that point and when? Who is responsible for the implementation

change control method responsible for implementation

end date

TEF- Arnold

13.01.2015

Buck Buck

describtion of the change control method

result

name

maintenance and restart check sheet

ok

Sanders

20.01.2015

training plan completed

ok

Miller

15.01.2015

ECR closed, first serial No. with new material ..861

ok

Richards

tdb

Richards

follow-up

Buck

Haynes Miller

TPM instructions not followed

Control Method

Confirmation

Quality release form

Shop floor Mgmt.

Restart Checklist

Supervisor

Test instruction / SPC TPM instruction

Goal: Traceability and information of all changes over all shifts 10

result confirmation

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Incidental

Intentional

4M Change Management Case Examples for 4M change points

11

Men

Machine

Material

Method

• Personnel Change / Rotation • Support from other dept. • New Operator • Change of standardized work • No of operators in the loop • Work after planed holidays

• MAE modification • replacement of measuring and testing equipment • software change / software update • replacement of MAE components • restart • exchange of tooling, fixture

• new component • Design Change • subsidiary material change • overstay of storage life

• Process Engineering Change according to CDQ • change of process specification • change of test specification • change of TPM specification

• incidental absent of operator • incidental support from / to others

• machine breakdown • damage of tooling, fixture • blackout of medium supply (air, cooling water)

• material outside specification • material defect • lot change • transport damage

• deviation from production process

Internal | GS/QMM C/MPE | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session Overview Content (details see PNMD-505 4M Change Management) Mandatory Elements Change Matrix Intentional Change Management Schedule Change Point record Sheet

Shared Content Detection of incidental change Operator skill matrix Standardized Work

Optional Elements Operator allocation Change Point Indication Card

12

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Sustainable implementation in rules and standards QMS Powertrain: PNMD-505 4M | Change Management PNPI-312.01 – Manage Product and Process changes for ECR (Engineering Change request) PNMD-522 14 Q – Basics Value Stream (Maturity Evaluation for e.g. P9 – Restart) BPS Guidelines: Link to Daily Management / “Daily Shop Floor Routine” Link to BPS – System Approach and BPS elements BPS System approach • Daily Management / Shop Floor Routine • Link to BPS – System Approach • Link to BPS Elements in combination with 14 Q-Basics Value Stream 13

14 Q-Basics Maturity evaluation

QMS MD + PI • MD to describe standard, process and mandatory / optional elements of method • Integration in PI for ECR as mandatory standard for minor Changes (w/o ECR)

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

• • • •

P5 – Process Parameters P7 – TPM P8 – Tools P9 – Restart

4M Change Management - Briefing session QMS Powertrain documentation (PNPI-312.01 + PNMD-505)

14

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session PS BGN page 14 Q-Basics and 4M Change Management

15

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

IATF16949 AND 4M CHANGE MANAGEMENT

4M Change Management - Briefing session IATF 16949:2016 8.5.6.1 Control of changes — supplemental The organization shall have a documented process to control and react to changes that impact product realization. The effects of any change, including those changes caused by the organization, the customer, or any supplier, shall be assessed. The organization shall: a) define verification and validation activities to ensure compliance with customer requirements; b) validate changes before implementation; c) document the evidence of related risk analysis; d) retain records of veri fication and validation. Changes, including those made at suppliers, should require a production trial run for veri fication of changes (such as changes to part design, manufacturing location, or manufacturing process) to validate the impact of any changes on the manufacturing process. When required by the customer, the organization shall: e) notify the customer of any planned product realization changes atter the most recent product approval; f) obtain documented approval, prior to implementation of the change; g) complete additional veri fication or identification requirements, such as production trial run and new product validation.

First level:

8.5.6.1 Überwachung von Änderungen — Ergänzung Die Organisation muss über einen dokumentierten Prozess zur Lenkung von und Reaktion auf Änderungen verfügen, welche die Produktrealisierung beeinflussen. Die Auswirkungen jeder Änderung müssen bewertet werden, gleichgültig, ob sie durch die Organisation, den Kunden oder einen Lieferanten veranlasst werden. Die Organisation muss: a) Maßnahmen zu Veri fizierung und Validierung festlegen, um sicherzustellen, dass die Anforderungen der Kunden weiterhin erfüllt werden, b) Änderungen validieren, bevor sie umgesetzt werden, c) Nachweise für eftsprechend durchgeführte Risikoanalysen erbringen, d) Aufzeichnungen über Veri fizierungen und Validierungen aufbewahren. Um die Auswirkungen einer Änderung auf den Fertigungsprozess bewerten zu können, sollten alle Änderungen — auch Änderungen bei Lieferanten — einen Produktionsprobelauf zur Veri fizierung der Änderung erforderlich machen (wie zum Beispiel Änderungen an der Auslegung des Produktes, Verlagerung des Produktionsstandortes oder Änderungen am Fertigungsprozess). Wenn vom Kunden gefordert, muss die Organisation: e) den Kunden über jede beabsichtigte Änderung am Produktrealisierungsprozess nach der letztgültigen Freigabe informieren, f) eine dokumentierte Freigabe einholen, bevor die Änderung umgesetzt wird, g) alle Maßnahmen zur Erfüllung zusätzlicher Anforderungen zu Veri fizierung oder Kennzeichnung, wie Produktionsprobelauf oder erneute Produktvalidierung, abgeschlossen haben.

