Engineering Procedure

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Engineering Procedure as PDF for free.

More details

- Words: 8,494

- Pages: 35

Loading documents preview...

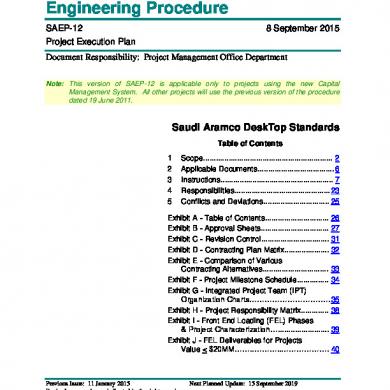

Engineering Procedure SAEP-303 Engineering Reviews of Project Documentation

21 November 2016

Document Responsibility: Electrical Systems Designs and Automation Standards Committee

Contents 1

Scope ................................................................ 2

2

Applicable Documents ....................................... 2

3

Definitions .......................................................... 3

4

Instructions ........................................................ 4

5

Reviews and Project Non-Conformity Resolution ................................................ 19

6

Responsibilities ................................................ 20

Revision Summary................................................. 22 Appendix A - Project Non-Conformity Escalation Process ................................... 23 Appendix B - List of all Equipment and Lines Carrying H2s ............................ 34 Appendix C - Engineering Design Review Submittal Checklist ................................... 35

Previous Issue: 13 December 2011

Next Planned Update: 21 November 2019 Page 1 of 35

Contact: Bugshan, Jamal A. (bugshaja) on phone +966-13-8809650 ©Saudi Aramco 2016. All rights reserved.

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

1

Scope 1.1

This Saudi Aramco Engineering Procedure (SAEP) establishes the instructions and responsibilities used by Saudi Aramco Reviewing Organizations (SAROs) when conducting formal engineering reviews of project packages relating to capital and non-capital projects.

1.2

The purpose of engineering reviews is to provide technical assurance to Saudi Aramco that the project is being developed in accordance with all applicable Saudi Aramco Standards, Procedures, and other mandatory requirements at all stages of project development. In addition, engineering reviews add value by applying recognized and generally-accepted good engineering practices by leveraging considerable domestic and international design and operational engineering experience. SAROs provide only a general review of the project. Full responsibility of the project is with PRO.

2

Applicable Documents The requirements contained in the following documents apply to the extent specified in this procedure: Saudi Aramco Engineering Procedures SAEP-12

Project Execution Plan

SAEP-13

Project Environmental Impact Assessments

SAEP-14

Project Proposal

SAEP-16

Project Execution Guide for Process Automation Systems

SAEP-21

Project Execution Requirements for Saudi Aramco Royalty/Custody Metering Systems

SAEP-27

Pipelines/Piping Hydraulic Surge Analysis

SAEP-125

Preparation of Saudi Aramco Engineering Standards

SAEP-127

Security and Control of Saudi Aramco Engineering Data

SAEP-334

Retrieval, Certification, and Submittal of Saudi Aramco Engineering and Vendor Drawings

SAEP-341

Equipment Life Cycle Cost Procedure

SAEP-360

Project Planning Guidelines Saudi Aramco: Company General Use

Page 2 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

SAEP-367

Value Improving Practices Requirements

SAEP-1350

Design Basis Scoping Paper (DBSP) Preparation and Revision Procedure

Saudi Aramco Engineering Standards SAES-A-030

Reliability, Availability, and Maintainability (RAM) Study Execution

SAES-A-202

Saudi Aramco Engineering Drawing Preparation

SAES-L-133

Corrosion Protection Requirements for Pipelines, Piping, and Process Equipment

SAES-P-100

Basic Power System Design Criteria

SAES-P-111

Grounding

SAES-T-481

In-Plant Voice Paging System

Saudi Aramco General Instruction GI-0002.710

3

Mechanical Completion and Performance Acceptance of Facilities

Definitions 3.1

Organizations and Reviewing Entities Saudi Aramco Reviewing Organizations (SAROs): This term refers to all Saudi Aramco organizations involved in reviewing project documents. Project Responsible Organization (PRO): The organization responsible for managing the project. For capital projects, this organization reports to the Vice President, Project Management. For non-capital projects, this organization is usually the proponent. MSAERs: Mandatory Saudi Aramco Engineering Requirements PMOD: Project Management Office Department

3.2

Review Documentation Design Basis Scoping Paper (DBSP): Refer to SAEP-1350. For projects using the Capital Management System (CMS), DBSP refers to the portion of FEL 2 after the Gate Alternative Selection and prior to the G2 Gate. Project Proposal (including Technical Proposal Documents within Contract Bid Packages): Refer to SAEP-14. For projects using the Capital Management Saudi Aramco: Company General Use

Page 3 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

System (CMS), Project Proposal refers to the portion of FEL 3 before the Project Proposal Approval. Detailed Design: A set of documents used for project construction and material procurement. For projects using the Capital Management System (CMS), Detailed Design refers to the Detailed Design portion of the Execution Phase. 3.3

Review Methods Engineering reviews are generally organized based on one of the two following methods: Across-the-Board Review (ABR): This is a review simultaneously carried out by all involved engineering disciplines. ABRs must be conducted through the eReview system. Discipline Specific Review (DSR): This is a review carried out by a specific engineering discipline. DSRs must be conducted through the Engineering Service Request system in SAP.

4

Instructions 4.1

Number, Type, and Method of Reviews ABRs are conducted by SAROs once during Project Proposal on the last issue of the Project Proposal review package before the Project Proposal Approval. ABRs are conducted by SAROs once during Detailed Design, preferably at the stage indicated in Section 4.5.1 for each discipline.

4.2

Requesting and Planning Engineering Reviews 4.2.1

To request an engineering review, either in the Project Proposal or Detailed Design phase, PRO shall address a letter to the Manager(s) of the appropriate SAROs requesting that a review be performed. The letter shall state the type of review to be performed, the review format to be used, expected start date, and the name of the PRO representative responsible for coordinating the review.

4.2.2

Include in the Project Proposal the proposed number, method, and type of the engineering reviews for the Detailed Design phase of the project. DSRs shall be carried out during the Detailed Design phase at the percent completion stage agreed to by PRO and SAROs during the Project Proposal meeting. Required percent completions are given for each discipline in Section 4.5.1. Saudi Aramco: Company General Use

Page 4 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

ABRs shall be carried out during the Detailed Design phase at the overall project percent completion stage agreed to by PRO and SAROs during the Project Proposal meeting. 4.3

Review Submittals 4.3.1

General The submittals described in this paragraph should bear the appropriate stamps identifying the stage of completion. All submittals are accompanied by a Saudi Aramco standard transmittal form identifying the package and the action to be taken by the receiving organization and the due date for the required action. All scheduled reviews shall be submitted via the eReview system. PRO must include a document in each Index for all Detailed Design review requests that indicates the cut-off dates for all MSAERs.

4.3.2

4.4

PRO must complete and attach the Engineering Design Review Submittal Checklist per Appendix C to the initial package submittal. Failure to do so will result in package rejection.

Review Schedule 4.4.1

Engineering reviews of DBSPs and Project Proposal packages require a minimum of 10 business days and Detailed Design packages require a minimum of 15 business days, respectively. Business days are as stated on the Saudi Aramco operational calendar. The review period begins on the day following the date that the review material was received by the SAROs. A shorter review period is allowed on written mutual agreement between PRO and SARO department managers under Section 4.2. PRO shall provide a longer review period at the request of the SARO. Review requests that do not meet the minimum number of days that do not have the above-mentioned written mutual agreement filed as a separate document in each index shall be rejected.

