Painting_systems_eng.pdf

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Painting_systems_eng.pdf as PDF for free.

More details

- Words: 2,330

- Pages: 15

Loading documents preview...

PAINTING SYSTEMS GLISS-COAT ®

Wet Paint

Powder Coating

CED

Optimum anti-friction properties

Use with low and high temperatures

Variety of colours

Suitable for cavities

Maintenance-free long-term lubrication

All sizes of components

Coatings up to 200 µm

Short turnaround time

PLATING plating

PAINTING SYSTEMS GLISS-COAT ®

What is GLISS-COAT ®? The GLISS-COAT ® brand denotes the range of dry lubricant coatings developed by AHC and designed to reduce friction and surface wear. The coating materials are watersoluble. Various methods of application are possible. The type of

application method depends upon the geometry and quantity of parts to be coated, the type of liquid coating material used, e.g. single or multiple component system, and the requirements of the final coating.

How are GLISS-COAT ® layers built-up? The coating systems are waterbased and are completely free of heavy metals. The flow behaviour is modified to avoid any undesirable edge build-up or any drop formation at edges or in bores. Individual parts are coated using automatic flat spray units while smaller series-produced parts, for instance, are treated in special barrel-plating devices.

Most GLISS-COAT ® layers must be dried after application of the coating to achieve the required properties with regard to adhesion, hardness, corrosion protection and lubrication. During the drying process temperatures below 100 °C are generally employed. The coated parts are spread out during drying in order to ensure uniform curing.

(All technical values published in this brochure are subject to the test conditions specified. We therefore emphasise that the applications and operating conditions, along with the end

user’s practical experience, will ultimately determine the level of performance achieved by the coating and/or coating system)

PLATING www.ahc-surface.com

2

PAINTING SYSTEMS GLISS-COAT ®

Flat spray unit with view of the coating chamber Centrifuge coating

Advantages of GLISS-COAT ® compared to lubricating grease and oil products helps repel dust and dirt forms a homogeneous lubricating surface tight anchorage with the substrate ecological advantages, since there is no removal of the medium

permanent protection against corrosion partial coating possible provides permanent lifetime lubrication in many cases minimise noise (e.g. squeaking and grinding noises) dry lubricant

Suitable materials for treatment with GLISS-COAT ® Depending on the processing variant all metals, light metals as well as plastics destined for industrial use can be treated. Among others, the following

substrates have been successfully treated for special applications: paper, non-woven fabrics, plastic foils, metal foils as well as ceramics.

plating 3

www.ahc-surface.com

PAINTING SYSTEMS GLISS-COAT ®

General coating characteristics optimum anti-friction properties long service life minimise noise maintenance-free long-term lubrication excellent adhesion when applied to metals and plastics

helps repel dust and dirt high level of chemical resistance good corrosion resistance homogeneous surface quality big cost savings

Colour Most GLISS-COAT ® layers are matt dark grey in colour, as plated. Under compressive stress they take on a shiny appearance and their

coefficient of friction decreases. Alternative colours are available at customer’s special request.

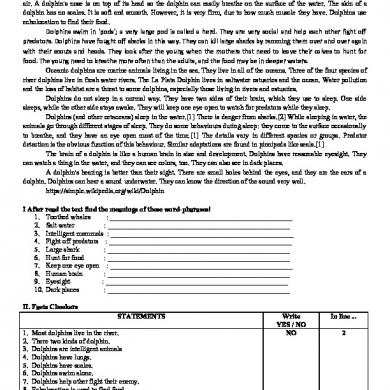

Frictional behaviour Disc Polyamide PA 66 30 % glas-fibre, non-coated Polyamide PA 66 30 % glas-fibre, 30 µm GLISS-COAT ® 200-W-60P Polyethyleneterephthalate (PET), non-coated Polyethyleneterephthalate (PET), 30 % GLISS-COAT ® 200-W-60P

Service life µ < 0,3 [number of revolutions]

Wear [10-15m2/N]

