Mensuration And Calculation

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Mensuration And Calculation as PDF for free.

More details

- Words: 4,505

- Pages: 35

Loading documents preview...

COMPETENCY BASED LEARNING MATERIAL

Unit of Competency: PERFORM MENSURATION AND BASIC CALCULATION

Module Title : PERFORMING MENSURATION AND BASIC CALCULATION

HOW TO USE THIS COMPETENCY BASED LEARNING MATERIAL Welcome to the module in one of the competency of Driving NCII QUALIFICATION. This module contains training materials and activities for you to complete. The unit of competency “PERFORM ESTIMATION AND BASIC CALCULATION” contains knowledge, skills and attitude required for TRAINEES. You are required to go through, a series of learning activities in order to complete each learning outcome of the module. In each learning outcome are Information Sheet, Self-Checks, Task Sheets and Job Sheets. The follow these activities on your own. If you have questions, don’t hesitate to ask your facilitator for assistance. The goal of this course is the development of practical skills in supervising work-based training. Tools in planning, monitoring and evaluation of work-based training shall be prepared during the workshop to support in the implementation of the training program. This will be the source of information for you to acquire knowledge and skills in this particular competency independently and at your own pace, with minimum supervision or help from your facilitator. Remember to: Work through all the information and complete the activities in each section. Read information sheets and complete the self-check. Answer keys are included in this package to allow immediate feedback. Answering the selfcheck will help you acquire the knowledge content of this competency. Perform the task sheets and job sheets until you are confident that your output conforms to the performance criteria checklist that follows the sheets. Submit outputs of the task sheets and job sheets to your facilitator for evaluation and recording in the Accomplishment Chart. Outputs shall serve as your portfolio during the institutional competency evaluation. A certificate of achievement will be awarded to you after passing the evaluation. You must pass the institutional competency evaluation for this competency before moving to another competency

LISTS OF COMMON COMPETENCIES No.

Unit of Competency

Module Title

1

Use Hand Tools

Using Hand Tools

2

Perform Mensuration and Calculation

Performing Mensuration and Calculation

3

4

5

Prepare and Interpret Technical Drawing

Preparing and Interpret Technical Drawing

Apply Quality Standards

Applying Quality Standards

Terminate and Connect Electrical Wiring and Electronic Circuits

Terminating and Connecting Electrical Wiring and Electronic Circuits

Code ELC311205 ELC311201

ELC311202

ELC311204

ELC311206

Unit of Competency : PERFORM ESTIMATION AND BASIC CALCULATION

Module Title : PERFORMING ESTIMATION AND BASIC CALCULATIONS Learning Outcome :

PERFORM ESTIMATION PERFORM BASIC WORKPLACE CALCULATIONS

Assessment Criteria:

Job requirements are identified from written or oral communications Quantities of materials and resources required to complete a work task are estimated The time needed to complete a work activity is estimated Accurate estimate for work completion are made Estimate of materials and resources are reported to appropriate person Perform basic workplace calculation Calculations to be made Calculations to be made are identified according to job requirement. Correct method of calculation identified. System and units of measurement to be followed are ascertained. Calculation needed to complete work task are performed using the four basic process of addition, subtraction multiplication and division. Calculate whole fraction, percentage and mixed when are used to complete the instructions. Number computed in self checked and completed for alignment.

Condition : • Mathematics Books • Ruler Steel Tape Measure • Calculators • Relevant tools and equipment for basic calculations • Recommended date References: • Mathematics books Learning Experiences Learning activities Special instructor 1. Move to the library and study, 2. If there is misunderstanding on practice solving problems using the topic, consult your T.I. for the different systems, processes further explanation. and operations.

i

Unit of Competency

PERFORM MENSURATION AND CALCULATION Module Title

PERFORMING MENSURATION AND CALCULATION

INTRODUCTION: This module contains information and suggested learning activities on Plumbing NC-I1 particularly on the competency “Maintain Tools and Equipment”. It includes instructions and procedure on how to maintain tools and equipment. It explains how to repair and replace tools and equipment. It also explains the proper use of inventory forms. SUMMARY OF LEARNING OUTCOMES: Upon completion of the module, you must be able to: LO1. select Measuring Instrument; and LO2. carry out Mensuration and Calculation. LOZA3. Maintain measuring instruments ASSESSMENT CRITERIA: LO 1. Select Measuring Instrument 1. Measuring tools are selected / identified as per job requirement. 2. Correct specifications are obtained from relevant sources. LO 2. Carry out Mensuration and Calculation 1. Accurate measurements are obtained according to job description. 2. Calculation needed to complete work/ task is correctly done based on the four (4) fundamental operations. 3. Work pieces are measured according to job description / requirements.

TECHNICAL TERMS 1. Accuracy means correctness, exactness, precision. 2. Area is any of space especially of ground or surface that is distinguishable from its surrounding in appearance or in certain distinctive features 3. Clearance is the space, allowance or gap between working part of an object. 4. English System is the old way of measurement that replaced the metric system. 5. Height may be used with reference whether high or low by a standard of companion. 6. Instrument is a device that measures or controls something. 7. Length refers to how long an object is 8. Measurement refers to the size, length, quantity or rate of something that has been measured. 9. Mensurations the calculation of geometric quantities such as length, area and volume from dimensions and angles that are already known. 10.

Metric System is the System of measurement which uses 10 as

its multiple in all its conversion is it in distance, volume, weight etc. 11.

PPE is an acronym that stands for Personal Protective Equipment

12.

Pressure is the force acting on a surface divided by the area

over which it acts. 13.

Volume refers to the magnitude size intent, dimension, areas, and

bulk, mass the total amount of something. 14.

Weight refers to the total quality of heaviness and things

determined by their mass or control acts efforts to lift or move them.

Learning Outcome # 1: Select Measuring Instrument Assessment Criteria: 1. Measuring tools are selected and identified as per job requirement. 2. Correct specifications are obtained from relevant sources.

INFORMATION SHEET # 2.1.1 Measuring Tools Measuring Tools Inside Caliper is used to measure the internal size of an object.

Outside Caliper is used to measure the external size of an object

Steel Square is a tool that carpenters and other tradesman use consisting of a large arm and a smaller arm which meet at an angle 90˚.Today the steel square is more commonly referred to as the framing square.

2

TRY SQUARE is a wood working or a metal working tool used for marking/measuring a piece of wood. It is primarily used to measure the accuracy of right angle (90˚ degrees) tried on any surface so as to check its straightness or correspondence to an adjoining surface.

PULL PUSH (Tape Measure) is a flexible tape measure which is available in lengths up to 50 feet. Other tapes that are 12 to 25 feet are usually considered adequate. Most tapes have an automatic power return that is useful but not necessary.

3

SELF-CHECK # 1.1

Measuring Tools in Plumbing Matching Type: Match the definition in Column A with the term Column B. COLUMN A 1. A tool used to measure the outside diameter of a pipe. 2. A tool which is made up of steel having divisions in metric system used for layout.

