Generator Protn

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Generator Protn as PDF for free.

More details

- Words: 5,739

- Pages: 111

Loading documents preview...

Generator Protection

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Generator Protection

The extent and types of protection specified will depend on the following factors :-

• Type of prime mover and generator construction • MW and voltage ratings • Mode of operation • Method of connection to the power system • Method of earthing

Generator Protection - P 2

Generator Protection • Types of Prime Mover − − − −

Steam Turbines Gas Turbines Hydro Diesel

• Construction

− Cylindrial Rotor − Salient Pole (Hydro and small generators)

• Mode of operation

− Base load − Peak lopping − Standby

• Ratings

− Power from 200kVA to 1000MVA − Voltage from 440V to 24kV

Generator Protection - P 3

Connection to the Power System 1. Direct :

2. Via Transformer :

Generator Protection - P 4

Generator Protection Requirements • To detect faults on the generator • To protection generator from the effects of abnormal power system operating conditions • To isolate generator from system faults not cleared remotely • Action required depends upon the nature of the fault. • Usual to segregate protection functions into : − Urgent − Non-urgent − Alarm Generator Protection - P 5

Generator Faults

Mixture of mechanical and electrical problems. Faults include :• Insulation Failure

• • • • • •

− Stator − Rotor

Excitation system failure Prime mover / governor failure Bearing Failure Excessive vibration Low steam pressure etc.

Generator Protection - P 6

System Conditions

• • • • •

Short circuits Overloads Loss of load Unbalanced load Loss of synchronism

Generator Protection - P 7

Generator Failure

Generator Protection - P 8

Generator Failure

Generator Protection - P 9

Generator Failure

Generator Protection - P 10

Generator Failure

Generator Protection - P 11

Stator Earth Fault Protection Fault caused by failure of stator winding insulation Leads to

burning of machine core welding of laminations

Rebuilding of machine core can be a very expensive process Earth fault protection is therefore a principal feature of any generator protection package TYPE OF PROTECTION

Generator Protection - P 12

OF

METHOD EARTHING

OF

METHOD CONNECTION

Method of Earthing

Machine stator windings are surrounded by a mass of earthed metal Most probable result of stator winding insulation failure is a phase-earth fault Desirable to earth neutral point of generator to prevent dangerous transient overvoltages during arcing earth faults Several methods of earthing are in use Damage resulting from a stator earth fault will depend upon the earthing arrangement

Generator Protection - P 13

Method of Earthing Solidly Earthed Machines : • Fault current is high

• Rapid damage occurs

− burning of core iron − welding of laminations

• Used on LV machines only

Generator Protection - P 14

Method of Earthing Generator - Transformer Units

IF ~ 10 15 A

IF ~ 200 300 A

Generator Protection - P 15

Method of Earthing Desirable to limit earth fault current : − limits damage − reduces possibility of developing into phase - phase fault

Degree to which fault current is limited must take into account : − detection of earth faults as near as possible to the neutral point − ease of discrimination with system earth fault protection (directly connected machines)

Generator Protection - P 16

Method of Earthing : Fault Current

F

Limitation of Earth

Earth faults on the power system are not seen by the generator earth fault protection.

Discrimination not required can limit current to very low value. Sometimes down to 5A

Generator Protection - P 17

Method of Earthing : Fault Current Limit To Generator Full Load Current

• Most popular. • Used for ease of fault detection and discrimination. • Residual connection of CTs can be used • Can result in serious core damage.

Generator Protection - P 18

Limitation of Earth

Stator Earth Fault Protection Directly Connected Generators :

51N

Earthed Generator : Earth fault relay must be time delayed for co-ordination with other earth fault protection on the power system.

Unearthed Generators : Other generators connected in parallel will generally be unearthed.

50N

51N

Protection is restricted to faults on the generator, grading with power system earth fault protection is not required. A high impedance instantaneous relay can be used (Balanced Earth Fault protection). Generator Protection - P 19

Percentage Winding Protected 11.5kV; 75,000KVA

xV

250/1A

IS

ΙF

xV R

For operation ΙS(PRIMARY)

ΙF xV R x.6600 x.200 33 1 x.200 x 0.8x 250

R

33 ΙS(SECONDARY)

For protection of 90% of winding; x = 1-0.9 = 0.1 Relay setting = 0.8 x 0.1 = 0.08A = 8% of 1A

Generator Protection - P 20

Stator Earth Fault Protection Generators connected via step-up transformer (resistance earthed) :

51N

50N

Instantaneous protection (50N) : System earth faults ARE not seen by generator earth fault protection instantaneous relay may be used. Set to 10% of resistor rating (avoids operation due to transient surges passed through generator transformer interwinding capacitance). Advantage : Fast

Generator Protection - P 21

Stator Earth Fault Protection

Time delayed protection (51N) : Time delay prevents operation on transient surges.

A more sensitive current setting may be used. Set to 5% of resistor rating. Advantage : Sensitive On large machines considered worthwhile to use both instantaneous and time delayed.

Generator Protection - P 22

Restricted Earth Fault Protection

RSTAB

64

Protects approx. 90 - 95% of generator winding.

Generator Protection - P 23

Connections for Biased REF 2000/1 ?

500/1 ?

P342/3 Relay Terminal CT Inputs

z E/F CT Input

• Smaller rating machines may have only one (neutral) tail CT brought out for connection Generator Protection - P 24

Biased REF Protection Operating Characteristic 3

Differential current (x In) =I

A

+I

B

+I

C

+k.I

2

Operate

N

1 Restrain

• High sensitivity (5%) • Unit Protection • FAST

K1 0

1

2

3

Effective bias (x In) = Max. phase current + k . I 2

Generator Protection - P 25

4

N

Neutral Displacement / Residual Overvoltage - Earth Fault Protection

1 3

2

P340 Relay

(1) Derived measurement from 5-limb or 3 x 1 phase VT

(2) Directly measured from a broken delta VT input (3) Directly measured across an earthing resistor Generator Protection - P 26

Stator Earth Fault Protection

• 100% Stator Earth Fault Protection : • Standard relays only cover 95% of winding.

• Probability of fault occurring in end 5% is low. • On large machines 100% stator earth fault protection may be required.

• Two methods : − Low Frequency Injection − Third Harmonic Voltage Measurement Generator Protection - P 27

100% Stator Earth Fault Protection (27TN)

1 3

2

P340 Relay

(1) Derived measurement from 5-limb or 3 x 1 phase VT (2) 3rd harmonic overvoltage (3) 3rd harmonic undervoltage • 3rd harmonic undervoltage supervised by 3 phase undervoltage and W/VA/Var at generator terminals Generator Protection - P 28

100% Stator Earth Fault Protection

Distribution of 3rd harmonic voltage along the stator winding • (a) normal operation • (b) stator earth fault at star point • (c) stator earth fault at the terminals Generator Protection - P 29

100% Stator Earth Fault Low Frequency Injection For Large Machines Only

• Injection Frequency 12.5 20Hz

Injection Transformer

51

Alternative Injection Points

• Provides protection during run up & Standstill • High cost due to injection equipment.

Generator Protection - P 30

Overcurrent Protection • For small generators this may be the only protection applied. • With solid earthing it will provide some protection against earth faults. • For a single generator, CTs must be connected to neutral end of stator winding.

51

Generator Protection - P 31

Overcurrent Protection • For parallel generators, CTs can be located on line side.

51

Generator Protection - P 32

Differential Protection • Provides high speed protection for all fault types • May be : High impedance type : Biased (low impedance) type CT’s required in neutral end of winding

Relay Generator Protection - P 34

Differential Protection - Biased

BIAS

BIAS

OPERATE

Biased Differential Scheme Generator Protection - P 35

Differential Protection

INTERPOSING C.T.

Overall Differential Scheme

Generator Protection - P 36

Interturn Protection (50DT)

IA2

IB2

IC2

Independent current settings per phase Single stage definite time delay Generator Protection - P 37

Neutral Displacement / Residual Overvoltage - Interturn Protection (59N)

1 3

2

Gen Relay

(1) Interturn, derived measurement from 5-limb or 3 x 1 phase VT (2) Interturn, directly measured from a broken delta VT input (3) 95% stator earth fault protection across an earthing resistor

Generator Protection - P 38

Prime Mover Failure Isolated Generators : Machine slows down and stops. Other protection initiates shut down.

Parallel Sets : System supplies power - generator operates as a motor. Seriousness depends on type of drive.