ECR (Engineering Change request) Documented Process

Second level:

Changes w/o formal ECR process (Acc. CDQ0404) Documented process (4M Matrix, Change Management Schedule, Change Point Record Sheet)

17

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

MODIFIED

4M Change Management - Briefing session CDQ0404 – Attachment 4: Customer involvement matrix Links: CDQ0404 CDQ0404-Att 4 CDQ0404-Att 5

Changes without formal ECR Process: changes without formal ECR process are process-/ method-related changes for optimization of processes and flows within the limits specified with the customer and within the internally specified limits (no change with respect to fit, form, function and reliability of components). The change is classified on the basis of Attachment 4 "Customer Involvement matrix” footnote 1). If a change does not have any effect on the product bill of materials (BOM), test specifications, offer drawings, TCD, drawings (product drawings, tool-drawings with effect on product) or similar, then it can be handled as change without formal ECR process and in these cases without formal documentation. Safeguarding against risks must be carried out and documented. The documentation must suffice the basic principles of traceability. (extract from CDQ0404 Att 5) 18

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session IATF 16949:2016 8.5.6.1.1 Temporary change of process controls 8.5.6.1.1 Zeitlich begrenzte Änderungen in der Produktionsprozesslenkung The organization shall identify, document, and maintain a list of the process controls, including inspection, measuring, test, and error- Die Organisation muss eine Liste der Produktionsprozesslenkungsmaßnahmen — einschließlich der Prüf- und Messmittel — erstellen, proofing devices, that includes the primary process control and the approved back-up or alternate methods. dokumentieren und pflegen, die sowohl die ursprünglich geplanten Methoden zur Prozesslenkung enthält als auch die freigegebenen „Backup“- oder Alternativmethoden. The organization shall document the process that manages the use of alternate control methods. The organization shall include in Die Organisation muss den Prozess dokumentieren, mit dem der Einsatz alternativer Steuerungs- und Überwachungsmethoden geregelt this process, based on risk analysis (such as FMEA), severity, and the internal approvals to be obtained prior to production wird. Die Organisation muss in diesem Prozess festlegen, dass — auf Risikoanalysen (wie FMEA) und der Tragweite basierend — zunächst implementation of the alternate control method. interne Freigaben erfolgen müssen, bevor die alternativen Steuerungs- und Überwachungsmethoden in der Produktion umgesetzt werden. Before shipping product that was inspected or tested using the alternate method, if required, the organization shall obtain approval Bevor das mit alternativen Steuerungs- und Überwachungsmethoden geprüfte Produkt ausgeliefert wird, muss die Organisation eine from the customer(s). The organization shall maintain and periodically review a list of approved alternate process control methods entsprechende Freigabe des (der) Kunden einholen, sofern gefordert. Die Organisation muss eine Liste der freigegebenen und im PLP that are referenced in the control plan. referenzierten alternativen Methoden zur Produktionsprozesslenkung führen und in regelmäßigen Abständen überprüfen. Standard work instructions shall be available for each alternate process control method. The organization shall review the operation Für alle alternativen Produktionsprozesslenkungsmaßnahmen müssen entsprechende Arbeitsanweisungen (standard work) vorliegen. Die of alternate process controls on a daily basis, at a minimum, to verify implementation of standard work with the goal to retum to the Organisation muss die Anwendung der alternativen ProduktionsprozessIenkungsmaßnahmen mindestens einmal täglich überprüfen, um standard process as defined by the control plan as soon as possible. Example methods include but are not limited to the following: sicherzustellen, dass die Anweisungen auch tatsächlich befolgt werden. Ziel ist es, so bald wie möglich zu den ursprünglichen, im a) daily quality focused audits (e.g., layered process audits, as applicable); Produktionslenkungsplan geplanten Methoden zur Prozesslenkung zurückzukehren. Beispielhafte Überprüfungen sind Folgende und b) daily leadership meetings. Weitere: Restart verification is documented for a defined period based on severity and confirmation that all features of the error-proofing device a) tägliche qualitätsbezogene Audits (z. B. LPA — Layered Process Audits, wenn anwendbar), b) tägliche Treffen auf Leitungsebene. or process are effectively reinstated. The organization shall implement traceability of all product produced while any altemate process control devices or processes are being used (e.g., veri fication and retention of first piece and last piece from every shift).

NEW IATF16949:2016

Nach Wiedereinsetzen der ursprünglich geplanten Maßnahmen zur Prozesslenkung sind entsprechende Überprüfungen für einen festgelegten Zeitraum aufrechtzuerhalten und zu dokumentieren. Für den Überprüfungszeitraum maßgebend sind die Tragweite und die Bestätigung, dass alle Funktionen/Eigenschaften der ursprünglichen Prüf- und Messmittel oder -prozesse wirksam wiederhergestellt sind. Die Organisation muss die Rückverfolgbarkeit aller produzierten Produkte sicherstellen, die während des Einsatzes von alternativen Prüfund Messmitteln oder -prozessen hergestellt wurden (z. B. Überprüfung und Aufbewahrung der Erststücke und Letztteile jeder Schicht).

Documentation of process that manages the use of alternate methods incl. standard work instructions Internal approvals prior to implementation defined in 4M Change Matrix e.g. Concession

Daily leadership meeting / LPA and LPC (Process Confirmation) 4M Integration in Daily shop floor routine / Daily management

Restart verification documented and assured that all features of error-proofing device are effectively installed 19

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session IATF 16949:2016 8.5.1.3 Verifi cation of job set— ups The organization shall: a) verify job set-ups when performed, such as an initial run of a job, material changeover, or job change that requires a new set-up; b) maintain documented information for set-up personnel; c) use statistical methods of veri fication, where applicable; d) perform first-off/last-off part validation, as applicable; where appropriate, first-off parts should be retained for comparison with the last-off parts; where appropriate, last-off-parts should be retained for comparison with firstoff parts in subsequent runs; e) retain records of process and product approval following set-up and first— off/last-off part

8.5.1.3 Verifi zierung von Einrichtvorgängen Die Organisation muss: a) Einrichtvorgänge überprüfen, unter anderem bei einem Erstanlauf der Fertigung, nach Materialwechsel oder nach Anderungen am Fertigungsablauf, die eine Neueinrichtung der Fertigungsanlagen erfordem, b) dokumentierte Informationen für die Maschineneinrichter aufrechterhalten, c) statistische Verfahren zur Verifizierung einsetzen, sofem möglich, d) Erst-lLetztteilbewertungen durchführen, soweit anwendbar. Wo angebracht, sollten die Erststücke zum Vergleich mit den Letztteilen aufbewahrt werden. Wo angebracht, sollten die Letztteile zum Vergleich mit den Erststücken nachfolgender Fertigungsläufe aufbewahrt werden, e) Aufzeichnungen über die den Einrichtvorgängen und Erststück-Letztteilbewertungen folgenden Produktionsprozess- und Produktfreigaben aufbewahren.