4.4.2 4.5

The review period to perform a DSR shall be established via the approval mechanism in the Engineering Service Request system in SAP.

Review Documentation 4.5.1

Review Requirements In these tables, the first column gives the documentation required for Saudi Aramco: Company General Use

Page 5 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

both ABRs and DSRs. The second column gives details of the required documentation as well as the required percent completion for each discipline for DSRs. All review requests, including Project Proposal reviews, must contain all of the listed documents. PRO must include a document in each Index showing the file name(s) of the review documents corresponding to the required documents. Review Requirements Document

Comments

Architectural (Project Proposal) 1

Site Plan: Generals site arrangement – new and existing buildings, building access, roads, and parking.

Plans

Floor Plans: Functional plan and circulation. 2

Indicate building classifications (tiers)

3

For Tier 1, perform LEED certification requirements, if needed.

Architectural (30% Detailed Design)

Typical % completion for DSRs = 30%

1

Site Plan: Generals site arrangement – new and existing buildings, building access, roads, and parking (75% complete)

Plans

Floor Plans: Functional plan and circulation, building system, grids, and overall dimensions (100% complete) 2

Building sections

General structure, building volumes, floor heights, vertical circulation elements (100% complete)

3

Building elevations

Overall elevations – shapes, heights, and volumes (100% complete)

Architectural (60% Detailed Design)

Typical % completion for DSRs = 60%

1

Site Plan: New, support, and existing buildings, roads, parking, and open areas (100% complete)

Plans

Floor Plans: Detailed layout – openings, circulation, exits, egress routes, floor levels, generals finishes, wall assemblies, dimensions – exterior and interior (100% complete) Roof Plan: Primary and secondary roof grain systems, access and equipment (if applicable), levels, slopes, outlets, parapet walls, structures at adjacent levels (below/above), overall dimensioning (100% complete) Reflected Ceilings: Acoustic ceiling layouts, lighting (100% complete) Saudi Aramco: Company General Use

Page 6 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

2

Building sections

Assemblies – floors, finishes, walls, roofs, overhangs, relation to structural elements, wall types, levels – interior and exterior (100% complete)

3

Building Elevations

Detailed elevations – volumes, openings, heights, façade elements, finishing material descriptions (100% complete)

4

Schedules

Doors and windows: Shapes, sizes, specifications, materials (100% complete)

Architectural (90% Detailed Design)

Typical % completion for DSRs = 90%

1

Site Plan: New, support, and existing buildings, roads, parking, hard and soft scape, setting-out, vertical planning (100% complete)

Plans

Floor Plans: Circulation, exits, egress routes, guards and railings, vertical circulation elements, internal levels, interior dimensions (100% complete) Roof Plan: Roof circulation and protection, draining systems, full dimensioning (100% complete) Reflected Ceilings: Electrical/mechanical coordination (100% complete) 2

Sections

Building Sections: Assembly fire ratings, fire-protection assemblies, section call-outs: insulation, joints, flashings, copings – descriptive references, levels, vertical dimensioning – interior and exterior (100% complete) Wall Sections: Building-envelope assemblies – walls, sills, headers, thresholds, eaves, gutters (100% complete)

3

Elevations and Elevation Call-outs

Secondary façade elements – sills, cladding, grooving, flashings, coping, etc. – descriptive references, levels and vertical dimensioning, architectural finishes (100% complete)

4

Building Details

Construction/assembly methods. Shapes, sizes, specifications, and finishing materials (100% complete)

5

Architectural Finishes

Interior and exterior finishing material schedules (100% complete)

Asset Integrity

Typical % completion for DSRs = 90%

1

Plot Diagrams, P&ID and PFD

Drawing, 90%

2

Hazardous area classification

Design Document 90%

Saudi Aramco: Company General Use

Page 7 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

3

Risk assessments studies as basis for identifying all Safety critical elements

Design Document 60%

4

List of Safety critical elements under the associated barrier in the AIMS manual

Design Document 90%

5

MOC process covering (design alteration) for all SCE’s throughout the design phase

Design Document 90%

6

Cause and effect diagrams

Drawing, 90%

7

Integrity Operating Windows (critical process Parameters) related to SCE’s

Design Document 90%

8

Material specifications

Material Spec, 90%

9

Project Construction and QA/QC Plans (when available)

QA document 90%

10

Construction, inspection/testing and maintenance procedures

Design Document, 90%

11

Pre-start up review, close-out and handover procedures

Design Document, 90%

12

Samples of Integrity Performance Standards

Design Document 90%

Asset Reliability

Typical % completion for DSRs = 90%

1

Engineering Study 90%

Updated RAM Study per SAES-A-030

Cathodic Protection

Typical % completion for DSRs = 90%

1

Plot Plans

Show existing and new structures

2

Design Calculations

Include resistivity data

3

Details of Buried Structures

Type, size, material, location

4

Vessels and Tanks Details

Size, contents, foundations, grading

5

Existing C.P. Systems Details

6

C.P. Remote Monitoring Systems

Civil (Roads, Grading, etc.)

Typical % completion for DSRs = 60%

1

Plot Plans

2

Calculations - Roads, Pavements, and geometry, Grading (Water run off)

3

Foundation Location Plans

100% completion

Saudi Aramco: Company General Use

Page 8 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

4

Site Grading Plans, Layouts, Sections, Details

5

Foundation Drawings, including details

6

Reflect the approved Concrete Exposures from DBSP

7

Concrete Mix (concrete type, Cement type, aggregates

8

Road Safety Audit Assessment report

9

Fence classifications

10

Indicate soil improvement if any and what would be the achieved CBR value

11

Road Classifications

12

Storm water system layout and flow direction

13

Storm water calculation indicating the frequency

14

For projects going to use existing concrete structures, provide concrete assessment report.

Communications

Typical % completion for DSRs = 60%

1

Scope of Work

2

Drawings

3

Project Plan

4

Material List

5

Show all disciplines including: Outside plant systems, structured cabling system, Data Network System, Wireless System, Telephone Switching, Special circuits and services, Video Conferencing, VSAT Communications Towers, fiber optics backbone network, microwave systems, SCADA connectivity solutions, and Communications Facilities with required civil, Mechanical, DC/AC power, and Plant Demilitarized Zone (DMZ) Architecture and all of its components. Saudi Aramco: Company General Use

Page 9 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

6

In-plant voice paging system

Refer to SAES-T-481

7

Process Automation Network, Security, and CCTV Fiber Optic cables

All fiber optic cables that are being covered by Communication Discipline

Control Systems

Typical % completion for DSRs = 90%

1

P&IDs

At 30%.

