Ieee

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Ieee as PDF for free.

More details

- Words: 18,376

- Pages: 52

Loading documents preview...

IEEE Standard Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

IEEE Power and Energy Society Sponsored by the Switchgear Committee

IEEE 3 Park Avenue New York, NY 10016-5997 USA

IEEE Std C37.63™-2013 (Revision of IEEE Std C37.63-2005)

26 April 2013

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63™-2013 (Revision of IEEE Std C37.63-2005)

IEEE Standard Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV Sponsor

IEEE Switchgear Committee of the

IEEE Power and Energy Society Approved 6 March 2013

IEEE-SA Standards Board

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Abstract: Required definitions, ratings, procedures for performing design tests and production tests, constructional requirements, and application considerations for overhead and padmounted, dry-vault, and submersible automatic line sectionalizers for ac systems are specified. Keywords: automatic line sectionalizers, cutout type, dry-vault, IEEE C37.63TM, pad-mounted, sectionalizers, submersible

The Institute of Electrical and Electronics Engineers, Inc. 3 Park Avenue, New York, NY 10016-5997, USA Copyright © 2013 by The Institute of Electrical and Electronics Engineers, Inc. All rights reserved. Published 26 April 2013. Printed in the United States of America. IEEE is a registered trademark in the U.S. Patent & Trademark Office, owned by The Institute of Electrical and Electronics Engineers, Incorporated. PDF: Print:

ISBN 978-0-7381-8327-5 ISBN 978-0-7381-8328-2

STD98185 STDPD98185

IEEE prohibits discrimination, harassment, and bullying. For more information, visit http://www.ieee.org/web/aboutus/whatis/policies/p9-26.html. No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Notice and Disclaimer of Liability Concerning the Use of IEEE Documents: IEEE Standards documents are developed within the IEEE Societies and the Standards Coordinating Committees of the IEEE Standards Association (IEEE-SA) Standards Board. IEEE develops its standards through a consensus development process, approved by the American National Standards Institute, which brings together volunteers representing varied viewpoints and interests to achieve the final product. Volunteers are not necessarily members of the Institute and serve without compensation. While IEEE administers the process and establishes rules to promote fairness in the consensus development process, IEEE does not independently evaluate, test, or verify the accuracy of any of the information or the soundness of any judgments contained in its standards. Use of an IEEE Standard is wholly voluntary. IEEE disclaims liability for any personal injury, property or other damage, of any nature whatsoever, whether special, indirect, consequential, or compensatory, directly or indirectly resulting from the publication, use of, or reliance upon any IEEE Standard document. IEEE does not warrant or represent the accuracy or content of the material contained in its standards, and expressly disclaims any express or implied warranty, including any implied warranty of merchantability or fitness for a specific purpose, or that the use of the material contained in its standards is free from patent infringement. IEEE Standards documents are supplied “AS IS.” The existence of an IEEE Standard does not imply that there are no other ways to produce, test, measure, purchase, market, or provide other goods and services related to the scope of the IEEE standard. Furthermore, the viewpoint expressed at the time a standard is approved and issued is subject to change brought about through developments in the state of the art and comments received from users of the standard. Every IEEE standard is subjected to review at least every ten years. When a document is more than ten years old and has not undergone a revision process, it is reasonable to conclude that its contents, although still of some value, do not wholly reflect the present state of the art. Users are cautioned to check to determine that they have the latest edition of any IEEE standard. In publishing and making its standards available, IEEE is not suggesting or rendering professional or other services for, or on behalf of, any person or entity. Nor is IEEE undertaking to perform any duty owed by any other person or entity to another. Any person utilizing any IEEE Standards document, should rely upon his or her own independent judgment in the exercise of reasonable care in any given circumstances or, as appropriate, seek the advice of a competent professional in determining the appropriateness of a given IEEE standard. Translations: The IEEE consensus development process involves the review of documents in English only. In the event that an IEEE standard is translated, only the English version published by IEEE should be considered the approved IEEE standard. Official Statements: A statement, written or oral, that is not processed in accordance with the IEEE-SA Standards Board Operations Manual shall not be considered the official position of IEEE or any of its committees and shall not be considered to be, nor be relied upon as, a formal position of IEEE. At lectures, symposia, seminars, or educational courses, an individual presenting information on IEEE standards shall make it clear that his or her views should be considered the personal views of that individual rather than the formal position of IEEE. Comments on Standards: Comments for revision of IEEE Standards documents are welcome from any interested party, regardless of membership affiliation with IEEE. However, IEEE does not provide consulting information or advice pertaining to IEEE Standards documents. Suggestions for changes in documents should be in the form of a proposed change of text, together with appropriate supporting comments. Since IEEE standards represent a consensus of concerned interests, it is important to ensure that any responses to comments and questions also receive the concurrence of a balance of interests. For this reason, IEEE and the members of its societies and Standards Coordinating Committees are not able to provide an instant response to comments or questions except in those cases where the matter has previously been addressed. Any person who would like to participate in evaluating comments or revisions to an IEEE standard is welcome to join the relevant IEEE working group at http://standards.ieee.org/develop/wg/. Comments on standards should be submitted to the following address: Secretary, IEEE-SA Standards Board 445 Hoes Lane Piscataway, NJ 08854 USA Photocopies: Authorization to photocopy portions of any individual standard for internal or personal use is granted by The Institute of Electrical and Electronics Engineers, Inc., provided that the appropriate fee is paid to Copyright Clearance Center. To arrange for payment of licensing fee, please contact Copyright Clearance Center, Customer Service, 222 Rosewood Drive, Danvers, MA 01923 USA; +1 978 750 8400. Permission to photocopy portions of any individual standard for educational classroom use can also be obtained through the Copyright Clearance Center.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Notice to users Laws and regulations Users of IEEE Standards documents should consult all applicable laws and regulations. Compliance with the provisions of any IEEE Standards document does not imply compliance to any applicable regulatory requirements. Implementers of the standard are responsible for observing or referring to the applicable regulatory requirements. IEEE does not, by the publication of its standards, intend to urge action that is not in compliance with applicable laws, and these documents may not be construed as doing so.