3,100

3.3

3,164.000

1.7

300

47.0

> 9,556,000

0.7

Slide test with pin-disc-tribometer FN = 5 N; v = 6 m/min.; T = 24 °C; rel. humidity: 50 %, pin (ball): Ø 6 mm, 100 Cr 6

PLATING www.ahc-surface.com

4

PAINTING SYSTEMS GLISS-COAT ®

Frictional behaviour The service life and the coefficient of friction of a GLISS-COAT ® hard film depends on the type of coating and on the hardness characteristics of the material to which it is applied. Ideal friction characteristics are fulfilled when the coating is applied to two hard metal surfaces which move against each other with a uniformly applied medium pressure and at a comparatively high speed.

Optimum friction behaviour, especially for aluminium, magnesium and titanium alloys, can be achieved by the application of the GLISS-COAT ® process variant 2000 and the use of anodic intermediate layers (HART-COAT ®, anodising, KEPLA-COAT ®, MAGOXID-COAT ®).

Piston valves and transmission guides with GLISS-COAT ® 200-W-60P

Pressure springs for automotive shock absorbers, treated with GLISS-COAT ® 200-W-60P Cover picture: Latches for motor vehicle locks coated with GLISS-COAT ® 200-W

Service life µ < 0,3 [number of revolutions]

Disc

Wear [10-15m2/N]

AlMgSi1, 30 µm GLISS-COAT ® 200-W-60P

1,305,000

5.6

AlMgSi1, 40 µm GLISS-COAT ® 2010-W-033

3,605,090

2.7

Steel 1.4571, 30 µm GLISS-COAT ® 200-W-60P

1,058,900

11.3

Slide test with pin-disc-tribometer FN = 5 N; v = 6 m/min.; T = 24 °C; rel. humidity: 50 %, pin (ball): Ø 6 mm, 100 Cr 6

plating 5

www.ahc-surface.com

PAINTING SYSTEMS GLISS-COAT ®

Applications vehicle door locks seat bolting devices slide bearings, bushes toothed wheels bolts, screws, nuts guide mechanisms, rollers spindles, shafts valves, stopcocks roller bearings

coil compression springs for damping systems movable vehicle interior components, e.g. hinge pins, bearing bolts, seat adjustment components, guide plates bearings fitted to drive systems, turbines and rotors insert/outsert injection moulding technology

Basic coating 200-W

water-based (solvent-free) coating system that can be applied to all substrates destined for industrial use

Typical layer thickness: for example 30 ± 10 µm on flat parts Typical drying temperature: 80 °C to 100 °C Temperature resistance: up to 200 °C

Layer characteristics: anti-friction properties helps prevent squeaking and grinding noises pressure resistant suitable for consumer goods, food compatible good chemical resistance high alkali resistance free of heavy metals according to the EU End-of-Life Vehicle Directive a layer thickness of approx. 35 µm on steel with corresponding pre-treatment withstands up to 250 hours of testing according to DIN EN ISO 9227 (neutral salt spray test)

PLATING www.ahc-surface.com

6

PAINTING SYSTEMS GLISS-COAT ®

Shafts and springs made of steel as well as plastic locking pins for seat area of passenger cars. Each part is coated with GLISS-COAT ®.

Actuating drives with GLISS-COAT ®-treated covers

Small parts, treated with GLISS-COAT ®

For functional applications 200-W-60P 200-W-100P 200-W-PG

These coatings have various compositions which contain significant increase of antifriction properties improved running-in behaviour

200-W-KP

lubricating additions.

very ductile well suited for the coating of plastics

with corrosion protecting additions

improved corrosion protection compared to basic coating system good anti-friction properties

plating 7

www.ahc-surface.com

PAINTING SYSTEMS GLISS-COAT ®

Optical variant with additional colour pigment 200-W-S03

black-dyed surface with antifriction properties

Cup holder for vehicles, treated with GLISS-COAT ® 200-W-S03

Anti-friction coating C03

water-based (solvent-free) coating system suitable for dip-spin and spray application

