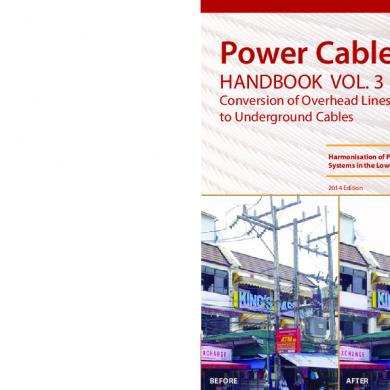

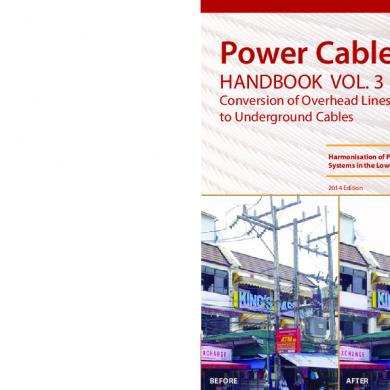

Power Cable: Handbook Vol. 3

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Power Cable: Handbook Vol. 3 as PDF for free.

More details

- Words: 22,272

- Pages: 108

Loading documents preview...

Distribution utilities in the Lower Mekong Subregion (LMS) are rehabilitating their power distribution systems to accelerate the economic development of their respective countries. They are embracing underground cabling systems for transformational change in urban areas. But they also face complex technical, capital and workforce challenges in the conversion of overhead lines to underground cables. The harmonisation of underground cabling systems and processes can help LMS utilities to serve as goals that they can work towards to in the conversion from overhead lines to underground cabling in their electricity grids. The objectives of this handbook are to: • Standardise and document guidelines for best practices in the conversion of overhead lines to underground cabling. • Enhance the knowledge and skills of LMS Utilities on the processes for converting overhead lines to underground cabling. • Promote the correct and efficient usage and application of underground cables.

This is part of a technical initiative by | Electricite du Cambodge | Electricite du Laos | Metropolitan Electricity Authority, Thailand | Provincial Electricity Authority, Thailand | Hanoi Power Corporation, Vietnam | Ho Chi Minh City Power Corporation, Vietnam | Northern Power Corporation, Vietnam | Central Power Corporation, Vietnam | Southern Power Corporation, Vietnam

A Best Practices Handbook for Conversion of Overhead Lines to Underground Cabling in the Lower Mekong Sub-region

A joint effort of LMS Technical Working Group 3 and Provincial Electricity Authority, Thailand for the LMS Harmonisation Programme

Power Cable HANDBOOK VOL. 3

Conversion of Overhead Lines to Underground Cables Harmonisation of Power Distribution Systems in the Lower Mekong Subregion 2014 Edition

|| 2014 Edition

BEFORE

AFTER

Specially published for the benefit of power utilities companies, power engineers, power designers and supply chain in the Lower Mekong Subregion

Power Cable Handbook Volume Three Conversion of Overhead Lines to Underground Cables

Copyright © 2014 International Copper Association Southeast Asia Ltd & Provincial Electricity Authority

All rights reserved. No part of this publication may be reproduced or distributed in any form or by any means, or stored in a database or retrieval system, without the prior written permission of the publisher. Printed in Thailand

Conversion of Overhead Lines to Underground Cabling Handbook | i

Message from PEA Governor

Provincial Electricity Authority is responsible for the provision of standardized electricity services and related business to attain the customers’ satisfaction on products and services through PEA’s continual corporate development plans with the recognition of social and environmental responsibility. In response to the mission, PEA continuously improves the power system to achieve the highest level of efficiency, safety and reliability. For the development of power distribution system, PEA has a vision in developing the system in several dimensions such as expansion of power distribution system in new power service areas, construction of a strong power system, focus on social responsibilities and environmental sustainability as well as provision on beautiful landscapes in cities and tourist attractions. Therefore, PEA has launched the project of “Conversion Overhead System to Underground System” by commencing in the well-prepared and appropriate areas. Currently, PEA has already completed this project in many areas across the country. As a result, PEA employees have gained particular knowledge, know-how and experiences from the project. According to the collaboration between PEA and International Copper Association Southeast Asia, PEA has developed the 2nd Handbook of Underground Cabling Design, Construction and Installation which focuses on how PEA converting the Overhead System to Underground System starting from the very first step to the end including project planning, financial analysis, technical analysis, system design and construction site management. The collaboration on the development of the handbook arising from the potential benefits that PEA was devoted to can make fruitful advantages to Utilities in LMS.

ii | Conversion of Overhead Lines to Underground Cabling

Lastly, I do hope that the content of this handbook will benefit in power system development to be well established, effective and trustworthy in Thailand and neighboring countries in the Mekong Sub Region. As a result, it will directly impact to both economic and social development. Moreover, it will also raise the quality of life of people in ASEAN equivalent to other developed countries.

Mr. Numchai Lowattanatakul PEA Governor

Conversion of Overhead Lines to Underground Cabling Handbook | iii

Foreword

It is my pleasure to write the foreword for this LMS Handbook on the “Conversion of Overhead Power Lines to Underground Cabling”. The development of this handbook was tasked to Technical Working Group No. 3 (TWG #3) which was set up in 2011 under the Program for the Harmonization of Power Distribution Systems in The Lower Mekong Sub-Region (LMS). TWG #3 was a regional collaborative effort with participation from nine Power Distribution Utilities in the four LMS countries, namely Hanoi Power Corporation (EVNHANOI), Ho Chi Minh City Power Corporation (EVNHCMC), Central Power Corporation (EVNCPC), DaNang Power Company (EVNCPC PC DaNang), HaiPhong Power Company (EVNNPC PC HaiPhong) from Vietnam; Provincial Electricity Authority (PEA) and Metropolitan Electricity Authority (MEA) from Thailand; Electricite du Laos (EDL), from Lao People’s Democratic Republic; and Electricite du Cambodge (EDC), from Cambodia. The terms of reference for TWG #3 was to investigate the best practices in the conversion from overhead power lines to underground cabling system. I am thankful to the Provincial Electricity Authority (PEA), Thailand for dedicating a team to write the draft content for this handbook. And it was also made possible with support from the International Copper Association Southeast Asia (ICASEA). As the Chairman of this Group, I also extend my appreciation to expert members of the PEA team for their effort and time in writing the contents. This handbook focuses on international standards and practical solutions in all aspects of the conversion exercise - from planning, design, construction methods, financial source strategy, implementation management, operation & maintenance to case studies such as Local Government Policies, City Centers, Tourist or Historical Areas, Coastal Areas etc. This initiative is to assist LMS Power Distribution Utilities

iv | Conversion of Overhead Lines to Underground Cabling

to learn from successful procedures of conversion from overhead power line to underground cabling system in order to increase their efficiency and improve their delivery of power supply. Ultimately, the Utilities will stand to gain from a system that is more reliable and with a safer environment at a lower cost. TWG #3 held two meetings. The first in Pattaya hosted by PEA and the second in Ho Chi Minh City hosted by EVNHCMC. The fruitful outcome of these two meetings were made possible with the support and warm hospitality from PEA and EVNHCMC. The sharing of their valuable experiences, practical knowledge and expertise from the site visits have enabled the members of TWG #3 to better understand the practical ways of converting overhead power lines to an underground cabling system.