Copyrights This document is copyrighted by the IEEE. It is made available for a wide variety of both public and private uses. These include both use, by reference, in laws and regulations, and use in private selfregulation, standardization, and the promotion of engineering practices and methods. By making this document available for use and adoption by public authorities and private users, the IEEE does not waive any rights in copyright to this document.

Updating of IEEE documents Users of IEEE Standards documents should be aware that these documents may be superseded at any time by the issuance of new editions or may be amended from time to time through the issuance of amendments, corrigenda, or errata. An official IEEE document at any point in time consists of the current edition of the document together with any amendments, corrigenda, or errata then in effect. In order to determine whether a given document is the current edition and whether it has been amended through the issuance of amendments, corrigenda, or errata, visit the IEEE-SA Website at http://standards.ieee.org/index.html or contact the IEEE at the address listed previously. For more information about the IEEE Standards Association or the IEEE standards development process, visit IEEE-SA Website at http://standards.ieee.org/index.html.

Errata Errata, if any, for this and all other standards can be accessed at the following URL: http://standards.ieee.org/findstds/errata/index.html. Users are encouraged to check this URL for errata periodically.

Patents Attention is called to the possibility that implementation of this standard may require use of subject matter covered by patent rights. By publication of this standard, no position is taken by the IEEE with respect to the existence or validity of any patent rights in connection therewith. If a patent holder or patent applicant has filed a statement of assurance via an Accepted Letter of Assurance, then the statement is listed on the IEEE-SA Website at http://standards.ieee.org/about/sasb/patcom/patents.html. Letters of Assurance may indicate whether the Submitter is willing or unwilling to grant licenses under patent rights without compensation or under reasonable rates, with reasonable terms and conditions that are demonstrably free of any unfair discrimination to applicants desiring to obtain such licenses.

iv

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Essential Patent Claims may exist for which a Letter of Assurance has not been received. The IEEE is not responsible for identifying Essential Patent Claims for which a license may be required, for conducting inquiries into the legal validity or scope of Patents Claims, or determining whether any licensing terms or conditions provided in connection with submission of a Letter of Assurance, if any, or in any licensing agreements are reasonable or non-discriminatory. Users of this standard are expressly advised that determination of the validity of any patent rights, and the risk of infringement of such rights, is entirely their own responsibility. Further information may be obtained from the IEEE Standards Association.

v

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Participants At the time this IEEE standard was completed, the C37.63 Sectionalizer Working Group had the following membership: David T. Stone, Chair Craig Befus, Vice Chair Peter Agliata Chris Ambrose Robert Behl Antone Bonner Eldridge Byron Gilbert Carmona Frank DeCesaro

Leslie Falkingham Mietek Glinkowski Gary Haynes Edward Jankowich Chris Lettow Steve Meiners Sachin Puranik

Larry Putman Timothy Royster R. Kirkland Smith Francois Soulard James Swank Nenad Uzelac Jan Zawadzki