Layer thicknesses: depending on process variant Typical drying temperature: max. 100 °C

Layer characteristics: anti-friction properties helps prevent squeaking and grinding noises pressure resistant free of heavy metals according to the EU End-of-Life Vehicle Directive formation of a shiny lubricant film, if subject to pressure resistant to soiling

Temperature resistance: for use at up to 200 °C

PLATING www.ahc-surface.com

8

PAINTING SYSTEMS GLISS-COAT ®

Multi-functional combination coatings from one source 2000

Multi-functional combination coatings, consist of a first layer and a second, so-called top layer. With this process, the top layer is a decorative and / or functional paint coat.

GLISS-COAT ® 2000 is the generic term for multi-functional combination coatings and does not exclusively signify dry-lubricant coating systems.

2001-W-033

Example of multi-functional combination coatings, dependent on kind of base material and requirements of coating system:

Hard anodic base coat plus antifriction coating on aluminium alloys low coefficient of friction with maximum service life high wear and corrosion resistance excellent adherence to base material high electrical insulation properties pressure resistant suitable for consumer goods, food compatible

Z-table for scan microscopy, coated with KEPLA-COAT ® plus TOP-COAT black

Typical nominal layer thicknesses: 40 - 80 µm Drying temperature: from 20 °C to 150 °C Multi-functional combination coatings for knife handles combine decorative requirements with a high corrosion protection

Temperature resistance: up to 200 °C

Development products Our own development department formulates and modifies further variants. It is possible to respond to customer’s specific requirements if they cannot be met by existing process variants.

Examples: high-temperature resistant layers decorative anti-friction properties with corrosion protection

plating 9

www.ahc-surface.com

PAINTING SYSTEMS WET PAINT/KTL

What is wet paint? Wet paint is a spray paint process during which hydro paint systems or solvent-based paint systems are

applied. The process offers optimum flexibility with regard to paint application.

With wet painting, surfaces are produced that are decoratively appealing regarding structure and colour on almost every base material. A wet paint layer may also have functional properties.

In combination with a primer, for example, it is possible to achieve high corrosion protection. It is also possible to treat very small batches which offers high flexibility.

Plastic component

Metallic component

Pre-treatment

Pre-treatment

Advantages of wet paint

Wet paint process flow Example – process flow charts for plastic and metallic components

1. degreasing

alkaline

1. degreasing

alkaline

2. degreasing

alkaline

2. degreasing

alkaline

3. rinse

neutral

3. rinse

neutral

4. primer / fluorination /

4. activation (where required)

flame treatment

5. zinc-manganesephosphatizing

drying

as required

wet painting

tri-cation

6. rinse

neutral

7. passivation

organic

8. rinse

deionised water

9. rinse

purest deionised water

drying

about 50 –150 °C

wet painting all colours / effects

drying in ofen

all colours / effects drying in ofen

about 50 - 150 °C

as required

PLATING www.ahc-surface.com

10

PAINTING SYSTEMS WET PAINT/KTL

Wet paint – fields of use Wet paint processes can be used to paint the most diverse plastic materials, e.g., ABS / PC, PP, PPO or PA6, as well as metallatic materials. If required, a corresponding pretreatment (primer / fluorination) can be applied.

Applications the automotive sector (accessories for the interior) decorative surface appearance haptically appealing surface (soft-touch effect) temperature-sensitive components

Titelmotiv: Nasslackierung mittels Roboter mit Power-Wash-Vorbehandlung

Special wet paint applications Automotive industry – Panel Base material: ABS Process: hydro soft paint Layer thickness: 40 - 50 µm Requirements / applications: decoration haptics Panel

Automotive industry – Air vent Base material: ABS Process : soft paint Layer thickness: 30 - 40 µm Requirements / applications: decoration haptics

plating

Air vents

11

www.ahc-surface.com

PAINTING SYSTEMS POWDER COATING

What is powder coating? Powder coating is an electro-static coating process during which electrically charged paint particles are applied, by means of a spray gun, to the surface of a metallic workpiece that is grounded.