Surapon Soponkanaporn Chairman, TWG #1 (Transformers) & TWG #3 (Conversion of Overhead to Underground)

Conversion of Overhead Lines to Underground Cabling Handbook | v

Introduction The Lower Mekong Subregion (LMS) Harmonisation Programme Cambodia, Lao People’s Democratic Republic (Lao PDR), Thailand and Vietnam have achieved different levels of economic development. These countries in the Lower Mekong Sub-region (LMS) have strong economic inter-dependence. Being developing countries, their power distribution systems, which are an essential infrastructure, play a significant role in their economic development. Energy end-users are dependent on the availability, reliability, and quality of electricity from the power distribution systems. The level of development and advancement of power distribution systems has direct impact on the developmental potential and economic growth, especially in urban areas. The power distribution systems in the urban areas of these LMS countries, however, are not at the same level of physical and technological development. It is widely acknowledged that harmonisation in the development of power distribution systems can benefit these countries and accelerate their economic growth. In 2005, six power utilities signed a Memorandum of Understanding (MOU) with the expressed intention of close cooperation to share knowledge and experiences towards harmonisation of power distribution systems in four LMS countries: Cambodia, Lao PDR, Thailand and Vietnam. The founding partners are: •

Electricité du Cambodge (EDC), Cambodia

•

Electricité du Laos (EDL), Lao PDR

•

Ho Chi Minh City Power Company (HCMC PC), Vietnam

•

Hanoi Power Company (HNPC), Vietnam

•

Metropolitan Electricity Authority (MEA), Thailand

•

International Copper Association Southeast Asia (ICASEA) [formerly known as Copper Development Centre • Southeast Asia]

vi | Conversion of Overhead Lines to Underground Cabling

This MOU initiated a comprehensive review of power distribution systems of the signatory utility partners in Cambodia, Lao PDR and Vietnam which resulted in the preparation of a regional cooperation roadmap and action plan. Building on the success of the first MOU, ICASEA and MEA inked a second MOU to continue their strategic partnership in conducting further studies and facilitating programmes as outlined in phase 2 of the road map and action plan. This impetus is to enable the LMS countries to make further progress towards harmonisation and the realisation of the objectives as set out in the MOU with all the partner utilities. The study of power distribution systems in the LMS countries under the first MOU had revealed that there exist many differences in the design and operation of power distribution systems in this region. The objective of this second MOU was to narrow down the differences in six key areas and enable the LMS countries to move towards greater harmonization of their power distribution systems. Since then, the following LMS Utilities have joined the Harmonisation Programme: •

Danang Power Company (DNPC), Vietnam in 2009

•

HaiPhong Power Company (HPPC), Vietnam in 2009

•

Provincial Electricity Authority (PEA), Thailand in 2010

•

Central Power Corporation (EVNCPC), Vietnam in 2010

•

Northern Power Corporation (EVNNPC), Vietnam in 2012

•

Southern Power Corporation (EVNSPC), Vietnam in 2012

Conversion of Overhead Lines to Underground Cabling Handbook | vii

Preface Overhead power lines, a familiar sight in many old cities, are slowly disappearing from city skylines. A noticeable trend towards underground power cabling is gathering momentum around the world. And nowhere else is this more evident than in Asia. City after city, professionals involved in city planning and development, from planners and architects to consultants and engineers, are deciding in favour of underground power distribution, realising the immense benefits that it offers. LMS Utilities are also committed to its public responsibilities to carry out various projects and activities for society and the environment. And one of these is to bury power lines in cities and tourist sites to preserve the beauty of the original landscape. Underground power cable systems offer far reaching benefits. Not only do these systems dramatically improve the skyline of a city, they also result in better environment, lower power distribution costs, higher reliability and greater protection against hazards associated with overhead power lines. The formation of a Technical Working Group for the Conversion of Overhead Power Lines to Underground Cabling is a progression of the two previous successful TWGs. One for transformers and the other for power cables. The views of and input from participating Utilities are crucial in the development of best practices for the harmonisation of conversion of overhead power lines to underground cabling in the LMS. And with acceptance and implementation of the best practices LMS Utilities can realise the immense benefits that it offers. The objective of this TWG is to gather the views of and input from participating LMS Utilities on the conversion of overhead power lines to underground cabling. This is crucial in the development of a regional handbook if it is to serve as a useful guide for LMS Utilities to adopt best practices based on international standards for the conversion of Overhead to Underground with efficient cables. viii | Conversion of Overhead Lines to Underground Cabling

Technical Working Group #3 for the Conversion of Overhead Lines to Underground Cables: Surapon Soponkanaporn Chairman Mana Papamakajonpon Secretary/Coordinator Iv Visal Deputy Director - Distribution Dept, EDC Mixay Chittirath Deputy Manager – Vientiane Capital Region, EDL Dr Asawin Rajakrom Director - Substation Equipment and UG Cable Installation Div, MEA Somchai Songsiri Manager, Power System Maintenance Division, PEA Nguyen Tien Dat Expert - Technical Dept, EVNHANOI

Titti Trakulsinthong Deputy Manager, Power System Maintenance Division Mana Patamakajonpong Assistant Manager, Training Division Watchara Panchang Chief of Section, Transmission System Design Division (Central) Somchai Sripoom Chief of Section, Special Project Office 1 Nongluk Suvanjumrat Chief of Section, Power System Maintenance Division Komkrish Dornpromyung Chief of Section, Corporate Social Responsibility Project Management Division

Nguyen Ngoc Khoa Manager – Technical Dept, EVNHCMC

Phisutthisak Dulyapaphat Chief of Section, Power System Construction Division (Central, South)

Tran Van Gia Deputy Director - Technical Dept, EVNCPC

Technical Reviewer & Editor for Thai Version of the Handbook:

Nguyen Dac Trung Deputy Manager - Technical Dept, DNPC Nguyen Quoc Khanh Manager - Technical Dept, HPPC PEA Content Development Team: Somchai Songsiri Manager, Power System Maintenance Division Songwut Khandee Manager, Distributed Generation Planning Division Somchoke Boonchaisri Deputy Manager, Distribution System Project Office 1

Surapon Soponkanaporn Chairman, LMS Technical Working Group #1 and #3 International Copper Association Southeast Asia (ICASEA): Louis Koh Program Consultant, Power Distribution Piyadith Lamaisathien Country Manager - Thailand Huynh Hong Tan Country Manager - Vietnam

Conversion of Overhead Lines to Underground Cabling Handbook | ix

Acknowledgements The harmonisation of power distribution systems in the LMS will contribute to the expansion of the ASEAN Power Grid. However, harmonisation requires a robust partnership and sustained effort over many years. The harmonization of technical specifications together with the development of this handbook is taking the process a step closer towards the realization of the objectives as set out in the strategic roadmap for the harmonization of power distribution systems in the LMS. Strengthening regional cooperation to build the capacity of both technical and functional staff would not have been possible without the endorsement and support of: Electricité du Cambodge (EDC), Cambodia: Keo Rottanak, Managing Director Dr Chan Sodavath, Deputy Managing Director Electricité du Laos (EDL), Lao PDR: Sisavath Thiravong, Managing Director & CEO Hanoi Power Corporation (EVNHANOI), Vietnam: Nguyen Anh Tuan, General Director Vu Quang Hung, Deputy General Director Ho Chi Minh Power Corporation (EVNHCMC), Vietnam: Le Van Phuoc, General Director Tran Khiem Tuan, Vice General Director Central Power Corporation (EVNCPC), Vietnam: Tran Dinh Thanh, General Director Nguyen Thanh, Vice General Director

EVNNPC Haiphong Power Company, Vietnam: Vu Duc Hoan, Director EVNCPC Danang Power Company, Vietnam: Le Thanh Minh, Director Provincial Electricity Authority (PEA), Thailand: Numchai Lowattanatakul, Governor Chusak Anusaksatein, Deputy Governor – Human Resource Development Metropolitan Electricity Authority (MEA), Thailand: Arthorn Sinsawad, Governor International Copper Association Southeast Asia (ICASEA): Steven Sim, Chief Executive Officer Bek Chee Jin, Chief Operating Officer

Southern Power Corporation (EVNCPC), Vietnam: Nguyen Thanh Duy, General Director Ho Quang Ai, Deputy CEO x | Conversion of Overhead Lines to Underground Cabling