8.5.1.4 Verifi cation after shutdown The organization shall define and implement the necessary actions to ensure product compliance with requirements after a planned or unplanned production shutdown period.

8.5.1.4 Verifi zierung nach Produktionsstillstand Die Organisation muss notwendige Maßnahmen definieren und einleiten, um sicherzustellen, dass die Produkte nach einer geplanten oder ungeplanten Unterbrechung der Fertigung die Anforderungen erfüllen.

MODIFIED IATF16949:2016

NEW IATF16949:2016

Direct Link to IQP (Integrated Quality Planning) and 14 Q-Basics (VS) P6: Check the Checker P9: Restart

(8.5.1.2 Verification of job set-ups…requires new set-up definition with 4M Change Matrix)

P7: TPM All these principles have a strong planning topic and are considered in the IQP Process 20

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

COACHING AND SUPPORT CONCEPT

Q-Basics (VS) Strategy 2017 / 2018 Coaching and Support Concept based on CRI (IQIS BA10,20,21 – 0 km / 0 mileage) CRI violating – Q-Basics Planning MRC…”Not planned” IQP – Integrated Quality Planning ** Prepare Series * Production BPS PGL * SE – Team / ISEC * 8D, PS, LL + IPN LL / Transfer ** (Lead plant)

CRI violating – Q-Basics Execution MRC…“Not fulfilled” Working according to Standards LPC / Daily routine 4M Change - Management Mindset / Leadership 8 D / Problem Solving

Coaching / Support Concept IQP • Maturity Evaluation for IQP • Briefing Sessions for IQP • FMEA and CP • SPC, Capabilities, … • Inspection Strategy Product <-> Process

Q-Basics • Maturity Evaluation for 14 Q-Basics (VS) • Training / Coaching in CIP (e.g. KPI) • LPC – Process Confirmation • Learn to See • 4M Change management

* Preventive Approach – Before SOP; ** Preventive – Before SOP + Event-driven Reviews – After SOP e.g. 8D, ECR, LL in IPN, … 22

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Q-Basics (VS) Strategy 2017 / 2018 Coaching Concept

Event driven Support

• CRI (Customer Related Incidents) • Deviations (Audit, iDC, …)

• LPC (Layered Process Confirmation)

• Maturity Evaluation • Improvement Work – PDCA 23

Coaching / Enabling

• IQP (Integrated Quality Planning) • Capability and SPC • 14 Q-Basics (VS) + BPS PGL • 4M Change Mgmt. • Mini - Training e.g. Restart

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Mature Organization

• Preventive Approach in SE Teams • Mature Products and Processes • Safe Launch and high productivity • True North: Zero defects

WS EXAMPLES FOR 4M RODEZ: RESTART CUSTOMER (RENAULT) REQUIREMENT FOR PROCEDURE AFTER MAINTENANCE

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart WS 4M Change Management / Restart after TPM – RzP (DS)

25

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

•

4M Matrix – Template 4M

•

Restart form – AdP

•

Q-”Wiederfreigabe” – WaP

•

Restart Flow Chart – RzP

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart Listing of interventions on the machine FMEA

FMEA as important input

for Priorisation / criticality for product quality! Machine Dressing of tool Tool change

Maintenance Preventive ‒

Shop floor

‒

TEF

‒

Set-up mechanic

Curative ‒

TEF

‒

Set-up mechanic

Adjustment Changes in process Changes in personnel, … 26

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Deep dive into details Which elements? Who is responsible? Test performed after intervention? What kind / how many parts? Where are is it documented? …

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart Results after WS – Matrix and Release form 4M Change Matrix

Release from for Restart Fiche de validation de redémarrage

Matrice du changement 4M Atelier:

Est-ce que ce cas est pris en compte dans la matrice 4M : OUI / NON Est-ce que ce cas influence la qualité : OUI / NON Si le cas influence la qualité et qu'il n'est pas pris en compte dans la matrice 4M alors prévenir le N+1

Ligne: Rectification aiguille HTT

MSN At 970

Atelier

Est-ce que ce cas est pris en compte dans la matrice 4M : OUI / NON Est-ce que ce cas influence la qualité : OUI / NON Si le cas influence la qualité et qu'il n'est pas pris en compte dans la matrice 4M alors prévenir le N+1 Désignation des modifications planifiées et non planifiées des critères de vérification

Procédure:

Réalisation conformément Tableau

Légende:

Défini Autorise Réalise Valide

Modification / Changement

Machine

Main d'œuvre

Nouveau personnel sur le processus

--> --> --> -->

défini la méthode de redémarrage Autorise la réalisation du changement Réalise le changement Valide le changement Méthode de Documentation Validation surveillance / pour la validation du chagement Q contrôle Matrice de compétence

Emettre une Feuile de validation

Carte de modif sur la machine

OP

Fiche de formation au poste TEF6

Régleur

CEq.

●

◎

Matrice de polyvalence

X

Usure / Cassé / Défaut provenant du process amont

Ligne:

Arrêt / Problème sur machine/ Augmentation du taux de rebut

Matrice d'affectation

Non

Oui

Possible

(Si "oui" et "possible" bloquer et trier les pièces)

Raison du non : Non

Oui

Type:

Nombre:

Pièces triées?

Non

Oui

Type:

Nombre:

Réflexion à mener avant de faire un tri

Procédure: PM-25-01a_Rapport_tris

(par exempl. 100% visuel des pièces défectueuses)

Résultat tri:

●◎

Action / Modification (par exemple. Réparation, Changement, Réglage, ...)