The following members of the individual balloting committee voted on this standard. Balloters may have voted for approval, disapproval, or abstention. William Ackerman S. Aggarwal Chris Ambrose Thomas Barnes Craig Befus Robert Behl Wallace Binder Antone Bonner Harvey Bowles Ted Burse Eldridge Byron Thomas Callsen Paul Cardinal Glenn Davis Frank DeCesaro Gary Donner Randall Dotson Edgar Dullni Gary Engmann Leslie Falkingham Marcel Fortin Paul Found Fredric Friend David Gilmer Mietek Glinkowski

Robert Goodin Edwin Goodwin Randall Groves Jerry Harness Timothy Hayden Gary Haynes Jeffrey Helzer Gary Heuston Joseph Jancauskas Edward Jankowich Andrew Jones Joseph Koepfinger Jim Kulchisky Chung-Yiu Lam Michael Lauxman John Leach Greg Luri William McBride Nigel McQuin Steve Meiners Peter Meyer Georges Montillet Michael S. Newman Joe Nims Ted Olsen Lorraine Padden

Donald Parker Larry Putman Moises Ramos Reynaldo Ramos Michael Roberts Charles Rogers Thomas Rozek Bartien Sayogo Gil Shultz James Smith Jeremy Smith Jerry Smith R. Kirkland Smith Francois Soulard Gary Stoedter David T. Stone James Swank John Vergis Ilia Voloh William Walter Steven Whalen Kenneth White Jian Yu Janusz Zawadzki Matthew Zeedyk

vi

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

When the IEEE-SA Standards Board approved this standard on 6 March 2013, it had the following membership: John Kulick, Chair David L. Law, Vice Chair Richard Hulett, Past Chair Konstantinos Karachalios, Secretary Masayuki Ariyoshi Peter Balma Farooq Bari Ted Burse Wael William Diab Stephen Dukes Jean-Philippe Faure

Alex Gelman Mark Halpin Gary Hoffman Paul Houzé Jim Hughes Mike Janezic Joseph Koepfinger* Oleg Logvinov

Ron Petersen Gary Robinson Jon Rosdahl Adrian Stephens Yatin Trivedi Phil Winston Yu Yuan

*Member Emeritus

Also included are the following nonvoting IEEE-SA Standards Board liaisons: Dick DeBlasio, DOE Representative Mike Janezic, NIST Representative Don Messina IEEE Standards Program Manager, Document Development Erin Spiewak IEEE Standards Program Manager, Technical Program Development

vii

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Introduction This introduction is not part of IEEE Std C37.63-2013, IEEE Standard Requirements for Overhead, Pad-Mounted, DryVault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV.

This standard has been revised and updated from the 2005 revision of IEEE Std C37.63. This revision incorporates significant improvements that reflect the present state of the art in automatic line sectionalizers. These improvements include changes and additions in the following areas:

The term sectionalizer has been restored to the definition in IEEE Std C37.100™.

Replacing reference to IEEE Std 1247™-1998 by adopting reference to IEEE Std C37.100.1™ or by incorporating specifications within this document.

Restricted fault-making current rating to devices that have independent manual operation, in 5.102.

General structure of the document has been made compatable with IEEE Std C37.100.1.

Revised limits of temperature and temperature rise to be consistent with common requirements IEEE Std C37.100.1 and the circuit breaker standard, IEEE Std C37.04™.

Radio influence voltage test has been deleted.

Partial discharge tests have been aligned with IEEE Std C37.60™-2012 (IEEE/IEC dual logo).

Added ice loading tests.