Table of Contents Executive Summary

1

Chapter 1 - Background 1.1 Introduction

3

1.2

Driving Forces

4

1.3

Return on Investment

6

Chapter 2 - Underground Cabling Plan 2.1 Introduction

8

2.2

Project Planning Criteria

8

2.3

Engineering Criteria

12

2.4

Key Success Factors

16

Chapter 3 - Underground Cabling System 3.1 Introduction

17

3.2

Site Survey and Detailed Design

17

3.3

Method for Construction

23

3.4

Construction Methods Comparison

28

3.5

Electrical Equipment for an Underground Power Cabling System

29

Chapter 4 - Financial & Economic Aspect 4.1

Introduction

39

4.2 Investment Cost

39

4.3

Sources of Funds and Cost Allocation

44

4.4

Operation and Maintenance Cost

45

4.5

Project Benefits

45

Conversion of Overhead Lines to Underground Cabling Handbook | xi

Chapter 5 - Implementation Management 5.1 Introduction

55

5.2

Sources of Funding

55

5.3

Project Management Organization

56

5.4

Construction Control for Underground Power Cabling System

59

Chapter 6 - Operation and Maintenance for Underground Cabling System 6.1 Introduction

63

6.2 Operation

64

6.3

Maintenance of Underground Power Cable

65

6.4

Training for Underground Power Cable System

71

Chapter 7 - Case Studies 7.1 Introduction

72

7.2

Local Government Policy Project

72

7.3

Coastal Area Project

76

7.4

Tourist and Historical Area Project

79

7.5

City Center Area Project

83

7.6

Lesson Learned

87

xii | Conversion of Overhead Lines to Underground Cabling

FIGURES Figure 1.1:

The statistical data for causes of power outage that happened in rural of Thailand in 2011

3

Figure 1.2:

Landscape in Chiang Mai province after constructing underground system 5

Figure 2.1:

22, 33 kV Underground cable structure

12

Figure 2.2: Radial system

14

Figure 2.3: Open loop system

14

Figure 2.4: Open loop system with special spare line

15

Figure 2.5: Close loop system

15

Figure 3.1: High pressure gas pipe

18

Figure 3.2: GPR testing equipment

19

Figure 3.3: An example result from GPR

19

Figure 3.4: An example of configuration used for construction

23

Figure 3.5: Concrete encased duct bank, RTRC (red), and HDPE (black)

24

Figure 3.6: Lay conduit using Concrete Spacer Block

24

Figure 3.7: Concrete slab and markers to show cable line

25

Figure 3.8: Cross-section of direct burial

25

Figure 3.9: HDD machine is working and pulling conduits

26

Figure 3.10: Horizontal Directional Drilling (HDD), drilling and pulling

26

Figure 3.11: Pushing a pipe by using Pipe jacking machine in sending manhole

27

Figure 3.12: Electrical conduits in pipe after injecting mortar

27

Figure 3.13: Transformer installed on single pole

30

Figure 3.14: Transformer installed on double pole

30

Figure 3.15: Undecorated Compact Unit Substation

30

Figure 3.16: Decorated Compact Unit Substation

30

Figure 3.17: SF6 Ring Main Unit

31

Figure 3.18: Riser pole 22kV

33

Figure 3.19: Riser wall for low voltage side

34

Figure 3.20: Riser pole for low voltage side

35

Figure 3.21: Distribution box

36

Figure 3.22: Meter cabinet and low voltage wiring

37

Figure 3.23: Fault indicator in line (left) and fault indicator inside RMU

37

Figure 3.24: Configuration of fault indicator

38

Figure 4.1: Pie chart for detailed cost analysis of underground power cable system in major city

41

Figure 4.2: Ideal Electrical Substations and layout so that feeders are 100%

efficiently utilized for distribution

41

Conversion of Overhead Lines to Underground Cabling Handbook | xiii

Figure 4.3: The substation service areas overlap and are not set out efficiently

41

Figure 4.4: Comparison among construction methods

42

Figure 4.5: Comparison among construction methods excluding low voltage and

connecting to end users

Figure 4.6: Net Present Value (NPV) for each end of planning period

42 43

Figure 4.7: Annual operating and maintenance cost (Baht/Km) between overhead line

and underground cable

Figure 4.8: PEA’s annual outage cost by types of customer in urban area

45 51

Figure 4.9: Annual losses of customer due to power outage for overhead and underground systems for a typical town (Chiang Mai) Figure 6.1: PEA’s underground cable test form

52 67

Figure 6.2: Example of Fault Locator

68

Figure 6.3: Example of a fault location

68

Figure 6.4: An example of OWTS tester

69

Figure 6.5: PD Mapping graph

71

Figure 7.1: Construction area

72

Figure 7.2: Landscape before the construction

75

Figure 7.3: Landscape before the construction

75

Figure 7.4: Landscape after completion

75

Figure 7.5: Landscape after completion

75

Figure 7.6: Construction area for underground power cable system

76

Figure 7.7: Landscape before the construction

79

Figure 7.8: Landscape before the construction

79

Figure 7.9: Landscape after completion

79

Figure 7.10: Landscape after completion

79

Figure 7.11: Construction area for underground power cable system

80

Figure 7.12: Landscape before the construction

83

Figure 7.13: Landscape before the construction

83

Figure 7.14: Landscape after completion

83

Figure 7.15: Landscape after completion

83

Figure 7.16: Construction area for underground power cable system

84

Figure 7.17: Landscape before the construction

87

Figure 7.18: Landscape before the construction

87

Figure 7.19: Landscape after completion

87

Figure 7.20: Landscape after completion

87

xiv | Conversion of Overhead Lines to Underground Cabling

TABLES Table 2.1: Table 2.2: Table 3.1: Table 3.2: Table 3.3: Table 3.4: Table 3.5: Table 4.1: Table 4.2: Table 4.3: Table 4.4: Table 4.5: Table 4.6 Table 4.7: Table 4.8: Table 5.1: Table 6.1: Table 7.1: Table 7.2: Table 7.3: Table 7.4: Table 7.5: Table 7.6: Table 7.7: Table 7.8: Table 7.9: Table 7.10: Table 7.11: Table 7.12: Table 7.13: Table 7.14: Table 7.15: Table 7.16: Table 7.17: Table 7.18: Table 7.19: Table 7.20:

The proposed security levels and design criteria for various supply areas 10 Technical Data of 22 kV XLPE Underground 13 The advantage and disadvantage of each construction method 28 Cost comparison of construction methods for 22kV per 1 circuit-km 29 Cost comparison of construction methods for low voltage 400/230V per 1 circuit-km 29 Cost comparison for transformer installation 32 Comparison factors to consider for transformer installation 32 Detailed cost analysis of underground power cable system in major city 40 A range of benefits from replacing overhead line to an underground power cable system 46 NPV for expense, operating and maintenance, and losses of overhead line and underground power cable 47 Losses of end users due to power outage 49 PEA system reliability statistics from October 98 to March 99 50 Cost of outage for existing overhead system in Chiang Mai 51 The customer’s cost during interruption of underground power cable system 53 Economic benefits of an underground power cable 53 Summary of problems and obstacles during construction 60 Recommended maintenance for differing values of PDIV 70 The detail of civil work for medium voltage side 74 The detail of civil work for low voltage side 74 The construction details for medium voltage side 74 The details for transformer installation 74 The construction details for low voltage side 75 The detail of civil work for medium voltage side 77 The detail of civil work for low voltage side 78 The construction details for medium voltage side 78 The details for transformer installation 78 The construction details for low voltage side 78 The detail of civil work for medium voltage side 81 The detail of civil work for low voltage side 81 The construction details for medium voltage side 82 The details for transformer installation 82 The construction details for low voltage side 82 The detail of civil work for medium voltage side 85 The detail of civil work for low voltage side 85 The construction details for medium voltage side 86 The details for transformer installation 86 The construction details for low voltage side 86 Conversion of Overhead Lines to Underground Cabling Handbook | xv

Executive Summary As part of the Harmonization of Power Distribution System in Lower Mekong Subregion, this handbook was prepared by International Copper Association Southeast Asia (ICASEA) and Provincial Electricity Authority (PEA) through the third LMS Technical Working Group (TWG #3) to discuss issues relating to the conversion of overhead lines to underground cables. Members of the third technical working group who are from Electricité du Cambodge (EDC), Electricité du Laos (EDL), Metropolitan Electricity Authority and Provincial Electricity Authority (MEA), and Electricity Authorities from Vietnam, EVN Hanoi, EVN Ho Chi Minh City, EVN Central, and EVN Da Nang shared their experiences in converting overhead power lines to underground power cabling system. Exchanging experience and learning from good practices help practitioners in developing and improving construction process.