COLUMN B a. Outside Caliper b. L-Square c. Pull Push Rule d. Try Square e. Inside Caliper

3. A measuring tools used to measure the inside diameters or width of pipe and slots. 4. A tool intended to measure the angle, if necessary. 5. A tool used to measure the length of a pipe.

4

INFORMATION SHEET #2. 1.2 Proper Handling of Measuring Tools

How to Handle Measuring Tool Each measuring tool has its specific way of handling. This must be followed by every student user to maintain its usefulness. Listed below are some of the measuring tools, there are also safety measures to be observed in handling each tool. Measuring Tools Inside Caliper is used to measure the internal size of an object.

Avoid using tip of the inside caliper to open the cover of any can.

Avoid

dropping

it

to

maintain

its

accuracy

in

taking

measurements.

5

Outside Caliper is a tool used to measure the external size of an object

Don‟t hold the outside caliper tightly so that you can adjust it easily. Don‟t take the diameter of a revolving type.

Steel Square is a tool that a carpenter and other tradesman use. It consists of a large arm and a smaller arm which meet at an angle of 90˚.Today the steel square is more commonly referred to as the framing square.

Hold the tool firmly and cautiously. See to it that it won‟t drop. It has a sharp pointed end and dangerous.

6

TRY SQUARE is a wood working or a metal working tool used for marking/measuring a piece of wood. It is primarily used to measure the accuracy of right angle (90˚ degrees) tried on any surface so as to check its straightness or correspondence to an adjoining surface.

Hold the try-square properly to maintain its straight edges which are used to get the desired angle. Don‟t use it for other purposes. Put it in its proper place. PULL PUSH RULE (Tape Measure) is a flexible tape measure available in lengths up to 50 feet. Other tapes that are 12 to 25 feet are usually considered adequate. Most tapes have an automatic power return that is useful but not necessary.

Hold the tip of the pull push rule when removing it from its housing. Put it slowly to avoid cut from the steel tape.

7

SELF – CHECK #2. 1.2 Directions: On a blank sheet. Write T if the statement is true and F if the statement is false. Test I. ______ 1. The steel tape in the housing of pull push rule should be avoided. ______ 2. It is safe to bend a try square. ______ 3. Any user can keep the tools at any place. ______ 4. Holding the outside caliper tightly make difficult adjustments. ______ 5. To get the desired data measuring tools should be handled properly.

8

ANSWER KEY

1. 2. 3. 4. 5.

F F F T T

Learning Outcome # 2: Carry out Mensuration and Calculation Assessment Criteria: 1. Accurate measurements are obtained according to the job description. 2. Calculation needed to complete work/ task is correctly done based on the four (4) fundamental operations. 3. Work pieces are measured according to job the description / requirements.

LEARNING EXPERIENCES/ACTIVITIES Learning Outcome # 2 Carry out Mensuration and Calculation

Learning Activities

Special Instructions

1. Read Information Sheet # 2.1 Unit Conversion Answer the Self- Check # 2.1

9

INFORMATION SHEET # 2.2.1 LINEAR MEASUREMENT (International System) Metric System Basic Measurement LINEAR MEASURE 1 1 1 1 1 1

Centimeter Decimeter Meter Decameter Hectometer Kilometer

= = = = = =

10 Millimeters 10 Centimeters 10 Decimeters 10 Meters 10 Decameter 1000 Meters

= = = = = = =

100 Sq. Millimeters 10,000 Sq. Centimeters 100 Sq. Meters 100 Acres 10,000 Sq. Meter 100 Hectares 1,000,000 Sq. Meters

= = =

1000 Cu. Millimeters 1000 Cu. Centimeters 1000 Cu. Decimeters

SQUARE MEASURE (AREA) 1 1 1 1

Sq. Centimeter Sq. Meter Acre Hectare

1 Sq. Kilometer CUBIC MEASURE (VOLUME) 1 Cubic Centimeter 1 Cubic Decimeters 1 Cubic Meter CAPACITY MEASURE (LIQUID) 1 1 1 1 1 1

Centiliter Deciliter Liter Deciliter Hectoliter Kiloliter

= = = = = = =

10 Milliliters 10 Centiliters 10 Deciliters 10 Liters 10 Decaliters 10 Hectoliters 100 Liters

METRIC CONVERSION IN TERMS OF LINEAR 1 1 1 1 1 1 1 1 1 1 1 1 1

inch mm inch cm foot inch foot yard foot meter yard yard centimeter

= = = = = = = = = = = = =

25.400 millimeters 0.03937 inch 2.54 cm 0.3937 inch 12 inches 0.08333 foot 0.333 yard 3 feet 0.30481 meter 3.2809 feet 36 inches 91.44 centimeters 0.9144 meter

1 meter 1 statute 1 kilometer 1 foot 1 rod 1 mile 1 meter 10 millimeters 10 centimeters 10 decimeters 1000 meters 100 hectometer

= = = = = = = = = = = =

1.0936 yards 5280 feet 3281 feet 12 inches 165 feet 5280 feet 39.37 inches 1 centimeter 1 decimeter 1 meter 1 kilometer = 3,281 ft. 1 kilometer = 3,28.1 ft.

LINEAR CONVERSION TABLE Inches 0.3937 .7874 1.1811 1.5748 1.9685 2.3622 2.7559 3.1496 3.5433

1 2 3 4 5 6 7 8 9

Centimeters 2.5399 5.0799 7.6199 10.1599 12.6999 15.2399 17.7799 20.3199 22.8599

Feet 3.2808 6.5617 9.8425 13.1234 16.4042 19.6850 22.9658 26.2467 29.5275

1 2 3 4 5 6 7 8 9

Centimeters 0.3048 .6069 .9144 1.2192 1.5240 1.8288 2.1336 2.4384 2.7432

Feet 1.0936 2.1872 3.2808 4.3744 5.4681 6.5616 7.6553 8.7489 9.8425

1 2 3 4 5 6 7 8 9

Centimeters 0.9144 1.8288 2.7432 3.6576 4.5720 5.4864 6.4008 7.3152 8.2296

11

METRIC CONVERSION IN TERMS OF SQ. MEASURE 1 sq. in. 1 sq. cm. 1 sq. ft. 1 sq. in. 1 sq. ft. 1 sq. cm. 1 sq. ft. 1 sq. m. 1 sq. yd 1 sq. ft. 1 sq. yd 1 sq. m. 640 acres 30-1/4 sq. yd. 40 sq. pole 1 rod

= = = = = = = = = = = = = = = =

6.4516 sq. cm. 0.15500 sq. ft. 144 sq. ft. 0.0094 sq. ft. 929.03 sq. cm. 0.00180 sq. ft. 0.092903 sq. m. 10.764 sq. ft. 9 sq. ft. 0.1111 sq. yd. 0.83612 sq. m. 1.196 sq. yd. 1 sq. mile 1 sq. pole 1 rod 1 acre