viii

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

Contents 1. Overview .................................................................................................................................................... 1 1.1 Scope ................................................................................................................................................... 1 1.2 Purpose ................................................................................................................................................ 1 2. Normative references.................................................................................................................................. 2 3. Definitions .................................................................................................................................................. 3 4. Normal (usual) and special (unusual) service conditions ........................................................................... 3 4.1 Normal (usual) service conditions ....................................................................................................... 3 4.2 Special (unusual) service conditions.................................................................................................... 4 5. Ratings........................................................................................................................................................ 4 5.1 Rating information............................................................................................................................... 4 5.2 Rated maximum voltage (V)................................................................................................................ 5 5.3 Rated insulation level .......................................................................................................................... 7 5.4 Rated power-frequency (f r ) ................................................................................................................. 7 5.5 Rated continuous (normal) current and temperature rise..................................................................... 7 5.6 Rated short-time withstand current (I k ) ............................................................................................... 7 5.7 Rated peak withstand current (I p ) ........................................................................................................ 7 5.8 Rated duration of short-circuit (t k ) ...................................................................................................... 7 5.9 Rated supply voltage of closing and opening devices and of auxiliary and control circuits (U a ) ....... 8 5.10 Rated supply frequency of closing and opening devices and of auxiliary circuits ............................ 8 5.11 Rated pressure of compressed gas supply for insulation and/or operation ........................................ 8 5.12 Rated filling levels for insulation and/or operation. .......................................................................... 8 5.101 Preferred minimum actuating current ratings (series coil sectionalizers) ........................................ 8 5.102 Preferred fault-making current rating .............................................................................................. 8 5.103 Rated load-switching current........................................................................................................... 9 5.104 Rated unloaded transformer switching current ................................................................................ 9 5.105 Preferred line charging and cable charging current ratings ............................................................. 9 6. Design and construction ............................................................................................................................. 9 6.1 Requirements for liquids in sectionalizers........................................................................................... 9 6.2 Requirements for gases in sectionalizers ........................................................................................... 10 6.3 Grounding provisions ........................................................................................................................ 10 6.4 Auxiliary and control equipment ....................................................................................................... 10 6.5 Dependent power operation............................................................................................................... 10 6.6 Stored energy operation..................................................................................................................... 10 6.7 Independent manual operation........................................................................................................... 10 6.8 Operation of releases ......................................................................................................................... 10 6.9 Low- and high-pressure interlocking and monitoring devices........................................................... 10 6.10 Nameplate markings ........................................................................................................................ 10 6.11 Interlocking devices......................................................................................................................... 12 6.12 Position/charge indicators................................................................................................................ 12 6.13 X-ray emission................................................................................................................................. 12 6.101 Counters......................................................................................................................................... 12 6.102 Instruction...................................................................................................................................... 12 6.103 Conductor terminal ........................................................................................................................ 13 6.104 Tank construction .......................................................................................................................... 13 6.105 Manual operating provision ........................................................................................................... 13

ix

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

7. Design (type) tests .................................................................................................................................... 14 7.1 General conditions for tests ............................................................................................................... 14 7.2 Insulation (dielectric) tests................................................................................................................. 17 7.3 Radio influence voltage tests (RIV)................................................................................................... 19 7.4 Measurement of the resistance of circuits.......................................................................................... 19 7.5 Temperature rise test ......................................................................................................................... 20 7.6 Short-time withstand current and peak withstand current tests ......................................................... 21 7.7 Verification of the degrees of protection provided by enclosures ..................................................... 22 7.8 Tightness tests.................................................................................................................................... 22 7.9 Electromagnetic compatibility tests................................................................................................... 22 7.10 Additional tests on auxiliary and control circuits ............................................................................ 22 7.11 X-radiation test procedure for vacuum interrupters......................................................................... 22 7.101 Switching tests............................................................................................................................... 23 7.102 Fault-making tests.......................................................................................................................... 24 7.103 Condition of the sectionalizer after switching tests, short-time withstand current tests, and fault-making current tests ............................................................................................................. 24 7.104 Mechanical operation tests ............................................................................................................ 25 7.105 Partial discharge tests .................................................................................................................... 26 7.106 Operating duty tests ....................................................................................................................... 27 7.107 Surge current test—series coil sectionalizers................................................................................. 29 7.108 Control electronic elements surge withstand capability tests ........................................................ 30 7.109 Minimum actuating current tests ................................................................................................... 30 7.110 Ice loading test............................................................................................................................... 30 8. Production tests (routine tests) ................................................................................................................. 34 8.1 General .............................................................................................................................................. 34 8.2 Dielectric withstand test; one minute dry power-frequency .............................................................. 34 8.3 Tests on auxiliary and control circuits............................................................................................... 34 8.4 Tightness tests.................................................................................................................................... 34 8.101 Operational calibration .................................................................................................................. 35 8.102 Partial discharge test ...................................................................................................................... 35 8.103 Mechanical tests ............................................................................................................................ 35 Annex A (informative) X/R ratios ............................................................................................................... 36 A.1 General.............................................................................................................................................. 36 A.2 Time constant and X/R ratio........................................................................................................... 36 A.3 Asymmetrical fault current ............................................................................................................... 36 Annex B (normative) Ratings for series coil sectionalizers.......................................................................... 38 B.1 Rating information ............................................................................................................................ 38 B.2 Series coil sectionalizer ratings......................................................................................................... 38 Annex C (informative) Bibliography............................................................................................................ 40

x

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV IMPORTANT NOTICE: IEEE Standards documents are not intended to ensure safety, health, or environmental protection, or ensure against interference with or from other devices or networks. Implementers of IEEE Standards documents are responsible for determining and complying with all appropriate safety, security, environmental, health, and interference protection practices and all applicable laws and regulations. This IEEE document is made available for use subject to important notices and legal disclaimers. These notices and disclaimers appear in all publications containing this document and may be found under the heading “Important Notice” or “Important Notices and Disclaimers Concerning IEEE Documents.” They can also be obtained on request from IEEE or viewed at http://standards.ieee.org/IPR/disclaimers.html.