PEA put together this handbook by gathering knowledge from theory and best practices

from past underground construction project. Most projects are required by municipalities to cater to both to landscape preservation and development as well as to safeguard public safety and property. These municipalities worked with PEA in launching underground projects with funding also from other agencies.

Under normal circumstances, space in a typical construction area is limited. There

is little or no space to install switchgear and unit substation which consist of a ring main unit and transformer. Residents at large were reluctant to let PEA conduct works at their premises, which resulted to positioning or installing equipment in small alleys. Hence, an underground power cable project must fulfil a set of appropriate guidelines or standards which spell the most feasible way to meet end users’ demands and goals.

An underground power cable project requires a large investment and is difficult

to measure benefits in terms of cost savings. Other benefits lie in public safety, reliability and stability of distribution system, reduction in operations and maintenance cost and tourism

1 |

Conversion of Overhead Lines to Underground Cabling Handbook

promotion. Hence, cable conversion projects need support in term of policy making and financing from other related parties, municipalities and other infrastructure agencies such as water work authority, telecommunication agency, cable TV, etc. Alternative sources of fund may be derived from government’s investment, joint investment from government and joint investment from municipality and/or internal investment. The sources of funding selected in each area will depend on the availability and suitability of a city, economy, and society. If a construction project takes a long period of time to complete, it may need financial help from the government and/or private bodies.

The key success factor in every conversion project lies in project control, stakeholder

management, and effective problem solving during construction. One of the most important tasks is to reduce disruptions and inconvenience such as traffic jam and traffic obstruction. Before construction, the management team shall make a construction plan, coordinate with municipality and community, and conduct public education. In reality, unforeseen challenges affect budgeting and the construction project at large.

This handbook discusses several important topics in seven chapters. Chapter 1

covers problems from obstacles and power stability including power security. Chapter 2 explains project planning, taking into consideration key success factors. Chapter 3 highlights construction details while existing system is maintained till the completion of underground cable project, and the comparison of construction methods, or selection of electrical equipment. Chapter 4 illustrates economic and financial strategies and explained construction cost details, sources of funds, cost allocation, and benefits. Chapter 5 presents key success factors, especially construction structure and management organization required for operating an undergrounding project. Chapter 6 offers operation and maintenance details for underground power cabling. Lastly, Chapter 7 shares experiences from successful case studies such as Nong Khai municipality, Pattaya municipality, Chiang Mai municipality, and Hat Yai municipality.

The editor and PEA executives together with the third LMS Technical Working Group

team from nine distribution utilities in four countries have contributed to the development of this handbook. Experience and knowledge discussed in this handbook would be helpful to develop an efficient underground power cabling project. This handbook would also be a solid foundation to move forward and share success among utilities in the Lower Mekong Subregion.

Conversion of Overhead Lines to Underground Cabling Handbook |

2

Chapter 1 BACKGROUND 1.1 Introduction A major portion of the power distribution networks in Lower Mekong Subregion is made up of overhead line systems because overhead lines offer the lowest investment cost, require minimum maintenance and are least difficult to operate. However, overhead line system is the least reliable or stable. The demand for electricity is growing to an extent that drives the extensive deployment of overhead line systems, especially when there is limited investment budget and a strong need for rapid infrastructure expansion. Over the past decades, the European and North America countries (including some countries in Asia) have used underground power distribution system. The drivers for this power distribution method lie in the need to increase power stability and prevent power outages caused by natural calamities such as thunderstorm, avalanche, causing widespread detriment especially in cold weather conditions. Major cities in Lower Mekong Subregion such as Bangkok, Hanoi, Ho Chi Minh City, Vientiane, and Phnom Penh have begun to convert a portion of their power distribution systems from overhead line to underground and this trend is growing.

Figure 1.1: Statistical data for power outage causes that took place in rural parts of Thailand in 2011

3 |

Conversion of Overhead Lines to Underground Cabling Handbook

Figure 1.1 illustrates statistical data of power outage causes that took place in rural parts of Thailand, from January to October 2011. Most of the power outages can be prevented by switching from overhead line to underground system.

1.2 Driving Forces The various drivers that are instrumental in power distribution system in Lower Mekong Subregion are as follows.

1.2.1 Natural Disasters Lower Mekong Subregion has been impacted by monsoon storms or typhoons resulting from the South China Sea or Pacific Ocean in Vietnam, Cambodia, and Thailand. Power reliability and safety in the use of overhead line system is affected by strong wind and fallen trees that hit power poles, causing power outage. In this case, underground power system can help to prevent such power outages. Figure 1.1 shows that natural disasters contribute 11% of overall power outages. 1.2.2 Operational Problem Overhead line system poses many challenges from permit license to design, and from construction to maintenance. If an underground system is designed and installed properly, its performance will be far better than that of an overhead line system. A well designed and constructed underground cabling system involves various configurations and cost consideration depending on service area and dexterity in operations. 1.2.3 Power Outage and Maintenance Underground cabling system is not directly affected by disturbance from living creatures and/or other objects that may come in contact with live conductors, causing short circuits as well as power outages. If power line is installed underground, such interference may be kept to a minimum and the cost spent on interference prevention will be drastically reduced, if not totally eliminated. 1.2.4 Safety of Life and Property Underground cabling system offers a lower level of risk in public hazard compared to

Conversion of Overhead Lines to Underground Cabling Handbook |

4

overhead lines that expose live conductors which may potentially be hazardous. In an underground cabling system, the chance of earth fault is minimized and transfer voltage that leads to property damages and fatalities is reduced. Figure 1.1 demonstrates that this aspect contributed to 2% of overall power outage. 1.2.5 Reliability and Stability of Power System The underground cabling system is not exposed to earth or ground. Reliability and stability of underground cabling system is far better than that of an overhead line system. Figure 1.1 demonstrates that this aspect contributed to 38% of overall power outage. 1.2.6 Loss Reduction Underground cabling system offers far more capacitance than overhead lines. As the capacitive reactive power can compensate the inductive reactive power produced in distribution lines, loss in underground cables is less than that of overhead lines. 1.2.7 Rights over Land and Safety Distance For maintenance purpose, overhead line system requires safety distance around 3-4 meters. This safety distance is nearly impossible to acquire in urban area. In some cases, it is not possible to expand overhead line system due to land use limitation. However, for underground cabling system, land area is required only during the construction process. When the construction is completed, only switchboards and transformers are installed above ground. 1.2.8 City Development and Landscape Planning

Figure 1.2: Landscape in Chiang Mai province after constructing underground system

5 |

Conversion of Overhead Lines to Underground Cabling Handbook

Underground cabling system offers advantages in city development and landscape planning. A beautiful and orderly landscape can be restored after an underground cabling system construction is completed. A beautiful and orderly landscape indirectly promotes tourism. See Figure 1.2.

1.3 Return on Investment Concern with reliability of power system and rising operating and maintenance cost, as well as safety issue and quality of life are growing in tandem. Power utilities recognize the importance in addressing the need for change from overhead line to underground system. This change will bring about better service to end users. Power distribution is a critical infrastructure for quality of life. If power is unavailable over a long period of time, there will be a huge loss in economic activity. Thus, underground cabling system is believed to be one of the key solutions contributing to the performance of a power distribution system. The benefits of underground cabling system are listed below. 1.3.1 Reduce loss resulting from natural disasters and above-ground infrastructure damages. 1.3.2 Reduce exposure to electromagnetic field (EMF). EMF is emitted from currents in conductors. Internal structure of cable and layout also contribute to magnitude of EMF. 1.3.3 Underground cable needs working space of just 3-5 meters. When the construction is completed, there is no further requirement for huge working space, which is different in the case of overhead lines that need more safety distance. 1.3.4 Pilferage and sabotage are less likely to take place in an underground cabling system. 1.3.5 Although an underground cabling system is more expensive than overhead lines, if considering the total life cycle cost including maintenance cost, power line outage cost of revenue income and electrocution throughout the expected service life of underground cable at least 20 years, then it results that underground cabling system may be more economic than overhead line system depending on cabling methods.