The impinging particles generate an opposite electric charge which affects the adhesion of the paint particles to the surface.

Advantages of powder coating Powder coatings with layer thicknesses between 40 µm and 140 µm are available in many different colours. The coatings offer an extremely high corrosion protection, chemical resistance, UV-resistance and stone impact resistance.

Commercial vehicle steps on a process rack

Powder coating process flow The following scheme shows a typical process sequence

Metallic component Pre-treatment 1. degreasing

alkaline

2. degreasing

alkaline

3. rinse

neutral

4. zinc-manganese-phosphatizing

tri-cation

5. rinse

neutral

6. passivation

organic

7. rinse

deionised water

8. rinse

purest deionised water

drying powder coating baking process

about 150 °C all colours 160 - 220 °C

PLATING www.ahc-surface.com

12

PAINTING SYSTEMS POWDER COATING

Powder coating – fields of use The paint systems are based on different resin types: epoxy resins predominantly for interior parts or polyester, polyurethane and acrylic resins for exterior applications. The resin systems determine the field of application and properties of the powder coating. Cover picture: Powder as a feedstock

polyester systems

polyurethane

corrosion protection

+

-

0

0+

adhesion

+

-

+

+

chemical resistance

+

0

+

0+

UV resistance

-

+

+

0+

overpaintability

+

+

-

+

Properties

hybrid systems

epoxy systems

(epoxy + polyester)

Properties of resin types

Specific powder coating applications Automotive industry – Inlet pipe of W-12-Zylinder Base material: sand casting magnesium alloy Process: chrome-free passivation MAGPASS-COAT ® plus powder coating Layer thickness: 180 - 200 µm

Requirements / applications: defined strength corrosion protection decoration

Domestic appliance sector - Chassis Base material: aluminium alloy Process: zinc phosphate plus powder coating Layer thickness: 80 - 120 µm

Requirements / applications: corrosion protection decoration

Inlet pipe for W-12-cylinder engine

plating

Chassis

13

www.ahc-surface.com

PAINTING SYSTEMS CED

What is CED? CED (cathodic electro-deposition) is a process during which the workpiece to be coated is negatively charged and then immersed into a paint bath with positively charged paint particles.

These paint particles are attracted to the workpiece on which they deposit and form a uniform film across the part. Subsequent to the application of the paint layer a heat treatment (baking) is carried out at 180 to 220 °C.

One of the benefits is that every crevice and corner is coated until the film reaches the specified layer thickness. Thus, a uniform coating thickness over all the parts is achieved. CED layers provide good corrosion protection and high impact strength.

In combination with the use of ultrafiltration technology, the highly-automated coating process offers an economically advantageous use of paint materials.

Advantages of CED

CED process flow Metallic component Pre-treatment 1. degreasing

alkaline

2. degreasing

alkaline

3. rinse

neutral

4. zinc-manganese-phosphatizing

tri-cation

5. rinse

neutral

6. passivation

organic

7. rinse

deionised water

8. rinse

purest deionised water

cleaning zone/blow off

110 °C

CED

RAL 9005 / 9011

baking process

180 - 220 °C

PLATING www.ahc-surface.com

14

PAINTING SYSTEMS CED

CED – fields of use Cathodic electro-deposition techniques are used in the automotive and mechanical engineering sectors to provide corrosion protection to a wide variety of components, e.g., stamped parts. CED increases the stone impact resistance and, as a consequence, is often used for grids which protect commercial vehicles against falling rocks. The coating process is well suited to complex shaped parts due to the uniform coating thickness produced.

Cover picture: Tubes for passenger cars/commercial vehicles (air conditioning systems, oil feed...)