2

DCS Block Diagrams

3

Logic Diagrams

4

Cause and Effect Diagrams

5

Control Rooms and PIB Rooms

6

Hardware Material List

(Preliminary list)

7

DCS Schematics

(Preliminary List)

8

Instrument Loop Diagrams

9

Estimated I/O Summary Tables

10

Structured Wiring Design

11

Control System Architecture Design

12

Human-Machine Interface Design

13

Reporting Design

14

Advanced Control Design

15

Sequence Control Design (e.g., OMSB)

16

Application Interpath Design

17

Control System Data Network Interconnect Diagrams

18

Control System Security Design

If there is ESD

Electrical

Typical % completion for DSRs = 30%

1

Electrical Design Data

Power source (including voltage and minimum and ultimate short-circuit levels and X/R ratios) and electrical load data (including calculations of maximum operating load and projected future load for each transformer)

2

Electrical Area Classification Drawings

Showing plan and section views

3

Material Specifications for major electrical equipment

Transformers, motors, switchgear, motor control centers, generators, UPS, high voltage (i.e., >1,000 V) switches

4

One Line Diagrams (Overall)

Showing all equipment ratings Saudi Aramco: Company General Use

Page 10 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

5

One Line Diagrams (Substation)

Showing all major equipment ratings (continuous kVA/HP/current, short circuit, interrupting, transformer impedance), basic protective relaying, circuit breaker and/or normal switching positions, power system automation block diagrams

6

Substation Drawings

Plan views showing equipment layout inside and outside the building, external elevations of building, grounding layout

7

System studies which form the basis of the equipment ratings shown on the one line diagrams

Should include: - load flow - short circuit - motor starting - arc flash - grounding calculations (as per SAES-P-111)

8

Additional power system studies as applicable

As per SAES-P-100

9

Typical installation drawings, electrical cable schedule, underground cable layout, grounding drawings and Conduit/cable tray/ junction box cable filling calculations

At 90% Detailed Design only

Environmental Engineering

Typical % completion for DSRs = 60%

1

Scope of Work

2

Project Description

3

Material Specifications and Data Sheets for wastewater treatment equipment

4

Wastewater treatment systems studies which for the basis of the equipment design

5

Specifications of Ambient Air Quality and Meteorology Monitoring Stations, if required by the project scope

6

Design details/drawings for groundwater monitoring wells, as required by the project scope

7

Construction Contractor Work Scope

8

Plot Plans

9

PFDs

Saudi Aramco: Company General Use

Page 11 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

10

P&IDs

11

Design Calculations

For any equipment with an environmental emission

12

Environmental Impact Assessment

All Reviews

13

Environmental/Social Health Impact Assessment (ESHIA)

All Reviews

14

Design details of radioactive storage facilities.

15

Manufacturer’s specifications for any sources of ionizing radiation (equipment generating ionizing radiation or radioactive sources) that are part of the design or required to carry out the project.

Geotechnical (off-shore)

Typical % completion for DSRs = 30%

1

Design Concept

Project Proposal only

2

Scope of Work

Detailed Design only

3

Pile Design and Installation

30% Detailed Design

4

On-bottom Stability and Mudmats

30% Detailed Design

5

Flooding and Grouting System Design and Drivability

90% Detailed Design

Geotechnical (on-shore)

Typical % completion for DSRs = 30%

1

Scope of Geotechnical Investigation

2

Geotechnical Report

3

Foundation Types and Load Indications

4

Earth Work Plans and Specifications

5

Construction Procedures for Special Projects

Heat Exchangers and Boilers

Typical % completion for DSRs = 30%

1

P&IDs and PFDs

2

Equipment Data Sheets

3

Pressure vessels & storage tanks

HVAC 1

P&IDs

2

Specifications

i.e., evaporation ponds and quay walls

At 60% Completion Typical % completion for DSRs = 60%

Saudi Aramco: Company General Use

Page 12 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document 3

Calculations

4

System Diagrams

5

Scope of Work

6

Equipment Layout

7

Equipment Schedules

Comments

Instrumentation

Typical % completion for DSRs = 30%

1

PFDs

Samples (for DSR only)

2

P&IDs

Samples

3

Instrument Installation Schedules

Samples

4

Instrument Specification Sheets

One sample for each different instrument

5

Console/Panel/Rack Drawings (C/P/R)

Only General Layouts

6

Instrument Interconnection Wiring Diagrams

Samples for JBs, Marshaling cabinets, C/P/R drawings

7

Layouts Instrument Points and Lines

Samples

8

ESD System Drawings

Samples of Cause and Effect, Basic Logic Diagram and ESD Logic Narrative

9

Equipment Protection System Drawings

Samples of Basic Logic Diagram, and Logic Narrative

10

Instrument Loop Diagrams

Sample for each different Loop Template

11

System Block Diagram

Full set, should be completed at the start of a project

12

Logic Diagrams and Logic Narrative for Batch or Sequential control

Samples

13

Typical installation drawings, electrical cable schedule, underground cable layout, grounding drawings and Conduit/cable tray/ junction box cable filling calculations

At 90% Detailed Design only

Materials and Corrosion Control

Typical % completion for DSRs = 30%

1

Scope of Work

Submit for background information

2

Process Flow Diagrams (including Process Description/Data)

Submit for background information

3

P&IDs

Submit before POs are issued

4

Material Specifications/Selection

Submit before POs are issued

Saudi Aramco: Company General Use

Page 13 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

5

Equipment and Lines with H2S (Appendix B)

Submit before PRs or POs are issued

6

Equipment Data Sheets

Submit before POs are issued

7

Corrosion Management Program (see SAES-L-133, Section 8)

Submit and get approval before POs are issued

Paints and Coatings

Typical % completion for DSRs = 60%

1

PFDs

Specify temperature, pressure, and fluid composition for internal coatings. Specify temperature for external coatings. Specify insulation, if any.

2

Material Specifications and Equipment Data Sheets

Identify which metallurgies are specified

3

Coating “Map”

Identify which coatings are specified for which services.

Piping

Typical % completion for DSRs = 60%

1

P&IDs and PFDs

2

Scope of Work

3

Piping Material Specifications

4

Plot Plans

5

Piping Plans, Layouts, Sections, and Details

6

Isometrics

7

Piping Support Details

8

Calculations

9

Safety Instruction Sheets

10

Hydrostatic Test Diagrams

Submit before PRs or POs are issued

At least 90% complete.

Plant Management Systems

Typical % completion for DSRs =60%

1

Installation and Commissioning Plan

2

Architecture Design

3

Application Design

4

Human Interface Design

5

Integration Design

6

Computer Room(s) Design

7

Structured Wiring Design Saudi Aramco: Company General Use

Page 14 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

8

Development Plan

9

Boundary Specification

10

Application Interpath Design

11

Communication Network Interconnect Diagrams

12

Plant Management System Security Diagrams

13

Flare Monitoring System

Plumbing and Utilities

Typical % completion for DSRs = 60%

1

P&IDs

2

Material Specifications

3

Plot Plans

4

Hazardous Area Classifications

5

Calculations

6

Layout Drawings, Sections, and Details

Pressure Vessels and Storage Tanks 1

Typical % completion for DSRs = 30%

Equipment Data Sheets

Process

Typical % completion for DSRs = 30%

1

Design Data Requirements

Project Proposal only

2

Process Simulation model

3

Process Simulation report

4

Process Flow Diagrams (PFDs)

5

Heat & Material Balance

6

Utility balances and Utility Flow Diagrams (UFDs)

7

Technology Licensor selection report

8

Process Equipment List

9

Piping & Instrumentation Diagrams (P&IDs)

10

Process Equipment datasheets

11

Hydraulic design reports.