Steam Turbine Sets : Steam acts as a coolant. Loss of steam causes overheating. Turbulence in trapped steam causes distortion of turbine blades. Motoring power 0.5% to 6% rated. Condensing turbines, rate of heating slow. Loss of steam instantly recognised.

Generator Protection - P 39

Prime Mover Failure Diesel Driven Sets : Prime mover failure due to mechanical fault. Serious mechanical damage if allowed to persist. Motoring power from 35% rated for stiff machine, to 5% rated for run in machine.

Gas Turbines : Motoring power 100% rated for single shaft machine, 10% to 15% rated for double shaft.

Hydro Sets : Mechanical precautions taken if water level drops. Low head types - erosion and cavitation of runner can occur. Additional protection may be required.

Generator Protection - P 40

Prime Mover Failure

Reverse Power Protection : Reverse power measuring relays used where protection required.

Single phase relay is sufficient as prime mover failure results in balanced conditions. Sensitive settings required - metering class CTs required for accuracy.

Generator Protection - P 41

Reverse Power Operational limits

P

a natural = 0.16 o

Q

a stable = 0.5 o

Unstable area

-P= P0

Unstable area Trip area

• Blinders at 0.5 degrees reduces operation area for low power settings where the power factor is low to improve reliability of reverse power element Generator Protection - P 42

Low Forward Power Operational limits Trip area

P

Unstable area Extended Trip area a stable = 0.5 o P= P0

0

Q

Trip area

• To reduce the risk of overspeed damage to steam turbine generators a low forward power element is used for interlocking the generator CB and excitation for non urgent trips (eg thermal protection, stator earth fault for high impedance earthing). • Turbine steam valves are tripped immediatelay and when power output has reduced the generator CB and excitation are tripped. Generator Protection - P 43

Loss of Excitation Effects Single Generator : − Loses output volts and therefore load. Parallel Generators :

− Operate as induction generator (> synch speed) − Flux provided by reactive stator current drawn from system-leading pf − Slip frequency current induced in rotor - abnormal heating Situation does not require immediate tripping, however, large machines have short thermal time constants - should be unloaded in a few seconds. Generator Protection - P 44

Loss of Excitation Impedance seen by relay follows locus shown below : X

Load Impedance

Impedance Locus

R Offset – Prevents operation on pole slips Diameter

Typically : Offset 50-75%X’d Diameter 50-100% XS Generator Protection - P 45

Relay Characteristic Time Delayed

Pole Slipping Sudden changes or shocks in an electrical power system may lead to power system oscillations - regular variations of I and V and angular system separation In a recoverable situation these oscillations will die away a power swing In an unrecoverable situation the oscillations become so severe that synchronisation between the generator and the power system is lost - out of step/pole slipping

Causes − − − −

Transient system faults Failure of the generator governor Failure of the generators excitation control Reconnection of an islanded system without synchronisation − Switching transients on a weak system Generator Protection - P 47

Pole slipping Recoverable Out-of-Step Power Swing

(Power System)

Unrecoverable Loss of Synchronism Pole-Slipping (Generator) Generator Protection - P 48

Theory of pole slipping

Simplified Two Machine System:

Where: EG represents the generator terminal voltage; ZG represents the generator reactance; ZT is the reactance of step-up transform;

Zs represents the impedance of the power system connected to the generation unit Es represents the system voltage.

Generator Protection - P 49

Loss of synchronisation Characteristics X EG/ES=1

S

EG/ES>1 L R

G

Generator Protection - P 51

EG/ES<1

Conventional Pole Slipping Protection Blinder X

Reactance Line

ZA

Zone 2

ZC

Zone 1

a

q

Lens ZB

Generator Protection - P 53

R

Pole Slipping Protection - 78

• Conventional lenticular (lens) characteristic − − − −

2 Zones defined by reactance line Zone 1 - pole slip in the generator Zone 2 - pole slip in the power system Separate counters per zone (1-20)

• Setting to detect pole slipping when : − Generating − Motoring − Both (Pumped storage generator)

Generator Protection - P 54

Pole Slipping Protection - 78

• Pole slip when generating − − − − − − − −

Impedance position on RHS of lens characteristic Impedance crosses lens on RHS Impedance spends >T1 (15ms) in RHS of lens Impedance spends >T2 (15ms) in LHS of lens Impedance leaves lens on LHS Zone 1 and 2 counter is incremented if in Z1 Zone 2 counter is incremented if in Z2 Trip when zone counter value exceeded

• Pole slipping when motoring is the opposite

Generator Protection - P 55

State Transition Diagram (Reset_Timer Time Out)

State Machine Entry

Actions are the same as State Machine Entry

Reset Trip_ Signals; Reset Start_ Signals; Reset Flag_Zone1; Reset All Counters; Reset All Timers;

No Signal Condition* Actions are the same as State Machine Entry

VTS-FAST-BLOCK Zm = R1 or R3

Actions are the same as State Machine Entry

IDLE Zm = R1 . Reset Start_Signals; Reset Flag_Zone1; IF(Any Trip_Signal) Reset Counters; Reset Trip_Signals;

Zm = R4 IF(Mode_Both) Flag_Mode=!Flag_Mode;

Zm = R2 Start Timer1 Zm = R1 or R4 Reset Timer1 Zm = R3 but Timer1

Zm = R4 or R2 or R3

DETECTED

Zm = R4 but Timer2 < T2 Reset Flag_Zone1; Reset Timer2;

(Zm = R4) & Timer2 > T2) If (C2==0) Start Reset_Timer; C2++; Set Zone2_Start; if(C2>=Count2) Set Zone2_Trip ; If (Flag_Zone1) C1++; Set Zone1_Start; if(C1>=Count1) Set Zone1_Trip; Reset Timer2;

Zm = R1 or R2 Reset Flag_Zone1; Reset Timer2;

Zm = R2

START

(Zm = R3) & Timer1 > T1) Flag_Zone1=Zone1Pu(); Reset Timer1; Start Timer2;

CONFIRM

*No Signal Condition (VA<1V or I <0.02A) Zm = R3

Generator Protection - P 56

RTDS Pole Slip Simulation

Local Load 132 kV BUS

T/line 140 km

132/13.5 kV

11 kV BUS

Yd1 Grid System

Generator Protection - P 57

Generator with AVR and Governor control

Pole Slipping - 80% Load, Local 3 ph fault

Generator Protection - P 58

Loss of excitation at 100% machine loading

Generator Protection - P 59

Rotor Thermal Protection

• Unbalanced loading leads to negative sequence current • Double frequency slip • Rapid overheating of rotor Generator Protection - P 60

Unbalanced Loading

• Gives rise to negative phase sequence (NPS) currents results in contra-rotating magnetic field

• Stator flux cuts rotor at twice synchronous speed • Induces double frequency current in field system and rotor body • Resulting eddy currents cause severe over heating − Use negative sequence overcurrent relay − Relay should have inverse time characteristic to match generator I22t withstand

Generator Protection - P 61

Unbalanced Loading

• Machines are assigned NPS current withstand values : − Continuous NPS rating, I2R (PU CMR) − Short time NPS rating, I22t (K)

• If possible level of system unbalance approaches machine continuous withstand, protection is required.

Generator Protection - P 62

Overload Protection high load current heating of stator and rotor insulation failure Governor Setting Should prevent serious overload automatically. Generator may lose speed if required load can not be met by other sources. Generator Protection - P 63

Stator Thermal Protection Current operated

− Over power protection − Overcurrent element − Thermal replica RTD Thermal Probes

− PT100 Platinum probes − Embedded in machine − Alarm and trip thresholds for each RTD

Generator Protection - P 64

Overload Protection (1)

• Thermal replica for stator overload protection − − − −

Current based on I1 and I2 Heating and cooling time constants Non-volatile memory thermal state Alarm output

Time

Current Generator Protection - P 65

Rotor Earth Fault Protection

Field circuit is an isolated DC system. • Insulation failure at a single point : − No fault current, therefore no danger − Increase chance of second fault occurring

• Insulation failure at a second point : − Shorts out part of field winding − Heating (burning of conductor) − Flux distortion causing violent vibration of rotor

• Desirable to detect presence of first earth fault and give an alarm.