Maintenance préventive faite par TEF

SAP

OT validé (SAP) Besoin de créer un doc de validation de redémarrage pour les différents niveaux d'intervention

X

oui

△

◎

Maintenance 1er Niveau

Fiche de maintenance

Listing SAP

-

-

●△

◎

Redémarrage après arrêt long

FC

AP de redémarrage

SPC + PV

non

Action / Modification réussie? Oui ●△

◎

Redémarrage après arrêt court

FC

AP de redémarrage

SPC

non

Changement Molette et turbine selon FR

FC

AP de redémarrage

X

oui

●△

◎

Changement des rouleaux d'entrainement

FC

AP de redémarrage (feuille de validation)

X

oui

●△

◎

Changement de broche porte meule

FC

Capabilité sur tous les critères de la FC (Q Stat)

X

oui

Changement de meule

FC

aucun

SPC

non

Intervention sur axe porte pièce ou axe meule

FC

AP de redémarrage (dans lequel est défini d'uil faut OE et capa)

X

non

●△

◎

◎

Non

Pas encore confirmée Exemple: voir SPC, équipe suivante, à surveiller pendant 3 jours, refaier un courant de foucault

Procédure suivante :

Préciser le nom et service de la personne qui est intervenue:

Validation après redémarrage: Validation sur pièces fabriquées après action ou modification: CTR suivant AP redémarrage (feuille américaine)

CTR avec pièces test (check the checker)

Test supplémentaire

Capabilité

●△

Test supplémentaire

A remplir que si on coche test supplémentaire Type:

Nombre:

Résultat:

Redémarrage fait: Date:

Heure:

Régleur / Chef d'équipe

ECR Nomenclature

Mode Op chez MSI

non

OK

Changement de pièces achetées (EZRS)

ECR Nomenclature

Mode Op chez MSI

non

Confirmation (au plutard le lendemain):

artie C:

Nouveau fournisseur de pièces achetées (EZRS)

ster oder Pl.

érial

Objectif de cette partie: Qu'est ce qu'on fait avec les pièces

Pièces bloquées?

(par expl. force d'arrchement, Métallo...)

27

en vert: non planifié

Station:

Evaluation sur les pièces déjà réalisées: (production également précédent) Impact sur les pièces fabriquées?

Tri :

Absence non planifiée (par exemple. La maladie, ...)

Heure:

Situation actuelle: Problème, Raison

Partie B: régleur / opérateur

4M

○ ◎ ● △

le numéro de série (en option) Reparation, Changement

Modif planifié

Date:

Partie A: réglageur / opérateur

Objectif:

Raison:

Date:

Non OK

Heure:

Contremaitre ou Responsable qualité du secteur

OK

Non OK

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart Results after WS – Restart Checklist with validation actions

Clear responsibilities documented in 4M Change Matrix Clear definition of documentation and control method for each change (intentional / incidental) Clear definition of which validation has to be done after each intervention Restart Checklist Release form for Restart incl. decision of parts handling Validation with 4-eye-principle and cross-check in daily management 28

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart Example for restart standard – AdP machine release verification

29

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Implementation Workshop Concept Lead: PS/QMM21 Workshop:

Lead: plant No. 3 + 4 (optional)

No. 1 + 2 Start: June

Current tools for change implementation - Survey of existing documents

Release by plant management July

Change Matrix Tracking of changes Operator allocation - Creation by plant team - Review by workshop team

Sep

Try out in the shop floor

Go live: roll-out along other products + IPN plants

IPN plant

1. produ ct

Use existing tools 30

Support concept acc. to PNPI301.03 Support Q-Methods

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

General approach 4M: 1st step skype clarification 2nd step briefing via skype 3rd step Workshop onsite or workshop support via skype

IMPLEMENTATION EXAMPLES FROM PLANTS WW

4M Change Management Examples for implementation in value stream Analog Visualization

Digital Visualization

5

Intern | QMS Powertrain | GS/QMM C/MPE | 15.01.2017 © Robert Bosch GmbH 2017. Alle Rechte vorbehalten, auch bzgl. jeder Verfügung, Verwertung, Reproduktion, Bearbeitung, Weitergabe sowie für den Fall von Schutzrechtsanmeldungen.

4M Change Management Example WaP Change point record sheet (Standard template) 4M Change Matrix

Terminierung von Änderungen (Standard Vorlage)

WaP 4M Procedure:

Existing plant specific document for validation of changes

33

Visualization on board

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example EhP

34

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example NuP1 1. Softwareänderungen:

35

2. Erprobung von Werkzeugen:

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example NuP1

36

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example BuP1

Each 4M change is followed up by a change card. Activities and responsibilities as defined in the change matrix. The communication about the change process is supported by the 4M Schedule Board. 37

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example BaP

Änderungsverfolgung

Visualisierung über Monitor

38

Mitarbeiterzuordnung über Monitor

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Änderungsmatrix

4M Change Management Good practice plants (w/o workshop support) Definition and Scope

ChP - GS

Example Change Points

SAP Work Order Sheet

HcP - GS

Change Matrix Visualization with board

All good practice examples will be listed on the QMS platform similar to the 14 Q-Basics (VS) E2016 MD in QMS format for further distribution. 39

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example AdP 4M Display board

40

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example BljP Visualization with board

4M Change Point Indication Card:

4M Change Management Schedule:

4M Change Matrix: 4M Change Point Record Sheet:

41

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Example CaP

42

Internal | GS/QMM2 | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Overview 4 M – Rollout @ GS in 2015 / 2016 What is 4M

Objective of 4M

• 4M is a method for planning and tracking of changes in the production process in accordance with defined responsibilities

• Visualisation and exchange of information about all intentional and incidental changes

• 4M is used in the shop floor

• Systematic tracking of changes

• the changes are classified into the 4M´s: Man, Machine, Material, Method

• Monitoring of the change control method and result confirmation

Procedure and status Plants group I: BaP; BhP; BuP1; EhP; FeP-Ru; MuP; NuP1; RBCB; RBEF; TbP; WaP Plants group II: AdP; CaP; ChP; DaeP; AmaP; UAES; HcP; TlP; SlpP; BljP; GanP

2

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Schedule

4M Change Management Big Picture Situation: Incidents, sorting actions , recursions • Instructions not followed • Changes not validated / not sufficiently validated • Responsibilities not clear / not clearly defined

Action: 4M is structuring specifications • • • •

Focus: minor changes (changes w/o formal ECR process) and implementation of ECR Strength: Communication and Visualization Clearly defined responsibilities Integrations in existing process landscape and tools

Result: standardized, validated procedure what, how, who, when • No “wild” changes in the shop floor • Validation of effectiveness • Traceability 3

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management 4M as part of daily management / daily routine Daily routine 4M: Review