12

Catalysts and Chemicals Summary

Project Proposal only

Project Proposal only

Saudi Aramco: Company General Use

Page 15 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

13

Process Hazard Analysis (PHA, HAZOP, LOPA, SIL, QRA, etc.) Report

14

Technical License Agreements

Project Proposal only

15

Environmental Impact Assessment (Final)

Project Proposal only

16

Plot Plans

Project Proposal only

17

Material Selection Diagrams (MSDs) and piping specifications

18

Hazardous Area Classification Determination and Drawings

19

Operating procedures / manual

20

Product and in-process QC sampling/testing plan

21

Project commissioning schedule.

Process Engineering

Typical % completion for DSRs = 30%

1

Scope of Work

2

Design Basis Documentation (Design Data Requirements)

3

PFDs

4

Heat and Material Balance (H&MB)

5

Process Simulation (model) and report

6

Utility Flow Diagram (UFD)

7

P&IDs

8

Process Equipment Data Sheets

9

Catalyst and Chemicals summary

Rotating Equipment 1

Process Description

2

Basic Engineering data

3

PFDs

4

P&IDs

5

Plot Plan

Detailed Design only

Typical % completion for DSRs = 90%

Saudi Aramco: Company General Use

Page 16 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

6

Rotating Equipment List, with indication of equipment to be evaluated and procured based on LCC (as per SAEP-341)

7

Equipment data sheets

8

RFQs showing Purchase Specifications

Structural (off-shore)

Typical % completion for DSRs = 90%

1

Design concept

Project Proposal only

2

Float-over analysis/design/procedures

Project Proposal only

3

Floatation analysis

Project Proposal only

4

Weight reporting

5

Scope of Work

Detailed Design only

6

In-Place Design

Detailed Design only

7

Float-over analysis/design/procedures

Detailed Design only

8

In-place Fatigue

Detailed Design only

9

Upending Analysis/Procedures

Detailed Design only

10

Riser/Riser Guard/J-tube Design

Detailed Design only

11

Primary Steel Drawings/Joints/Details

Detailed Design only

12

Boat Collision Checks

Detailed Design only

13

Boat Landing/Boat Fender Design

Detailed Design only

14

Earthquake Analysis

Detailed Design only

15

Flooding and Grouting System Design

Detailed Design only

16

Resolved comments from Project Proposal

Detailed Design only

17

Soft copy of the design data (computer input file) as applicable (SACS/STAAD model).

Structural (on-shore)

Typical % completion for DSRs = 90%

1

Scope of Work

100% completion

2

Plot Plans

100% completion

3

Calculations, including concrete foundations

100% completion

4

Foundation Location Plans

100% completion Saudi Aramco: Company General Use

Page 17 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

5

General Structural Drawings

90% completion

6

Detailed Structural Drawings, including connections and foundations

90% completion

7

Soft copy of the design data (computer input file) as applicable (SACS/STAAD model).

Notes: a. The review of structural steel shop drawings or material take-off's is not considered part of the normal structural design package review. b. The submittal should contain “typical” design calculations and structural drawings of different structural elements such as: beams, columns, bracing, steel connections, anchor bolts, frames, pipe racks, pipe supports, buildings (Process Interface Buildings, Control Buildings, Substations, Offices, Villas, etc.), platforms, equipment foundations (pump, compressor, turbine, generator, etc.), structure foundation.

Valves

Typical % completion for DSRs = 90%.

1

P&IDs

2

Material Specifications

3

Piping Layout

Or location of vertical valves

Welding

Typical % completion for DSRs = 90%

1

Material specifications and equipment data sheets

Include thicknesses and materials

2

Welding Specifications

4.5.2

All documents for review shall contain evidence of design agency quality assurance and quality control through: (a)

Document revision control numbering, dating, and marking in accordance with SAES-A-202,

(b)

A general note citing the applicable engineering standards cut-off date for project (see SAEP-125 Sec 3.1 and SAEP-14, Sec 3.2.8.1),

(c)

“Designed by” designer initials,

(d)

“Checked by” checker initials (i.e., design verified via intradiscipline review) and

(e)

“Approved by” responsible engineer initials (i.e., design is validated via project-team inter-discipline design review and offproject discipline engineering review). Saudi Aramco: Company General Use

Page 18 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

PRO must include a document in each Index that contains a list of the full names, initials, roles, and qualifications of the engineers who have initialed documents in that index. 4.5.3

5

The review shall enable the following: (a)

Reviewers shall have access to documentations in the system for all design cycles.

(b)

Formal system to track all documentation that have been or will be submitted for review throughout the design cycle.

Reviews and Project Non-Conformity Resolution 5.1

SARO Engineers shall perform the review of design documentation and make appropriate comments in the eReview system.

5.2

SARO comments shall clearly reference the issue being discussed (e.g., state equipment name, tag number, drawing number), clearly state the issue and provide recommended resolution. All comments must be properly classified in the eReview system.

5.3

PRO shall generate responses to all SARO comments and enter these responses into the eReview Comments Management System such that the relevant SARO Engineer is notified of the proposed resolution.

5.4

PRO shall update the status of all comments in the eReview Comments Management System such that everyone involved in the project can access all comments and their proposed resolutions.

5.5

After all Project Proposal Reviews are completed, PRO shall compile the “Project Proposal Review Report”, per the CMS Manuals, RAPID Matrix, and book of deliverables, detailing all comments and their resolutions, and distribute to all SAROs.

5.6

Using the eReview Comments Management System, PRO shall request approval to close a review comment from the SARO Engineer who entered a comment.

5.7

SARO Engineer shall respond in a timely manner to PRO requests to close items and make every effort to work with SARO to come to an appropriate resolution.

5.8

All review comments must be closed in the eReview Comments Management System before the commencement of the next review cycle.

5.9

Review comments cannot be marked as closed until they are approved in the eReview Comments Management System by the SARO Engineer who entered Saudi Aramco: Company General Use

Page 19 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

the comment. 5.10

Where a resolution to an outstanding issue or review comment cannot be reached, SARO Engineer shall escalate significant issues using the escalation procedure in Appendix A.

5.11

Per the CMS Manuals, RAPID Matrix, and book of deliverables, certain SAROs have to “Agree” to the DBSP and Project Proposal Packages. This means that the Managers of these SARO shall approve these packages before the project progresses past this point. 5.11.1 All review comments must be closed in the eReview Comments Management System before the commencement of the approval workflow. 5.11.2 When all review comments are resolved, PRO shall route the approval workflows for these packages, via the SAP application “e-Approval” to these SAROs for approval.

5.12

When a SARO receives an approval workflow for DBSP or Project Proposal, 5.12.1 SARO shall verify that all comments have been closed via the eReview Comments Management System. 5.12.1 If all comments have been closed to SARO's satisfaction, approval workflows shall be approved. If comments have not been resolved to SARO's satisfaction, approval workflows shall be rejected.

6

Responsibilities 6.1

PRO is responsible for: 1.

2.

Obtaining agreement with SAROs for: a)

The number, method(s), type, timing, and required documentation for the Project Proposal Review(s).

b)

The number, method(s), type, timing, and required documentation for Detailed Design Review(s).

Planning, forecasting, and requesting engineering reviews a minimum of two weeks in advance of the review, and notifying appropriate SAROs of anticipated reviews. PRO is must include a copy of the required communication requesting the review. Failure to produce the copy of the communication requesting the review will extend the review period by two weeks. Saudi Aramco: Company General Use

Page 20 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

3.

Conducting in-house preliminary reviews prior to requesting an engineering review be performed. PRO must provide a separate document for each Index containing the comments and resolutions resulting from the preliminary in-house review for that Index.

4.