Conversion of Overhead Lines to Underground Cabling Handbook |

6

1.3.6 Although locating fault in overhead line is seem to be easier than in underground system, due to technology for underground cabling system is more advanced, so that the prevention of equipment damages and short circuit is more reliable and fault location is faster than overhead line. 1.3.7 Since underground cabling system is not visible to the public eye, it does not attract attention to cut or steal the cables. 1.3.8 Underground cabling system may be damaged by ground subsidence. Therefore, the survey for underground cabling system is mandatory. A well-designed system can last up to 50 years. On the other hand, overhead lines is subjected to accidental damages resulting from natural disasters and human error and tension caused by pulling other cables such as telephone and traffic signals. Implementing an underground cabling systems enhnces the beauty of the landscape. It reduces power outages. And it reduces maintenance cost. It also reduce the failure rate of overhead lines by 50%.

7 |

Conversion of Overhead Lines to Underground Cabling Handbook

Chapter 2 UNDERGROUND CABLING PLAN 2.1 Introduction Today, most of the power distribution systems in Thailand are made up of overhead lines as it is much cheaper than underground cabling. With the fast-paced economic and population growth in major cities, the demand for electricity is increasing rapidly. To meet the increasing demand, Provincial Electricity Authority (PEA) has to expand its distribution networks amidst construction restrictions in overhead lines and growing demand for power quality and safety. Therefore, PEA has planned to build new underground cabling systems so as to enhance and expand its power distribution network. PEA has also committed to change a portion of overhead line systems to underground cabling. However, both short and long term planning was required for this series of changes as PEA needed to consider its operating capability and availability of financial and human resources. There is also an obligation to cause minimal disruption to the public transportation system during the course of construction. In essence, PEA was resolute to serve its strategic objectives to deliver service quality and achieve business growth.

2.2 Project Planning Criteria 2.2.1 Objectives

• • • • • •

To change from overhead line to underground cabling system. To increase power system stability and reliability To enhance urban landscape To increase safety of electrical systems at public places To improve electrical systems according to the requirement of the Government and other agencies To serve the increasing demand from the end-users

Conversion of Overhead Lines to Underground Cabling Handbook |

8

2.2.2 Scope of Work

• To change from 22, 33 kV overhead line system to underground cabling system

• To change from low voltage utility pole to underground cabling system • To enhance undergrounding systems in urban area and/or municipal areas that requires power reliability and security

2.2.3 Location Surveying and Selection As undergrounding conversion warrants huge investment, PEA takes into consideration specific needs per land type based on the nature of dwellings and land use.

• • • • • •

Area Type 1: High Technology Industry Areas Area Type 2: Provincial Large Town Central Business District Area Type 3: Commercial Tourist Center Areas Area Type 4: Historical and/or Aesthetically Important Areas Area Type 5: Suburban New Housing Development Areas Area Type 6: Municipal Policy and Funding: areas designed for underground power cable system

Power distribution for Areas 1, 2, and 3 must provide high level of power stability, power reliability, and power quality. Because Area 4 contains land use of historic and aesthetic importance, it is necessary to design a power supply system that protects the original environment with minimal disturbance in its surrounding landscape. In Area 5 which is mainly made up of new housing development, an undergrounding system will have to be incorporated into the overall design of the township. Lastly, Area 6 must be planned and designed to meet safety requirement and power reliability according to the municipal policy. The proposed security levels and design criteria for various supply areas is given in Table 2.1. 2.2.4 Project Management 2.2.4.1 Organizational Management Structure PEA collaborates with the municipality who supports in terms of construction budgeting, provision of facilities within the construction area and coordination of other infrastructure such as telecommunication and waterworks. PEA

9 |

Conversion of Overhead Lines to Underground Cabling Handbook

Type

Description

Security and Reliability Level

1

Provincial large town central business district

N-1 open loop system, < 1 min interruption or N-1 closed loop system, no outage

2

Areas of historic and/or aesthetic importance

N-0 radial system or N-1 open loop system, > 1 min interruption

3

Commercial tourist center N-1 open loop system, > 1 min interruption area

4

High technology industry area

N-1 closed loop system, no outage

5

Suburban new housing development area

N-1 open loop system, > 1 min interruption

6

Municipal policy and funding areas

N-0 radial system or N-1 open loop system, > 1 min interruption

Table 2.1: The proposed security levels and design criteria for the various supply areas • • •

N is number of system components, 0 and 1 is the number of spare system component N-0 means that the power system has a reserved capacity or a configuration such that in the event of an outage of any single component, the power supply can be continued or restored without the need to repair the faulted system component. N-1 means that the power system has a reserved capacity or a configuration such that in the event of an outage of any single component, the power supply can be continued or restored without the need to repair the faulted system component.

takes key responsibility of overall construction supervision, inclusive of budgeting for underground power cable system and coordination with other affiliated agencies. The construction office is made up of a project manager and engineers who have experience in implementing action plans and running construction projects. The undergrounding system is designed in accordance to PEA’s standards while the project manager holds the responsibility to provide situational assessment in adopting standard procedures. 2.2.4.2 Acquisition and Procurement Procedure All construction material acquisition and procurement must be made based on PEA Material Acquisition Policy. The construction office provides technical specifications for tender documents and also evaluates technical and price proposals from all potential vendors. While a municipality is responsible for civil works such as creating duct bank, manhole and other related works, PEA is responsible for designing underground power cabling system, providing

Conversion of Overhead Lines to Underground Cabling Handbook |

10

and installing electrical equipment. Thereafter, PEA shall sign procurement contracts with contractors and hands over the construction area within one year after the end of the civil works. In the event the civil works is delayed or discontinued, PEA shall retain the right to postpone signing a contract or call off tender offers without having to make compensation. 2.2.4.3 Design and Construction Underground cabling system shall be designed to comply with PEA’s standard and installed to comply with the standard of Engineering Institute of Thailand in ensuring minimum disturbance to residents in the construction area. A permit to allow the installation of electrical equipment will be helpful in resolving disputes in the future. Undergound cabling system construction is carried out by PEA or a contractor working under the close supervision of PEA’s engineers and officers at every stage of the construction. 2.2.4.4 Construction Project Planning To raise the quality of life as in developed countries and to attract more tourists, major cities are planning to offer beautiful landscapes and/or scenery that portrays facets of modernization in a developed city. An approach to make cities more beautiful is to convert overhead lines to underground cabling system and reduce visual pollution through disuse of power poles and telecommunication wiring. Power cable conversion can also reduce traffic accidents that cause power outage in the event where power poles were hit by moving vehicles. With the above in perspective, PEA carries out project planning as follows:A. Long Term Plan - PEA sets the sequence of each construction activity during the period of construction such as a five-year plan. The fundamental data must be prepared as listed below:-

• • • •

11 |

Current electricity demand List of street names and the exact location for the construction area Details of investment plan Basic assumption and financial statement letter

Conversion of Overhead Lines to Underground Cabling Handbook

•

Information of ongoing and completed underground power cable systems

B. Short Term Plan - the construction office adjusts the construction plan to cope with arising problems. Under normal circumstances, short term planning is carried out annually by assessing long term plan and adapting with current situation. With this information, the designer indicates scope of work, objectives, extent of work, and budget requirement. Range of short term plan may be around one year. 2.2.4.5 Follow Up and Evaluation PEA shall follow up and evaluate at every phase of the project. The construction office writes a progress report every three months and submits this to related agencies and PEA’s senior executives. A progress report covers details of construction progress, expenditure status, and project setbacks including resolutions to problems.

2.3 Engineering Criteria To serve as guidelines for the design and construction of underground cabling system and clear work procedures, the engineering criteria are illustrated as follows. 2.3.1 Cable Type and Size Underground power cable shall be single core copper XLPE cable with copper screen. The underground cable structure is shown in Figure 2.1 and cable size is shown in Table 2.2.