Process Confirmation of last / shortly implemented changes

Actual

Which changes are running / planned for today

Preview

Which (additional) changes are planned for the upcoming days

Implementation of ECR on shop floor

Change / Maintenance St. 130

Change of gauges

New employee

Softwarechange St. 10

Change of process parameters

New PQI / Instruction

Participants: Team leader, QMM, supporting function e.g. TEF, MOE-Planner Advantages: • Regular and systematic information exchange • All concerned functions are participating in daily routine • Preventive Approach: Problem avoidance instead of problem solving 4

Internal | GS/QMM2 - Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management 4M as part of daily management / shop floor routine Daily Management •

Focus: Deviation Management Strength: • Detect deviations • Measures to return to standard

5

4M Change Management •

Focus: Change Management Strength: • Avoid deviations • Method to implement changes w/o negative impact on the production porcess

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Supporting Documents Rules and Standards: 4M Change Matrix • Overview (existing) specification for implementing and validation of changes • Clear responsibilities • …

Outlook: 4M Intentional Change Management Schedule • Visualization: Which changes are planned? • Communication: One document instead of loads of e-mails, verbal information, … • Common understanding (shift overlapping)

Systematic implementation: 4M Change Point Record Sheet • Documentation of actual changes • What is changing / has changed • Who is therefore responsible • Effectiveness validation

Advantages: • Well-defined procedure for implementation changes in the shop floor No firefighting • 4M templates are available; plant specific modifications are explicitly allowed 6

Internal | GS/QMM2 - Steff | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Management Briefing “How to” – Central Theme 4M Change Matrix: Listing of intended and incidental changes with control and documentation method purpose:

Specification of intentional / incidental change point with control method and responsibilities

procedure:

see the following matrix

legend:

4M

○ ◎ ● △ Category

intentional change

preparation approval implementation confirmation Change Point

intentional change

Method

incidental change

7

control method

documentation method

Fitter

SAP

SAP

replacement of measuring and testing equipment

inspection of measuring and testing equipment

PM-Info

●*3

additional measuring and testing equipment MAE regular maintenance (TPM) relocation of MAE exchange of workpiece carrier exchange of tooling, fixture

test instruction TPM instruction ECR TPM instruction TPM instruction

KEB-Production TMP check sheet Serial Release TMP check sheet TMP check sheet

●

● ●△

● ●

○●△◎ ○●△◎

Change over

maintenance and restart check sheet

maintenance and restart check sheet

maintenance and restart check sheet ECR

maintenance and restart check sheet Oracle DB (SAP)

restart

maintenance and restart check sheet

maintenance and restart check sheet

●△

damage of workpiece carrier damage of tooling, fixture

TPM instruction TPM instruction

E-Mail to Planner E-Mail to Planner

●△ ●△

machine breakdown, error without TEF support

maintenance and restart check sheet

maintenance and restart check sheet

●△

machine breakdown, error with TEF support maschine stop with andon cord / high scarp rate

malfunction message escalation model

SAP Shift book

restart after breakdown / andon cord

Quality release form

Quality release form / Change Point record sheet

Change of tool after tool break / crash

Quality release form

SPC mesurement

Process Engineering Change according to CDQ Change of process specification Change of test specification

ECR process data sheet test instruction maintenance and restart check sheet

Change of maintenance and restart specification deviation from production process

E-Mail to Planner

Restart Checklist

Responsibilities Operator

planned maintenance (additional to TPM)

MAE modification

incidental change

Quality release form

--> planning of the change --> approval for implementation --> Implementation of the change --> result confirmation

replacement of MAE components (e.g. repair work) Machine

Control Method

Teamleader Shift Supervisor Supervisor

△

Planner

Senior Manager

○●△

◎

○●

○△ ○ ○●

◎ ◎ ◎

… ◎

●

○△ ○

Test instruction / SPC TPM instruction

△

◎ ● ◎

●

Documentation Method

◎

SAP / Shop floor documentation

●

△ △ ●△

◎

●

○●△

◎

SAP KEB-Production KEB-Production

● ●

◎ ◎

○●△ ○●△ ○●△

◎ ◎ ◎

KEB-Production

●

◎

○●△

◎

Outlook

TEF

○◎*2 ◎ ◎

○△

QMM

◎

△

●

Director

● ◎

●△

Restart Checklist Change Point record sheet

◎

●△

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

TPM check sheet …

Responsibilities

4M Change Management - Management Briefing “How to” – Central Theme Example for Quality Release form: Werkstatt Grund:

laufende Nummer (optional) geplanter Umbau

Uhrzeit:

Datum:

Beschädigung / Crash / BA

Reparatur, Tausch

Linie:

Störung / Stillstand / hoher AS

Station:

Teil A: Durch Einsteller/Maschinenführer

IST-Situation: Problem, Ursache

Beurteilung Auswirkung auf bereits gefertigte Teile: (auch Vorgängerfertigung) Auswirkung auf gefertigte Teile?

Nein

Ja

Möglich

(bei "Ja" und "möglich" müssen Teile gesperrt und rückverlesen werden)

Begründung bei NEIN: Teile gesperrt?

Nein

Ja

Typ:

Anzahl:

Teile rückverlesen?

Nein

Ja

Typ:

Anzahl:

(z.B. 100% Sichtprüfung auf Beschädigung)

Ergebnis Rückverlesen:

Teil B: Durch Einsteller/Maschinenführer

☐ Block / sorting / scarp / rework? ☐ How many parts blocked / sorted and result of sorting ☐ Short description of action or change effectuated

Aktion / Änderung erfolgreich? Ja

Nein

☐ Validation of action / change by responsible for action / change

Noch nicht abschätzbar

Weiteres Vorgehen:

Bei Unterstützung Service-MA Name und Abteilung für Rückfragen angeben:

☐ Validation of quality of the produced parts after change

Q-Wiederfreigabeprüfung nach Neustart Fertigung: Beurteilung der nach Aktion / Änderung gefertigten Teile durch: Prüfung nach PA

Dummyprüfung

Zusatzprüfung

Art der Zusatzprüfung: (z.B. Abzugskraft, Schliff, ...)