Ensuring the functional requirements of the Design Basis Scoping Paper and/or Project Proposal are met.

5.

Coordinating and implementing SAEP-compliant engineering reviews. PRO shall not be able to shorten the required review period specified in Section 4 without including the required written mutual agreement as a document in each Index.

6.

Timely delivery of complete and legible review documents to the appropriate SAROs. PRO shall ensure that all documents are submitted in (.pdf format) such that comments can be added using the “sticky note” functionality.

7.

Notifying all SAROs if documents are added to, or deleted from, the engineering review. Any documents added to the review resets the review Start Date to the first business day following the date the last document was added and the review End Date to the period specified in paragraph 4.4.1.

8.

Providing adequate time for SAROs to perform the requested review.

9.

Providing any additional documents needed to assist in the review effort (e.g., draft purchase requisitions for items of critical equipment that may need to be issued prior to the scheduled Detailed Design Review).

10.

Resolving SAROs’ review comments using the Comments Management System within the eReview system.

11.

Administering the electronic reviews so that the review process and comment resolution appears seamless to the review agents.

12.

Developing a design that is sound and meets all relevant Saudi Aramco, Industry, International and National Codes and Standards. Reviews conducted by SAROs do not relieve PRO of their responsibility to produce a quality design package.

13.

Submitting a form with each review request that specifies the disciplines for each SARO that are included in the review.

14.

Maintaining all classification data associated with each review comment “as entered” in the eReview system. Any and all changes to the classification data require the approval of the comment originator. It is completely unacceptable for PRO to require SAROs take the time to enter classification data, such as comment type (Standard Violation, Saudi Aramco: Company General Use

Page 21 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Clarification, etc.), for each comment only to have PRO not use this unaltered metadata in the PRO reporting statistics. 6.2

6.3

SAROs are responsible for: 1.

Reviewing design documents within the agreed time frame.

2.

Allocating appropriate resources to conduct the review.

3.

Notifying the PRO if the review cannot be completed within the period specified by the PRO.

4.

Providing specific comments, not general statements, and suggesting alternatives where appropriate to correct engineering deficiencies and non-compliances.

5.

Recommending further reviews depending on the technical complexity of the project and initial review findings.

6.

Establishing a single point of contact for the project in each Engineering Department.

7.

Providing review comments to PRO in the mutually acceptable electronic format.

8.

Notifying PRO if there are no comments.

9.

Obtaining the necessary skill sets through the PMOD training center to conduct electronic reviews.

PRO may elect to utilize a third party review at any design stage for CMS Project Characterization C1 projects as defined in SAEP-360. 1.

PRO remains accountable for the design and review of the design.

2.

PRO shall cause third party to comply with all review responsibilities highlighted under Section 6.2.

Revision Summary 13 December 2011 21 November 2016

Major revision. Major revision is required in order to align SAEP-303 with the CMS system and to incorporate many enhancements required to improve the review and implementation of recommendations.

Saudi Aramco: Company General Use

Page 22 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Appendix A - Project Non-Conformity Escalation Process A.1

Scope of the Escalation Process This Annex provides escalation process and instructions of non-conformities during projects to Mandatory Saudi Aramco Engineering Requirements or GIs including delinquency that have direct impact on the projects’ safety, integrity, and cost.

A.2

Purpose The purpose of this Escalation Process is to: Define a structured Escalation Process during projects with clear roles and responsibilities, non-conformities Levels, escalation level, and escalation notification approach. Implement a unified and timely method for escalating non-conformities and delinquency in matters related to projects’ safety, integrity, and cost.

A.3

Definitions ACD: Agreed Completion Date Escalation Process: A structured mechanism to progressively escalate new or pending Non-Conformities and technical deficiencies to the concerned management. NCA: Non-Conformities Action starts the Escalation Process by sending the Non-Conformity Form (NCF) to the Saudi Aramco organizations and/or Contractors responsible for Non-conforming actions. NCF: Non-Conformity Form (NCF) issued to the Saudi Aramco organizations and/or Contractors responsible for Non-conforming actions. Non-Conformities or Technical Deficiencies: Non-compliance to any MSAER or project specifications in projects or operating facilities. MSAER: Mandatory Saudi Aramco Engineering Requirements (Standards, Procedures, Materials Specifications, Engineering Manuals) MCC: Mechanical Completion Certificate. Repeated Non-Conformity: A non-compliance of the same MSAER, project specifications or standard drawings in the same activity area that occurred more than once within a year. Saudi Aramco: Company General Use

Page 23 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Integrity Non-Conformity: Asset Non-compliance to MSAER that have potential impact on life, capital assets, or environment, see Table 1. Table 1 - Definition of Integrity Non-Conformity Tier I and Tier II Integrity Non-Conformity Tier Level

Potential Integrity Impact Life (People Safety)

Capital Assets (Property / Production)

Environment

Tier I

One or more fatalities or major injuries (hospitalization or days off work).

A fire or explosion resulting in greater than $25,000 of direct cost.

A release of Hazardous or Toxic material above Tier 1 level (see Section A.9)

Tier II

Minor injury

A fire or explosion resulting in greater than or equal to $2,500 of direct cost.

A release of Hazardous or Toxic material above Tier 2 level (see Section A.9)

A.4

Non-Conformities Levels The non-conformities Levels can be categorized into three levels: Major, Medium, and Minor. The following table summarizes the non-conformities Levels and approval levels. Table 2 - Summary of Non-Conformity Level vs Approval Levels Escalation Level Non-Conformity Level

Manager

Major

O

Medium

Division Head

Unit Head or Group Leader

O

Minor

O

O: Approval

Saudi Aramco: Company General Use

Page 24 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

4.1

Major Non-conformities 4.1.1

Non-conformity in project design or missing requirements in project design that may lead to a Safety or Integrity Non-Conformity Tier I (see Table 1), typically characterized by immediate or short term (within a year) impact realization.

4.1.2

Non-Conformities or Technical Deficiencies that result in more than $1MM loss to the company per year or per the project.

4.1.3

Actions that violate the corporate values by submitting forged reports and counterfeit materials.

4.1.4

Starting a project or design document which excludes ANY Mandatory Saudi Aramco Engineering Requirement (MSAER) or GIs, without securing the required waiver approved by applicable management level authority.

4.1.5

Non-conformities to MSAER or GIs, project specifications and drawings that if it is not corrected, the safety and integrity of the next phase will be jeopardized; or if such Non-conformity, if not corrected in a timely manner, will lead to either:

4.2

More severe damage, Additional cost for project/operation phases, or More complexity in project/operation phases.

4.1.6

Non-Conformities or Technical Deficiencies that result in a delay for ANY project deadline/Phase.

4.1.7

Delinquent Medium Non-Conformity level item.

4.1.8

Repeated Medium or Major Non-Conformity item within a year.

Medium Non-conformities 4.2.1

Integrity Non-Conformity Tier II (see Table 1), typically characterized by med-term (1-3 year) impact realization.

4.2.2

Non-Conformities to MSAER or GI, project documents and drawings that if it is not corrected, the safety and integrity will be impacted in the med-term; or Non-Conformity, if not corrected in a timely manner, may lead to a rework on the design, change in the material procurement or change/rework during the project construction / commissioning. Saudi Aramco: Company General Use

Page 25 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

4.3

A.5

4.2.3

The Non-Conformity will be categorized ‘YES’ item as defined in GI-0002.710 during the partial MCC stage.

