Furnace Construction & Operations

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Furnace Construction & Operations as PDF for free.

More details

- Words: 1,162

- Pages: 30

Loading documents preview...

Furnace Construction & Operations Prepared by Osama Hasan GTE Amm 3 Engro Fertilizers 1

2

What is Furnace? Converts Chemical/Electrical Energy to Thermal Energy Examples Household Furnace Metallurgical Furnace Industrial Process Furnace Non Reactive e.g. start-up furnace Reactive e.g. primary reformer in ammonia plant

3

Types Draft

Construction

Fuel

Process Type

Burner Arrangement

Heating Method

Tubes Arrangement

Natural Draft

Vertical

Coal Fired

Continuous

Top Fired

Direct

Horizontal Inline

Forced Draft

Horizontal

Gas Fired

Batch

Bottom Fired

Indirect

Horizontal Staggered

Induced Draft

Oil Fired

Side-wall Fired

Vertical Inline

Balanced Draft

Electric Current

Terrace-wall Fired

Vertical Staggered

4

Types: Construction

Vertical Furnace

Horizontal Furnace

5

Types: Draft The slight pressure difference between firebox and the atmospheric pressure that produces the flow of gases due to temperature difference Forced Mechanical

Induced

Natural

Balanced

Draft

6

Types: Burners

7

Natural Draft Furnace Air Registers

Controls the air flow partially

Damper

Controls the furnace pressure by manipulating the resistance in flow of the flue gas Excessive opening leads to a significant decrease in furnace pressure Excessive closing leads to pressure building in furnace

Reduced furnace pressure:

Increased furnace pressure:

Burner Lifting Burner backfire Increase in draft Flue gases leak from peep door Flame-out Explosion Refractory Damage Rise in radiation zone temp. Incomplete combustion of fuel Drop of heat duty in convection coil Radiation zone temperature decreases

8

Zones Zones

Tube Banks Radiant

Radiation Shock

Furnace

Convection

Convection

9

Zones: Radiation Fire Box

Area around the burners where gas combustion occurs to produce heat and radiation

Burners

Devices used to inject, mix and burn the fuel

Refractory

Wall lining / insulation that accumulates, insulates and radiates heat back to the tubes and increases the heat transfer

10

Zones: Radiation Radiant Tubes

High Pressure and high flow rate process pipelines loaded with catalyst receiving heat via radiation from burners and refractory

Shock Tubes

Tubes which receive heat via radiation and convection both

Types of Tubes:

Bare

Finned

Studded

11

Zones: Convection Also called Heat Recovery Section Arch section

Space between the convection section and radiant section, where flue gases are mixed to offer uniform heat transfer in convection zone

Convection Coils

Coils carrying some fluid which recovers heat from the flue gases

Breeching

Area between the convection section and stack

12

Zones: Convection

Arch Section Convection Coil

Breeching Section

13

Zones: Convection Vent Stack

The chimney that exhausts the flue gases from breeching to atmosphere

Exhaust Damper

Draft regulator which works similar to a butter fly valve to control the air and heat flow

14

Burners Raw Gas Burners

Air and gas is mixed and burnt at spider or burner ring Air inlet is controlled via back and forth movement of air doors Stable operating range is determined by the fuel gas pressure at the burner inlet

15

Burners Pre Mix Burners

Uses a jet of gas to draw the air into aspirator Turbulence is maintained throughout the length of the burner tube due to shape of the aspirator and the velocity difference

16

Burners Combination Burner

Primary Air: Drawn intro aspirator by force of the gas jet. Mixed with gas before it reaches burner spider Secondary Air: Drawn into thimble and meets the mixture at spider.

17

Burners Oil Burner / Gun

Uses steam to atomize oil into a fine mist Stable operating range is determined by fuel oil pressure at the burner inlet and the atomizing steam pressure at the burner inlet

Combination Burner

Operated on oil or gas or both Startup is done via gas supply

18

Refractories

Heat resistant materials which insulate and protect equipment structure due to their excellent resistance to heat, chemical attack and mechanical damage in high temperatures and/or corrosive environment Low iron-low silica content refractories:

Insulating castable Insulating brick Ceramic fiber Ceramic module

19

Metallurgy In-service degradation mechanisms: Thermal degradation (creep) The primary damage mechanism for hightemperature service Metal dusting Metal dusting is a high-temperature corrosion mechanism that occurs in gaseous environments where the carbon activity exceeds one and the metal temperatures are in the range of 450 to 700 °C Stress relaxation cracking Cracking of a metal because of stress relaxation that occurs during post weld heat treatment (PWHT) or during service at elevated temperature

Furnace Operations

20

21

Impingement Burner Flame touching a tube in the firebox Causes:

Increased gas header pressure Low furnace pressure High draft across furnace Mechanical defect / damage of tubes

Problems:

Hotspot on tube Uneven expansion of the tube Tube rupture

Remedy:

Installation Peep doors for monitoring Regular inspection

22

Flame Color Blue Flame:

Complete combustion Desired heating value

Yellow Flame:

Oxygen deficient / starving Carbon monoxide rich Less thermal energy Increased fuel consumption

23

Post Burning Causes

Excess / false air Tube leakage Fuel gas preheat coil leakage Un-burnt fuel carry over

Reaction

Combustion of un-burnt fuel Oxidation of carbon monoxide

Consequences

Loss of energy Explosion

24

Heat Recovery

May be used in forced draft furnaces

Recuperative

Limited heat recovery

Regenerative

Blowing + heating / cooling of air supply / flue gases

25

Instrumentation Skin Couples/TMT

Check tube wall metal temperatures

Draft Gauges

Measures draft inside the furnace

Flue Gas Analyzers

Analyzes for excess oxygen supply

Damper

Regulates air flow outward

26

Startup: Checkup Remove

•Flammable materials •Tools and other sources of danger

Check

•Burner •Pilot Burner Valves •Stack Damper

Open

•Stack Damper •Secondary air registers on furnace

Close

•Peep Holes •Fuel Valves

27

Startup: Purging

Creates a draft and remove all flammable vapors or gas from furnace Purging time should be long enough to ensure all flammable vapors have been removed Purging ensures elements of combustion (fuel, air and heat) are under controlled before we light the burners Natural draft furnace uses steam;

Steam not only purges the furnace but also preheats it and creates an initial draft

Mechanical draft furnace uses air

28

Startup: Lighting the Burners Purging is immediately followed by lighting the burners via pilot / torch To-Do

Introduce torch via secondary air inlet Crack the burner gas valve Steady the burner flame pattern by air registers adjustment If fuel doesn’t ignite, purge again.

Ensure

Satisfactory gas header pressure Safety precautions

29

Shutdown Reduce fuel / heat

Reduce charge flow

Shutdown all burners

Close Gas header valve

Shut off Gas pilot

Reduce steam

Open Bleeder valves

Open air doors and stack damper

Install blinds in fuel lines

30

Thank you Prepared by Osama Hasan Graduate Trainee Engineer Ammonia III – Plant II

[email protected] [email protected]

2

What is Furnace? Converts Chemical/Electrical Energy to Thermal Energy Examples Household Furnace Metallurgical Furnace Industrial Process Furnace Non Reactive e.g. start-up furnace Reactive e.g. primary reformer in ammonia plant

3

Types Draft

Construction

Fuel

Process Type

Burner Arrangement

Heating Method

Tubes Arrangement

Natural Draft

Vertical

Coal Fired

Continuous

Top Fired

Direct

Horizontal Inline

Forced Draft

Horizontal

Gas Fired

Batch

Bottom Fired

Indirect

Horizontal Staggered

Induced Draft

Oil Fired

Side-wall Fired

Vertical Inline

Balanced Draft

Electric Current

Terrace-wall Fired

Vertical Staggered

4

Types: Construction

Vertical Furnace

Horizontal Furnace

5

Types: Draft The slight pressure difference between firebox and the atmospheric pressure that produces the flow of gases due to temperature difference Forced Mechanical

Induced

Natural

Balanced

Draft

6

Types: Burners

7

Natural Draft Furnace Air Registers

Controls the air flow partially

Damper

Controls the furnace pressure by manipulating the resistance in flow of the flue gas Excessive opening leads to a significant decrease in furnace pressure Excessive closing leads to pressure building in furnace

Reduced furnace pressure:

Increased furnace pressure:

Burner Lifting Burner backfire Increase in draft Flue gases leak from peep door Flame-out Explosion Refractory Damage Rise in radiation zone temp. Incomplete combustion of fuel Drop of heat duty in convection coil Radiation zone temperature decreases

8

Zones Zones

Tube Banks Radiant

Radiation Shock

Furnace

Convection

Convection

9

Zones: Radiation Fire Box

Area around the burners where gas combustion occurs to produce heat and radiation

Burners

Devices used to inject, mix and burn the fuel

Refractory

Wall lining / insulation that accumulates, insulates and radiates heat back to the tubes and increases the heat transfer

10

Zones: Radiation Radiant Tubes

High Pressure and high flow rate process pipelines loaded with catalyst receiving heat via radiation from burners and refractory

Shock Tubes

Tubes which receive heat via radiation and convection both

Types of Tubes:

Bare

Finned

Studded

11

Zones: Convection Also called Heat Recovery Section Arch section

Space between the convection section and radiant section, where flue gases are mixed to offer uniform heat transfer in convection zone

Convection Coils

Coils carrying some fluid which recovers heat from the flue gases

Breeching

Area between the convection section and stack

12

Zones: Convection

Arch Section Convection Coil

Breeching Section

13

Zones: Convection Vent Stack

The chimney that exhausts the flue gases from breeching to atmosphere

Exhaust Damper

Draft regulator which works similar to a butter fly valve to control the air and heat flow

14

Burners Raw Gas Burners

Air and gas is mixed and burnt at spider or burner ring Air inlet is controlled via back and forth movement of air doors Stable operating range is determined by the fuel gas pressure at the burner inlet

15

Burners Pre Mix Burners

Uses a jet of gas to draw the air into aspirator Turbulence is maintained throughout the length of the burner tube due to shape of the aspirator and the velocity difference

16

Burners Combination Burner

Primary Air: Drawn intro aspirator by force of the gas jet. Mixed with gas before it reaches burner spider Secondary Air: Drawn into thimble and meets the mixture at spider.