1. Overview

1.1 Scope This standard applies to all overhead, pad-mounted, dry-vault, and submersible single-pole or multipole alternating-current automatic line sectionalizers for rated maximum voltages above 1 kV and up to 38 kV. Voltages above 38 kV shall be considered special applications. In order to simplify the terminology in this standard, the term sectionalizer has been substituted for automatic line sectionalizer wherever possible.

1.2 Purpose The purpose of this standard is to describe the requirements for sectionalizers. Qualification to this standard should give reasonable assurance to the user that equipment meeting the requirements of this standard will perform in a satisfactory manner, provided that it has been properly selected for the intended application and is installed in accordance with the manufacturer’s recommendations. 1

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

2. Normative references The following referenced documents are indispensable for the application of this document (i.e., they must be understood and used, so each referenced document is cited in text and its relationship to this document is explained). For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments or corrigenda) applies. ANSI C37.85, American National Standard for Switchgear—AC High-Voltage Power Vacuum Interrupters— Safety Requirements for X-Radiation Limits. 1 IEC 60502, Power Cables with Extruded Insulation and Their Accessories for Rated Voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV). 2 IEEE Std 4TM, IEEE Standard Techniques for High-Voltage Testing. 3, 4 IEEE Std 386TM, IEEE Standard for Separable Insulated Connector Systems for Power Distribution Systems Above 600 V. IEEE Std 1247TM-2005, IEEE Standard for Interrupter Switches for Alternating Current, Rated Above 1000 V. IEEE Std C37.09 TM-1999, IEEE Standard Test Procedure for AC High-Voltage Circuit Breakers Rated on a Symmetrical Current Basis. IEEE Std C37.42™, IEEE Standard Specifications for High-Voltage (> 1000 V) Expulsion-Type DistributionClass Fuses, Fuse and Disconnecting Cutouts, Fuse Disconnecting Switches, and Fuse Links and Accessories Used with These Devices. IEEE/ISO/IEC Std C37.60-2012, High-Voltage Switchgear and Controlgear—Part 111: Automatic Circuit Reclosers and Fault Interrupters for Alternating Current Systems up to 38 kV. IEEE Std C37.100™, IEEE Standard Definitions for Power Switchgear. IEEE Std C37.100.1™-2007, IEEE Standard of Common Requirements for High Voltage Power Switchgear Rated Above 1000 V. IEEE Std C37.301™, IEEE Standard for High-Voltage Switchgear (Above 1000 V) Tests Techniques—Partial Discharge Measurements. IEEE Std C57.12.28™-2005, IEEE Standard for Pad-Mounted Equipment—Enclosure Integrity. IEEE Std C57.12.32™, IEEE Standard for Submersible Equipment—Enclosure Integrity.

1 ANSI publications are available from the Sales Department, American National Standards Institute, 25 West 43rd Street, 4th Floor, New York, NY 10036, USA (http://www.ansi.org/). 2 IEC publications are available from the Sales Department of the International Electrotechnical Commission, Case Postale 131, 3, rue de Varembé, CH-1211, Genève 20, Switzerland/Suisse (http://www.iec.ch/). IEC publications are also available in the United States from the Sales Department, American National Standards Institute, 25 West 43rd Street, 4th Floor, New York, NY 10036, USA (http://www.ansi.org/). 3 IEEE publications are available from the Institute of Electrical and Electronics Engineers, Inc., 445 Hoes Lane, P.O. Box 1331, Piscataway, NJ 08855-1331, USA (http://standards.ieee.org/). 4 The IEEE standards or products referred to in this clause are trademarks of the Institute of Electrical and Electronics Engineers, Inc.

2

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

3. Definitions For the purposes of this document, the following terms and definitions apply. The IEEE Standards Dictionary Online should be consulted for terms not defined in this clause. 5 An asterisk (*) indicates that at the time this standard was approved, there were no corresponding definitions in IEEE Std C37.100. automatic line sectionalizer: A self-contained circuit-opening device that automatically opens the main electrical circuit through it after sensing and responding to a predetermined number of successive main current impulses equal to or greater than a predetermined magnitude. It opens while the main electrical circuit is de-energized. It may also have provision to be manually operated to interrupt loads. cutout type sectionalizers: An automatic line sectionalizer, typically single-phase, that is very similar in outward appearance to a distribution open dropout type fuse cutout and is used in a distribution cutout fuse support (mounting).* NOTE—Cutout type sectionalizers usually have ratings that are associated with the distribution cutout mounting in which they are applied. 6

minimum actuating current: The minimum actuating current of sectionalizers is the minimum rms (root-meansquare) current that actuates a counting operation or an automatic operation.* non-sustained disruptive discharge (NSDD): Disruptive discharge associated with current interruption that does not result in the resumption of power frequency current or, in the case of capacitive current interruption, does not result in current in the main load circuit. series coil sectionalizer: A sectionalizer in which main circuit current impulses above a specified value, flowing through a solenoid or operating coil, provide the energy required to operate the counting mechanism.