4.2.4

Non-Conformities or Technical Deficiencies that result in more than $250M but less than $1MM loss to the company per year or per the project.

4.2.5

Delinquent Minor Non-Conformity level item.

4.1.6

Repeated Minor Non-Conformity item within a year.

Minor Non-conformities 4.3.1

Integrity Non-Conformity with potential long term impact realization.

4.3.2

Non-Conformities to MSAER, project specifications and approved drawings provided the next phase of work is not dependent on the correction of the Non-Conformities.

4.3.3

The Non-Conformity will be categorized ‘NO’ item as defined in GI-0002.710 during the partial MCC stage.

4.3.4

Non-Conformities or Technical Deficiencies that result in more than $10M but less than $250M loss to the company per year or per the project.

Escalation Levels 5.1

Major Non-Conformity Escalation Non-conformity Form (NCF) Level III, signed by the responsible ES Manager, shall be addressed to the responsible Manager of the Proponent (Projects and/or Operations). Non-conformity Level III Form shall include the Non-Conformity description, non-compliance reasons, and business impact.

5.2

Medium Non-Conformity Escalation Non-conformity Form (NCF) Level II, signed by the ES Division Head, shall be addressed to the responsible Department Head of the Proponent (Projects and/or Operations). Non-conformity Level II Form shall include the Non-Conformity description, non-compliance reasons, and business impact.

5.3

Minor Non-Conformity Escalation Non-conformity Form (NCF) Level I, signed by the responsible ES Unit Head, shall be addressed to the responsible Project Manager. Non-conformity Level I Saudi Aramco: Company General Use

Page 26 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Form shall include the Non-Conformity description, non-compliance reasons, and business impact. A.6

Instructions and Process 6.1

The process outlined in Figures 1 and 2 of this section shall be used for all nonconformity Escalation.

6.2

Non-Conformity or technical deficiencies shall be reported/logged in a timely manner in the “Non-Conformity and Escalation Actions Log” with clear description, appropriate Non-conformities Levels, and status of actions/delinquency.

6.3

The status of “Non-Conformity and Escalation Actions Log” shall be updated regularly by the ES Responsible Engineer.

Figure 1 - Escalation Process Detail Steps

Saudi Aramco: Company General Use

Page 27 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Non-Conformity Level

Minor

Medium

Initiate NCA

Meet ACD?

Yes

Meet ACD?

Yes

No

No

No

Grant Extension?

Grant Extension?

Grant Extension?

Yes

Yes

No

Completed On new ACD? Yes No

Close NCA

Initiate NCA

Initiate NCA

Meet ACD?

Yes

Major

No

Completed On new ACD? Yes No

Next level Escalation

Close NCA

Next level Escalation

Yes

No

Completed On new ACD? Yes No

Close NCA

Escalation to AA Head or Auditing

Figure 2 - Escalation Process per Non-Conformity Level

A.7

6.4

The “Non-Conformity and Escalation Actions Log” shall be reviewed monthly in the Department Communication Meeting.

6.5

Incomplete or delinquent Major Non-Conformity Items shall be escalated to ES Admin Area Head or reported to Auditing.

6.6

Typically, Non-Conformity Escalation Process shall be initiated when the comment are not closed and implemented by the project during the design review comment resolution meeting. However, Non-Conformity Escalation Process can be initiated at any project cycle when such Non-Conformity is identified and not addressed in due time.

Responsibilities 7.1

Responsible ES Manager 7.1.1

Review the “Non-Conformity and Escalation Actions Log” on monthly basis.

7.1.2

Approve the escalation of Non-Conformity items to the next level.

Saudi Aramco: Company General Use

Page 28 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

7.2

7.3

7.4

Responsible ES Division Head 7.2.1

Categorize submitted Non-Conformity items as Minor, Medium or Major; reflect such categorization in the “Non-Conformity and Escalation Actions Log”.

7.2.2

Communicate the Non-Conformity items in writing to the Responsible Manager.

7.2.3

Approve the Moderate NCF with the initial Agreed completion date.

7.2.4

Escalate overdue moderate Non-conformity action to the next level.

Responsible ES Unit Head or Group Leader 7.3.1

Report immediately Non-Conformity items to the Responsible ES Division Head.

7.3.2

Assign the required resources and backup to address the NonConformity items.

7.3.3

Approve the NCF form for minor Non-conformity action with the initial Agreed completion date.

7.3.4

Escalate overdue minor Non-conformity action to the next level.

Responsible ES Engineer 7.4.1

Report immediately Non-Conformity items to the Responsible ES Unit Head and Responsible Division Head.

7.4.2

Fill the initial Non-Conformity Form (NCF).

7.4.3

Report/Flag delinquency or incompletion of the Non-Conformity items.

7.4.4

Update periodically the status of the Non-Conformity items in the “Non-Conformity and Escalation Actions Log”.

Saudi Aramco: Company General Use

Page 29 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

A.8

Samples of Non-Conformities and Their Level

No.

Sample of Non-conformity or Technical Deficiency

Non-conformity Level

1

Non-compliance to MSAER or technical deficiencies that have potential impact on life, capital assets, or environment.

Major

2

Starting a project or project document which excludes ANY MSAER, without securing the required waiver approved.

Major

3

Forged Quality/testing/verification Documents

Major

4

Technical Integrity deficiencies with immediate or short term impact

Major

5

Procurement and/or Installation of counterfeit materials

Major

6

Placing RVL/Inspectable materials and equipment with unapproved source

Medium

7

Not addressing Critical AIMS assessment recommendations on time

Medium

8

Use of non-approved products

Medium

9

Use of non-approved Service providers

Medium

10

Processing Modification without MoC

Medium

11

Poor or incomplete quality submittals or documentations

Minor

12

Technical deficiencies yielding loss of greater than $10,000 but less than $250M.

Minor

Saudi Aramco: Company General Use

Page 30 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

A.9

Integrity Non-Conformity - Material Release Threshold

Table 3 - Material Release Threshold for Tier I and Tier II Integrity Non-Conformity

Material Hazard Classification (with example materials) Flammable Gases – e.g.: Methane, ethane, propane, butane, Natural gas Ethyl mercaptan Liquids with Boiling Point ≤ 35°C (95°F) and Flash Point < 23°C (73°F) – e.g.: Liquefied petroleum (LPG) Liquefied natural gas (LNG) isopentane Liquids with Boiling Point > 35°C (95°F) and Flash Point < 23°C (73°F) e.g.: gasoline/petrol, toluene, xylene, condensate methanol ˃15 API Gravity crude oils (unless actual flashpoint available) Liquids with Flash Point ≥ 23°C (73°F) and ≤ 60°C (140°F) – e.g.: Diesel, most kerosenes, ˂15 API Gravity crude oils (unless actual flashpoint available) Liquids with Flash Point > 60°C (140°F) released at a temperature at or above its flash point – e.g.: Asphalts, molten Sulphur, Ethylene glycol, propylene glycol, Lubricating oil

Tier 1 (Categories below refer to API/ANSI standard RP 754) Outdoor Indoor release release

Tier 2 (Categories below refer to API/ANSI standard RP 754) Outdoor Indoor release release

