Guidelines On Compressor Sizing And Selection

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Guidelines On Compressor Sizing And Selection as PDF for free.

More details

- Words: 1,057

- Pages: 35

Loading documents preview...

COMPRESSOR SELECTION OUTLINE OF DISCUSSION Importance of selection, factors to consider Process of compressor selection Discuss preliminary selection Present the equations Define its terms Introduce the Ns-Ds chart Discuss the ranges of N and D of each compressor Sample problem

IMPORTANCE of Compressor Selection Selecting the right compressor is essential because much as in the case for pumps, this saves on energy as well as makes the pressure increase appropriate for the application intended for the compressor.

KEY FACTORS for Compressor Selection

KEY FACTORS for Compressor Selection

GAS FLOW RATE (Volume of gas that passes through a particular point in a particular period of time). Some compressors handle typically higher gas flows than other weaker compressors. INLET AND DISCHARGE PRESSURE (Indicates degree of compression). Different compressors have different pressure capacities. Some may only function at high pressures while some only at low pressures. ELEVATION (Used to determine the local barometric pressure). the more higher the elevation, the more powerful/stronger compressor must be required.

KEY FACTORS for Compressor Selection

CAPACITY (The volume the gas will occupy at the compressor's suction). Different nozzle sizes of the compressors have corresponding glow rates. SUCTION AND DISCHARGE TEMPERATURE. (Affects the condition of the gas). Gases might behave dangerously to certain operating conditions.

KEY FACTORS for Compressor Selection

GAS PROPERTIES. Includes viscosity, corrosive nature, elastic nature, and toxicity. ● Viscosity. Affects the heat generation in the gears and pistons of the compressor since it opposes relative motion into the surface of the compressor chamber thus creating friction. ● Corrosive Nature. Some gases may cause corrosion under some operating conditions. ● Elastic Nature. Refers to how much kinetic energy a gas can absorb in the process of compression.

● Toxicity. Dictates how sealed should the compressor will be.

KEY FACTORS for Compressor Selection

COST (Includes installation, equipment, power consumption, service maintenance). The compressor is an investment of the company. ENVIRONMENT. Includes noise, vibration, being gas-tight. Minimizing the risk of hazards.

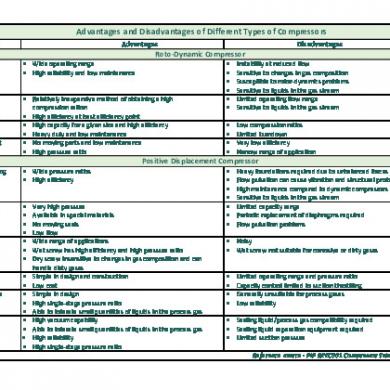

TRENDS for Compressor Selection There are numerous trends for the different types of compressors. These classifications are often made according to pressure ratio induced, volumetric flow rate, or adiabatic head.

Q and R Trends for Various Compressors

Flow rate

Pressure ratio

Positivedisplacement

LOW

HIGH

Centrifugal

MED

HIGH

HIGH

LOW

Axial -Flow

From PERRY’s

VARIABLES FOR USE WITH CHART

Specific Speed

• Ns = specific speed • N = rotative speed of the impeller (rpm) • Q = capacity of compressor at the best efficiency point (cfs) • H = head of a single stage of the compressor at best efficiency point (ft)

VARIABLES FOR USE WITH CHART

Specific Diameter 𝐷𝑆 =

𝐷𝐻

0.25

𝑄

Ds = specific diameter D = impeller diameter (ft) H = head of a single stage of the compressor at best efficiency point (ft) Q = capacity of compressor at the best efficiency point (cfs)

PRELIMINARY SELECTION OF COMPRESSOR TYPE

From PERRY’s

Alternative Selection Process FROM AMERICAN INSTITUTE OF CHEMICAL ENGINEERS

Determine

Select

Select

compression ratio

compressor model

options

Choose

Determine

number of stages

theo rpm, actual rpm

Calculate

Calculate

discharge T, %VE, PD

power required

SAMPLE Problems

PROBLEM 3.3-3 (GEANKOPLIS)

ADIABATIC COMPRESSION OF AIR. A compressor operating adiabatically is to compress 2.83 m3/min of air at 29.4⁰C AND 102.7 kN/m2 TO 311.6 kN/m2. Calculate the power required if the efficiency of the compressor is 75%. Also calculate the outlet temperature.