Generator Protection - P 66

Rotor Earth Fault Protection Potentiometer Method

Exciter

R

• Required sensitivity approximately 5% exciter voltage. • No auxiliary supply required. • “Blind spot” - require manually operated push button to vary tapping point. Generator Protection - P 67

Rotor Earth Fault Protection AC Injection Method

• Brushless Machines

AC Auxiliary Supply R

• No access to rotor circuit • Require special slip rings for measurement • If slip rings not present, must use telemetering techniques (expensive) Generator Protection - P 68

Rotor Earth Fault Protection Brushless Machine A brushless generator has an excitation system consisting of: − A main excitor with rotating armature and stationary field windings − A rotating rectifier assembly, carried on the main shaft line out − A controlled rectifier producing the d.c. field voltage for the main exciter field from the a.c. source (often a small `pilot` exciter) Hence: − − − −

Generator Protection - P 69

No brushes are required in the field circuit All control is carried out in the field circuit of the main exciter Detection of rotor circuit earth fault is still necessary Based on dedicated rotor-mounted system that has a telemetry link to provide an alarm/data

Generator Back-Up Protection Overcurrent Protection Typical use : − Very or extremely inverse for LV machines − Normal inverse for HV machines

Must consider generator voltage decrement characteristic for close-in faults. With reliable AVR system, “conventional” overcurrent relays may be used. Otherwise, voltage controlled / restrained relays are required. 10 x FL

with AVR Full Load

Generator Protection - P 70

no AVR Cycles

Generator Back-Up Protection Overcurrent Protection Voltage Restrained • •

Operating characteristic is continuously varied depending on measured volts. Alternatively, use impedance relay.

Voltage Controlled •

Relay switches between fault characteristic and load characteristic depending on measured volts.

F

Generator Protection - P 71

Generator Back-Up Protection (2) 10 O/L CHARAC

1.0

FAULT CHARAC LARGEST OUTGOING FEEDER

t sec

GENERATOR DECREMENT CURVE

0.1

0.01 100

240 600 1000 3000

Generator Protection - P 72

10,000 AMPS

6.6kV 5MVA 115% XS 500/5 200/5

Voltage Dependent Overcurrent Protection (51V)

I>

I> Fault

Load

k.I>

Fault

Load

k.I> Terminal Volts Voltage control

Generator Protection - P 73

Terminal Volts Voltage restraint

Impedance Relay X Load Fault R Underimpedance

• 2 Zones of protection − Zone 1 - Set to operate at 70% rated load impedance. Back-up protection for generator-transformer, busbar and outgoing feeders. Time delayed for co-ordination with external feeder phase fault protection. − Zone 2 – Set to 50% transformer impedance. Back-up protection for generator phase faults. Faster time delay to coordinate with generator phase fault protection Generator Protection - P 74

Under & Over Frequency Conditions

Over Frequency

• Results from generator over speed caused by sudden loss of load. • In isolated generators may be due to failure of speed governing system.

• Over speed protection may be provided by mechanical means. • Desirable to have over frequency relay with more sensitive settings.

Generator Protection - P 75

Under & Over Frequency Conditions Under Frequency • Results from loss of synchronous speed due to excessive overload. • In isolated generators may be due to failure of speed governing system. • Under frequency condition gives rise to: − Overfluxing of stator core at nominal volts − Plant drives operating at lower speeds - can affect generator output − Mechanical resonant condition in turbines

• Desirable to supply an under frequency relay. • Protection may be arranged to initiate load shedding as a first step. Generator Protection - P 76

df/dt (81R) Loadshedding df/dt+t: Time Delayed ROCOF

• • • •

Df/dt can operate quicker than underfrequency for large changes in frequency Rolling window is better than fixed window as gives faster operation Averaging cycles is typically 5 to provide some stability for power system oscillations Stages can be used for load shedding or alarm/tripping of the generator

Generator Protection - P 77

Under & Over Voltage Conditions

Protection

• Under & over voltage protection usually provided as part of excitation system. • For most applications an additional high set over voltage relay is sufficient.

• Time delayed under and over voltage protection may be provided.

Generator Protection - P 78

Under & Over Voltage Conditions Over Voltage

• Results from generator over speed caused by sudden loss of load. • May be due to failure of the voltage regulator. • An over voltage condition : − −

Causes overfluxing at nominal frequency Endangers integrity of insulation

Under Voltage • No danger to generator. May cause stalling of motors. • Prolonged under voltage indicates abnormal conditions. Generator Protection - P 79

Generator Abnormal Frequency Protection (81AB) • 6 independent bands of abnormal frequency protection • Accumulation of time up to 1000 hours in each band • Band data provided by generator manufacturer • Bands match resonance, blade stress frequencies … •

Dead band timer before accumulation starts allows time for resonance to established

• When generator is off-line bands can be blocked Generator Protection - P 80

Generator Abnormal Frequency Protection (81AB) Band 1 f nom Band 2

Band 3 Band 4

Timer 1 Timer 2 Timer 3 Timer 4 Generator Protection - P 81

Application Negative Sequence Overvoltage (47)

Busbar

Swapping of 2 phases to motor (pump water) CB

a b c

b a c

Generator/Motor

Block CB Close

Generator/Motor 47

Negative Sequence Overvoltage

Hydro machines can operate as motors/pumps by swapping 2 phases (phase rotation is reversed) Generator Protection - P 82

Use of Alternative Setting Groups Example : Pumped Storage Unit When the units are being used to generate power the protection could be as below:

87G 27 & 59 81U & 81O 32R 51N 40 51V 46

Generator differential Under & over voltage Under & over frequency Reverse power Stator earth fault Loss of excitation Voltage dependent overcurrent Negative phase sequence

1 2 3 4 When the units pump water the protection applied will change

Generator Protection - P 83

Four groups available

Phase Rotation • Phase rotation for hydro generator/motor applications where 2 phases are swapped to make the machine operate as a pump (motor) CT1

CT2

G

x Phase Reversal Switches

P340 Case 1 : Phase Reversal Switches affecting all CTs and VTs

CT1

CT2

G

x Phase Reversal Switches

P343/4/5

Case 2 : Phase Reversal Switches affecting CT1 only Generator Protection - P 84

Phase Rotation • Phase rotation settings can be changed for generator/motor operation using 2 setting groups Setting SYSTEM CONFIG Phase Sequence VT Reversal

CT1 Reversal

CT2 Reversal (P343/4/5 only)

Generator Protection - P 85

Range

Default

Standard ABC / Reverse ACB No Swap / A-B Swapped / B-C Swapped / C-A Swapped No Swap / A-B Swapped / B-C Swapped / C-A Swapped No Swap / A-B Swapped / B-C Swapped / C-A Swapped

Standard ABC No Swap

No Swap

No Swap

Unintentional Energisation at Standstill

50

&

27 &

tPU tDO

VTS • Overcurrent element detects breaker flashover or starting current (as motor) • Three phase undervoltage detection • VTS function checks no VT anomalies Generator Protection - P 86

Trip

Check Synch (25)

• Check is used when closing generator CB to ensure synchronism with system voltage. • Check synch relay usually checks 3 things: − Phase angle difference − Voltage − Frequency difference

Generator Protection - P 87

Check Synchronising (25) • Phase angle difference − Single phase comparison • Can select either A-N, B-N, C-N, A-B, B-C, C-A is settings

− Typical setting is 20º to reduce mechanical stresses on generators.

• Voltage − Check synch relay inoperative if :• Generator/busbar voltage is below or above preset limit (independent settings for generator and busbar under/overvoltages) • voltage difference exceeds preset limit

− Typical settings for undervoltage: 80 - 85% Vn − Typical settings for difference voltage: 6 - 10% Vn

• Frequency difference − Usually measured by time to traverse phase angle limits or direct slip frequency measurement (Fgen – Fbus) • Eg Timer setting of 2 secs over 20º : • Slip frequency = 2 x (20 x ½) / 360 = 0.055Hz = 0.11% (50Hz) • Timer usually set to 2 secs or 10 x C.B. closing time whichever is greater). Generator Protection - P 88

Check Synchronising (25) • Check synch has 2 stages – Check Sync 1/2 − Usually only 1 stage is required for generator applications − Check Sync 2 has CB closing time compensation − Check Sync2 only permits closure for decreasing angles of slip

• Check synch has vector compensation to account for phase shift across transformer with Main VT Vect Grp setting 0-11 • Check synch has ratio correction to correct ratio errors of VTs • Voltage monitors for dead/live generator/busbar • System Split output operates for phase angle > setting adjustable from 90 to 175 degrees

Generator Protection - P 89

Check Synch (25)

Check synch stages 1 and 2 Generator Protection - P 90

Typical Schemes

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Protection Package for Diesel Generator

87 G

32 64R 64S 51V

64 R 32

51 V

Reverse Power Rotor Earth Fault Stator Earth Fault Voltage Dependent Overcurrent 87G Generator Differential Protection P343

64 R

Generator Protection - P 93

Overall Protection of Generator Installation Generator Feeder Protn. Overcurrent Voltage Restraint

51 V

Restricted E/F

Buchholz Winding Temp.