Specific cathodic electro-deposition (CED) applications Measuring technology – Mounting device for gauge Base material: steel Process: CED Layer thickness: 20 - 30 µm Requirements / applications: decoration corrosion protection Mounting device for gauge

Automotive industry – Guide rail Base material: steel Process: CED Layer thickness: 20 - 30 µm Requirements / applications: corrosion protection

AHC / 07.09

Guide rail

plating 15

www.ahc-surface.com

Wet Paint

Powder Coating

CED

Optimum anti-friction properties

Use with low and high temperatures

Variety of colours

Suitable for cavities

Maintenance-free long-term lubrication

All sizes of components

Coatings up to 200 µm

Short turnaround time

PLATING plating

PAINTING SYSTEMS GLISS-COAT ®

What is GLISS-COAT ®? The GLISS-COAT ® brand denotes the range of dry lubricant coatings developed by AHC and designed to reduce friction and surface wear. The coating materials are watersoluble. Various methods of application are possible. The type of

application method depends upon the geometry and quantity of parts to be coated, the type of liquid coating material used, e.g. single or multiple component system, and the requirements of the final coating.

How are GLISS-COAT ® layers built-up? The coating systems are waterbased and are completely free of heavy metals. The flow behaviour is modified to avoid any undesirable edge build-up or any drop formation at edges or in bores. Individual parts are coated using automatic flat spray units while smaller series-produced parts, for instance, are treated in special barrel-plating devices.

Most GLISS-COAT ® layers must be dried after application of the coating to achieve the required properties with regard to adhesion, hardness, corrosion protection and lubrication. During the drying process temperatures below 100 °C are generally employed. The coated parts are spread out during drying in order to ensure uniform curing.

(All technical values published in this brochure are subject to the test conditions specified. We therefore emphasise that the applications and operating conditions, along with the end

user’s practical experience, will ultimately determine the level of performance achieved by the coating and/or coating system)

PLATING www.ahc-surface.com

2

PAINTING SYSTEMS GLISS-COAT ®

Flat spray unit with view of the coating chamber Centrifuge coating

Advantages of GLISS-COAT ® compared to lubricating grease and oil products helps repel dust and dirt forms a homogeneous lubricating surface tight anchorage with the substrate ecological advantages, since there is no removal of the medium

permanent protection against corrosion partial coating possible provides permanent lifetime lubrication in many cases minimise noise (e.g. squeaking and grinding noises) dry lubricant

Suitable materials for treatment with GLISS-COAT ® Depending on the processing variant all metals, light metals as well as plastics destined for industrial use can be treated. Among others, the following

substrates have been successfully treated for special applications: paper, non-woven fabrics, plastic foils, metal foils as well as ceramics.

plating 3

www.ahc-surface.com

PAINTING SYSTEMS GLISS-COAT ®

General coating characteristics optimum anti-friction properties long service life minimise noise maintenance-free long-term lubrication excellent adhesion when applied to metals and plastics

helps repel dust and dirt high level of chemical resistance good corrosion resistance homogeneous surface quality big cost savings

Colour Most GLISS-COAT ® layers are matt dark grey in colour, as plated. Under compressive stress they take on a shiny appearance and their

coefficient of friction decreases. Alternative colours are available at customer’s special request.

Frictional behaviour Disc Polyamide PA 66 30 % glas-fibre, non-coated Polyamide PA 66 30 % glas-fibre, 30 µm GLISS-COAT ® 200-W-60P Polyethyleneterephthalate (PET), non-coated Polyethyleneterephthalate (PET), 30 % GLISS-COAT ® 200-W-60P

Service life µ < 0,3 [number of revolutions]

Wear [10-15m2/N]

3,100

3.3

3,164.000

1.7

300

47.0

> 9,556,000

0.7

Slide test with pin-disc-tribometer FN = 5 N; v = 6 m/min.; T = 24 °C; rel. humidity: 50 %, pin (ball): Ø 6 mm, 100 Cr 6

PLATING www.ahc-surface.com

4

PAINTING SYSTEMS GLISS-COAT ®

Frictional behaviour The service life and the coefficient of friction of a GLISS-COAT ® hard film depends on the type of coating and on the hardness characteristics of the material to which it is applied. Ideal friction characteristics are fulfilled when the coating is applied to two hard metal surfaces which move against each other with a uniformly applied medium pressure and at a comparatively high speed.