Figure 2.1: 22, 33 kV Underground Cable Structure

Conversion of Overhead Lines to Underground Cabling Handbook |

12

Nominal crosssectional area of conductor (mm2)

35

50

95

120

185

240

400

500

Min. number of wires in conductor

6

6

15

18

30

34

53

53

6.95

8.33

11.45

12.95

15.98

18.47

23.39

26.67

28

30.5

35.5

39.0

Diameter of conductor + 1% (mm) Approx conductor screen thickness (mm)

0.5

Thickness of insulation (mm)

5.5

Diameter over insulation, approx. (mm)

19.0

20.5

23.5

25

Thickness of insulation screen, approx. (mm)

0.5

Total crosssectional area of copper wire screen, minimum (mm2)

10

10

10

10

25

25

25

25

Number of wire screen, minimum

20

20

20

20

30

30

30

30

Thickness of nonmetallic sheath (mm)

1.8

1.8

1.9

2.0

2.1

2.2

2.4

2.6

Overall diameter, approx. (mm)

28

30

33

34

38

42

48

52

Max. DC resistance of conductor at 20°C (Ω/km)

0.524

0.387

0.193

0.153

0.0991

0.0754

0.0470

0.0366

Table 2.2: Technical Data of 22 kV XLPE Underground

13 |

Conversion of Overhead Lines to Underground Cabling Handbook

2.3.2 Electrical Distribution Configuration 2.3.2.1 Radial System This configuration of underground system has only one supply side and distributes power to users via switch and circuit break according to PEA’s specification as shown in Figure 2.2.

Figure 2.2: Radial System

2.3.2.2 Open Loop System This configuration of underground system has at least two supply sides and users receive power from one side (not both); and distributes power to end customers via switch and circuit breaker according to PEA’s specification as shown in Figure 2.3.

Figure 2.3: Open Loop System

2.3.2.3 Open Loop System with Special Spare Line This configuration of underground system has at least two supply sides and users receive power from one side (not both); and distributes power to end

Conversion of Overhead Lines to Underground Cabling Handbook |

14

customers via switch and circuit breaker according to PEA’s specification. There is a special spare line in case of emergency. Figure 2.4 shows Open Loop System with Special Spare Line. 2.3.2.4 Closed Loop System This configuration of underground system has at least two supply sides and users receive power from one side (not both), and distributes power to end customers via circuit breaker and automatic switch, shown in Figure 2.5, but this system is not popular since it requires large capital investment.

Figure 2.4: Open Loop System with Special Spare Line

Figure 2.5: Close Loop System

15 |

Conversion of Overhead Lines to Underground Cabling Handbook

2.3.3 Type of Construction 2.3.3.1 Open-cut method (1) Concrete Encased Duct Bank (2) Semi-Direct Burial (3) Direct Burial 2.3.3.2 No-dig method (1) Horizontal Directional Drilling (HDD) (2) Pipe Jacking The construction methods are explained in Chapter 3.

2.4

Key Success Factors

The key success factors for converting overhead line to underground power cabling system lie in the hands of many parties. Among these are municipalities, telecommunication agencies, and infrastructure agencies. Therefore, coordination is a crucial factor, leading to the success of a project. Other factors are:

• • • •

Mutual Agreement and community participation in the construction process such as construction planning, design, and control budget etc. The coordination among parties related to project Availability of capital investment and cost appraisal Efficiency in project management and resource planning because it requires coordination with other infrastructure agencies in the construction area to prepare budget and time frame to relocate other telecommunication systems during or before completion of construction

Last but not least, city planning is also one of the critical considerations to ensure construction efficiency. A good plan can support the construction of other infrastructures. For example, the determination of an exact location of infrastructures will help to reduce land revocation to construct sidewalk or road surface.

Conversion of Overhead Lines to Underground Cabling Handbook |

16

Chapter 3 UNDERGROUND CABLING SYSTEM 3.1 Introduction Having a sound construction design in an undergrounding project affects power security, investment, and living conditions of residents who live or work near the affected area. Among the many construction designs, the designer must study and understand how to select the most appropriate construction method and equipment to avoid extensive road repairs and disruption to the public transportation system.

3.2 Site Survey and Detailed Design 3.2.1 Site Survey The design engineer must survey site location before the actual on-site construction starts work. Key information relating to design requirement include: 1) Information on existing overhead line system – in order to plan and design the distribution system for underground cables, the survey engineer needs to gather existing electrical information on the construction area in order to study how the current electrical system is configured such as the number of medium and low voltage circuits that are installed; the types, sizes and number of conductors used; the number of transformers (owned by PEA as well as end users) that are installed in the construction area; and the total electricity load in the construction area. After collecting the information and data, the surveying engineer has to validate data accuracy against PEA’s GIS data. Because there is a huge amount of data collected, the surveying engineer also has to take pictures of the area surveyed to serve as references for design and validation purposes. 2) Physical characteristics of the survey area - Physical characteristics of the survey area will determine the appropriate construction types or methods.

17 |

Conversion of Overhead Lines to Underground Cabling Handbook

Information on the density and sizes of building, street dimensions, dimensions for sidewalks and walkways must be recorded for plannning and designing the preliminary cable layout. If there is enough space at the sidewalks, power cables can be laid underneath sidewalks. If there is not enough space, power cables are laid underneath the road surface. 3) Current demand and future forecast - this information is vital to determine the number and sizes of transformers or the appropriate configuration including a five year power distribution plan upon completion of an underground cabling system. Current demand may be calculated based on electricity tariff; while future forecast may be a projection computed based on power usage from all circuits of power substations supplying to the construction site. 4) Visible and invisible infrastructure in the construction area – The survey engineer shall coordinate with all agencies and obtain rightful information from respective agencies on visible and invisible infrastructure in the affected area. These include pipe work, telecommunication system and existing underground power cable. Surveyors must also conduct preliminary check of all signs such as utility pipe sign, water work sign, and so on. Figure 3.1 shows the sign for a high pressure gas pipe.

Figure 3.1: High pressure gas pipe warning - “Caution! High pressure gas pipe. Do not bury, dig or construct before permission. In case of leakage or damaging, please inform PTT (Petrolium company)”

Physical examination of the road structure can be carried out by using an underground detection instrument, also known as Ground Penetration Radar (GPR). GPR is a fast-performing and a non-destructive testing equipment that

Conversion of Overhead Lines to Underground Cabling Handbook |

18

uses electromagnetic waves to detect reflection wave and analyze road structure such as ground surface density. Figure 3.2 shows the GPR testing equipment. Figure 3.3 illustrates the result from GPR.

Figure 3.2: GPR testing equipment

Figure 3.3: An example result from GPR

5) A well-furnished construction plan, covering both present and future needs, helps the design engineer to factor in additional or future development, e.g. annual development plan of municipalities. The design engineer estimates the power capacity required to support future expansion plans in terms of sizes and transformers’ location, sizes and circuit’s cables, preparation for appropriate extra manholes and conduits.

19 |

Conversion of Overhead Lines to Underground Cabling Handbook

6) Cable layout and equipment arrangement determine area size for an undergrounding route and the position of equipment fixture to avoid colliding with other agencies’ installation. 7) The types and methods of an undergrounding construction (e.g. compact unit substation or platform, open-cut method or no-dig method) must meet the specifications of land area and resource budget, because the area density is crucial in determining the type of constructions. For instance, sidewalks in some cities may have enough space to accumulate a compact unit substation or Ring Main Unit (RMU), while others offers limited space which only platform type may be suitable. 8) There are several types of important information that contribute to the success of the project. Knowing which time slot in a day to carry out construction works helps to reduce the traffic congestion. Rainfall information or maximum flood water level is important in determining the height of equipment installation and the foundation work of manholes i.e. whether concrete reinforcement is needed. 3.2.2 Design After gathering all the important data, the design engineer evaluates and checks for data accuracy. The steps for design construction are described below. 1) Group end users by current and future electricity usage; and consider load density when designing load distribution to support load expansion 2) In designing electrical system based on PEA’s standards, the design engineer uses commercial software such as Auto CAD to design 2D dimensions, as 3D designing software is not adopted yet. However, the design plan corresponds with data from the survey and complies with PEA’s design regulations in order to support current and future expansion:•

Service continuity is an important consideration in configuring the underground cabling system which must comply with PEA’s regulations and be appropriate for respective site locations. For instance, if the cable of PEA’s main feeder is damaged, an open loop system is preferred. For

Conversion of Overhead Lines to Underground Cabling Handbook |

20

customer’s feeder, the choice between open loop and radial distribution is considered as proper. For electrical equipment such as transformer platforms, riser pole, compact unit substation, ring main unit (RMU), meters etc, the installation should be appropriate for the area. Electrical equipment is installed on side road to minimize visual pollution or obstruction. •

The size of transformers is based on normal load operations. In most situations, PEA has several popular sizes of transformer, 500 kVA and 100 kVA. Transformers are installed at the center of loads taking into account voltage drop and cable tension. The installation or placement of other electrical equipment i.e. distribution box, meter cabinet, and ground connection must comply with PEA’s regulation.