Reverse Power

32

Field Failure

40

Generator Differential Rotor E/F

64R

Overall Gen/Trans Diffl Protn.

Generator Protection - P 94

87

Prime Mover Protection Negative Phase Sequence

Stator E/F

64S

46

Overall Protection of Generator Installation Generator Feeder Protection O/C

Circuit Breaker Fail

Busbar Protection

Restricted E/F

Buchholz Winding Temperature

O/C + E/F

Buchholz

O/C

V.T.s Transformer Overfluxing Permissive (Low Power) Interlock

Standby E/F Restricted E/F

Pole Slipping

Field Failure Generator Differential

Unit Transformer Differential Protn.

Overall Generator Transformer Differential Protn.

Rotor E/F

Low Steam Pressure, Loss of Vacuum Loss of Lubricating Oil Loss of Boiler Water Governor Failure Vibration, Rotor Distortion Negative Phase Sequence

Stator E/F Protection

Generator Protection - P 95

Embedded Generation

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Co-generation/Embedded Machines

AR?

81U/O

Frequency

27/59

Voltage

50/51N 47/46

59N

Residual Voltage

df/dt

ROCOF

dV

Voltage Vector Shift

Generator Protection - P 97

O/C & E/F NPS Voltage NPS O/C

25

PES system

Check Synch

Islanded load fed unearthed

Embedded Generation

USED TO PROVIDE:

• Emergency Power Upon Loss Of Main Supply • Operate In Parallel To Reduce Site Demand • Excess Generation May Be Exported Or Sold

Generator Protection - P 98

Engineering Recommendation G59

• ER G59 relates to the connection of generating plant to the distribution systems of licensed distribution network operators (DNOs) • ER G83/1 covers connection of generating units rated < 16A / phase in parallel with LV distribution system • ER G59 COVERS: − − − −

Safety Aspects Legal Requirements Operation Protection

Generator Protection - P 99

Engineering Recommendation G59 General Requirements Protective Equipment • The main function of the protection systems and settings is to prevent Generating Plant supporting an islanded section of the Distribution System when it would or could pose a hazard to the Distribution System or customers connected to it.

Generator Protection - P 100

Engineering Recommendation G59 LoM (Loss of Mains = Islanding) Protection Requirements • To disconnect the Generating Plant from the Distribution System in the event of loss of one or more phases of the DNOs supply. • LoM is required to ensure requirements for earthing and out of synch closure are complied with and customers are not supplied with voltage and frequency outside statutory limits

Generator Protection - P 101

Loss of Mains Problem • Loss of mains is where a generator is inadvertently isolated from the grid and continues to supply local load

33kV DISTRIBUTION

33/11kV

CIRCUIT BREAKER

BUS-BAR FAULT

• Loss of mains can be caused by: − Protection tripping

SECTIONALISING SWITCH

400V DG

Generator Protection - P 102

− Accidentally due to network reconfiguration

Loss of Mains Problem

Islanding is unacceptable for a number of reasons: − Safety risk - for example, through personnel working on the network under the assumption that no parts of the network are energised − Stresses from out of synchronism re-closure

− Loss of system earth where the earth is on the star winding of a network transformer. This can cause problems for existing earth fault protection to detect earth faults if the system is unearthed. − Utility is legally bound to maintaining quality of supply (frequency and voltage ) to local demand.

Generator Protection - P 103

Existing LoM Methods – Performance Assessment

• Loss of mains performance can be assessed in terms of sensitivity and stability • Sensitivity − Smallest possible mismatch between local generation and the demand at the instant of islanding. − Also referred to as non-detection zone

• Stability − Stability for different fault types with varying duration and retained voltage at the point of measurement

• When designing LoM method objective is to have a small non detection zone and be stable for as many fault characteristics as possible STABILITY Network faults

SENSITIVITY Generator/demand Imbalance Generator Protection - P 104

Existing Loss of Mains Methods • Passive Methods − Under/over frequency and voltage • Requires large change in load, time delayed − Df/dt – rate of change of frequency • Sensitive, fast operating − Voltage vector shift • Not as sensitive as df/dt, fast operating − Direct inter-tripping • Not load dependent, fast, expensive, signalling can be complex

• Active Methods − Active frequency drift − Reactive Error export

• There is an abundance of active methods proposed in the technical literature, however, their application in practice has been limited to date. The traditional protection philosophy of independence from other systems makes the introduction of these methods difficult. Generator Protection - P 105

Loss of Mains Methods – Voltage Vector Shift

Single phase line diagram showing generator parameters

jX

R E

Generator Protection - P 107

IL VT

Loss of Mains Methods – Voltage Vector Shift

Vector Diagram Representing Steady State Condition

E

IL

Generator Protection - P 108

VT

IL X ILR

Loss of Mains Methods – Voltage Vector Shift Transient voltage vector change q due to change in load current IL

E

q

IL

VT VT

IL Generator Protection - P 109

ILX ILR

ILX”

Loss of Mains Methods - ROCOF df/dt The rate of change of speed, or frequency, following a power disturbance can be approximated by: P.f df/dt =

where

2GH

P = Change in power output between synchronised and islanded operation f = Rated frequency G = Machine rate MVA H = Inertia constant

Generator Protection - P 110

Loss of Mains Methods - ROCOF P341 df/dt calculation

df/dt =

Fn - fn - 3 cycle

3 cycle Two consecutive calculations must give a result above the setting threshold before a trip decision can be initiated

Generator Protection - P 111

Loss of Mains Methods - ROCOF df/dt+t: Time Delayed ROCOF t Start

Pick up cycles

Trip f

Time delay df/dt Setting

Generator Protection - P 112

G59 Other Protection • Neutral voltage • Overcurrent • Earth fault • Phase unbalance • Reverse power − Used when generator does not export power during normal operation

Generator Protection - P 113

G59 Protection Settings Protection Settings for Long-Term Parallel Operation Prot Function

Small Power Station LV Connected

Medium Power Station HV Connected

Setting

Time

Setting

Time

Setting

Time

U/V st 1

Vph-n -13%

2.5s*

Vph-ph -13%

2.5s

Vph-ph -20%

2.5s*

U/V st 2

Vph-n -20%

0.5s

Vph-ph -20%

0.5s

O/V st 1

Vph-n +10%

1.0s

Vph-ph +10%

1.0s

Vph-ph +10%

1.0s

O/V st 2

Vph-n +15%

0.5s

Vph-ph +13%

0.5s

U/F st 1

47.5Hz

20s

47.5Hz

20s

47.5Hz

20s

U/F st 2

47Hz

0.5s

47Hz

0.5s

47Hz

0.5s

O/F st 1

51.5Hz

90s

51.5Hz

90s

51.5Hz

90s

O/F st 2

52Hz

0.5s

52Hz

0.5s

LoM (Vector Shift)

K1 x 6 degrees

K1 x 6 degrees

Intertripping expected

LoM (RoCoF)

K1 x 0.125 Hz/s

K2 x 0.125Hz/s

Intertripping expected

Notes: K1 = 1.0 (low impedance networks or 1.66-2 (high impedance networks) K2 = 1.0 (low impedance networks or 1.6 (high impedance networks) A fault level of < 10% system design max fault level is high impedance * Might need to be reduced if auto-reclose time <3s Generator Protection - P 114

G59 Protection for HV Generator connected to DNO HV System for Parallel Operation Only

Generator Protection - P 115

G59 Protection for HV Generator connected to DNO HV System for Standby and Parallel Operation

Generator Protection - P 116

www.alstom.com

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Generator Protection

The extent and types of protection specified will depend on the following factors :-

• Type of prime mover and generator construction • MW and voltage ratings • Mode of operation • Method of connection to the power system • Method of earthing

Generator Protection - P 2

Generator Protection • Types of Prime Mover − − − −

Steam Turbines Gas Turbines Hydro Diesel

• Construction

− Cylindrial Rotor − Salient Pole (Hydro and small generators)

• Mode of operation

− Base load − Peak lopping − Standby

• Ratings

− Power from 200kVA to 1000MVA − Voltage from 440V to 24kV

Generator Protection - P 3

Connection to the Power System 1. Direct :

2. Via Transformer :

Generator Protection - P 4

Generator Protection Requirements • To detect faults on the generator • To protection generator from the effects of abnormal power system operating conditions • To isolate generator from system faults not cleared remotely • Action required depends upon the nature of the fault. • Usual to segregate protection functions into : − Urgent − Non-urgent − Alarm Generator Protection - P 5

Generator Faults

Mixture of mechanical and electrical problems. Faults include :• Insulation Failure

• • • • • •

− Stator − Rotor

Excitation system failure Prime mover / governor failure Bearing Failure Excessive vibration Low steam pressure etc.