Typ:

Anzahl:

Ergebnis:

Wiederfreigabe erfolgt am: Datum:

Uhrzeit:

☐ Additional test / serial test including results and quantity

Einsteller / Anlagenführer

i.O.

Teil C:

☐ What do we have to do with the already produces parts?

☐ Action / Change Point

Aktion / Änderung (z.B. Reparatur, Tausch, Justierung, ...)

Meister oder Pl.

☐ Short description of problem / cause ☐ Planned action or breakdown / high scrap rate etc.

Rückverlesen nach:

8

☐ What happened?

n.i.O.

Kenntnisnahme (spätestens am Folgetag): Datum: Uhrzeit:

W.-Meister oder Meister oder Planer:

i.O.

n.i.O.

Aufnahme in Teilelebenslauf:

Ja

Nein Bei ja Info an Planer zum Eintrag in Lebenslauf

Prüfen ob Vorgang LL relevant:

Ja

Nein Bei ja Info an WaP LL Koordinator über Planer

☐ Validation by Supervisor latest in morning meeting ☐ Transfer in 4M Matrix / Input for LL / Input for CIP projects

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Management Briefing “How to” – Central Theme Example for Restart / Machine Release from:

☐ Definition of interventions on the machine / stations ☐ Maintenance actions / Regular Maintenance ☐ Repairs and Replacement of different organs of the machine / station

☐ Adjustment on the machine / stations ☐ Process parameters / high adjustment / …

☐ Definition of which inspections / test have to be done after intervention ☐ Allocation of test numbers from table below

☐ Definition of different inspections / test to be done ☐ Definition of what, how, how many ☐ Definition of responsibility for inspection / test (e.g. Technician, MFE) ☐ Numeration for allocation the interventions in table above

☐ Validation by Supervisor 9

☐ Validation by different sections if necessary (e.g. MFT, TEF, MOE, Planner, …) Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Management Briefing “How to” – Central Theme 4M Change Point Record Sheet: Listing of all effectuated intended and incidental changes Change Point describtion and implementation consecutive NO

start date

added by

4M

station

Change Point describtion

1

13.01.2015

Miller

machine

testing

replacement of proximity switch No. 251-A

2

15.01.2015

Buck

man

3

15.01.2015

Buck

material

assembly

4

19.01.2015

Miller

method

testing

5

23.01.2015

Miller

machine

assembly

visual inspection new operator old: holding plate …05 254 new: ..05 257 new process specification St3: 25mA --> 19mA planned maintenance St. 3-6

Change Point Decryption Classified in the 4M – Man, Machine, Material, Method Concerned station / machine / area Who added that point and when? Who is responsible for the implementation

change control method responsible for implementation

end date

TEF- Arnold

13.01.2015

Buck Buck

describtion of the change control method

result

name

maintenance and restart check sheet

ok

Sanders

20.01.2015

training plan completed

ok

Miller

15.01.2015

ECR closed, first serial No. with new material ..861

ok

Richards

tdb

Richards

follow-up

Buck

Haynes Miller

TPM instructions not followed

Control Method

Confirmation

Quality release form

Shop floor Mgmt.

Restart Checklist

Supervisor

Test instruction / SPC TPM instruction

Goal: Traceability and information of all changes over all shifts 10

result confirmation

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Incidental

Intentional

4M Change Management Case Examples for 4M change points

11

Men

Machine

Material

Method

• Personnel Change / Rotation • Support from other dept. • New Operator • Change of standardized work • No of operators in the loop • Work after planed holidays

• MAE modification • replacement of measuring and testing equipment • software change / software update • replacement of MAE components • restart • exchange of tooling, fixture

• new component • Design Change • subsidiary material change • overstay of storage life

• Process Engineering Change according to CDQ • change of process specification • change of test specification • change of TPM specification

• incidental absent of operator • incidental support from / to others

• machine breakdown • damage of tooling, fixture • blackout of medium supply (air, cooling water)

• material outside specification • material defect • lot change • transport damage

• deviation from production process

Internal | GS/QMM C/MPE | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session Overview Content (details see PNMD-505 4M Change Management) Mandatory Elements Change Matrix Intentional Change Management Schedule Change Point record Sheet

Shared Content Detection of incidental change Operator skill matrix Standardized Work

Optional Elements Operator allocation Change Point Indication Card

12

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management Sustainable implementation in rules and standards QMS Powertrain: PNMD-505 4M | Change Management PNPI-312.01 – Manage Product and Process changes for ECR (Engineering Change request) PNMD-522 14 Q – Basics Value Stream (Maturity Evaluation for e.g. P9 – Restart) BPS Guidelines: Link to Daily Management / “Daily Shop Floor Routine” Link to BPS – System Approach and BPS elements BPS System approach • Daily Management / Shop Floor Routine • Link to BPS – System Approach • Link to BPS Elements in combination with 14 Q-Basics Value Stream 13

14 Q-Basics Maturity evaluation

QMS MD + PI • MD to describe standard, process and mandatory / optional elements of method • Integration in PI for ECR as mandatory standard for minor Changes (w/o ECR)

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

• • • •

P5 – Process Parameters P7 – TPM P8 – Tools P9 – Restart

4M Change Management - Briefing session QMS Powertrain documentation (PNPI-312.01 + PNMD-505)

14

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session PS BGN page 14 Q-Basics and 4M Change Management

15

Internal | PS/QMM21-Steffl | 24.08.2018 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

IATF16949 AND 4M CHANGE MANAGEMENT

4M Change Management - Briefing session IATF 16949:2016 8.5.6.1 Control of changes — supplemental The organization shall have a documented process to control and react to changes that impact product realization. The effects of any change, including those changes caused by the organization, the customer, or any supplier, shall be assessed. The organization shall: a) define verification and validation activities to ensure compliance with customer requirements; b) validate changes before implementation; c) document the evidence of related risk analysis; d) retain records of veri fication and validation. Changes, including those made at suppliers, should require a production trial run for veri fication of changes (such as changes to part design, manufacturing location, or manufacturing process) to validate the impact of any changes on the manufacturing process. When required by the customer, the organization shall: e) notify the customer of any planned product realization changes atter the most recent product approval; f) obtain documented approval, prior to implementation of the change; g) complete additional veri fication or identification requirements, such as production trial run and new product validation.