AREA Sq. Inches 0.1550 0.3100 0.4650 0.6200 0.7750 0.9300 1.0850 1.2400 1.3950

1 2 3 4 5 6 7 8 9

Sq. Centimeters 6.4515 12.9030 19.3545 25.8060 32.2575 38.7090 45.1605 51.6120 58.0635

Sq. Feet 10.7638 21.5276 32.2914 43.0552 53.8190 64.5828 75.3466 86.1104 96.8742

1 2 3 4 5 6 7 8 9

Sq. Meters 0.0930 0.1860 0.2790 0.3720 0.4650 0.5580 0.6510 0.7440 0.8370

Sq. Yards 1.1960 2.3920 3.5880 4.7840 5.9800 7.1760 8.3720 9.5680 10.7640

1 2 3 4 5 6 7 8 9

Sq. Meters 0.8361 1.6723 2.5084 3.3445 4.1806 5.0168 5.8529 6.6890 7.5252

12

METRIC CONVERSION IN TERMS OF VOLUME 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

cu. in cu. ft. cu. in. gallon cu. in. cu. cm. cu. in cu. in cu. ft. cu. in cu. ft. gallon cu. ft. cu. m. cu. ft. liter cu. yd cu. ft. pint liter quart pint quart gallon quart cu. in quart cu. ft. quart liter gallon cu. in. gallon liter kiloliter

1

hectoliter

1 1

liter centiliter

1

milliliter

1000 cu. millimeters 1000 cu. centimeters 1000 cu. decimeters 728 cu. inches 27 cu. feet 128 cu. ft. 24-1/4 cu. ft.

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

0.00051787 cu. ft. 1728 cu. inches 0.004329 gallons 231 cu. inches 16.93 cu. m. 0.06102 cu. in. 0.00001639 cu. m. 61023 cu. m. 1728 cu. inches 0.0005787 cu. ft. 7481 gallons 0.1337 cu. ft. 0.0283 cu. m. 35.31 cu. ft. 28.32 liters 0.03531 cu. ft. 27 cu. ft. 0.300873 cu. yd 0.4732 liters 2.11327 pints 2 pints 0.50 quarts 0.25 gallons 4 quarts 57.75 cu. inches 0.17316 quarts 0.03342 cu. ft. 29.9222 quarts 0.9464 liter 1.057 quarts 231 cu. inches 0.004329 gallons 3.78 liters 0.2642 gallon 1,000 liters 1.308 cu. yards or 264.18 gallons 100 liters 2.838 bushels or 26.418 gallons 0.908 quart or 1.057 quarts 0.01 liter 0.0610 cu. inch or .338 ft. ounce 0.001 liter 0.061 cu. inch or .271 ft. dram 1 cu. centimeter 1 cu. decimeter 1 cu. meter 1 cu. foot 1 cu. yard 1 core of wd 1 ph of stone

13

Cubic Inches 0.0610 0.1220 0.1830 0.2440 0.3050 0.3660 0.4270 0.4880 0.5490

1 2 3 4 5 6 7 8 9

Cubic Centimeters 16.3871 32.7742 49.1613 65.5484 81.9355 98.3226 114.7097 131.0968 147.4839

Cubic Feet 35.3145 70.6289 105.9434 141.2578 176.5723 211.8867 247.2042 282.5156 317.8301

1 2 3 4 5 6 7 8 9

Cubic Meters 0.0283 0.0566 0.0850 0.1133 0.1416 0.1699 0.1982 0.2266 0.2550

WEIGHT CONVERSION IN METRIC 1 Kilogram 1 Hectogram 1 Gram 1 Centigram 1 Milligram 1 1 1 1 1 1 1 1 1

Ounce Gram Ounce Kilogram Pound Ounce Pound Gram Pound

OUNCES TO POUNDS 0.03573 0.0705 0.1058 0.1429 0.1787 0.2144 0.2501 0.2858 0.3216

= = = = = = = = = = = = = = = = = =

100 Grams 2.205 Pounds 10 Grams 3.527 Ounces 0.035 Ounce 0.01 Gram .154 Grain (Troy) 0.001 Gram (gr.) 0.015 Grain (Troy) 28.35 Grams 0.03537 Ounce (oz.) 0.2835 Kilogram (kg.) 35.274 Ounces. 16 Ounces 0.0625 Pounds 453.6 Grams 0.002205 Pounds .4536 Joules Gram 1 2 3 4 5 6 7 8 9

28.3495 56.6990 85.0486 113.3980 141.7475 170.0970 198.4465 226.7960 255.1455

14

OUNCES TO POUNDS 2.2046 4.4092 6.6139 8.8185 11.0231 13.2277 15.4323 17.6370 19.8416

1 2 3 4 5 6 7 8 9

0.4536 0.9072 1.3608 1.8144 2.2680 2.7215 3.1751 3.6287 4.0823

TROY (WEIGHT) 24 Grains 12 Ounces 12 Ounces

= = =

1Penny-Weight 1Ounce Weight 1Pound

AVOIRDUPOIS (WEIGHT) 16 Drams 16 Ounces 100 Pounds 112 Pounds 20 Hundred

= = = = =

1 Ounce 1 Pound 1 Short Hundred Weight 1 Long Hundred Weight 1 Ton Weight

APOTHECARIES (WEIGHT) 20 Grains 3 Scruples 8 Drams 12 Ounces

= = = =

1 Scruple 1 Dram 1 Ounce 1 Ton Weight

1 2 3 4 5 6 7 8 9

0.4732 0.9464 1.4196 1.8928 2.3660 2.8392 3.3124 3.7856 4.2588

LIQUID MEASUREMENT Pint to Liters 2.1134 4.2268 6.3402 8.4536 10.5670 12.6804 14.7938 16.9072 19.0206

15

IDENTIFY MEASURING TOOL AND INSTRUMENT IN MEASURING OBJECTS BASIC MEASURING TOOLS Graduations on a Rule Inches

1

2

3

Halves

1

2

3

Quarters

1

2

3

1

2

3

1

2

3

Eights

Sixteenths

16

Thirty-Seconds

Reading Fourths on a Rule

¼” ½” ¾” 1”

1¾

Reading Eights on a Rule 1

/8”

¼” 3

/8”

½” 5

/8”

¾” 7

/8”

1” 1

5

/8”

17

BASIC TYPES OF OBJECTS ON ITS REGULAR GEOMETRIC SHAPE Types of Geometric Figures a. Square

-

Figure having four sides of equal length and four right angles

Example:

b. Rectangle - Figure with two parallel ends of equal length, two parallel sides of equal length, and four right angles. Example:

c. Triangle

-

Figure having three sides and three angles

-

Flat, round figure formed by one curved line, all points of which are equidistant from center point

-

Figure having no right angles and four sides of equal length

Example:

d. Circle

Example:

e. Rhombus

Example:

f.

Parallelogram -Figure such as a square, rectangle or rhombus with two parallel ends of equal length and two parallel sides of equal length. Example:

18

g. Trapezoid

-

Figure with only one pair of parallel opposite sides.