Generator Protection - P 6

System Conditions

• • • • •

Short circuits Overloads Loss of load Unbalanced load Loss of synchronism

Generator Protection - P 7

Generator Failure

Generator Protection - P 8

Generator Failure

Generator Protection - P 9

Generator Failure

Generator Protection - P 10

Generator Failure

Generator Protection - P 11

Stator Earth Fault Protection Fault caused by failure of stator winding insulation Leads to

burning of machine core welding of laminations

Rebuilding of machine core can be a very expensive process Earth fault protection is therefore a principal feature of any generator protection package TYPE OF PROTECTION

Generator Protection - P 12

OF

METHOD EARTHING

OF

METHOD CONNECTION

Method of Earthing

Machine stator windings are surrounded by a mass of earthed metal Most probable result of stator winding insulation failure is a phase-earth fault Desirable to earth neutral point of generator to prevent dangerous transient overvoltages during arcing earth faults Several methods of earthing are in use Damage resulting from a stator earth fault will depend upon the earthing arrangement

Generator Protection - P 13

Method of Earthing Solidly Earthed Machines : • Fault current is high

• Rapid damage occurs

− burning of core iron − welding of laminations

• Used on LV machines only

Generator Protection - P 14

Method of Earthing Generator - Transformer Units

IF ~ 10 15 A

IF ~ 200 300 A

Generator Protection - P 15

Method of Earthing Desirable to limit earth fault current : − limits damage − reduces possibility of developing into phase - phase fault

Degree to which fault current is limited must take into account : − detection of earth faults as near as possible to the neutral point − ease of discrimination with system earth fault protection (directly connected machines)

Generator Protection - P 16

Method of Earthing : Fault Current

F

Limitation of Earth

Earth faults on the power system are not seen by the generator earth fault protection.

Discrimination not required can limit current to very low value. Sometimes down to 5A

Generator Protection - P 17

Method of Earthing : Fault Current Limit To Generator Full Load Current

• Most popular. • Used for ease of fault detection and discrimination. • Residual connection of CTs can be used • Can result in serious core damage.

Generator Protection - P 18

Limitation of Earth

Stator Earth Fault Protection Directly Connected Generators :

51N

Earthed Generator : Earth fault relay must be time delayed for co-ordination with other earth fault protection on the power system.

Unearthed Generators : Other generators connected in parallel will generally be unearthed.

50N

51N

Protection is restricted to faults on the generator, grading with power system earth fault protection is not required. A high impedance instantaneous relay can be used (Balanced Earth Fault protection). Generator Protection - P 19

Percentage Winding Protected 11.5kV; 75,000KVA

xV

250/1A

IS

ΙF

xV R

For operation ΙS(PRIMARY)

ΙF xV R x.6600 x.200 33 1 x.200 x 0.8x 250

R

33 ΙS(SECONDARY)

For protection of 90% of winding; x = 1-0.9 = 0.1 Relay setting = 0.8 x 0.1 = 0.08A = 8% of 1A

Generator Protection - P 20

Stator Earth Fault Protection Generators connected via step-up transformer (resistance earthed) :

51N

50N

Instantaneous protection (50N) : System earth faults ARE not seen by generator earth fault protection instantaneous relay may be used. Set to 10% of resistor rating (avoids operation due to transient surges passed through generator transformer interwinding capacitance). Advantage : Fast

Generator Protection - P 21

Stator Earth Fault Protection

Time delayed protection (51N) : Time delay prevents operation on transient surges.

A more sensitive current setting may be used. Set to 5% of resistor rating. Advantage : Sensitive On large machines considered worthwhile to use both instantaneous and time delayed.

Generator Protection - P 22

Restricted Earth Fault Protection

RSTAB

64

Protects approx. 90 - 95% of generator winding.

Generator Protection - P 23

Connections for Biased REF 2000/1 ?

500/1 ?

P342/3 Relay Terminal CT Inputs

z E/F CT Input

• Smaller rating machines may have only one (neutral) tail CT brought out for connection Generator Protection - P 24

Biased REF Protection Operating Characteristic 3

Differential current (x In) =I

A

+I

B

+I

C

+k.I

2

Operate

N

1 Restrain

• High sensitivity (5%) • Unit Protection • FAST

K1 0

1

2

3

Effective bias (x In) = Max. phase current + k . I 2

Generator Protection - P 25

4

N

Neutral Displacement / Residual Overvoltage - Earth Fault Protection

1 3

2

P340 Relay

(1) Derived measurement from 5-limb or 3 x 1 phase VT

(2) Directly measured from a broken delta VT input (3) Directly measured across an earthing resistor Generator Protection - P 26

Stator Earth Fault Protection

• 100% Stator Earth Fault Protection : • Standard relays only cover 95% of winding.

• Probability of fault occurring in end 5% is low. • On large machines 100% stator earth fault protection may be required.

• Two methods : − Low Frequency Injection − Third Harmonic Voltage Measurement Generator Protection - P 27

100% Stator Earth Fault Protection (27TN)

1 3

2

P340 Relay

(1) Derived measurement from 5-limb or 3 x 1 phase VT (2) 3rd harmonic overvoltage (3) 3rd harmonic undervoltage • 3rd harmonic undervoltage supervised by 3 phase undervoltage and W/VA/Var at generator terminals Generator Protection - P 28

100% Stator Earth Fault Protection

Distribution of 3rd harmonic voltage along the stator winding • (a) normal operation • (b) stator earth fault at star point • (c) stator earth fault at the terminals Generator Protection - P 29

100% Stator Earth Fault Low Frequency Injection For Large Machines Only

• Injection Frequency 12.5 20Hz

Injection Transformer

51

Alternative Injection Points

• Provides protection during run up & Standstill • High cost due to injection equipment.

Generator Protection - P 30

Overcurrent Protection • For small generators this may be the only protection applied. • With solid earthing it will provide some protection against earth faults. • For a single generator, CTs must be connected to neutral end of stator winding.

51

Generator Protection - P 31

Overcurrent Protection • For parallel generators, CTs can be located on line side.

51

Generator Protection - P 32

Differential Protection • Provides high speed protection for all fault types • May be : High impedance type : Biased (low impedance) type CT’s required in neutral end of winding

Relay Generator Protection - P 34

Differential Protection - Biased

BIAS

BIAS

OPERATE

Biased Differential Scheme Generator Protection - P 35

Differential Protection

INTERPOSING C.T.

Overall Differential Scheme

Generator Protection - P 36

Interturn Protection (50DT)

IA2

IB2

IC2

Independent current settings per phase Single stage definite time delay Generator Protection - P 37

Neutral Displacement / Residual Overvoltage - Interturn Protection (59N)

1 3

2

Gen Relay

(1) Interturn, derived measurement from 5-limb or 3 x 1 phase VT (2) Interturn, directly measured from a broken delta VT input (3) 95% stator earth fault protection across an earthing resistor

Generator Protection - P 38

Prime Mover Failure Isolated Generators : Machine slows down and stops. Other protection initiates shut down.

Parallel Sets : System supplies power - generator operates as a motor. Seriousness depends on type of drive.

Steam Turbine Sets : Steam acts as a coolant. Loss of steam causes overheating. Turbulence in trapped steam causes distortion of turbine blades. Motoring power 0.5% to 6% rated. Condensing turbines, rate of heating slow. Loss of steam instantly recognised.

Generator Protection - P 39

Prime Mover Failure Diesel Driven Sets : Prime mover failure due to mechanical fault. Serious mechanical damage if allowed to persist. Motoring power from 35% rated for stiff machine, to 5% rated for run in machine.

Gas Turbines : Motoring power 100% rated for single shaft machine, 10% to 15% rated for double shaft.