Optimum friction behaviour, especially for aluminium, magnesium and titanium alloys, can be achieved by the application of the GLISS-COAT ® process variant 2000 and the use of anodic intermediate layers (HART-COAT ®, anodising, KEPLA-COAT ®, MAGOXID-COAT ®).

Piston valves and transmission guides with GLISS-COAT ® 200-W-60P

Pressure springs for automotive shock absorbers, treated with GLISS-COAT ® 200-W-60P Cover picture: Latches for motor vehicle locks coated with GLISS-COAT ® 200-W

Service life µ < 0,3 [number of revolutions]

Disc

Wear [10-15m2/N]

AlMgSi1, 30 µm GLISS-COAT ® 200-W-60P

1,305,000

5.6

AlMgSi1, 40 µm GLISS-COAT ® 2010-W-033

3,605,090

2.7

Steel 1.4571, 30 µm GLISS-COAT ® 200-W-60P

1,058,900

11.3

Slide test with pin-disc-tribometer FN = 5 N; v = 6 m/min.; T = 24 °C; rel. humidity: 50 %, pin (ball): Ø 6 mm, 100 Cr 6

plating 5

www.ahc-surface.com

PAINTING SYSTEMS GLISS-COAT ®

Applications vehicle door locks seat bolting devices slide bearings, bushes toothed wheels bolts, screws, nuts guide mechanisms, rollers spindles, shafts valves, stopcocks roller bearings

coil compression springs for damping systems movable vehicle interior components, e.g. hinge pins, bearing bolts, seat adjustment components, guide plates bearings fitted to drive systems, turbines and rotors insert/outsert injection moulding technology

Basic coating 200-W

water-based (solvent-free) coating system that can be applied to all substrates destined for industrial use

Typical layer thickness: for example 30 ± 10 µm on flat parts Typical drying temperature: 80 °C to 100 °C Temperature resistance: up to 200 °C

Layer characteristics: anti-friction properties helps prevent squeaking and grinding noises pressure resistant suitable for consumer goods, food compatible good chemical resistance high alkali resistance free of heavy metals according to the EU End-of-Life Vehicle Directive a layer thickness of approx. 35 µm on steel with corresponding pre-treatment withstands up to 250 hours of testing according to DIN EN ISO 9227 (neutral salt spray test)

PLATING www.ahc-surface.com

6

PAINTING SYSTEMS GLISS-COAT ®

Shafts and springs made of steel as well as plastic locking pins for seat area of passenger cars. Each part is coated with GLISS-COAT ®.

Actuating drives with GLISS-COAT ®-treated covers

Small parts, treated with GLISS-COAT ®

For functional applications 200-W-60P 200-W-100P 200-W-PG

These coatings have various compositions which contain significant increase of antifriction properties improved running-in behaviour

200-W-KP

lubricating additions.

very ductile well suited for the coating of plastics

with corrosion protecting additions

improved corrosion protection compared to basic coating system good anti-friction properties

plating 7

www.ahc-surface.com

PAINTING SYSTEMS GLISS-COAT ®

Optical variant with additional colour pigment 200-W-S03

black-dyed surface with antifriction properties

Cup holder for vehicles, treated with GLISS-COAT ® 200-W-S03

Anti-friction coating C03

water-based (solvent-free) coating system suitable for dip-spin and spray application

Layer thicknesses: depending on process variant Typical drying temperature: max. 100 °C

Layer characteristics: anti-friction properties helps prevent squeaking and grinding noises pressure resistant free of heavy metals according to the EU End-of-Life Vehicle Directive formation of a shiny lubricant film, if subject to pressure resistant to soiling

Temperature resistance: for use at up to 200 °C

PLATING www.ahc-surface.com

8

PAINTING SYSTEMS GLISS-COAT ®

Multi-functional combination coatings from one source 2000

Multi-functional combination coatings, consist of a first layer and a second, so-called top layer. With this process, the top layer is a decorative and / or functional paint coat.

