Compressor Selection Guideline

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Compressor Selection Guideline as PDF for free.

More details

- Words: 350

- Pages: 1

Loading documents preview...

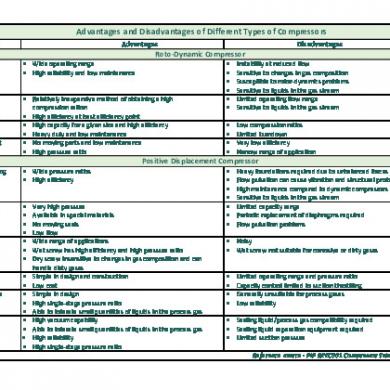

Advantages and Disadvantages of Different Types of Compressors Types

Advantages

Disadvantages

Roto-Dynamic Compressor Centrifugal

• Wide operating range • High reliability and low maintenance

Integrally Geared Centrifugal Axial

• Relatively inexpensive method of obtaining a high compression ration • High efficiency at best efficiency point • High capacity for a given size and high efficiency • Heavy duty and low maintenance • No moving parts and low maintenance • High pressure ratio

Thermal/Jet

• • • • • •

Instability at reduced flow Sensitive to changes in gas composition Susceptible to rotor-dynamics problems Sensitive to liquids in the gas stream Limited operating flow range Sensitive to liquids in the gas stream

• • • •

Low compression ratios Limited turndown Very low efficiency Narrow range of application

Positive Displacement Compressor Reciprocating (Piston)

• Wide pressure ratios • High efficiency

Diaphragm

• • • • • • •

Screw

Lobe Sliding Vane

Liquid Ring

• • • • • • • • •

Very high pressure Available in special materials No moving seals Low flow Wide range of applications Wet screw has high efficiency and high pressure ratio Dry screw insensitive to changes in gas composition and can handle dirty gases Simple in design and construction Low cost Simple in design High single-stage pressure ratio Able to tolerate small quantities of liquids in the process gas High vacuum capability Able to tolerate small quantities of liquids in the process gas High reliability High single-stage pressure ratio

• • • • • • •

Heavy foundations required due to unbalanced forces Flow pulsation can cause vibration and structural problems High maintenance compared to dynamic compressors Sensitive to liquids in the gas stream Limited capacity range Periodic replacement of diaphragms required Flow pulsation problems

• Noisy • Wet screw not suitable for corrosive or dirty gases

• • • •

Limited operating range and pressure ratio Capacity control limited to suction throttling Generally unsuitable for process gases Low reliability

• Sealing liquid/process gas compatibility required • Sealing liquid separation equipment required • Limited suction pressure Reference source - PIP REEC001 Compressor Selection Guidelines

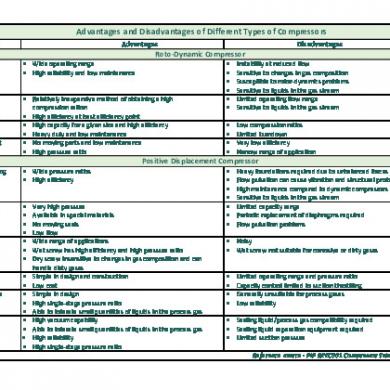

Advantages

Disadvantages

Roto-Dynamic Compressor Centrifugal

• Wide operating range • High reliability and low maintenance

Integrally Geared Centrifugal Axial

• Relatively inexpensive method of obtaining a high compression ration • High efficiency at best efficiency point • High capacity for a given size and high efficiency • Heavy duty and low maintenance • No moving parts and low maintenance • High pressure ratio

Thermal/Jet

• • • • • •

Instability at reduced flow Sensitive to changes in gas composition Susceptible to rotor-dynamics problems Sensitive to liquids in the gas stream Limited operating flow range Sensitive to liquids in the gas stream

• • • •

Low compression ratios Limited turndown Very low efficiency Narrow range of application

Positive Displacement Compressor Reciprocating (Piston)

• Wide pressure ratios • High efficiency

Diaphragm

• • • • • • •

Screw

Lobe Sliding Vane

Liquid Ring

• • • • • • • • •

Very high pressure Available in special materials No moving seals Low flow Wide range of applications Wet screw has high efficiency and high pressure ratio Dry screw insensitive to changes in gas composition and can handle dirty gases Simple in design and construction Low cost Simple in design High single-stage pressure ratio Able to tolerate small quantities of liquids in the process gas High vacuum capability Able to tolerate small quantities of liquids in the process gas High reliability High single-stage pressure ratio

• • • • • • •

Heavy foundations required due to unbalanced forces Flow pulsation can cause vibration and structural problems High maintenance compared to dynamic compressors Sensitive to liquids in the gas stream Limited capacity range Periodic replacement of diaphragms required Flow pulsation problems

• Noisy • Wet screw not suitable for corrosive or dirty gases

• • • •

Limited operating range and pressure ratio Capacity control limited to suction throttling Generally unsuitable for process gases Low reliability

• Sealing liquid/process gas compatibility required • Sealing liquid separation equipment required • Limited suction pressure Reference source - PIP REEC001 Compressor Selection Guidelines

Related Documents

Compressor Selection Guideline

January 2021 1

Selection Of Gas Compressor-2

February 2021 1

Selection Of Gas Compressor-1

February 2021 1

Guidelines On Compressor Sizing And Selection

March 2021 0

Guideline For Pump Beraing Lubrication Selection

March 2021 0

Compressor

February 2021 2More Documents from "Paras Palsatkar"