Hydro Sets : Mechanical precautions taken if water level drops. Low head types - erosion and cavitation of runner can occur. Additional protection may be required.

Generator Protection - P 40

Prime Mover Failure

Reverse Power Protection : Reverse power measuring relays used where protection required.

Single phase relay is sufficient as prime mover failure results in balanced conditions. Sensitive settings required - metering class CTs required for accuracy.

Generator Protection - P 41

Reverse Power Operational limits

P

a natural = 0.16 o

Q

a stable = 0.5 o

Unstable area

-P= P0

Unstable area Trip area

• Blinders at 0.5 degrees reduces operation area for low power settings where the power factor is low to improve reliability of reverse power element Generator Protection - P 42

Low Forward Power Operational limits Trip area

P

Unstable area Extended Trip area a stable = 0.5 o P= P0

0

Q

Trip area

• To reduce the risk of overspeed damage to steam turbine generators a low forward power element is used for interlocking the generator CB and excitation for non urgent trips (eg thermal protection, stator earth fault for high impedance earthing). • Turbine steam valves are tripped immediatelay and when power output has reduced the generator CB and excitation are tripped. Generator Protection - P 43

Loss of Excitation Effects Single Generator : − Loses output volts and therefore load. Parallel Generators :

− Operate as induction generator (> synch speed) − Flux provided by reactive stator current drawn from system-leading pf − Slip frequency current induced in rotor - abnormal heating Situation does not require immediate tripping, however, large machines have short thermal time constants - should be unloaded in a few seconds. Generator Protection - P 44

Loss of Excitation Impedance seen by relay follows locus shown below : X

Load Impedance

Impedance Locus

R Offset – Prevents operation on pole slips Diameter

Typically : Offset 50-75%X’d Diameter 50-100% XS Generator Protection - P 45

Relay Characteristic Time Delayed

Pole Slipping Sudden changes or shocks in an electrical power system may lead to power system oscillations - regular variations of I and V and angular system separation In a recoverable situation these oscillations will die away a power swing In an unrecoverable situation the oscillations become so severe that synchronisation between the generator and the power system is lost - out of step/pole slipping

Causes − − − −

Transient system faults Failure of the generator governor Failure of the generators excitation control Reconnection of an islanded system without synchronisation − Switching transients on a weak system Generator Protection - P 47

Pole slipping Recoverable Out-of-Step Power Swing

(Power System)

Unrecoverable Loss of Synchronism Pole-Slipping (Generator) Generator Protection - P 48

Theory of pole slipping

Simplified Two Machine System:

Where: EG represents the generator terminal voltage; ZG represents the generator reactance; ZT is the reactance of step-up transform;

Zs represents the impedance of the power system connected to the generation unit Es represents the system voltage.

Generator Protection - P 49

Loss of synchronisation Characteristics X EG/ES=1

S

EG/ES>1 L R

G

Generator Protection - P 51

EG/ES<1

Conventional Pole Slipping Protection Blinder X

Reactance Line

ZA

Zone 2

ZC

Zone 1

a

q

Lens ZB

Generator Protection - P 53

R

Pole Slipping Protection - 78

• Conventional lenticular (lens) characteristic − − − −

2 Zones defined by reactance line Zone 1 - pole slip in the generator Zone 2 - pole slip in the power system Separate counters per zone (1-20)

• Setting to detect pole slipping when : − Generating − Motoring − Both (Pumped storage generator)

Generator Protection - P 54

Pole Slipping Protection - 78

• Pole slip when generating − − − − − − − −

Impedance position on RHS of lens characteristic Impedance crosses lens on RHS Impedance spends >T1 (15ms) in RHS of lens Impedance spends >T2 (15ms) in LHS of lens Impedance leaves lens on LHS Zone 1 and 2 counter is incremented if in Z1 Zone 2 counter is incremented if in Z2 Trip when zone counter value exceeded

• Pole slipping when motoring is the opposite

Generator Protection - P 55

State Transition Diagram (Reset_Timer Time Out)

State Machine Entry

Actions are the same as State Machine Entry

Reset Trip_ Signals; Reset Start_ Signals; Reset Flag_Zone1; Reset All Counters; Reset All Timers;

No Signal Condition* Actions are the same as State Machine Entry

VTS-FAST-BLOCK Zm = R1 or R3

Actions are the same as State Machine Entry

IDLE Zm = R1 . Reset Start_Signals; Reset Flag_Zone1; IF(Any Trip_Signal) Reset Counters; Reset Trip_Signals;

Zm = R4 IF(Mode_Both) Flag_Mode=!Flag_Mode;

Zm = R2 Start Timer1 Zm = R1 or R4 Reset Timer1 Zm = R3 but Timer1

Zm = R4 or R2 or R3

DETECTED

Zm = R4 but Timer2 < T2 Reset Flag_Zone1; Reset Timer2;

(Zm = R4) & Timer2 > T2) If (C2==0) Start Reset_Timer; C2++; Set Zone2_Start; if(C2>=Count2) Set Zone2_Trip ; If (Flag_Zone1) C1++; Set Zone1_Start; if(C1>=Count1) Set Zone1_Trip; Reset Timer2;

Zm = R1 or R2 Reset Flag_Zone1; Reset Timer2;

Zm = R2

START

(Zm = R3) & Timer1 > T1) Flag_Zone1=Zone1Pu(); Reset Timer1; Start Timer2;

CONFIRM

*No Signal Condition (VA<1V or I <0.02A) Zm = R3

Generator Protection - P 56

RTDS Pole Slip Simulation

Local Load 132 kV BUS

T/line 140 km

132/13.5 kV

11 kV BUS

Yd1 Grid System

Generator Protection - P 57

Generator with AVR and Governor control

Pole Slipping - 80% Load, Local 3 ph fault

Generator Protection - P 58

Loss of excitation at 100% machine loading

Generator Protection - P 59

Rotor Thermal Protection

• Unbalanced loading leads to negative sequence current • Double frequency slip • Rapid overheating of rotor Generator Protection - P 60

Unbalanced Loading

• Gives rise to negative phase sequence (NPS) currents results in contra-rotating magnetic field

• Stator flux cuts rotor at twice synchronous speed • Induces double frequency current in field system and rotor body • Resulting eddy currents cause severe over heating − Use negative sequence overcurrent relay − Relay should have inverse time characteristic to match generator I22t withstand

Generator Protection - P 61

Unbalanced Loading

• Machines are assigned NPS current withstand values : − Continuous NPS rating, I2R (PU CMR) − Short time NPS rating, I22t (K)

• If possible level of system unbalance approaches machine continuous withstand, protection is required.

Generator Protection - P 62

Overload Protection high load current heating of stator and rotor insulation failure Governor Setting Should prevent serious overload automatically. Generator may lose speed if required load can not be met by other sources. Generator Protection - P 63

Stator Thermal Protection Current operated

− Over power protection − Overcurrent element − Thermal replica RTD Thermal Probes

− PT100 Platinum probes − Embedded in machine − Alarm and trip thresholds for each RTD

Generator Protection - P 64

Overload Protection (1)

• Thermal replica for stator overload protection − − − −

Current based on I1 and I2 Heating and cooling time constants Non-volatile memory thermal state Alarm output

Time

Current Generator Protection - P 65

Rotor Earth Fault Protection

Field circuit is an isolated DC system. • Insulation failure at a single point : − No fault current, therefore no danger − Increase chance of second fault occurring

• Insulation failure at a second point : − Shorts out part of field winding − Heating (burning of conductor) − Flux distortion causing violent vibration of rotor

• Desirable to detect presence of first earth fault and give an alarm.

Generator Protection - P 66

Rotor Earth Fault Protection Potentiometer Method

Exciter

R

• Required sensitivity approximately 5% exciter voltage. • No auxiliary supply required. • “Blind spot” - require manually operated push button to vary tapping point. Generator Protection - P 67

Rotor Earth Fault Protection AC Injection Method

• Brushless Machines

AC Auxiliary Supply R

• No access to rotor circuit • Require special slip rings for measurement • If slip rings not present, must use telemetering techniques (expensive) Generator Protection - P 68

Rotor Earth Fault Protection Brushless Machine A brushless generator has an excitation system consisting of: − A main excitor with rotating armature and stationary field windings − A rotating rectifier assembly, carried on the main shaft line out − A controlled rectifier producing the d.c. field voltage for the main exciter field from the a.c. source (often a small `pilot` exciter) Hence: − − − −

Generator Protection - P 69

No brushes are required in the field circuit All control is carried out in the field circuit of the main exciter Detection of rotor circuit earth fault is still necessary Based on dedicated rotor-mounted system that has a telemetry link to provide an alarm/data

Generator Back-Up Protection Overcurrent Protection Typical use : − Very or extremely inverse for LV machines − Normal inverse for HV machines

Must consider generator voltage decrement characteristic for close-in faults. With reliable AVR system, “conventional” overcurrent relays may be used. Otherwise, voltage controlled / restrained relays are required. 10 x FL

with AVR Full Load

Generator Protection - P 70

no AVR Cycles

Generator Back-Up Protection Overcurrent Protection Voltage Restrained • •

Operating characteristic is continuously varied depending on measured volts. Alternatively, use impedance relay.