Example:

Units of Measure and their Equivalents: a. Inch (“)

-

Equal to one-twelfth of a foot (1/12) or one thirty-sixth of a yard (1/36 yard)

b. Foot („)

-

Equal to twelve inches (12”) or one-third of a yard (1/3 yard)

c. Yard

-

Equal to three feet (3‟) or thirty-six inches (36”)

d. Rod

-

Equal to sixteen and one-half feet (161/2)

e. Mile

-

Equal to five thousand, two hundred and eighty feet (5280‟)

Sample of Calculation on Conversion of unit A. English to Metric System 1. 3 inches - cm 3 inches x 2.54 = 7. 62cm 1 inch 2. 10 cm – inch 10cm x 1 inch = 3.94inch 2.54 B. Unit in Metric System 1. 79.33 mm x 1 cm x 1 dm = 7.933 dm Mm 10cm C. Unit in English System 1. 13 inch – yard 13 inch x 1 ft

x 1 yard = 0.393 yards

19

12 inch

3 ft

SELF – CHECK # 2.2.1

Metric System 10 millimeter – 1 centimeter 10 centimeter – 1 decimeter 10 decimeter – 1 meter English System 12 inches – 1 foot 3 feet - 1 yard Metric – English 1 1 1 1

millimeter – 0.03993 inches inch – 2.54 centimeter foot – 0.3048 millimeter yard – 0.9144 millimeter Using the given conversion table above solve for the desire units 1. 64 cm - ---------------------- inches 2. 59 yards - --------------------- feet 3. 95.5 dm - --------------------- meter 4. 19 inches - ------------------- centimeter 5. 47 feet - ----------------------- inches

20

Self Check #2.2.1 ANSWER KEY 1. 64 cm x 1 inch = 25.20inch 2.54cm 2. 59 yards x 3 ft = 177ft 1 yard 3. 95.5 dm x

1m = 9.55m 10dm

4. 19 inches x 2.54 cm = 48.26cm 1 inch 5. 47 feet x 12 inches = 5.64 inches 1 ft

22

Learning Outcome # 3: Maintain measuring instruments Assessment Criteria: 3.1. Measuring instruments are not dropped to avoid damage 3.2. Measuring instruments are cleaned before and after using. 3.3. Proper storage of instruments undertaken according to manufacturer’s specifications and standard operating procedures.

Information sheet 2.3-1 Measuring tools, by their very nature, are meant to be perfectly precise and to keep them that way they will have to be cared for and maintained properly. There are a lot of different tools for measuring a lot of different things. But, no matter which ones you have, proper care is required if you want to be able to depend on them for accuracy. Disregard this advice at your own risk! Measuring devices that have been abused and not maintained as they should have been are apt to be off. In fact, they may be way, way off. Imagine ruining a whole job because you couldn't be bothered to give your hard working tools the care they deserve. Some tools used for measuring are, of course, more delicate than others and need more care than something like a measuring tape. There are many types of tools used to measure. Types of Measuring Tools Here are a few of the type of tools available for measuring various things:

Calipers Lasers Micrometers Telescopic Gauges And More

Some of these tools have to be extremely accurate down to fractions of a millimeter, so you can imagine how precise they are and how important it is to keep them that way. Care of Measuring Tools Caring for your measuring implements will mean that they will serve you well, often for a lifetime. Not caring for them means you'll have to replace them far sooner than you would have if you had taken the time to provide the right sort of maintenance. Here are some tips on how to care for your measuring tools:

Always wipe not only the measuring faces of your tools, but of the work piece being measured as well. This will help prevent dust or dirt from marring your tools. Generally speaking, it is best not to use such tools as vernier calipers or micrometers on rough, abrasive surfaces if you can possibly avoid it.

Always keep your tools used for measuring separate from your hand tools to save them being knocked about and damaged. Never lay your tools on something like a lathe, either, because the vibrations could compromise the accuracy of the tool. Always use your tools used for measuring for that alone - measuring. This means don't use your micrometers for little hammers or a vernier caliper as a line marker, for instance. This will certainly damage them. Always keep your tools used for measuring at or around room temperature. Never lay them on a heat source or in direct sunlight as doing so could really mess them up so that their accuracy is affected. Always be wary of laying or using your tools too close to a magnet or magnetized surface. Magnets can wreak havoc with many of these precision tools. Always clean your tools after use. Unless they're made of stainless steel, each tool should have some anti-rust oil dabbed on it and then stored by itself in a dry place.

Measuring tools will provide you with years of dependable service if you care for them properly. Lubrication Method Proper lubrication, as suggested to care for your measuring tools, is important to prevent damage due to corrosion and oxidation. Using a thin film of mineral oil such as WD40, on a soft rag or cloth, wipe the tool over ensuring to cover all the metal parts of the tool. Be sure to wipe away any excess oil. Your measuring tools should be cleaned regularly, ideally once a week. However, your cleaning routine all depends on a couple factors. The environment If you use your tools in a dusty manufacturing environment, for example, you may need to clean them more often than if you work in a relatively controlled lab environment. The task What you are using the tool for will also have an impact on how often you will need to clean it. For example, pressure gage maintenance may involve cleaning it more often if you use it with liquids, as opposed to solid items. Also, if the measurements are so precise that small amounts of dirt or residue could throw them off, you’ll need to clean your instruments more frequently.

Legal Requirements Some industries may require you to clean your tools more often depending on their rules and regulations. For example, food-related businesses must adhere to higher cleanliness standards.

Self Check 2.3-1 Name at least 3 methods in maintaining Measuring equipment

Answer Key 2.3-1

Lubrication Method The environment Legal Requirements The task

REFERENCES Barba, Joshua A. , Plumbing, ConvergeLink Books Corp., Philippines, 2006. Better Homes and Gardens Plumbing, Meredith Books Desmoines , Iowa , 2003 Burghardt , Henry D. et al, Machine Tool Operation, 5th Edition, Mc Graw Hill Book Co., New York , 1963 Fajardo Jr. , Max B , Plumbing Design and Estimate, 5138 Trading Philippines , 1975 Matthias Jr. , AJ and Smith , Esles Sr., How to Design and Install Plumbing , 4th Edition, Navotas Press, Philippines Morgan , Robert E , The Complete Handbook of Plumbing, TAB Books Inc., Phils. , 1962 Oravetz , Jules Revised by Re Miller, Audel Questions and Answers for Plumbers‟ Examination, 3rd Edition Mac Millan Publishing Co., New York. www.google.com www.wikipedia.com