500 kg

250 kg

50 kg

25 kg

500 kg

250 kg

50 kg

25 kg

1,000 kg or 7 bbl

500 kg or 3.5 bbl

100 kg or 1 bbl

50 kg or 0.5bbl

2,000 kg or 14 bbl

1,000 kg or 7 bbl

100kg or 1 bbl

50 kg or 0.5 bbl

2,000 kg or 14 bbl

1,000 kg or 7 bbl

100 kg or 1 bbl

50 kg or 0.5 bbl

Saudi Aramco: Company General Use

Page 31 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Material Hazard Classification (with example materials) Liquids with Flash Point < 60, °C (140, °F) released at a temperature at or below its flash point – e.g.: Asphalts, molten Sulphur, Ethylene glycol, propylene glycol, Lubricating oil TIH Zone A Materials – includes: Acrolein (stabilized) TIH Zone B Materials- includes: Hydrogen sulphide (H2S). Chlorine (CL2) TIH Zone C Materials –includes: Sulphur Dioxide (SO2). Hydrogen Chloride (HCL) TIH Zone D Materials –includes: Ammonia (NH3). Carbon monoxide (CO) Other Packing Group I Materials – includes: Aluminum alkyls Some liquid amines Sodium cyanide Sodium peroxide Hydrofluoric acid (> 60% solution) Other Packing Group II Materials – includes: Aluminum chloride phenol calcium carbide carbon tetrachloride some organic peroxides Hydrofluoric acid (˂ 60% solution)

Tier 1 (Categories below refer to API/ANSI standard RP 754) Outdoor Indoor release release

Tier 2 (Categories below refer to API/ANSI standard RP 754) Outdoor Indoor release release

Not applicable

Not applicable

1,000 kg or 10 bbl

500 kg or 5 bbl

5 kg

2.5 kg

0.5 kg

0.25 kg

25 kg

12.5 kg

2.5 kg

1.3 kg

100 kg

50 kg

10 kg

5 kg

200 kg

100 kg

20 kg

10 kg

500 kg

250 kg

50 kg

25 kg

1,000 kg or 7 bbl

500 kg or 3.5 bbl

100 kg or 1 bbl

50 kg or 0.5bbl

Saudi Aramco: Company General Use

Page 32 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Material Hazard Classification (with example materials) Other Packing Group III Materials – includes: Sulphur Lean amine Calcium oxide Activated carbon Chloroform Some organic peroxides Sodium fluoride Sodium nitrate Strong Acids or Bases – includes: Sulphuric acid, hydrochloric acid Sodium hydroxide (caustic) Calcium hydroxide (lime) Moderate Acids or Bases – includes: Diethylamine (corrosion inhibitor)

Tier 1 (Categories below refer to API/ANSI standard RP 754) Outdoor Indoor release release

Tier 2 (Categories below refer to API/ANSI standard RP 754) Outdoor Indoor release release

2,000 kg or 14 bbl

1,000 kg or 7 bbl

100 kg or 1 bbl

50 kg or 0.5 bbl

2,000 kg or 14 bbl

1,000 kg or 7 bbl

100 kg or 1 bbl

50 kg or 0.5 bbl

None

None

1,000 kg or 10 bbl

500 kg or 5 bbl

kg: Kilogram bbl: barrels

Saudi Aramco: Company General Use

Page 33 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee Issue Date: 21 November 2016 Next Planned Update: 21 November 2019

SAEP-303 Engineering Reviews of Project Documentation

Appendix B - List of all Equipment and Lines Carrying H2S BI-

Project:

Package:

Prepared by:

Reviewed by:

Date:

No.

Pipe circuit or Type of Wet H2S equipment no. service concent. exposed to H2S* carrying H2S (ppm)

H2S partial Design/ Design/ HIC-resistant pressure operating operating steel specified Justification (psia) temp (ºC) pressure (psia) (Y/N)?

PR/PO number (if developed)

SAIR comments

1 2 3 4 5 6 7 8 9 10 11 12 13 14 * This numbering shall be easily traced back to attached drawings. SA Project Manager Signature:

Proponent Rep Concurrence:

SAIR Signature:

CSD Approval:

Page 34 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Appendix C - Engineering Design Review Submittal Checklist BI #

BI Title

Order #

Order Title

Following Capital Management System (CMS)

☐ Yes

IPT Leader and Members

Project Stage:

☐ No

Department

☐ FEL-1

☐ FEL-2

Login ID

☐ FEL-3

Skip next part

Deliverable Duration (including Notification period) Contract type

☐ DBSP ☐ 15 Business Days

☐ Project Proposal ☐ 20 Business Days

☐ LSTK

☐ LSPB

Design office Cycle

☐ Detailed design ☐ 25 Business Days ☐ LS

Contact ☐ 30%

☒ 60%

☐ 90%

☐ A letter signed by the project department manager has been sent. Design agency quality assurance and control including: ☐ Citing MSAER’s cut-off date for project. ☐ Designer initials. ☐ Checker initials. ☐ Approval initials. ☐ Submittals should bear the appropriate watermarking identifying the stage of completion. ☐ Comments log for previous review cycle is attached except for 30% of PP

Page 35 of 35

21 November 2016

Document Responsibility: Electrical Systems Designs and Automation Standards Committee

Contents 1

Scope ................................................................ 2

2

Applicable Documents ....................................... 2

3

Definitions .......................................................... 3

4

Instructions ........................................................ 4

5

Reviews and Project Non-Conformity Resolution ................................................ 19

6

Responsibilities ................................................ 20

Revision Summary................................................. 22 Appendix A - Project Non-Conformity Escalation Process ................................... 23 Appendix B - List of all Equipment and Lines Carrying H2s ............................ 34 Appendix C - Engineering Design Review Submittal Checklist ................................... 35

Previous Issue: 13 December 2011

Next Planned Update: 21 November 2019 Page 1 of 35

Contact: Bugshan, Jamal A. (bugshaja) on phone +966-13-8809650 ©Saudi Aramco 2016. All rights reserved.

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

1

Scope 1.1

This Saudi Aramco Engineering Procedure (SAEP) establishes the instructions and responsibilities used by Saudi Aramco Reviewing Organizations (SAROs) when conducting formal engineering reviews of project packages relating to capital and non-capital projects.

1.2

The purpose of engineering reviews is to provide technical assurance to Saudi Aramco that the project is being developed in accordance with all applicable Saudi Aramco Standards, Procedures, and other mandatory requirements at all stages of project development. In addition, engineering reviews add value by applying recognized and generally-accepted good engineering practices by leveraging considerable domestic and international design and operational engineering experience. SAROs provide only a general review of the project. Full responsibility of the project is with PRO.