Voltage Controlled •

Relay switches between fault characteristic and load characteristic depending on measured volts.

F

Generator Protection - P 71

Generator Back-Up Protection (2) 10 O/L CHARAC

1.0

FAULT CHARAC LARGEST OUTGOING FEEDER

t sec

GENERATOR DECREMENT CURVE

0.1

0.01 100

240 600 1000 3000

Generator Protection - P 72

10,000 AMPS

6.6kV 5MVA 115% XS 500/5 200/5

Voltage Dependent Overcurrent Protection (51V)

I>

I> Fault

Load

k.I>

Fault

Load

k.I> Terminal Volts Voltage control

Generator Protection - P 73

Terminal Volts Voltage restraint

Impedance Relay X Load Fault R Underimpedance

• 2 Zones of protection − Zone 1 - Set to operate at 70% rated load impedance. Back-up protection for generator-transformer, busbar and outgoing feeders. Time delayed for co-ordination with external feeder phase fault protection. − Zone 2 – Set to 50% transformer impedance. Back-up protection for generator phase faults. Faster time delay to coordinate with generator phase fault protection Generator Protection - P 74

Under & Over Frequency Conditions

Over Frequency

• Results from generator over speed caused by sudden loss of load. • In isolated generators may be due to failure of speed governing system.

• Over speed protection may be provided by mechanical means. • Desirable to have over frequency relay with more sensitive settings.

Generator Protection - P 75

Under & Over Frequency Conditions Under Frequency • Results from loss of synchronous speed due to excessive overload. • In isolated generators may be due to failure of speed governing system. • Under frequency condition gives rise to: − Overfluxing of stator core at nominal volts − Plant drives operating at lower speeds - can affect generator output − Mechanical resonant condition in turbines

• Desirable to supply an under frequency relay. • Protection may be arranged to initiate load shedding as a first step. Generator Protection - P 76

df/dt (81R) Loadshedding df/dt+t: Time Delayed ROCOF

• • • •

Df/dt can operate quicker than underfrequency for large changes in frequency Rolling window is better than fixed window as gives faster operation Averaging cycles is typically 5 to provide some stability for power system oscillations Stages can be used for load shedding or alarm/tripping of the generator

Generator Protection - P 77

Under & Over Voltage Conditions

Protection

• Under & over voltage protection usually provided as part of excitation system. • For most applications an additional high set over voltage relay is sufficient.

• Time delayed under and over voltage protection may be provided.

Generator Protection - P 78

Under & Over Voltage Conditions Over Voltage

• Results from generator over speed caused by sudden loss of load. • May be due to failure of the voltage regulator. • An over voltage condition : − −

Causes overfluxing at nominal frequency Endangers integrity of insulation

Under Voltage • No danger to generator. May cause stalling of motors. • Prolonged under voltage indicates abnormal conditions. Generator Protection - P 79

Generator Abnormal Frequency Protection (81AB) • 6 independent bands of abnormal frequency protection • Accumulation of time up to 1000 hours in each band • Band data provided by generator manufacturer • Bands match resonance, blade stress frequencies … •

Dead band timer before accumulation starts allows time for resonance to established

• When generator is off-line bands can be blocked Generator Protection - P 80

Generator Abnormal Frequency Protection (81AB) Band 1 f nom Band 2

Band 3 Band 4

Timer 1 Timer 2 Timer 3 Timer 4 Generator Protection - P 81

Application Negative Sequence Overvoltage (47)

Busbar

Swapping of 2 phases to motor (pump water) CB

a b c

b a c

Generator/Motor

Block CB Close

Generator/Motor 47

Negative Sequence Overvoltage

Hydro machines can operate as motors/pumps by swapping 2 phases (phase rotation is reversed) Generator Protection - P 82

Use of Alternative Setting Groups Example : Pumped Storage Unit When the units are being used to generate power the protection could be as below:

87G 27 & 59 81U & 81O 32R 51N 40 51V 46

Generator differential Under & over voltage Under & over frequency Reverse power Stator earth fault Loss of excitation Voltage dependent overcurrent Negative phase sequence

1 2 3 4 When the units pump water the protection applied will change

Generator Protection - P 83

Four groups available

Phase Rotation • Phase rotation for hydro generator/motor applications where 2 phases are swapped to make the machine operate as a pump (motor) CT1

CT2

G

x Phase Reversal Switches

P340 Case 1 : Phase Reversal Switches affecting all CTs and VTs

CT1

CT2

G

x Phase Reversal Switches

P343/4/5

Case 2 : Phase Reversal Switches affecting CT1 only Generator Protection - P 84

Phase Rotation • Phase rotation settings can be changed for generator/motor operation using 2 setting groups Setting SYSTEM CONFIG Phase Sequence VT Reversal

CT1 Reversal

CT2 Reversal (P343/4/5 only)

Generator Protection - P 85

Range

Default

Standard ABC / Reverse ACB No Swap / A-B Swapped / B-C Swapped / C-A Swapped No Swap / A-B Swapped / B-C Swapped / C-A Swapped No Swap / A-B Swapped / B-C Swapped / C-A Swapped

Standard ABC No Swap

No Swap

No Swap

Unintentional Energisation at Standstill

50

&

27 &

tPU tDO

VTS • Overcurrent element detects breaker flashover or starting current (as motor) • Three phase undervoltage detection • VTS function checks no VT anomalies Generator Protection - P 86

Trip

Check Synch (25)

• Check is used when closing generator CB to ensure synchronism with system voltage. • Check synch relay usually checks 3 things: − Phase angle difference − Voltage − Frequency difference

Generator Protection - P 87

Check Synchronising (25) • Phase angle difference − Single phase comparison • Can select either A-N, B-N, C-N, A-B, B-C, C-A is settings

− Typical setting is 20º to reduce mechanical stresses on generators.

• Voltage − Check synch relay inoperative if :• Generator/busbar voltage is below or above preset limit (independent settings for generator and busbar under/overvoltages) • voltage difference exceeds preset limit

− Typical settings for undervoltage: 80 - 85% Vn − Typical settings for difference voltage: 6 - 10% Vn

• Frequency difference − Usually measured by time to traverse phase angle limits or direct slip frequency measurement (Fgen – Fbus) • Eg Timer setting of 2 secs over 20º : • Slip frequency = 2 x (20 x ½) / 360 = 0.055Hz = 0.11% (50Hz) • Timer usually set to 2 secs or 10 x C.B. closing time whichever is greater). Generator Protection - P 88

Check Synchronising (25) • Check synch has 2 stages – Check Sync 1/2 − Usually only 1 stage is required for generator applications − Check Sync 2 has CB closing time compensation − Check Sync2 only permits closure for decreasing angles of slip

• Check synch has vector compensation to account for phase shift across transformer with Main VT Vect Grp setting 0-11 • Check synch has ratio correction to correct ratio errors of VTs • Voltage monitors for dead/live generator/busbar • System Split output operates for phase angle > setting adjustable from 90 to 175 degrees

Generator Protection - P 89

Check Synch (25)

Check synch stages 1 and 2 Generator Protection - P 90

Typical Schemes

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Protection Package for Diesel Generator

87 G

32 64R 64S 51V

64 R 32

51 V

Reverse Power Rotor Earth Fault Stator Earth Fault Voltage Dependent Overcurrent 87G Generator Differential Protection P343

64 R

Generator Protection - P 93

Overall Protection of Generator Installation Generator Feeder Protn. Overcurrent Voltage Restraint

51 V

Restricted E/F

Buchholz Winding Temp.

Reverse Power

32

Field Failure

40

Generator Differential Rotor E/F

64R

Overall Gen/Trans Diffl Protn.