Unit of Competency: PERFORM MENSURATION AND BASIC CALCULATION

Module Title : PERFORMING MENSURATION AND BASIC CALCULATION

HOW TO USE THIS COMPETENCY BASED LEARNING MATERIAL Welcome to the module in one of the competency of Driving NCII QUALIFICATION. This module contains training materials and activities for you to complete. The unit of competency “PERFORM ESTIMATION AND BASIC CALCULATION” contains knowledge, skills and attitude required for TRAINEES. You are required to go through, a series of learning activities in order to complete each learning outcome of the module. In each learning outcome are Information Sheet, Self-Checks, Task Sheets and Job Sheets. The follow these activities on your own. If you have questions, don’t hesitate to ask your facilitator for assistance. The goal of this course is the development of practical skills in supervising work-based training. Tools in planning, monitoring and evaluation of work-based training shall be prepared during the workshop to support in the implementation of the training program. This will be the source of information for you to acquire knowledge and skills in this particular competency independently and at your own pace, with minimum supervision or help from your facilitator. Remember to: Work through all the information and complete the activities in each section. Read information sheets and complete the self-check. Answer keys are included in this package to allow immediate feedback. Answering the selfcheck will help you acquire the knowledge content of this competency. Perform the task sheets and job sheets until you are confident that your output conforms to the performance criteria checklist that follows the sheets. Submit outputs of the task sheets and job sheets to your facilitator for evaluation and recording in the Accomplishment Chart. Outputs shall serve as your portfolio during the institutional competency evaluation. A certificate of achievement will be awarded to you after passing the evaluation. You must pass the institutional competency evaluation for this competency before moving to another competency

LISTS OF COMMON COMPETENCIES No.

Unit of Competency

Module Title

1

Use Hand Tools

Using Hand Tools

2

Perform Mensuration and Calculation

Performing Mensuration and Calculation

3

4

5

Prepare and Interpret Technical Drawing

Preparing and Interpret Technical Drawing

Apply Quality Standards

Applying Quality Standards

Terminate and Connect Electrical Wiring and Electronic Circuits

Terminating and Connecting Electrical Wiring and Electronic Circuits

Code ELC311205 ELC311201

ELC311202

ELC311204

ELC311206

Unit of Competency : PERFORM ESTIMATION AND BASIC CALCULATION

Module Title : PERFORMING ESTIMATION AND BASIC CALCULATIONS Learning Outcome :

PERFORM ESTIMATION PERFORM BASIC WORKPLACE CALCULATIONS

Assessment Criteria:

Job requirements are identified from written or oral communications Quantities of materials and resources required to complete a work task are estimated The time needed to complete a work activity is estimated Accurate estimate for work completion are made Estimate of materials and resources are reported to appropriate person Perform basic workplace calculation Calculations to be made Calculations to be made are identified according to job requirement. Correct method of calculation identified. System and units of measurement to be followed are ascertained. Calculation needed to complete work task are performed using the four basic process of addition, subtraction multiplication and division. Calculate whole fraction, percentage and mixed when are used to complete the instructions. Number computed in self checked and completed for alignment.

Condition : • Mathematics Books • Ruler Steel Tape Measure • Calculators • Relevant tools and equipment for basic calculations • Recommended date References: • Mathematics books Learning Experiences Learning activities Special instructor 1. Move to the library and study, 2. If there is misunderstanding on practice solving problems using the topic, consult your T.I. for the different systems, processes further explanation. and operations.

i

Unit of Competency

PERFORM MENSURATION AND CALCULATION Module Title

PERFORMING MENSURATION AND CALCULATION

INTRODUCTION: This module contains information and suggested learning activities on Plumbing NC-I1 particularly on the competency “Maintain Tools and Equipment”. It includes instructions and procedure on how to maintain tools and equipment. It explains how to repair and replace tools and equipment. It also explains the proper use of inventory forms. SUMMARY OF LEARNING OUTCOMES: Upon completion of the module, you must be able to: LO1. select Measuring Instrument; and LO2. carry out Mensuration and Calculation. LOZA3. Maintain measuring instruments ASSESSMENT CRITERIA: LO 1. Select Measuring Instrument 1. Measuring tools are selected / identified as per job requirement. 2. Correct specifications are obtained from relevant sources. LO 2. Carry out Mensuration and Calculation 1. Accurate measurements are obtained according to job description. 2. Calculation needed to complete work/ task is correctly done based on the four (4) fundamental operations. 3. Work pieces are measured according to job description / requirements.

TECHNICAL TERMS 1. Accuracy means correctness, exactness, precision. 2. Area is any of space especially of ground or surface that is distinguishable from its surrounding in appearance or in certain distinctive features 3. Clearance is the space, allowance or gap between working part of an object. 4. English System is the old way of measurement that replaced the metric system. 5. Height may be used with reference whether high or low by a standard of companion. 6. Instrument is a device that measures or controls something. 7. Length refers to how long an object is 8. Measurement refers to the size, length, quantity or rate of something that has been measured. 9. Mensurations the calculation of geometric quantities such as length, area and volume from dimensions and angles that are already known. 10.

Metric System is the System of measurement which uses 10 as

its multiple in all its conversion is it in distance, volume, weight etc. 11.

PPE is an acronym that stands for Personal Protective Equipment

12.

Pressure is the force acting on a surface divided by the area

over which it acts. 13.

Volume refers to the magnitude size intent, dimension, areas, and

bulk, mass the total amount of something. 14.

Weight refers to the total quality of heaviness and things

determined by their mass or control acts efforts to lift or move them.

Learning Outcome # 1: Select Measuring Instrument Assessment Criteria: 1. Measuring tools are selected and identified as per job requirement. 2. Correct specifications are obtained from relevant sources.

INFORMATION SHEET # 2.1.1 Measuring Tools Measuring Tools Inside Caliper is used to measure the internal size of an object.

Outside Caliper is used to measure the external size of an object

Steel Square is a tool that carpenters and other tradesman use consisting of a large arm and a smaller arm which meet at an angle 90˚.Today the steel square is more commonly referred to as the framing square.

2

TRY SQUARE is a wood working or a metal working tool used for marking/measuring a piece of wood. It is primarily used to measure the accuracy of right angle (90˚ degrees) tried on any surface so as to check its straightness or correspondence to an adjoining surface.

PULL PUSH (Tape Measure) is a flexible tape measure which is available in lengths up to 50 feet. Other tapes that are 12 to 25 feet are usually considered adequate. Most tapes have an automatic power return that is useful but not necessary.

3

SELF-CHECK # 1.1

Measuring Tools in Plumbing Matching Type: Match the definition in Column A with the term Column B. COLUMN A 1. A tool used to measure the outside diameter of a pipe. 2. A tool which is made up of steel having divisions in metric system used for layout.

COLUMN B a. Outside Caliper b. L-Square c. Pull Push Rule d. Try Square e. Inside Caliper

3. A measuring tools used to measure the inside diameters or width of pipe and slots. 4. A tool intended to measure the angle, if necessary. 5. A tool used to measure the length of a pipe.

4

INFORMATION SHEET #2. 1.2 Proper Handling of Measuring Tools

How to Handle Measuring Tool Each measuring tool has its specific way of handling. This must be followed by every student user to maintain its usefulness. Listed below are some of the measuring tools, there are also safety measures to be observed in handling each tool. Measuring Tools Inside Caliper is used to measure the internal size of an object.