GIVEN

Ws

Q = 2.83 m3/min P2= 311.6 kN/m2 T = 302.56 K P1 = 102.7 kN/m2 MOLAR MASS OF AIR = 29 g/mol

REQUIRED Power required and outlet temperature

SOLUTION Γ = CP /CV = 1.4

Substitute to Equation 3.3-14 -Ws = 113 290 J/Kg

Solve n using Ideal Gas Equation (PV=nRT) Where P= 102.7 Kn/m2 V= 2.83 m3/min * 1 min/60 s = 0.04717 m3/s Molar flow rate = 1.926 mol/s Mass rate = 1.926 mol/s * 29 g/mol = = 55.84 g/s

From the Equation 3.3-2 Substitute Wp, m:

kW= 8.44 kW GETTING THE OUTLET TEMPERATURE From Equation 3.3-15

T2 = 415.46 K

PROBLEM 21.22 (FOUST)

𝑓𝑡 3 𝑚𝑖𝑛

It is necessary to compress 600 of air at 70℉ and 14.7 psi to a final pressure of 2000 psig. Suggest a compressor type.

Given 3 Q = 600 ft /min T = 70 F P1 = 14.7 psi P2 = 2000 psig Required compressor type

Solution Solving for density,

•𝜌 = •𝜌 =

𝑀 𝑇𝑠 × 𝑉𝑠 𝑇 29 32+460 × 359 70+460

= 0.075

𝑙𝑏𝑚 𝑓𝑡 3

Solution (cont.) Solving for head,

•𝐻 = •𝐻 =

∆𝑃 𝜌 2000×144 0.075

=

𝑓𝑡 𝑙𝑏𝑓 3,840,000 𝑙𝑏𝑚

Solution (cont.) We can determine values for Ns and Ds by assuming initial values for N and D. Likely values for D are a few feet so we can begin with 1 ft as an initial value. The most common compressor types are centrifugal compressors, and we can plug in the conventional minimum and maximum N values (see table in next slide).

Centrifugal

N/ rpm

Ns

350012 000

30 3000

D

Ds

Q/ cfm

P2 (psig)

0.3 - 6

Axialcentrifugal /Axial

<20

1 -20

Reciprocating

300-1000

3-5 in

Rotary

~12 000

“few ft”

Cost

8-5000 >50000

Positive Displacement

H/ psig

<500

200025000

Up to 125 >5000

>12000 Low initial cost

12-125

Collated values for compressors.

Solution (cont.) Solving for specific diameter,

•𝐷𝑠 =

•𝐷𝑠 =

𝐷𝐻 0.25 𝑄 0.25 (1)(3840000) 600 60

= 14.0

Solution (cont.) Solving for specific speed, • 𝑁𝑠 = • 𝑁𝑠 =

𝑁 𝑄

𝐻 0.75 3500 600/60 (3,840,000)0.75

• 𝑁𝑠 = = 0.13 • 𝑁𝑠 =

𝑁 𝑄

𝐻 0.75 12000 600/60 (3,840,000)0.75

= 0.44

PRELIMINARY SELECTION OF COMPRESSOR TYPE LIKELY Ds VALUE

RANGE FOR Ns VALUE

Solution (cont.) Based on the calculations, the Ns value cannot reach the area for centrifugal compressors. However, upon checking the Ds value, the compressor types may fall under piston compressors. Upon checking the possible N values for compressors, N for piston compressors may reach approximately 12000 rpm, which is one of the values considered initially. Thus, we may declare the 12000 rpm value and 1 ft as valid approximations.

PRELIMINARY SELECTION OF COMPRESSOR TYPE

Likely compressor type

RANGE FOR Ns VALUE

LIKELY Ds VALUE

PROBLEM 21.22 (FOUST)

Suggestion: a rotary compressor Agrees with simpler classification chart, given Q and P ratio (assuming continued classification at higher P ratio) since rotary compressors fall under positive displacement.