Generator Protection - P 94

87

Prime Mover Protection Negative Phase Sequence

Stator E/F

64S

46

Overall Protection of Generator Installation Generator Feeder Protection O/C

Circuit Breaker Fail

Busbar Protection

Restricted E/F

Buchholz Winding Temperature

O/C + E/F

Buchholz

O/C

V.T.s Transformer Overfluxing Permissive (Low Power) Interlock

Standby E/F Restricted E/F

Pole Slipping

Field Failure Generator Differential

Unit Transformer Differential Protn.

Overall Generator Transformer Differential Protn.

Rotor E/F

Low Steam Pressure, Loss of Vacuum Loss of Lubricating Oil Loss of Boiler Water Governor Failure Vibration, Rotor Distortion Negative Phase Sequence

Stator E/F Protection

Generator Protection - P 95

Embedded Generation

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Co-generation/Embedded Machines

AR?

81U/O

Frequency

27/59

Voltage

50/51N 47/46

59N

Residual Voltage

df/dt

ROCOF

dV

Voltage Vector Shift

Generator Protection - P 97

O/C & E/F NPS Voltage NPS O/C

25

PES system

Check Synch

Islanded load fed unearthed

Embedded Generation

USED TO PROVIDE:

• Emergency Power Upon Loss Of Main Supply • Operate In Parallel To Reduce Site Demand • Excess Generation May Be Exported Or Sold

Generator Protection - P 98

Engineering Recommendation G59

• ER G59 relates to the connection of generating plant to the distribution systems of licensed distribution network operators (DNOs) • ER G83/1 covers connection of generating units rated < 16A / phase in parallel with LV distribution system • ER G59 COVERS: − − − −

Safety Aspects Legal Requirements Operation Protection

Generator Protection - P 99

Engineering Recommendation G59 General Requirements Protective Equipment • The main function of the protection systems and settings is to prevent Generating Plant supporting an islanded section of the Distribution System when it would or could pose a hazard to the Distribution System or customers connected to it.

Generator Protection - P 100

Engineering Recommendation G59 LoM (Loss of Mains = Islanding) Protection Requirements • To disconnect the Generating Plant from the Distribution System in the event of loss of one or more phases of the DNOs supply. • LoM is required to ensure requirements for earthing and out of synch closure are complied with and customers are not supplied with voltage and frequency outside statutory limits

Generator Protection - P 101

Loss of Mains Problem • Loss of mains is where a generator is inadvertently isolated from the grid and continues to supply local load

33kV DISTRIBUTION

33/11kV

CIRCUIT BREAKER

BUS-BAR FAULT

• Loss of mains can be caused by: − Protection tripping

SECTIONALISING SWITCH

400V DG

Generator Protection - P 102

− Accidentally due to network reconfiguration

Loss of Mains Problem

Islanding is unacceptable for a number of reasons: − Safety risk - for example, through personnel working on the network under the assumption that no parts of the network are energised − Stresses from out of synchronism re-closure

− Loss of system earth where the earth is on the star winding of a network transformer. This can cause problems for existing earth fault protection to detect earth faults if the system is unearthed. − Utility is legally bound to maintaining quality of supply (frequency and voltage ) to local demand.

Generator Protection - P 103

Existing LoM Methods – Performance Assessment

• Loss of mains performance can be assessed in terms of sensitivity and stability • Sensitivity − Smallest possible mismatch between local generation and the demand at the instant of islanding. − Also referred to as non-detection zone

• Stability − Stability for different fault types with varying duration and retained voltage at the point of measurement

• When designing LoM method objective is to have a small non detection zone and be stable for as many fault characteristics as possible STABILITY Network faults

SENSITIVITY Generator/demand Imbalance Generator Protection - P 104

Existing Loss of Mains Methods • Passive Methods − Under/over frequency and voltage • Requires large change in load, time delayed − Df/dt – rate of change of frequency • Sensitive, fast operating − Voltage vector shift • Not as sensitive as df/dt, fast operating − Direct inter-tripping • Not load dependent, fast, expensive, signalling can be complex

• Active Methods − Active frequency drift − Reactive Error export

• There is an abundance of active methods proposed in the technical literature, however, their application in practice has been limited to date. The traditional protection philosophy of independence from other systems makes the introduction of these methods difficult. Generator Protection - P 105

Loss of Mains Methods – Voltage Vector Shift

Single phase line diagram showing generator parameters

jX

R E

Generator Protection - P 107

IL VT

Loss of Mains Methods – Voltage Vector Shift

Vector Diagram Representing Steady State Condition

E

IL

Generator Protection - P 108

VT

IL X ILR

Loss of Mains Methods – Voltage Vector Shift Transient voltage vector change q due to change in load current IL

E

q

IL

VT VT

IL Generator Protection - P 109

ILX ILR

ILX”

Loss of Mains Methods - ROCOF df/dt The rate of change of speed, or frequency, following a power disturbance can be approximated by: P.f df/dt =

where

2GH

P = Change in power output between synchronised and islanded operation f = Rated frequency G = Machine rate MVA H = Inertia constant

Generator Protection - P 110

Loss of Mains Methods - ROCOF P341 df/dt calculation

df/dt =

Fn - fn - 3 cycle

3 cycle Two consecutive calculations must give a result above the setting threshold before a trip decision can be initiated

Generator Protection - P 111

Loss of Mains Methods - ROCOF df/dt+t: Time Delayed ROCOF t Start

Pick up cycles

Trip f

Time delay df/dt Setting

Generator Protection - P 112

G59 Other Protection • Neutral voltage • Overcurrent • Earth fault • Phase unbalance • Reverse power − Used when generator does not export power during normal operation

Generator Protection - P 113

G59 Protection Settings Protection Settings for Long-Term Parallel Operation Prot Function

Small Power Station LV Connected

Medium Power Station HV Connected

Setting

Time

Setting

Time

Setting

Time

U/V st 1

Vph-n -13%

2.5s*

Vph-ph -13%

2.5s

Vph-ph -20%

2.5s*

U/V st 2

Vph-n -20%

0.5s

Vph-ph -20%

0.5s

O/V st 1

Vph-n +10%

1.0s

Vph-ph +10%

1.0s

Vph-ph +10%

1.0s

O/V st 2

Vph-n +15%

0.5s

Vph-ph +13%

0.5s

U/F st 1

47.5Hz

20s

47.5Hz

20s

47.5Hz

20s

U/F st 2

47Hz

0.5s

47Hz

0.5s

47Hz

0.5s

O/F st 1

51.5Hz

90s

51.5Hz

90s

51.5Hz

90s

O/F st 2

52Hz

0.5s

52Hz

0.5s

LoM (Vector Shift)

K1 x 6 degrees

K1 x 6 degrees

Intertripping expected

LoM (RoCoF)

K1 x 0.125 Hz/s

K2 x 0.125Hz/s

Intertripping expected

Notes: K1 = 1.0 (low impedance networks or 1.66-2 (high impedance networks) K2 = 1.0 (low impedance networks or 1.6 (high impedance networks) A fault level of < 10% system design max fault level is high impedance * Might need to be reduced if auto-reclose time <3s Generator Protection - P 114

G59 Protection for HV Generator connected to DNO HV System for Parallel Operation Only

Generator Protection - P 115

G59 Protection for HV Generator connected to DNO HV System for Standby and Parallel Operation

Generator Protection - P 116

www.alstom.com

GRID Technical Institute

This document is the exclusive property of Alstom Grid and shall not be transmitted by any means, copied, reproduced or modified without the prior written consent of Alstom Grid Technical Institute. All rights reserved.

Related Documents

Generator Protn

March 2021 0

Generator

January 2021 1

Generator Protection

January 2021 1

A.c. Generator

February 2021 0

Generator Protection

March 2021 0

Generator Protection

January 2021 1More Documents from "varadarajanrengasamy"

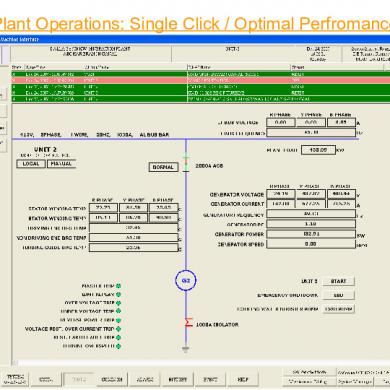

Plant Operations: Single Click / Optimal Perfromance

March 2021 0

Generator Protn

March 2021 0

Opticoelectron 2017 Presentation-v5

January 2021 1