GLISS-COAT ® 2000 is the generic term for multi-functional combination coatings and does not exclusively signify dry-lubricant coating systems.

2001-W-033

Example of multi-functional combination coatings, dependent on kind of base material and requirements of coating system:

Hard anodic base coat plus antifriction coating on aluminium alloys low coefficient of friction with maximum service life high wear and corrosion resistance excellent adherence to base material high electrical insulation properties pressure resistant suitable for consumer goods, food compatible

Z-table for scan microscopy, coated with KEPLA-COAT ® plus TOP-COAT black

Typical nominal layer thicknesses: 40 - 80 µm Drying temperature: from 20 °C to 150 °C Multi-functional combination coatings for knife handles combine decorative requirements with a high corrosion protection

Temperature resistance: up to 200 °C

Development products Our own development department formulates and modifies further variants. It is possible to respond to customer’s specific requirements if they cannot be met by existing process variants.

Examples: high-temperature resistant layers decorative anti-friction properties with corrosion protection

plating 9

www.ahc-surface.com

PAINTING SYSTEMS WET PAINT/KTL

What is wet paint? Wet paint is a spray paint process during which hydro paint systems or solvent-based paint systems are

applied. The process offers optimum flexibility with regard to paint application.

With wet painting, surfaces are produced that are decoratively appealing regarding structure and colour on almost every base material. A wet paint layer may also have functional properties.

In combination with a primer, for example, it is possible to achieve high corrosion protection. It is also possible to treat very small batches which offers high flexibility.

Plastic component

Metallic component

Pre-treatment

Pre-treatment

Advantages of wet paint

Wet paint process flow Example – process flow charts for plastic and metallic components

1. degreasing

alkaline

1. degreasing

alkaline

2. degreasing

alkaline

2. degreasing

alkaline

3. rinse

neutral

3. rinse

neutral

4. primer / fluorination /

4. activation (where required)

flame treatment

5. zinc-manganesephosphatizing

drying

as required

wet painting

tri-cation

6. rinse

neutral

7. passivation

organic

8. rinse

deionised water

9. rinse

purest deionised water

drying

about 50 –150 °C

wet painting all colours / effects

drying in ofen

all colours / effects drying in ofen

about 50 - 150 °C

as required

PLATING www.ahc-surface.com

10

PAINTING SYSTEMS WET PAINT/KTL

Wet paint – fields of use Wet paint processes can be used to paint the most diverse plastic materials, e.g., ABS / PC, PP, PPO or PA6, as well as metallatic materials. If required, a corresponding pretreatment (primer / fluorination) can be applied.

Applications the automotive sector (accessories for the interior) decorative surface appearance haptically appealing surface (soft-touch effect) temperature-sensitive components

Titelmotiv: Nasslackierung mittels Roboter mit Power-Wash-Vorbehandlung

Special wet paint applications Automotive industry – Panel Base material: ABS Process: hydro soft paint Layer thickness: 40 - 50 µm Requirements / applications: decoration haptics Panel

Automotive industry – Air vent Base material: ABS Process : soft paint Layer thickness: 30 - 40 µm Requirements / applications: decoration haptics

plating

Air vents

11

www.ahc-surface.com

PAINTING SYSTEMS POWDER COATING

What is powder coating? Powder coating is an electro-static coating process during which electrically charged paint particles are applied, by means of a spray gun, to the surface of a metallic workpiece that is grounded.

The impinging particles generate an opposite electric charge which affects the adhesion of the paint particles to the surface.

Advantages of powder coating Powder coatings with layer thicknesses between 40 µm and 140 µm are available in many different colours. The coatings offer an extremely high corrosion protection, chemical resistance, UV-resistance and stone impact resistance.