17

Burners Oil Burner / Gun

Uses steam to atomize oil into a fine mist Stable operating range is determined by fuel oil pressure at the burner inlet and the atomizing steam pressure at the burner inlet

Combination Burner

Operated on oil or gas or both Startup is done via gas supply

18

Refractories

Heat resistant materials which insulate and protect equipment structure due to their excellent resistance to heat, chemical attack and mechanical damage in high temperatures and/or corrosive environment Low iron-low silica content refractories:

Insulating castable Insulating brick Ceramic fiber Ceramic module

19

Metallurgy In-service degradation mechanisms: Thermal degradation (creep) The primary damage mechanism for hightemperature service Metal dusting Metal dusting is a high-temperature corrosion mechanism that occurs in gaseous environments where the carbon activity exceeds one and the metal temperatures are in the range of 450 to 700 °C Stress relaxation cracking Cracking of a metal because of stress relaxation that occurs during post weld heat treatment (PWHT) or during service at elevated temperature

Furnace Operations

20

21

Impingement Burner Flame touching a tube in the firebox Causes:

Increased gas header pressure Low furnace pressure High draft across furnace Mechanical defect / damage of tubes

Problems:

Hotspot on tube Uneven expansion of the tube Tube rupture

Remedy:

Installation Peep doors for monitoring Regular inspection

22

Flame Color Blue Flame:

Complete combustion Desired heating value

Yellow Flame:

Oxygen deficient / starving Carbon monoxide rich Less thermal energy Increased fuel consumption

23

Post Burning Causes

Excess / false air Tube leakage Fuel gas preheat coil leakage Un-burnt fuel carry over

Reaction

Combustion of un-burnt fuel Oxidation of carbon monoxide

Consequences

Loss of energy Explosion

24

Heat Recovery

May be used in forced draft furnaces

Recuperative

Limited heat recovery

Regenerative

Blowing + heating / cooling of air supply / flue gases

25

Instrumentation Skin Couples/TMT

Check tube wall metal temperatures

Draft Gauges

Measures draft inside the furnace

Flue Gas Analyzers

Analyzes for excess oxygen supply

Damper

Regulates air flow outward

26

Startup: Checkup Remove

•Flammable materials •Tools and other sources of danger

Check

•Burner •Pilot Burner Valves •Stack Damper

Open

•Stack Damper •Secondary air registers on furnace

Close

•Peep Holes •Fuel Valves

27

Startup: Purging

Creates a draft and remove all flammable vapors or gas from furnace Purging time should be long enough to ensure all flammable vapors have been removed Purging ensures elements of combustion (fuel, air and heat) are under controlled before we light the burners Natural draft furnace uses steam;

Steam not only purges the furnace but also preheats it and creates an initial draft

Mechanical draft furnace uses air

28

Startup: Lighting the Burners Purging is immediately followed by lighting the burners via pilot / torch To-Do

Introduce torch via secondary air inlet Crack the burner gas valve Steady the burner flame pattern by air registers adjustment If fuel doesn’t ignite, purge again.

Ensure

Satisfactory gas header pressure Safety precautions

29

Shutdown Reduce fuel / heat

Reduce charge flow

Shutdown all burners

Close Gas header valve

Shut off Gas pilot

Reduce steam

Open Bleeder valves

Open air doors and stack damper

Install blinds in fuel lines

30

Thank you Prepared by Osama Hasan Graduate Trainee Engineer Ammonia III – Plant II

[email protected] [email protected]

Related Documents

Furnace Construction & Operations

March 2021 0

Construction Planning & Scheduling

January 2021 1

Induction Furnace

January 2021 1

Jct Design & Construction

January 2021 0

Construction R&r

February 2021 1

Induction Furnace

January 2021 1More Documents from "shaishav upadhyay"

Furnace Construction & Operations

March 2021 0

Valves, Types And Operations

February 2021 4

20 Best Steroids

February 2021 0

Pi Bab 9 Perumusan Kebijakan Perdagangan Nasional

January 2021 1

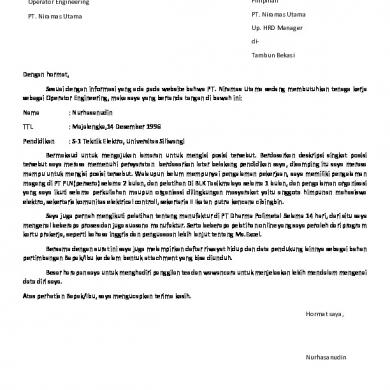

Surat Lamaran.pdf

January 2021 1