4. Normal (usual) and special (unusual) service conditions Clause 2 of IEEE Std C37.100.1™-2007 applies.

4.1 Normal (usual) service conditions Subclause 2.1 of IEEE Std C37.100.1-2007 applies. 4.1.1 Indoor switchgear Subclause 2.1.1 of IEEE Std C37.100.1-2007 applies.

5

IEEE Standards Dictionary Online subscription is available at: http://www.ieee.org/portal/innovate/products/standard/standards_dictionary.html. 6 Notes in text, tables, and figures are given for information only and do not contain requirements needed to implement this standard.

3

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

4.1.2 Outdoor switchgear Subclause 2.1.2 of IEEE Std C37.100.1-2007 applies with the following addition. i)

Flooding

A Submersible Automatic Line Sectionalizer (subsurface or vault) that is installed in a below-grade enclosure may be subject to occasional flooding to a depth not exceeding 3 m above the top of the switchgear. Exposure to chemical or electrochemical reactions may be encountered in a below-grade environment. The below-grade environment may contain chemicals that contribute to mild corrosive reactions. j)

Icing conditions

The ice coating shall be considered in the range from 1 mm up to, but not exceeding, 20 mm.

4.2 Special (unusual) service conditions Subclause 2.2, and all of its subclauses, of IEEE Std C37.100.1-2007 apply.

5. Ratings

5.1 Rating information The list of ratings given in the first paragraph of Clause 4 of IEEE Std C37.100-2007.1 does not apply and is replaced by the following list of ratings. a)

Rated maximum voltage

b)

Rated lightning impulse withstand voltage

c)

Rated power frequency

d)

Rated continuous current

e)

Rated short-time (symmetrical) withstand current and duration

f)

Rated peak withstand current

g)

Rated control voltages (where applicable)

The following switching ratings are optional; they only apply to sectionalizers that are designed for the respective switching ratings. a)

Rated load-switching current

b)

Rated line charging and cable charging current

c)

Rated unloaded transformer switching current

d)

Rated fault-making current

e)

Rated ice breaking capability

NOTE—Ice rating of 1 mm is assumed unless a higher rating is declared by the manufacturer. See 7.110.2.

4

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

5.2 Rated maximum voltage (V) NOTE—In IEC standards, rated maximum voltage is denoted by U r . Subclause 4.1, and its subclauses, of IEEE Std C37.100.1-2007 do not apply. The rated maximum voltage indicates the upper limit of the highest voltage of systems for which the switchgear is intended. The preferred values of rated maximum voltage are given in Table 1 and Table 2. Special ratings for series coil sectionalizers are given in Annex B.

5

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

Table 1 — Preferred voltage ratings for sectionalizers (except those covered in Table 2) Rated power-frequency Rated power-frequency dry withstand voltage wet withstand voltage (kV) (kV) (See Note 2) (See Note 2)

Line no. (See Note 1)

Rated maximum voltage (kV)

Rated lightning impulse withstand voltage (kV) (See Note 2)

Col. 1 1 2 3 4

Col. 2 15.0 15.5 27.0 38.0

Col. 3 95 110 125 150

Col. 4 36 50 60 70

Col. 5 30 45 50 60

11 12 13 14

12.0 17.5 24.0 36.0

75 95 125 170

28 38 50 70

28 38 50 70

NOTE 1—Lines 11 to 14 refer to distribution systems commonly found outside of North America; the test withstand levels in column 3 and 4 were selected from Table 1a of IEC 62271-1-2007 [B2]. NOTE 2—Cutout type sectionalizers usually have ratings that are associated with the distribution cutout mounting in which they are applied. IEEE Std C37.42 gives preferred values for the distribution cutout fuse support.