Commercial vehicle steps on a process rack

Powder coating process flow The following scheme shows a typical process sequence

Metallic component Pre-treatment 1. degreasing

alkaline

2. degreasing

alkaline

3. rinse

neutral

4. zinc-manganese-phosphatizing

tri-cation

5. rinse

neutral

6. passivation

organic

7. rinse

deionised water

8. rinse

purest deionised water

drying powder coating baking process

about 150 °C all colours 160 - 220 °C

PLATING www.ahc-surface.com

12

PAINTING SYSTEMS POWDER COATING

Powder coating – fields of use The paint systems are based on different resin types: epoxy resins predominantly for interior parts or polyester, polyurethane and acrylic resins for exterior applications. The resin systems determine the field of application and properties of the powder coating. Cover picture: Powder as a feedstock

polyester systems

polyurethane

corrosion protection

+

-

0

0+

adhesion

+

-

+

+

chemical resistance

+

0

+

0+

UV resistance

-

+

+

0+

overpaintability

+

+

-

+

Properties

hybrid systems

epoxy systems

(epoxy + polyester)

Properties of resin types

Specific powder coating applications Automotive industry – Inlet pipe of W-12-Zylinder Base material: sand casting magnesium alloy Process: chrome-free passivation MAGPASS-COAT ® plus powder coating Layer thickness: 180 - 200 µm

Requirements / applications: defined strength corrosion protection decoration

Domestic appliance sector - Chassis Base material: aluminium alloy Process: zinc phosphate plus powder coating Layer thickness: 80 - 120 µm

Requirements / applications: corrosion protection decoration

Inlet pipe for W-12-cylinder engine

plating

Chassis

13

www.ahc-surface.com

PAINTING SYSTEMS CED

What is CED? CED (cathodic electro-deposition) is a process during which the workpiece to be coated is negatively charged and then immersed into a paint bath with positively charged paint particles.

These paint particles are attracted to the workpiece on which they deposit and form a uniform film across the part. Subsequent to the application of the paint layer a heat treatment (baking) is carried out at 180 to 220 °C.

One of the benefits is that every crevice and corner is coated until the film reaches the specified layer thickness. Thus, a uniform coating thickness over all the parts is achieved. CED layers provide good corrosion protection and high impact strength.

In combination with the use of ultrafiltration technology, the highly-automated coating process offers an economically advantageous use of paint materials.

Advantages of CED

CED process flow Metallic component Pre-treatment 1. degreasing

alkaline

2. degreasing

alkaline

3. rinse

neutral

4. zinc-manganese-phosphatizing

tri-cation

5. rinse

neutral

6. passivation

organic

7. rinse

deionised water

8. rinse

purest deionised water

cleaning zone/blow off

110 °C

CED

RAL 9005 / 9011

baking process

180 - 220 °C

PLATING www.ahc-surface.com

14

PAINTING SYSTEMS CED

CED – fields of use Cathodic electro-deposition techniques are used in the automotive and mechanical engineering sectors to provide corrosion protection to a wide variety of components, e.g., stamped parts. CED increases the stone impact resistance and, as a consequence, is often used for grids which protect commercial vehicles against falling rocks. The coating process is well suited to complex shaped parts due to the uniform coating thickness produced.

Cover picture: Tubes for passenger cars/commercial vehicles (air conditioning systems, oil feed...)

Specific cathodic electro-deposition (CED) applications Measuring technology – Mounting device for gauge Base material: steel Process: CED Layer thickness: 20 - 30 µm Requirements / applications: decoration corrosion protection Mounting device for gauge

Automotive industry – Guide rail Base material: steel Process: CED Layer thickness: 20 - 30 µm Requirements / applications: corrosion protection

AHC / 07.09

Guide rail

plating 15

www.ahc-surface.com

More Documents from "Anggoro Bernardi"

Painting_systems_eng.pdf

February 2021 1

La Maquina De Matar - Nicolas Marquez

January 2021 0

La Guerrilla En Tucuman-una Historia No Escrita (1)

January 2021 1

Soal Text Report.docx

January 2021 1