Avoid using tip of the inside caliper to open the cover of any can.

Avoid

dropping

it

to

maintain

its

accuracy

in

taking

measurements.

5

Outside Caliper is a tool used to measure the external size of an object

Don‟t hold the outside caliper tightly so that you can adjust it easily. Don‟t take the diameter of a revolving type.

Steel Square is a tool that a carpenter and other tradesman use. It consists of a large arm and a smaller arm which meet at an angle of 90˚.Today the steel square is more commonly referred to as the framing square.

Hold the tool firmly and cautiously. See to it that it won‟t drop. It has a sharp pointed end and dangerous.

6

TRY SQUARE is a wood working or a metal working tool used for marking/measuring a piece of wood. It is primarily used to measure the accuracy of right angle (90˚ degrees) tried on any surface so as to check its straightness or correspondence to an adjoining surface.

Hold the try-square properly to maintain its straight edges which are used to get the desired angle. Don‟t use it for other purposes. Put it in its proper place. PULL PUSH RULE (Tape Measure) is a flexible tape measure available in lengths up to 50 feet. Other tapes that are 12 to 25 feet are usually considered adequate. Most tapes have an automatic power return that is useful but not necessary.

Hold the tip of the pull push rule when removing it from its housing. Put it slowly to avoid cut from the steel tape.

7

SELF – CHECK #2. 1.2 Directions: On a blank sheet. Write T if the statement is true and F if the statement is false. Test I. ______ 1. The steel tape in the housing of pull push rule should be avoided. ______ 2. It is safe to bend a try square. ______ 3. Any user can keep the tools at any place. ______ 4. Holding the outside caliper tightly make difficult adjustments. ______ 5. To get the desired data measuring tools should be handled properly.

8

ANSWER KEY

1. 2. 3. 4. 5.

F F F T T

Learning Outcome # 2: Carry out Mensuration and Calculation Assessment Criteria: 1. Accurate measurements are obtained according to the job description. 2. Calculation needed to complete work/ task is correctly done based on the four (4) fundamental operations. 3. Work pieces are measured according to job the description / requirements.

LEARNING EXPERIENCES/ACTIVITIES Learning Outcome # 2 Carry out Mensuration and Calculation

Learning Activities

Special Instructions

1. Read Information Sheet # 2.1 Unit Conversion Answer the Self- Check # 2.1

9

INFORMATION SHEET # 2.2.1 LINEAR MEASUREMENT (International System) Metric System Basic Measurement LINEAR MEASURE 1 1 1 1 1 1

Centimeter Decimeter Meter Decameter Hectometer Kilometer

= = = = = =

10 Millimeters 10 Centimeters 10 Decimeters 10 Meters 10 Decameter 1000 Meters

= = = = = = =

100 Sq. Millimeters 10,000 Sq. Centimeters 100 Sq. Meters 100 Acres 10,000 Sq. Meter 100 Hectares 1,000,000 Sq. Meters

= = =

1000 Cu. Millimeters 1000 Cu. Centimeters 1000 Cu. Decimeters

SQUARE MEASURE (AREA) 1 1 1 1

Sq. Centimeter Sq. Meter Acre Hectare

1 Sq. Kilometer CUBIC MEASURE (VOLUME) 1 Cubic Centimeter 1 Cubic Decimeters 1 Cubic Meter CAPACITY MEASURE (LIQUID) 1 1 1 1 1 1

Centiliter Deciliter Liter Deciliter Hectoliter Kiloliter

= = = = = = =

10 Milliliters 10 Centiliters 10 Deciliters 10 Liters 10 Decaliters 10 Hectoliters 100 Liters

METRIC CONVERSION IN TERMS OF LINEAR 1 1 1 1 1 1 1 1 1 1 1 1 1

inch mm inch cm foot inch foot yard foot meter yard yard centimeter

= = = = = = = = = = = = =

25.400 millimeters 0.03937 inch 2.54 cm 0.3937 inch 12 inches 0.08333 foot 0.333 yard 3 feet 0.30481 meter 3.2809 feet 36 inches 91.44 centimeters 0.9144 meter

1 meter 1 statute 1 kilometer 1 foot 1 rod 1 mile 1 meter 10 millimeters 10 centimeters 10 decimeters 1000 meters 100 hectometer

= = = = = = = = = = = =

1.0936 yards 5280 feet 3281 feet 12 inches 165 feet 5280 feet 39.37 inches 1 centimeter 1 decimeter 1 meter 1 kilometer = 3,281 ft. 1 kilometer = 3,28.1 ft.

LINEAR CONVERSION TABLE Inches 0.3937 .7874 1.1811 1.5748 1.9685 2.3622 2.7559 3.1496 3.5433

1 2 3 4 5 6 7 8 9

Centimeters 2.5399 5.0799 7.6199 10.1599 12.6999 15.2399 17.7799 20.3199 22.8599

Feet 3.2808 6.5617 9.8425 13.1234 16.4042 19.6850 22.9658 26.2467 29.5275

1 2 3 4 5 6 7 8 9

Centimeters 0.3048 .6069 .9144 1.2192 1.5240 1.8288 2.1336 2.4384 2.7432

Feet 1.0936 2.1872 3.2808 4.3744 5.4681 6.5616 7.6553 8.7489 9.8425

1 2 3 4 5 6 7 8 9

Centimeters 0.9144 1.8288 2.7432 3.6576 4.5720 5.4864 6.4008 7.3152 8.2296

11

METRIC CONVERSION IN TERMS OF SQ. MEASURE 1 sq. in. 1 sq. cm. 1 sq. ft. 1 sq. in. 1 sq. ft. 1 sq. cm. 1 sq. ft. 1 sq. m. 1 sq. yd 1 sq. ft. 1 sq. yd 1 sq. m. 640 acres 30-1/4 sq. yd. 40 sq. pole 1 rod

= = = = = = = = = = = = = = = =

6.4516 sq. cm. 0.15500 sq. ft. 144 sq. ft. 0.0094 sq. ft. 929.03 sq. cm. 0.00180 sq. ft. 0.092903 sq. m. 10.764 sq. ft. 9 sq. ft. 0.1111 sq. yd. 0.83612 sq. m. 1.196 sq. yd. 1 sq. mile 1 sq. pole 1 rod 1 acre

AREA Sq. Inches 0.1550 0.3100 0.4650 0.6200 0.7750 0.9300 1.0850 1.2400 1.3950

1 2 3 4 5 6 7 8 9

Sq. Centimeters 6.4515 12.9030 19.3545 25.8060 32.2575 38.7090 45.1605 51.6120 58.0635

Sq. Feet 10.7638 21.5276 32.2914 43.0552 53.8190 64.5828 75.3466 86.1104 96.8742

1 2 3 4 5 6 7 8 9

Sq. Meters 0.0930 0.1860 0.2790 0.3720 0.4650 0.5580 0.6510 0.7440 0.8370

Sq. Yards 1.1960 2.3920 3.5880 4.7840 5.9800 7.1760 8.3720 9.5680 10.7640

1 2 3 4 5 6 7 8 9

Sq. Meters 0.8361 1.6723 2.5084 3.3445 4.1806 5.0168 5.8529 6.6890 7.5252

12

METRIC CONVERSION IN TERMS OF VOLUME 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

cu. in cu. ft. cu. in. gallon cu. in. cu. cm. cu. in cu. in cu. ft. cu. in cu. ft. gallon cu. ft. cu. m. cu. ft. liter cu. yd cu. ft. pint liter quart pint quart gallon quart cu. in quart cu. ft. quart liter gallon cu. in. gallon liter kiloliter

1

hectoliter

1 1

liter centiliter

1

milliliter

1000 cu. millimeters 1000 cu. centimeters 1000 cu. decimeters 728 cu. inches 27 cu. feet 128 cu. ft. 24-1/4 cu. ft.

= = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = =

0.00051787 cu. ft. 1728 cu. inches 0.004329 gallons 231 cu. inches 16.93 cu. m. 0.06102 cu. in. 0.00001639 cu. m. 61023 cu. m. 1728 cu. inches 0.0005787 cu. ft. 7481 gallons 0.1337 cu. ft. 0.0283 cu. m. 35.31 cu. ft. 28.32 liters 0.03531 cu. ft. 27 cu. ft. 0.300873 cu. yd 0.4732 liters 2.11327 pints 2 pints 0.50 quarts 0.25 gallons 4 quarts 57.75 cu. inches 0.17316 quarts 0.03342 cu. ft. 29.9222 quarts 0.9464 liter 1.057 quarts 231 cu. inches 0.004329 gallons 3.78 liters 0.2642 gallon 1,000 liters 1.308 cu. yards or 264.18 gallons 100 liters 2.838 bushels or 26.418 gallons 0.908 quart or 1.057 quarts 0.01 liter 0.0610 cu. inch or .338 ft. ounce 0.001 liter 0.061 cu. inch or .271 ft. dram 1 cu. centimeter 1 cu. decimeter 1 cu. meter 1 cu. foot 1 cu. yard 1 core of wd 1 ph of stone

13

Cubic Inches 0.0610 0.1220 0.1830 0.2440 0.3050 0.3660 0.4270 0.4880 0.5490

1 2 3 4 5 6 7 8 9

Cubic Centimeters 16.3871 32.7742 49.1613 65.5484 81.9355 98.3226 114.7097 131.0968 147.4839

Cubic Feet 35.3145 70.6289 105.9434 141.2578 176.5723 211.8867 247.2042 282.5156 317.8301

1 2 3 4 5 6 7 8 9

Cubic Meters 0.0283 0.0566 0.0850 0.1133 0.1416 0.1699 0.1982 0.2266 0.2550

WEIGHT CONVERSION IN METRIC 1 Kilogram 1 Hectogram 1 Gram 1 Centigram 1 Milligram 1 1 1 1 1 1 1 1 1

Ounce Gram Ounce Kilogram Pound Ounce Pound Gram Pound

OUNCES TO POUNDS 0.03573 0.0705 0.1058 0.1429 0.1787 0.2144 0.2501 0.2858 0.3216

= = = = = = = = = = = = = = = = = =

100 Grams 2.205 Pounds 10 Grams 3.527 Ounces 0.035 Ounce 0.01 Gram .154 Grain (Troy) 0.001 Gram (gr.) 0.015 Grain (Troy) 28.35 Grams 0.03537 Ounce (oz.) 0.2835 Kilogram (kg.) 35.274 Ounces. 16 Ounces 0.0625 Pounds 453.6 Grams 0.002205 Pounds .4536 Joules Gram 1 2 3 4 5 6 7 8 9

28.3495 56.6990 85.0486 113.3980 141.7475 170.0970 198.4465 226.7960 255.1455

14

OUNCES TO POUNDS 2.2046 4.4092 6.6139 8.8185 11.0231 13.2277 15.4323 17.6370 19.8416

1 2 3 4 5 6 7 8 9

0.4536 0.9072 1.3608 1.8144 2.2680 2.7215 3.1751 3.6287 4.0823

TROY (WEIGHT) 24 Grains 12 Ounces 12 Ounces

= = =

1Penny-Weight 1Ounce Weight 1Pound

AVOIRDUPOIS (WEIGHT) 16 Drams 16 Ounces 100 Pounds 112 Pounds 20 Hundred

= = = = =

1 Ounce 1 Pound 1 Short Hundred Weight 1 Long Hundred Weight 1 Ton Weight

APOTHECARIES (WEIGHT) 20 Grains 3 Scruples 8 Drams 12 Ounces

= = = =

1 Scruple 1 Dram 1 Ounce 1 Ton Weight

1 2 3 4 5 6 7 8 9

0.4732 0.9464 1.4196 1.8928 2.3660 2.8392 3.3124 3.7856 4.2588

LIQUID MEASUREMENT Pint to Liters 2.1134 4.2268 6.3402 8.4536 10.5670 12.6804 14.7938 16.9072 19.0206

15

IDENTIFY MEASURING TOOL AND INSTRUMENT IN MEASURING OBJECTS BASIC MEASURING TOOLS Graduations on a Rule Inches

1

2

3

Halves

1

2

3

Quarters

1

2

3

1

2

3

1

2

3

Eights

Sixteenths

16

Thirty-Seconds

Reading Fourths on a Rule

¼” ½” ¾” 1”

1¾

Reading Eights on a Rule 1

/8”

¼” 3

/8”

½” 5

/8”

¾” 7

/8”

1” 1

5

/8”

17

BASIC TYPES OF OBJECTS ON ITS REGULAR GEOMETRIC SHAPE Types of Geometric Figures a. Square

-

Figure having four sides of equal length and four right angles

Example:

b. Rectangle - Figure with two parallel ends of equal length, two parallel sides of equal length, and four right angles. Example:

c. Triangle

-

Figure having three sides and three angles

-

Flat, round figure formed by one curved line, all points of which are equidistant from center point

-

Figure having no right angles and four sides of equal length

Example:

d. Circle

Example:

e. Rhombus

Example:

f.

Parallelogram -Figure such as a square, rectangle or rhombus with two parallel ends of equal length and two parallel sides of equal length. Example:

18

g. Trapezoid

-

Figure with only one pair of parallel opposite sides.