2

Applicable Documents The requirements contained in the following documents apply to the extent specified in this procedure: Saudi Aramco Engineering Procedures SAEP-12

Project Execution Plan

SAEP-13

Project Environmental Impact Assessments

SAEP-14

Project Proposal

SAEP-16

Project Execution Guide for Process Automation Systems

SAEP-21

Project Execution Requirements for Saudi Aramco Royalty/Custody Metering Systems

SAEP-27

Pipelines/Piping Hydraulic Surge Analysis

SAEP-125

Preparation of Saudi Aramco Engineering Standards

SAEP-127

Security and Control of Saudi Aramco Engineering Data

SAEP-334

Retrieval, Certification, and Submittal of Saudi Aramco Engineering and Vendor Drawings

SAEP-341

Equipment Life Cycle Cost Procedure

SAEP-360

Project Planning Guidelines Saudi Aramco: Company General Use

Page 2 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

SAEP-367

Value Improving Practices Requirements

SAEP-1350

Design Basis Scoping Paper (DBSP) Preparation and Revision Procedure

Saudi Aramco Engineering Standards SAES-A-030

Reliability, Availability, and Maintainability (RAM) Study Execution

SAES-A-202

Saudi Aramco Engineering Drawing Preparation

SAES-L-133

Corrosion Protection Requirements for Pipelines, Piping, and Process Equipment

SAES-P-100

Basic Power System Design Criteria

SAES-P-111

Grounding

SAES-T-481

In-Plant Voice Paging System

Saudi Aramco General Instruction GI-0002.710

3

Mechanical Completion and Performance Acceptance of Facilities

Definitions 3.1

Organizations and Reviewing Entities Saudi Aramco Reviewing Organizations (SAROs): This term refers to all Saudi Aramco organizations involved in reviewing project documents. Project Responsible Organization (PRO): The organization responsible for managing the project. For capital projects, this organization reports to the Vice President, Project Management. For non-capital projects, this organization is usually the proponent. MSAERs: Mandatory Saudi Aramco Engineering Requirements PMOD: Project Management Office Department

3.2

Review Documentation Design Basis Scoping Paper (DBSP): Refer to SAEP-1350. For projects using the Capital Management System (CMS), DBSP refers to the portion of FEL 2 after the Gate Alternative Selection and prior to the G2 Gate. Project Proposal (including Technical Proposal Documents within Contract Bid Packages): Refer to SAEP-14. For projects using the Capital Management Saudi Aramco: Company General Use

Page 3 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

System (CMS), Project Proposal refers to the portion of FEL 3 before the Project Proposal Approval. Detailed Design: A set of documents used for project construction and material procurement. For projects using the Capital Management System (CMS), Detailed Design refers to the Detailed Design portion of the Execution Phase. 3.3

Review Methods Engineering reviews are generally organized based on one of the two following methods: Across-the-Board Review (ABR): This is a review simultaneously carried out by all involved engineering disciplines. ABRs must be conducted through the eReview system. Discipline Specific Review (DSR): This is a review carried out by a specific engineering discipline. DSRs must be conducted through the Engineering Service Request system in SAP.

4

Instructions 4.1

Number, Type, and Method of Reviews ABRs are conducted by SAROs once during Project Proposal on the last issue of the Project Proposal review package before the Project Proposal Approval. ABRs are conducted by SAROs once during Detailed Design, preferably at the stage indicated in Section 4.5.1 for each discipline.

4.2

Requesting and Planning Engineering Reviews 4.2.1

To request an engineering review, either in the Project Proposal or Detailed Design phase, PRO shall address a letter to the Manager(s) of the appropriate SAROs requesting that a review be performed. The letter shall state the type of review to be performed, the review format to be used, expected start date, and the name of the PRO representative responsible for coordinating the review.

4.2.2

Include in the Project Proposal the proposed number, method, and type of the engineering reviews for the Detailed Design phase of the project. DSRs shall be carried out during the Detailed Design phase at the percent completion stage agreed to by PRO and SAROs during the Project Proposal meeting. Required percent completions are given for each discipline in Section 4.5.1. Saudi Aramco: Company General Use

Page 4 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

ABRs shall be carried out during the Detailed Design phase at the overall project percent completion stage agreed to by PRO and SAROs during the Project Proposal meeting. 4.3

Review Submittals 4.3.1

General The submittals described in this paragraph should bear the appropriate stamps identifying the stage of completion. All submittals are accompanied by a Saudi Aramco standard transmittal form identifying the package and the action to be taken by the receiving organization and the due date for the required action. All scheduled reviews shall be submitted via the eReview system. PRO must include a document in each Index for all Detailed Design review requests that indicates the cut-off dates for all MSAERs.

4.3.2

4.4

PRO must complete and attach the Engineering Design Review Submittal Checklist per Appendix C to the initial package submittal. Failure to do so will result in package rejection.

Review Schedule 4.4.1

Engineering reviews of DBSPs and Project Proposal packages require a minimum of 10 business days and Detailed Design packages require a minimum of 15 business days, respectively. Business days are as stated on the Saudi Aramco operational calendar. The review period begins on the day following the date that the review material was received by the SAROs. A shorter review period is allowed on written mutual agreement between PRO and SARO department managers under Section 4.2. PRO shall provide a longer review period at the request of the SARO. Review requests that do not meet the minimum number of days that do not have the above-mentioned written mutual agreement filed as a separate document in each index shall be rejected.

4.4.2 4.5

The review period to perform a DSR shall be established via the approval mechanism in the Engineering Service Request system in SAP.

Review Documentation 4.5.1

Review Requirements In these tables, the first column gives the documentation required for Saudi Aramco: Company General Use

Page 5 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

both ABRs and DSRs. The second column gives details of the required documentation as well as the required percent completion for each discipline for DSRs. All review requests, including Project Proposal reviews, must contain all of the listed documents. PRO must include a document in each Index showing the file name(s) of the review documents corresponding to the required documents. Review Requirements Document

Comments

Architectural (Project Proposal) 1

Site Plan: Generals site arrangement – new and existing buildings, building access, roads, and parking.

Plans

Floor Plans: Functional plan and circulation. 2

Indicate building classifications (tiers)

3

For Tier 1, perform LEED certification requirements, if needed.

Architectural (30% Detailed Design)

Typical % completion for DSRs = 30%

1

Site Plan: Generals site arrangement – new and existing buildings, building access, roads, and parking (75% complete)

Plans

Floor Plans: Functional plan and circulation, building system, grids, and overall dimensions (100% complete) 2

Building sections

General structure, building volumes, floor heights, vertical circulation elements (100% complete)

3

Building elevations

Overall elevations – shapes, heights, and volumes (100% complete)

Architectural (60% Detailed Design)

Typical % completion for DSRs = 60%

1

Site Plan: New, support, and existing buildings, roads, parking, and open areas (100% complete)

Plans

Floor Plans: Detailed layout – openings, circulation, exits, egress routes, floor levels, generals finishes, wall assemblies, dimensions – exterior and interior (100% complete) Roof Plan: Primary and secondary roof grain systems, access and equipment (if applicable), levels, slopes, outlets, parapet walls, structures at adjacent levels (below/above), overall dimensioning (100% complete) Reflected Ceilings: Acoustic ceiling layouts, lighting (100% complete) Saudi Aramco: Company General Use

Page 6 of 35

Document Responsibility: Electrical Systems Designs and Automation Standards Committee SAEP-303 Issue Date: 21 November 2016 Next Planned Update: 21 November 2019 Engineering Reviews of Project Documentation

Review Requirements Document

Comments

2

Building sections

Assemblies – floors, finishes, walls, roofs, overhangs, relation to structural elements, wall types, levels – interior and exterior (100% complete)

3

Building Elevations

Detailed elevations – volumes, openings, heights, façade elements, finishing material descriptions (100% complete)

4

Schedules

Doors and windows: Shapes, sizes, specifications, materials (100% complete)

Architectural (90% Detailed Design)

Typical % completion for DSRs = 90%

1

Site Plan: New, support, and existing buildings, roads, parking, hard and soft scape, setting-out, vertical planning (100% complete)

Plans

Floor Plans: Circulation, exits, egress routes, guards and railings, vertical circulation elements, internal levels, interior dimensions (100% complete) Roof Plan: Roof circulation and protection, draining systems, full dimensioning (100% complete) Reflected Ceilings: Electrical/mechanical coordination (100% complete) 2

Sections