Table 2 — Preferred voltage ratings and related test requirements for pad-mounted, dry-vault, and submersible sectionalizers Line no. (See Note 1)

Rated power-frequency Rated powerRated lightning Rated maximum dry withstand voltage frequency wet impulse voltage voltage (kV) (kV) withstand voltage (kV) (See Notes 2) (kV)

DC withstand voltage (kV) (See Note 3)

Col. 1 1 2 3 4

Col. 2 15.5 — 27.0 38.0

Col. 3 95 — 125 150

Col. 4 35 — 40 50

Col. 5 Not required — Not required Not required

Col. 6 53 — 78 103

11 12 13 14

12.0 17.5 24.0 36.0

60 75 95 145

28 38 50 70

Not required Not required Not required Not required

42 57 78 103

NOTE 1— Lines 11 to 14 refer to distribution systems commonly found outside of North America; the test withstand levels in column 3 and 4 were selected from Table 1a of IEC 62271-1-2007. NOTE 2— The rated power-frequency dry withstand voltage for North America (line 1, line 3, and line 4) is reduced, as compared to Table 1, to take into account the reduced withstand capability of some cable components (i.e., elbows, tee connectors). NOTE 3—DC voltage testing of field-aged cables is not a recommended practice. Refer to IEEE Std 400.1 [B3] and IEEE Std 400.2 [B4] for guidelines on testing of dielectric shielded cables. Refer also to IEEE Std 433 [B5] for comparisons of some characteristics of high-voltage testing using 60 Hz ac, dc, and 0.1 Hz methods. The dc withstand test requirement on the sectionalizer demonstrates its capability to withstand either dc or VLF testing of connected cables.

6

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

5.3 Rated insulation level Subclause 4.2 of IEEE Std C37.100.1-2007 does not apply. The preferred values of insulation level voltage are given in Table 1 and Table 2. In these tables, the withstand voltage applies at the standardized reference atmosphere [temperature (20 °C), pressure (101.3 kPa), and humidity (11 g/m3)] specified in IEEE Std 4TM. Insulation withstand capability is affected by altitude. For special service conditions, see 4.2.

5.4 Rated power-frequency (f r ) Subclause 4.3 of IEEE Std C37.100.1-2007 applies.

5.5 Rated continuous (normal) current and temperature rise 5.5.1 Rated continuous (normal) current (I r ) Subclause 4.4.1 of IEEE Std C37.100.1-2007 applies with the following additions. Series coil sectionalizers have special ratings determined by the series coil itself. The continuous current and the load-switching current ratings of series coil sectionalizers are given in Annex B (see Table B.1 and Table B.2). 5.5.2 Temperature rise Subclauses 4.4.2 and 4.4.3 of IEEE Std C37.100.1-2007 apply.

5.6 Rated short-time withstand current (I k ) Subclause 4.5 of IEEE Std C37.100.1-2007 does not apply. Preferred values for the rated short-time withstand currents for series coil sectionalizers are given in Table B.2. Preferred values for the rated short-circuit withstand current of the main circuit of all other sectionalizers are as follows: 1 kA, 1.25 kA, 2 kA, 4 kA, 6 kA, 8 kA, 10 kA, 12.5 kA, 16 kA, or 20 kA.

5.7 Rated peak withstand current (I p ) Subclause 4.6 of IEEE Std C37.100.1-2007 applies with the following modification. The preferred peak withstand current levels for series coil sectionalizers are given in Table B.2.

5.8 Rated duration of short-circuit (t k ) Subclause 4.7 of IEEE Std C37.100.1-2007 does not apply. 7

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

The rated short-circuit withstand current duration shall be 1 s. Sectionalizers shall also have a related, required capability for a 10 s short-time withstand current. The preferred 10 s short-circuit withstand current rating is 32.5% of the rated 1 s short-time withstand current rating. NOTE—The 1 s and 10 s short-time withstand current tests provide two points on a damage curve to assist the user in coordinating the device with upstream reclosers and downstream fuses and transformers. Refer to IEEE Std C37.48.1 [B6] for additional information.

5.9 Rated supply voltage of closing and opening devices and of auxiliary and control circuits (U a ) Subclause 4.8, and its subclauses, of IEEE Std C37.100.1-2007 apply.

5.10 Rated supply frequency of closing and opening devices and of auxiliary circuits Subclause 4.9 of IEEE Std C37.100.1-2007 applies.

5.11 Rated pressure of compressed gas supply for insulation and/or operation Subclause 4.10 of IEEE Std C37.100.1-2007 applies.

5.12 Rated filling levels for insulation and/or operation. Subclause 4.11 of IEEE Std C37.100.1-2007 applies.

5.101 Preferred minimum actuating current ratings (series coil sectionalizers) For series coil sectionalizers, the preferred minimum actuating current ratings are given in Annex B.