Example:

Units of Measure and their Equivalents: a. Inch (“)

-

Equal to one-twelfth of a foot (1/12) or one thirty-sixth of a yard (1/36 yard)

b. Foot („)

-

Equal to twelve inches (12”) or one-third of a yard (1/3 yard)

c. Yard

-

Equal to three feet (3‟) or thirty-six inches (36”)

d. Rod

-

Equal to sixteen and one-half feet (161/2)

e. Mile

-

Equal to five thousand, two hundred and eighty feet (5280‟)

Sample of Calculation on Conversion of unit A. English to Metric System 1. 3 inches - cm 3 inches x 2.54 = 7. 62cm 1 inch 2. 10 cm – inch 10cm x 1 inch = 3.94inch 2.54 B. Unit in Metric System 1. 79.33 mm x 1 cm x 1 dm = 7.933 dm Mm 10cm C. Unit in English System 1. 13 inch – yard 13 inch x 1 ft

x 1 yard = 0.393 yards

19

12 inch

3 ft

SELF – CHECK # 2.2.1

Metric System 10 millimeter – 1 centimeter 10 centimeter – 1 decimeter 10 decimeter – 1 meter English System 12 inches – 1 foot 3 feet - 1 yard Metric – English 1 1 1 1

millimeter – 0.03993 inches inch – 2.54 centimeter foot – 0.3048 millimeter yard – 0.9144 millimeter Using the given conversion table above solve for the desire units 1. 64 cm - ---------------------- inches 2. 59 yards - --------------------- feet 3. 95.5 dm - --------------------- meter 4. 19 inches - ------------------- centimeter 5. 47 feet - ----------------------- inches

20

Self Check #2.2.1 ANSWER KEY 1. 64 cm x 1 inch = 25.20inch 2.54cm 2. 59 yards x 3 ft = 177ft 1 yard 3. 95.5 dm x

1m = 9.55m 10dm

4. 19 inches x 2.54 cm = 48.26cm 1 inch 5. 47 feet x 12 inches = 5.64 inches 1 ft

22

Learning Outcome # 3: Maintain measuring instruments Assessment Criteria: 3.1. Measuring instruments are not dropped to avoid damage 3.2. Measuring instruments are cleaned before and after using. 3.3. Proper storage of instruments undertaken according to manufacturer’s specifications and standard operating procedures.

Information sheet 2.3-1 Measuring tools, by their very nature, are meant to be perfectly precise and to keep them that way they will have to be cared for and maintained properly. There are a lot of different tools for measuring a lot of different things. But, no matter which ones you have, proper care is required if you want to be able to depend on them for accuracy. Disregard this advice at your own risk! Measuring devices that have been abused and not maintained as they should have been are apt to be off. In fact, they may be way, way off. Imagine ruining a whole job because you couldn't be bothered to give your hard working tools the care they deserve. Some tools used for measuring are, of course, more delicate than others and need more care than something like a measuring tape. There are many types of tools used to measure. Types of Measuring Tools Here are a few of the type of tools available for measuring various things:

Calipers Lasers Micrometers Telescopic Gauges And More

Some of these tools have to be extremely accurate down to fractions of a millimeter, so you can imagine how precise they are and how important it is to keep them that way. Care of Measuring Tools Caring for your measuring implements will mean that they will serve you well, often for a lifetime. Not caring for them means you'll have to replace them far sooner than you would have if you had taken the time to provide the right sort of maintenance. Here are some tips on how to care for your measuring tools:

Always wipe not only the measuring faces of your tools, but of the work piece being measured as well. This will help prevent dust or dirt from marring your tools. Generally speaking, it is best not to use such tools as vernier calipers or micrometers on rough, abrasive surfaces if you can possibly avoid it.

Always keep your tools used for measuring separate from your hand tools to save them being knocked about and damaged. Never lay your tools on something like a lathe, either, because the vibrations could compromise the accuracy of the tool. Always use your tools used for measuring for that alone - measuring. This means don't use your micrometers for little hammers or a vernier caliper as a line marker, for instance. This will certainly damage them. Always keep your tools used for measuring at or around room temperature. Never lay them on a heat source or in direct sunlight as doing so could really mess them up so that their accuracy is affected. Always be wary of laying or using your tools too close to a magnet or magnetized surface. Magnets can wreak havoc with many of these precision tools. Always clean your tools after use. Unless they're made of stainless steel, each tool should have some anti-rust oil dabbed on it and then stored by itself in a dry place.

Measuring tools will provide you with years of dependable service if you care for them properly. Lubrication Method Proper lubrication, as suggested to care for your measuring tools, is important to prevent damage due to corrosion and oxidation. Using a thin film of mineral oil such as WD40, on a soft rag or cloth, wipe the tool over ensuring to cover all the metal parts of the tool. Be sure to wipe away any excess oil. Your measuring tools should be cleaned regularly, ideally once a week. However, your cleaning routine all depends on a couple factors. The environment If you use your tools in a dusty manufacturing environment, for example, you may need to clean them more often than if you work in a relatively controlled lab environment. The task What you are using the tool for will also have an impact on how often you will need to clean it. For example, pressure gage maintenance may involve cleaning it more often if you use it with liquids, as opposed to solid items. Also, if the measurements are so precise that small amounts of dirt or residue could throw them off, you’ll need to clean your instruments more frequently.

Legal Requirements Some industries may require you to clean your tools more often depending on their rules and regulations. For example, food-related businesses must adhere to higher cleanliness standards.

Self Check 2.3-1 Name at least 3 methods in maintaining Measuring equipment

Answer Key 2.3-1

Lubrication Method The environment Legal Requirements The task

REFERENCES Barba, Joshua A. , Plumbing, ConvergeLink Books Corp., Philippines, 2006. Better Homes and Gardens Plumbing, Meredith Books Desmoines , Iowa , 2003 Burghardt , Henry D. et al, Machine Tool Operation, 5th Edition, Mc Graw Hill Book Co., New York , 1963 Fajardo Jr. , Max B , Plumbing Design and Estimate, 5138 Trading Philippines , 1975 Matthias Jr. , AJ and Smith , Esles Sr., How to Design and Install Plumbing , 4th Edition, Navotas Press, Philippines Morgan , Robert E , The Complete Handbook of Plumbing, TAB Books Inc., Phils. , 1962 Oravetz , Jules Revised by Re Miller, Audel Questions and Answers for Plumbers‟ Examination, 3rd Edition Mac Millan Publishing Co., New York. www.google.com www.wikipedia.com

Related Documents

Mensuration And Calculation

February 2021 1

3 Perform Mensuration And Calculation

February 2021 0

Mensuration Calculation: And In Baking

February 2021 1

Pump And Hydraulic Calculation

February 2021 1

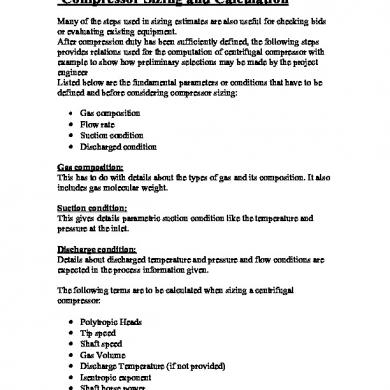

Compressor Sizing And Calculation

March 2021 0

Calculation

March 2021 0More Documents from "Salman Faisal"

Mensuration And Calculation

February 2021 1