END OF REPORT

IMPORTANCE of Compressor Selection Selecting the right compressor is essential because much as in the case for pumps, this saves on energy as well as makes the pressure increase appropriate for the application intended for the compressor.

KEY FACTORS for Compressor Selection

KEY FACTORS for Compressor Selection

GAS FLOW RATE (Volume of gas that passes through a particular point in a particular period of time). Some compressors handle typically higher gas flows than other weaker compressors. INLET AND DISCHARGE PRESSURE (Indicates degree of compression). Different compressors have different pressure capacities. Some may only function at high pressures while some only at low pressures. ELEVATION (Used to determine the local barometric pressure). the more higher the elevation, the more powerful/stronger compressor must be required.

KEY FACTORS for Compressor Selection

CAPACITY (The volume the gas will occupy at the compressor's suction). Different nozzle sizes of the compressors have corresponding glow rates. SUCTION AND DISCHARGE TEMPERATURE. (Affects the condition of the gas). Gases might behave dangerously to certain operating conditions.

KEY FACTORS for Compressor Selection

GAS PROPERTIES. Includes viscosity, corrosive nature, elastic nature, and toxicity. ● Viscosity. Affects the heat generation in the gears and pistons of the compressor since it opposes relative motion into the surface of the compressor chamber thus creating friction. ● Corrosive Nature. Some gases may cause corrosion under some operating conditions. ● Elastic Nature. Refers to how much kinetic energy a gas can absorb in the process of compression.

● Toxicity. Dictates how sealed should the compressor will be.

KEY FACTORS for Compressor Selection

COST (Includes installation, equipment, power consumption, service maintenance). The compressor is an investment of the company. ENVIRONMENT. Includes noise, vibration, being gas-tight. Minimizing the risk of hazards.

TRENDS for Compressor Selection There are numerous trends for the different types of compressors. These classifications are often made according to pressure ratio induced, volumetric flow rate, or adiabatic head.

Q and R Trends for Various Compressors

Flow rate

Pressure ratio

Positivedisplacement

LOW

HIGH

Centrifugal

MED

HIGH

HIGH

LOW

Axial -Flow

From PERRY’s

VARIABLES FOR USE WITH CHART

Specific Speed

• Ns = specific speed • N = rotative speed of the impeller (rpm) • Q = capacity of compressor at the best efficiency point (cfs) • H = head of a single stage of the compressor at best efficiency point (ft)

VARIABLES FOR USE WITH CHART

Specific Diameter 𝐷𝑆 =

𝐷𝐻

0.25

𝑄

Ds = specific diameter D = impeller diameter (ft) H = head of a single stage of the compressor at best efficiency point (ft) Q = capacity of compressor at the best efficiency point (cfs)

PRELIMINARY SELECTION OF COMPRESSOR TYPE

From PERRY’s

Alternative Selection Process FROM AMERICAN INSTITUTE OF CHEMICAL ENGINEERS

Determine

Select

Select

compression ratio

compressor model

options

Choose

Determine

number of stages

theo rpm, actual rpm

Calculate

Calculate

discharge T, %VE, PD

power required

SAMPLE Problems

PROBLEM 3.3-3 (GEANKOPLIS)

ADIABATIC COMPRESSION OF AIR. A compressor operating adiabatically is to compress 2.83 m3/min of air at 29.4⁰C AND 102.7 kN/m2 TO 311.6 kN/m2. Calculate the power required if the efficiency of the compressor is 75%. Also calculate the outlet temperature.