•

The positions of high voltage cable riser and low voltage cable riser are laid down in PEA’s regulation.

•

Cable sizes are dependent on current and future loads and will determine the number of medium voltage and low voltage circuits. For 22 kV systems, PEA normally uses single core conductor with 240 sq mm. For connection to individual customers, the main feeder shall be 185 sq mm. and the customer feeder shall be 95 sq mm.

•

In converting overhead lines to underground cabling the existing ground system may cause high current short circuit if it is direct grounding. The neutral grounding resistor or resonance grounding should therefore be replaced to extend equipment lifespan and increase safety as well as to improve power quality.

3) Civil works must be done in compliance with PEA standards and electrical works:•

Types of construction methods (open cut or no-dig method) are dependent on on-site factors such as whether excavation can be carried out over a period of time and the road traffic conditions. Design engineers shall work closely with local authorities to reduce congestion. Types of construction

21 |

Conversion of Overhead Lines to Underground Cabling Handbook

methods determine types of conduits. If open-cut method is used, High Density Polyethylene (HDPE), Reinforced Thermosetting Resin (RTRC) conduit, or steel conduit may be considered. If Horizontal Directional Drilling (HDD) is used, HDPE is a suitable solution, as it is more soft and flexible than that of RTRC and can be pulled by using HDD machine. Soil bearing capacity needs to be assessed to determine whether foundation piles are rquired in ethe construction of duct bank and manhole. •

The popular types, sizes, and numbers of conduit for an current and future underground power cable are 160 sq mm in 22 kV and 110 sq mm in low voltage and the number of spare conduits shall correspond with the number of power cables in future.

•

Types and location of medium voltage and low voltage hand holes must cater for current and future growth. The manhole selection shall be matched by applications. Also, the manhole shall accommodate enough conduits for expansion. Manhole position is normally located at T-junction or end users’ main entry. Additionally, there should be a number of medium voltage manholes for the future.

•

The number of cable entries for medium voltage and low voltage shall be made enough for all end users. Typically, cable entry’s location is located in “Soi” to avoid blocking scenery. Cable conduits for 22 kV are installed in end users’ area. For low voltage, one set of cable conduits is located at the corner of the buildings and it shall be connected to end user via the ceiling, but for single household, conduit location may be separately specified for each house.

•

Main switchboard and meters shall not block scenery and/or installed in high risk area that is prone to cause accidents. Main switchboard shall be located near loads to prevent voltage drop and losses for long distance cable line.

•

When design and construction plan are completed, the design engineer shall validate the construction plan and make physical examination on-site.

Conversion of Overhead Lines to Underground Cabling Handbook |

22

3.3 Method for Construction For the construction of underground cabling, the contractor must be familiar with the construction area, existing distribution system, and new distribution system including electrical equipment location as mentioned earlier. Figure 3.4 illustrates an example of configuration used for construction.

Figure 3.4: An example of configuration used for construction

Sidewalks are usually narrow and power cable cannot be buried underneath, but laid at the first traffic lane besides the sidewalk. Establishing a divert signboard or road barricades is recommended and a lid to cover the manhole is needed to ensure public safety. Several construction methods are available for consideration:3.3.1 Open Cut Methods Open cut method has 3 types: 1) Concrete Encased Duct Bank - This method uses High Density Polyethylene (HDPE) or Reinforced Thermosetting Resin Conduit (RTRC) to encase power

23 |

Conversion of Overhead Lines to Underground Cabling Handbook

cable and then enclose with reinforced concrete. Reinforced concrete provides mechanical protection for power cable. Concrete encased duct bank needs manholes to pull, splice and split power cables or if a contractor needs to lay power cable in a curved line, a contractor shall use cable route marker to show duct bank line. A hole is created deep and wide enough for the construction to take place. Then, before laying conduits, restoring and placing route marker, steel bars must be bound in place as shown in Figure 3.5.

Figure 3.5: Concrete encased duct bank, RTRC (red), and HDPE (black)

If concrete-encased duct bank or medium voltage manhole and low voltage hand hole, or prefabricated medium voltage manhole and low voltage hand hole is used, it will reduce the steps and duration of construction for civil works. 2) Semi-Direct Burial - For this method, the cable runs through a flexible corrugated conduit made of HDPE or RTRC. This construction method needs block of concrete spacers to maintain the distance between each conduit. Figure 3.6 illustrated the construction steps in creating a recess, compacting sand and laying conduit. Figure 3.7 illustrated steps in laying concrete slab, putting up warning sign straps, restoring area and installing markers to show cable line.

Figure 3.6: Lay conduit using Concrete Spacer Block

Conversion of Overhead Lines to Underground Cabling Handbook |

24

Figure 3.7: Concrete slab (right) and markers to show cable line (right)

However, like concrete encased duct bank, this method need route markers place along the route to indicate presence of manhole and hand hole. 3) Direct Burial - The cable does not run through conduits in reinforced concrete. Instead, the cable is laid directly in the soil at depth that is recommended in applied standard. Compacting sand, laying power cable, and then covering concrete slab and putting warning sign strap over the pavement, and restoring area are the steps involved in the construction. Cable route markers are placed along the route to indicate presence of an underground cable under the pavement. This also serves as a warning to other utilities and municipality contractors to be cautious when digging near the cable route area. This method does not require manhole and hand hole. Figure 3.8 show a cross-sectional view of this method.

Figure 3.8: Cross-section of direct burial (Note: unit is in millimeter, D is diameter of power cable)

25 |

Conversion of Overhead Lines to Underground Cabling Handbook

3.3.2 No-dig Methods No-dig methods consist of two methods as below: 1) Horizontal Directional Drilling (HDD) - The cable runs through a conduit made of High Density Polyethylene (HDPE) pipe. This construction method involves a machine to drill a line with a depth that is recommended before changing to back reaming and extending the drill hole progressively. After drilling is completed, the contractor pulls HDPE pipe starting from the finishing point. This construction method does not use encasement in concrete or concrete slabs to protect cables. Like concrete encased duck bank, this construction method needs route markers to indicate cable location and route as shown in Figure 3.9.

Figure 3.9: HDD machine is working (above) and pulling conduits (below)

Figure 3.10: Horizontal Directional Drilling (HDD), drilling (left) and pulling (right)

2) Pipe Jacking - This method starts with digging - two manholes, i.e. receiving manhole and sending manhole. A pipe jacking machine is installed at the sending

Conversion of Overhead Lines to Underground Cabling Handbook |

26

manhole, using hydrolic to push a pipe until it reaches the receiving manhole as shown in Figure 3.11. After installing HPDE or RTRC inside a pipe, contractor will inject mortar inside the pipe and restore area as shown in Figure 3.12. Cable route markers are installed to indicate cable location and route.

Figure 3.11: Pushing a pipe by using Pipe jacking machine in sending manhole

Figure 3.12: Electrical conduits in pipe after injecting mortar

Like concrete encased duct bank, this construction method needs manhole and hand hole and cable route markers are installed to indicate cable location and route. The advantage and disadvantage of these methods can be summarized in Table 3.1.

27 |

Conversion of Overhead Lines to Underground Cabling Handbook

3.4 Construction Methods Comparison The following tables discussed the different construction methods and the respective comparison of construction cost. Open Cut Methods

No-dig Methods

Direct Burial

Semi Direct Burial

Concrete Encased Duct Bank

HDD.