First level:

8.5.6.1 Überwachung von Änderungen — Ergänzung Die Organisation muss über einen dokumentierten Prozess zur Lenkung von und Reaktion auf Änderungen verfügen, welche die Produktrealisierung beeinflussen. Die Auswirkungen jeder Änderung müssen bewertet werden, gleichgültig, ob sie durch die Organisation, den Kunden oder einen Lieferanten veranlasst werden. Die Organisation muss: a) Maßnahmen zu Veri fizierung und Validierung festlegen, um sicherzustellen, dass die Anforderungen der Kunden weiterhin erfüllt werden, b) Änderungen validieren, bevor sie umgesetzt werden, c) Nachweise für eftsprechend durchgeführte Risikoanalysen erbringen, d) Aufzeichnungen über Veri fizierungen und Validierungen aufbewahren. Um die Auswirkungen einer Änderung auf den Fertigungsprozess bewerten zu können, sollten alle Änderungen — auch Änderungen bei Lieferanten — einen Produktionsprobelauf zur Veri fizierung der Änderung erforderlich machen (wie zum Beispiel Änderungen an der Auslegung des Produktes, Verlagerung des Produktionsstandortes oder Änderungen am Fertigungsprozess). Wenn vom Kunden gefordert, muss die Organisation: e) den Kunden über jede beabsichtigte Änderung am Produktrealisierungsprozess nach der letztgültigen Freigabe informieren, f) eine dokumentierte Freigabe einholen, bevor die Änderung umgesetzt wird, g) alle Maßnahmen zur Erfüllung zusätzlicher Anforderungen zu Veri fizierung oder Kennzeichnung, wie Produktionsprobelauf oder erneute Produktvalidierung, abgeschlossen haben.

ECR (Engineering Change request) Documented Process

Second level:

Changes w/o formal ECR process (Acc. CDQ0404) Documented process (4M Matrix, Change Management Schedule, Change Point Record Sheet)

17

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

MODIFIED

4M Change Management - Briefing session CDQ0404 – Attachment 4: Customer involvement matrix Links: CDQ0404 CDQ0404-Att 4 CDQ0404-Att 5

Changes without formal ECR Process: changes without formal ECR process are process-/ method-related changes for optimization of processes and flows within the limits specified with the customer and within the internally specified limits (no change with respect to fit, form, function and reliability of components). The change is classified on the basis of Attachment 4 "Customer Involvement matrix” footnote 1). If a change does not have any effect on the product bill of materials (BOM), test specifications, offer drawings, TCD, drawings (product drawings, tool-drawings with effect on product) or similar, then it can be handled as change without formal ECR process and in these cases without formal documentation. Safeguarding against risks must be carried out and documented. The documentation must suffice the basic principles of traceability. (extract from CDQ0404 Att 5) 18

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session IATF 16949:2016 8.5.6.1.1 Temporary change of process controls 8.5.6.1.1 Zeitlich begrenzte Änderungen in der Produktionsprozesslenkung The organization shall identify, document, and maintain a list of the process controls, including inspection, measuring, test, and error- Die Organisation muss eine Liste der Produktionsprozesslenkungsmaßnahmen — einschließlich der Prüf- und Messmittel — erstellen, proofing devices, that includes the primary process control and the approved back-up or alternate methods. dokumentieren und pflegen, die sowohl die ursprünglich geplanten Methoden zur Prozesslenkung enthält als auch die freigegebenen „Backup“- oder Alternativmethoden. The organization shall document the process that manages the use of alternate control methods. The organization shall include in Die Organisation muss den Prozess dokumentieren, mit dem der Einsatz alternativer Steuerungs- und Überwachungsmethoden geregelt this process, based on risk analysis (such as FMEA), severity, and the internal approvals to be obtained prior to production wird. Die Organisation muss in diesem Prozess festlegen, dass — auf Risikoanalysen (wie FMEA) und der Tragweite basierend — zunächst implementation of the alternate control method. interne Freigaben erfolgen müssen, bevor die alternativen Steuerungs- und Überwachungsmethoden in der Produktion umgesetzt werden. Before shipping product that was inspected or tested using the alternate method, if required, the organization shall obtain approval Bevor das mit alternativen Steuerungs- und Überwachungsmethoden geprüfte Produkt ausgeliefert wird, muss die Organisation eine from the customer(s). The organization shall maintain and periodically review a list of approved alternate process control methods entsprechende Freigabe des (der) Kunden einholen, sofern gefordert. Die Organisation muss eine Liste der freigegebenen und im PLP that are referenced in the control plan. referenzierten alternativen Methoden zur Produktionsprozesslenkung führen und in regelmäßigen Abständen überprüfen. Standard work instructions shall be available for each alternate process control method. The organization shall review the operation Für alle alternativen Produktionsprozesslenkungsmaßnahmen müssen entsprechende Arbeitsanweisungen (standard work) vorliegen. Die of alternate process controls on a daily basis, at a minimum, to verify implementation of standard work with the goal to retum to the Organisation muss die Anwendung der alternativen ProduktionsprozessIenkungsmaßnahmen mindestens einmal täglich überprüfen, um standard process as defined by the control plan as soon as possible. Example methods include but are not limited to the following: sicherzustellen, dass die Anweisungen auch tatsächlich befolgt werden. Ziel ist es, so bald wie möglich zu den ursprünglichen, im a) daily quality focused audits (e.g., layered process audits, as applicable); Produktionslenkungsplan geplanten Methoden zur Prozesslenkung zurückzukehren. Beispielhafte Überprüfungen sind Folgende und b) daily leadership meetings. Weitere: Restart verification is documented for a defined period based on severity and confirmation that all features of the error-proofing device a) tägliche qualitätsbezogene Audits (z. B. LPA — Layered Process Audits, wenn anwendbar), b) tägliche Treffen auf Leitungsebene. or process are effectively reinstated. The organization shall implement traceability of all product produced while any altemate process control devices or processes are being used (e.g., veri fication and retention of first piece and last piece from every shift).