GIVEN

Ws

Q = 2.83 m3/min P2= 311.6 kN/m2 T = 302.56 K P1 = 102.7 kN/m2 MOLAR MASS OF AIR = 29 g/mol

REQUIRED Power required and outlet temperature

SOLUTION Γ = CP /CV = 1.4

Substitute to Equation 3.3-14 -Ws = 113 290 J/Kg

Solve n using Ideal Gas Equation (PV=nRT) Where P= 102.7 Kn/m2 V= 2.83 m3/min * 1 min/60 s = 0.04717 m3/s Molar flow rate = 1.926 mol/s Mass rate = 1.926 mol/s * 29 g/mol = = 55.84 g/s

From the Equation 3.3-2 Substitute Wp, m:

kW= 8.44 kW GETTING THE OUTLET TEMPERATURE From Equation 3.3-15

T2 = 415.46 K

PROBLEM 21.22 (FOUST)

𝑓𝑡 3 𝑚𝑖𝑛

It is necessary to compress 600 of air at 70℉ and 14.7 psi to a final pressure of 2000 psig. Suggest a compressor type.

Given 3 Q = 600 ft /min T = 70 F P1 = 14.7 psi P2 = 2000 psig Required compressor type

Solution Solving for density,

•𝜌 = •𝜌 =

𝑀 𝑇𝑠 × 𝑉𝑠 𝑇 29 32+460 × 359 70+460

= 0.075

𝑙𝑏𝑚 𝑓𝑡 3

Solution (cont.) Solving for head,

•𝐻 = •𝐻 =

∆𝑃 𝜌 2000×144 0.075

=

𝑓𝑡 𝑙𝑏𝑓 3,840,000 𝑙𝑏𝑚

Solution (cont.) We can determine values for Ns and Ds by assuming initial values for N and D. Likely values for D are a few feet so we can begin with 1 ft as an initial value. The most common compressor types are centrifugal compressors, and we can plug in the conventional minimum and maximum N values (see table in next slide).

Centrifugal

N/ rpm

Ns

350012 000

30 3000

D

Ds

Q/ cfm

P2 (psig)

0.3 - 6

Axialcentrifugal /Axial

<20

1 -20

Reciprocating

300-1000

3-5 in

Rotary

~12 000

“few ft”

Cost

8-5000 >50000

Positive Displacement

H/ psig

<500

200025000

Up to 125 >5000

>12000 Low initial cost

12-125

Collated values for compressors.

Solution (cont.) Solving for specific diameter,

•𝐷𝑠 =

•𝐷𝑠 =

𝐷𝐻 0.25 𝑄 0.25 (1)(3840000) 600 60

= 14.0

Solution (cont.) Solving for specific speed, • 𝑁𝑠 = • 𝑁𝑠 =

𝑁 𝑄

𝐻 0.75 3500 600/60 (3,840,000)0.75

• 𝑁𝑠 = = 0.13 • 𝑁𝑠 =

𝑁 𝑄

𝐻 0.75 12000 600/60 (3,840,000)0.75

= 0.44

PRELIMINARY SELECTION OF COMPRESSOR TYPE LIKELY Ds VALUE

RANGE FOR Ns VALUE

Solution (cont.) Based on the calculations, the Ns value cannot reach the area for centrifugal compressors. However, upon checking the Ds value, the compressor types may fall under piston compressors. Upon checking the possible N values for compressors, N for piston compressors may reach approximately 12000 rpm, which is one of the values considered initially. Thus, we may declare the 12000 rpm value and 1 ft as valid approximations.

PRELIMINARY SELECTION OF COMPRESSOR TYPE

Likely compressor type

RANGE FOR Ns VALUE

LIKELY Ds VALUE

PROBLEM 21.22 (FOUST)

Suggestion: a rotary compressor Agrees with simpler classification chart, given Q and P ratio (assuming continued classification at higher P ratio) since rotary compressors fall under positive displacement.

END OF REPORT

Related Documents

Guidelines On Compressor Sizing And Selection

March 2021 0

Compressor Sizing And Calculation

March 2021 0

Compressor Sizing Cal

March 2021 0

Compressor Selection Guideline

January 2021 1

Selection Of Gas Compressor-2

February 2021 1

Selection Of Gas Compressor-1

February 2021 1More Documents from "dhanu_aqua"

Guidelines On Compressor Sizing And Selection

March 2021 0

What Are The 6 Harmonies Of Liuhebafa

March 2021 0

Hit Hard

January 2021 2

Original Tao - Harold D. Roth

March 2021 0

Makalah Pengelolaan Keuangan Negara

February 2021 1