Pipe Jacking

Safety of Underground Power Cables

*

**

***

**

***

Change or Increase Size of Cables in The Future

*

***

***

***

***

Avoidance Underground Obstacles During Installation

***

***

**

**

*

Cost of Construction

***

**

**

*

*

Items

Duration of Construction

***

**

*

**

*

Ventilation Ability

***

**

*

**

*

Damage to a Nearby Cable During Short Circuit

*

**

***

**

***

Cost of Restoring Surface

*

*

*

**

**

Subsidence Chance During Construction

**

**

**

*

*

Complexity in Construction

***

***

**

**

*

Construction Impact on Nearby Residents

*

*

*

**

**

Space for Installation of Construction Equipment

***

***

**

*

*

Table 3.1: The advantage and disadvantage of each construction method

Conversion of Overhead Lines to Underground Cabling Handbook |

28

Methods of Construction

Estimated Cost (Million Baht)

Multiplier* 0.75

Overhead Line 185 sq.mm.

Bare Cable

1.5

Aerial Cable

2.0

1

Underground XLPE Cable 240 sq.mm.

Direct Burial

11

5.5

Semi – Direct Burial

14.5

7.25

Duct Bank

15

7.5

Horizontal Directional Drilling (HDD)

16

8

Pipe Jacking (Small sleeve)

20

10

Table 3.2: Cost comparison of construction methods for 22kV per 1 circuit-kilometer

Methods of Construction

Estimated Cost (Million Baht)

Multiplier*

Overhead Line 95 sq.mm.

PVC Insulated Cables

0.8

1

Underground XLPE Cable 185 sq.mm.

Direct Burial

5.5

6.87

Semi – Direct Burial

6.5

8.12

Duct Bank

8

10

Horizontal Directional Drilling (HDD)

10

12.50

Table 3.3: Cost comparison of construction methods for low voltage 400/230 V per 1 circuit-kilometer

3.5 Electrical Equipment for an Underground Power Cable System 3.5.1 Transformers For an underground power cabling system, types of transformer installation are different depending on factors such as power security, capital investment, location for installation. Types of transformer installation can be divided into two types: 1) Transformer Platform - If compact unit substation cannot be installed on sidewalk, an alternative method is to use transformer platform. There are two types of transformer platforms, single pole and double poles. This method is relatively cheap and requires small installation area, because transformer and

29 |

Conversion of Overhead Lines to Underground Cabling Handbook

other electrical equipment are installed on power pole. Low voltage fuse and circuit breaker are equipped on single pole. 160kVA or 250 kVA transformer can be installed on single pole as shown in Figure 3.13. 315kVA, 400kVA, or 500kVA can be installed on double pole as shown in Figure 3.14.

Figure 3.13: Transformer installed on single pole

Figure 3.14: Transformer installed on double pole

2) Compact Unit Substation - Compact unit substation is used in the area where aesthetic preservation and power security are prerequisites. There must be enough space for the installation too. However, the downside is its high cost. Number of compact unit substations is dependent on load requirement. PEA has 630kVA and 1000kVA of compact unit substation as shown in Figure 3.15 and 3.16, respectively.

Figure 3.15: Undecorated Compact Unit Substation

Figure 3.16: Decorated Compact Unit Substation

Conversion of Overhead Lines to Underground Cabling Handbook |

30

Compact unit substation consists of three compartments, which are: a) High voltage room contains Ring Main Unit (RMU), 22kV or 33kV that connects to the open loop. RMU can be operated by closing or opening under load current. The transformer feeder can be equipped with fuse or circuit breaker as required. As PEA’s regulation, RMU is contained in totally SF6 gas insulated gas-tight steel tank and degree of protection is specified as IP34. RMU’s medium voltage part consists of two types of feeders: 1) cable feeder switch which normally has two to three switches, connecting to power feeder via XLPE cable size 240 sq.mm. 2) Transformer feeder switch which normally has at maximum two switches, connecting to transformer via XLPE cable size 50 sq.mm.

Figure 3.17: SF6 Ring Main Unit

b) Transformer room has IP34 enclosure protection. Transformer room shall have ventilation and is sealed to avoid pests like rodents. Types of transformer are three-phase oil immersed permanently sealed and completely oil filled system (without gas cushion), and natural self-cooled type. Transformer capacity is up to 1,000kVA. However, popular capacities are 500kVA and 630kVA with 22kV-400/230v and 33kV-400/230v

31 |

Conversion of Overhead Lines to Underground Cabling Handbook

c) Low voltage room has IP34 enclosure protection, containing low voltage switching, local control panel, distribution management system (DMS) interfacing equipment, and others. Incoming and outgoing is equipped with threephase molded case circuit-breaker; MCCB subject to IEC 60947-2 latest edition. Considerations of compact unit substation enclosure include:

• • •

Pass internal arc test according to PHELA No. 4, IEC 60298 latest edition, or IEC 61330 latest edition Strong enough to protect live parts of transformer and switchgear from external impact Numerous types to install in construction area

And internal arrangement include:

• • •

Frontal access (only single door is need to access equipment) Diagonal access (easy to arrange equipment and suitable for large equipment) Longitudinal access (narrow enclosure to avoid obstruction for sidewalk installation

Transformer Size (kVA)

Transformer Installation Cost (Million Baht) Single Pole

Double Poles

Compact Unit Substation

160

0.4

0.5

-

250

0.5

0.6

-

500

-

0.8

3

630

-

1.0

3.5

1,000

-

1.2

4

Table 3.4: Cost comparison for transformer installation

Consideration Factors

Transformer Installation Power Poles

Compact Unit Substation

Power Stability

*

**

Safety

*

**

***

*

*

**

***

*

Capital Investment Beauty Used Space

Table 3.5: Comparison factors to consider for transformer installation

Conversion of Overhead Lines to Underground Cabling Handbook |

32

3.5.2 Riser Pole Riser pole is medium voltage equipment for converting overhead line to underground power cable. Riser pole consists of cable termination, disconnecting switch or drop out fuse, lightning arrestor, and conduit protecting power cable. Grounding process includes measuring soil’s resistance at the spot of installation. Soil at some locations may need additional conductive element. The resistance measurement is subject to international standards such as IEC. The equipment’s selection, disconnecting switch or drop out fuse is dependent on load as proper. Riser pole is shown in Figure 3.18.

Figure 3.18: Riser pole 22kV

33 |

Conversion of Overhead Lines to Underground Cabling Handbook

3.5.3 Service Line Service line is used to feed power to end users. Main components of service line are service entrance, circuit breaker (mounted in box), steel conduit for protection for an underground cable, and grounding. Service line can be installed into building walls from feeder power with existing riser wall; or on power pole to feed power to end users who live in smaller lanes as shown in Figure 3.19 and 3.20, respectively.

Figure 3.19: Riser wall for low voltage side

Conversion of Overhead Lines to Underground Cabling Handbook |

34

Figure 3.20: Riser pole for low voltage side

3.5.4 Distribution Box Distribution box is low voltage distribution equipment that supplies power to end users and is connected to transformer for emergency case. Main components - two main circuit breakers and branch circuit breakers - feed power to each end user via electrical panel box. Figure 3.21 illustrates a distribution box.

35 |

Conversion of Overhead Lines to Underground Cabling Handbook

Figure 3.21: Distribution box

3.5.5 Meter Cabinet Meter cabinet is low voltage meter that cannot be installed at house’s wall as shown in Figure 3.22 with following recommendation:1) It can be installed near to a fence, house’s pole, or building’s pole 2) Water proof connection shall have the same rating as rated current or load and shall be disconnected whenever required. 3) Circuit breakers are installed at outgoing line to prevent short circuit in main feeder of main entrance or end users’ building. 4) Connect circuit breaker directly to equipment, but connection point shall be secured. 5) Use hinge that can be dismantled from steel frame. Water proof handle may be locked by master key. 6) Cable resistance between conductor and meter’s surface must higher than 0.5 mega ohms. 7) Wiring work in cabinet shall include warning sign, phase specification and the number of circuit for easy maintenance.

Conversion of Overhead Lines to Underground Cabling Handbook |

36