NEW IATF16949:2016

Nach Wiedereinsetzen der ursprünglich geplanten Maßnahmen zur Prozesslenkung sind entsprechende Überprüfungen für einen festgelegten Zeitraum aufrechtzuerhalten und zu dokumentieren. Für den Überprüfungszeitraum maßgebend sind die Tragweite und die Bestätigung, dass alle Funktionen/Eigenschaften der ursprünglichen Prüf- und Messmittel oder -prozesse wirksam wiederhergestellt sind. Die Organisation muss die Rückverfolgbarkeit aller produzierten Produkte sicherstellen, die während des Einsatzes von alternativen Prüfund Messmitteln oder -prozessen hergestellt wurden (z. B. Überprüfung und Aufbewahrung der Erststücke und Letztteile jeder Schicht).

Documentation of process that manages the use of alternate methods incl. standard work instructions Internal approvals prior to implementation defined in 4M Change Matrix e.g. Concession

Daily leadership meeting / LPA and LPC (Process Confirmation) 4M Integration in Daily shop floor routine / Daily management

Restart verification documented and assured that all features of error-proofing device are effectively installed 19

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

4M Change Management - Briefing session IATF 16949:2016 8.5.1.3 Verifi cation of job set— ups The organization shall: a) verify job set-ups when performed, such as an initial run of a job, material changeover, or job change that requires a new set-up; b) maintain documented information for set-up personnel; c) use statistical methods of veri fication, where applicable; d) perform first-off/last-off part validation, as applicable; where appropriate, first-off parts should be retained for comparison with the last-off parts; where appropriate, last-off-parts should be retained for comparison with firstoff parts in subsequent runs; e) retain records of process and product approval following set-up and first— off/last-off part

8.5.1.3 Verifi zierung von Einrichtvorgängen Die Organisation muss: a) Einrichtvorgänge überprüfen, unter anderem bei einem Erstanlauf der Fertigung, nach Materialwechsel oder nach Anderungen am Fertigungsablauf, die eine Neueinrichtung der Fertigungsanlagen erfordem, b) dokumentierte Informationen für die Maschineneinrichter aufrechterhalten, c) statistische Verfahren zur Verifizierung einsetzen, sofem möglich, d) Erst-lLetztteilbewertungen durchführen, soweit anwendbar. Wo angebracht, sollten die Erststücke zum Vergleich mit den Letztteilen aufbewahrt werden. Wo angebracht, sollten die Letztteile zum Vergleich mit den Erststücken nachfolgender Fertigungsläufe aufbewahrt werden, e) Aufzeichnungen über die den Einrichtvorgängen und Erststück-Letztteilbewertungen folgenden Produktionsprozess- und Produktfreigaben aufbewahren.

8.5.1.4 Verifi cation after shutdown The organization shall define and implement the necessary actions to ensure product compliance with requirements after a planned or unplanned production shutdown period.

8.5.1.4 Verifi zierung nach Produktionsstillstand Die Organisation muss notwendige Maßnahmen definieren und einleiten, um sicherzustellen, dass die Produkte nach einer geplanten oder ungeplanten Unterbrechung der Fertigung die Anforderungen erfüllen.

MODIFIED IATF16949:2016

NEW IATF16949:2016

Direct Link to IQP (Integrated Quality Planning) and 14 Q-Basics (VS) P6: Check the Checker P9: Restart

(8.5.1.2 Verification of job set-ups…requires new set-up definition with 4M Change Matrix)

P7: TPM All these principles have a strong planning topic and are considered in the IQP Process 20

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

COACHING AND SUPPORT CONCEPT

Q-Basics (VS) Strategy 2017 / 2018 Coaching and Support Concept based on CRI (IQIS BA10,20,21 – 0 km / 0 mileage) CRI violating – Q-Basics Planning MRC…”Not planned” IQP – Integrated Quality Planning ** Prepare Series * Production BPS PGL * SE – Team / ISEC * 8D, PS, LL + IPN LL / Transfer ** (Lead plant)

CRI violating – Q-Basics Execution MRC…“Not fulfilled” Working according to Standards LPC / Daily routine 4M Change - Management Mindset / Leadership 8 D / Problem Solving

Coaching / Support Concept IQP • Maturity Evaluation for IQP • Briefing Sessions for IQP • FMEA and CP • SPC, Capabilities, … • Inspection Strategy Product <-> Process

Q-Basics • Maturity Evaluation for 14 Q-Basics (VS) • Training / Coaching in CIP (e.g. KPI) • LPC – Process Confirmation • Learn to See • 4M Change management

* Preventive Approach – Before SOP; ** Preventive – Before SOP + Event-driven Reviews – After SOP e.g. 8D, ECR, LL in IPN, … 22

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Q-Basics (VS) Strategy 2017 / 2018 Coaching Concept

Event driven Support

• CRI (Customer Related Incidents) • Deviations (Audit, iDC, …)

• LPC (Layered Process Confirmation)

• Maturity Evaluation • Improvement Work – PDCA 23

Coaching / Enabling

• IQP (Integrated Quality Planning) • Capability and SPC • 14 Q-Basics (VS) + BPS PGL • 4M Change Mgmt. • Mini - Training e.g. Restart

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Mature Organization

• Preventive Approach in SE Teams • Mature Products and Processes • Safe Launch and high productivity • True North: Zero defects

WS EXAMPLES FOR 4M RODEZ: RESTART CUSTOMER (RENAULT) REQUIREMENT FOR PROCEDURE AFTER MAINTENANCE

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart WS 4M Change Management / Restart after TPM – RzP (DS)

25

Internal | GS/QMM2-Steffl | 04.07.2017 170072 © Robert Bosch GmbH 2017. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

•

4M Matrix – Template 4M

•

Restart form – AdP

•

Q-”Wiederfreigabe” – WaP

•

Restart Flow Chart – RzP

Mini – Training: 14 Q-Basics (VS) Principle 9 – Restart Listing of interventions on the machine FMEA

FMEA as important input

for Priorisation / criticality for product quality! Machine Dressing of tool Tool change

Maintenance Preventive ‒

Shop floor

‒

TEF

‒

Set-up mechanic