5.102 Preferred fault-making current rating For sectionalizers designed to have a fault-making rating, the preferred fault-making current is the powerfrequency, 1 s rated short-time withstand current, expressed in symmetrical rms amperes. The sectionalizer shall have the related ability to make and carry an asymmetrical current with a peak current of 2.6 times the symmetrical 1 s rated short-time withstand current, the circuit X/R being approximately 17 at 60 Hz. Only sectionalizers having a closing speed that is independent of operating personnel can have a fault-making current rating. Sectionalizers having a closing speed that is dependent on operating personnel may have a making current capability, which indicates that successful circuit closing is dependent upon proper operation of the device. See 6.10. The fault-making current rating carries the requirement of a design verification test and the rating is assigned to the sectionalizer on its nameplate. A making current capability is an asserted capability of the device by the manufacturer under conditions specified by that manufacturer. A making current capability is not shown on the nameplate. 8

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

5.103 Rated load-switching current The rated load-switching current is the maximum rms symmetrical power-frequency load current flowing in a circuit that the sectionalizer shall be required to make and interrupt at its rated maximum voltage.

5.104 Rated unloaded transformer switching current The rated unloaded transformer switching current is the maximum transformer exciting current that the switch shall be required to make and interrupt at its rated maximum voltage. The current is expressed in rms symmetrical amperes. Optionally, the rating may be expressed as the maximum transformer size associated with the exciting current that can be switched. NOTE—The making current may include a transient current several orders of magnitude larger than that of the rated unloaded transformer switching current.

5.105 Preferred line charging and cable charging current ratings The preferred line charging and cable charging interrupting current ratings for sectionalizers having this capability are as given in Table 3. Table 3 — Preferred line charging and cable charging switching current ratings Preferred current (rms amperes)

Rated maximum line voltage (kV) (See Note)

Line charging, overhead

Cable charging

15.0 & 15.5 27.0 38.0

2 5 5

10 25 40

12.0 17.5 24.0 36.0

2 2 5 5

10 10 25 40

NOTE—The first three lines refer to voltages commonly specified in North America. The last four lines refer to distribution systems commonly found outside of North America (see Note 1 of Table 1 and Table 2).

6. Design and construction

6.1 Requirements for liquids in sectionalizers Subclause 5.1, and its subclauses, of IEEE Std C37.100.1-2007 apply with the following addition. When oil is used as an insulating medium, provision shall be made to obtain a bottom oil sample.

9

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

6.2 Requirements for gases in sectionalizers Subclause 5.2 of IEEE Std C37.100.1-2007 applies.

6.3 Grounding provisions Subclause 5.3 of IEEE Std C37.100.1-2007 does not apply. A sectionalizer with a metal housing shall have provisions for the connection of a ground lead. The grounding connector shall accommodate a ground conductor of a size adequate to conduct the rated 1 s shorttime withstand current of the sectionalizer. Pad-mounted, dry-vault, and submersible sectionalizers shall have an additional grounding connection for each three-phase set of cable entrances.

6.4 Auxiliary and control equipment At the present time, there are no requirements defined for this subject.

6.5 Dependent power operation At the present time, there are no requirements defined for this subject.

6.6 Stored energy operation At the present time, there are no requirements defined for this subject.

6.7 Independent manual operation Subclause 5.7 of IEEE Std C37.100.1-2007 applies.

6.8 Operation of releases At the present time, there are no requirements defined for this subject.

6.9 Low- and high-pressure interlocking and monitoring devices Subclause 5.9 of IEEE Std C37.100.1-2007 applies.

6.10 Nameplate markings Subclause 5.10 of IEEE Std C37.100.1-2007 applies with the following additions. 10

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

The nameplates for sectionalizers shall be marked in accordance with Table 4. Series coil sectionalizers shall be provided with a separate nameplate that can be changed when the coil is changed and is permanently marked with the following information: a)

Rated continuous current.

b)

Rated short-circuit withstand current(s) and duration(s). The 1 s short-time withstand current value shall be shown. If the 10 s short-time current value, as specified in 5.5 is less than 32.5% of the 1 s value, then it too shall be listed on the nameplate.

c)

Rated minimum actuating current.

Nameplates shall be securely fixed in position and visible from the normal operating position. Table 4 — Nameplate marking Abbreviation (see Note 1)

Unit

Condition: marking only required if

Marking requirement

(2)

(3)

(4)

(5)

Manufacturer’s name

–

–

Manufacturer’s model or type designation

–

–

V or Ur

kV

X

Rated lightning impulse withstand voltage

Up

kV

X

Rated power-frequency

fr

Hz

Rated continuous current

Ir

A

(1)

Rated maximum voltage

X X

If not rated for both 50 Hz and 60 Hz

Y X

Rated for load switching

Rated load-switching current

–

A

Rated short-time withstand current

Ik

kA

Rated fault-making current

Ima

kA

Rated ice breaking capability

–

mm

Type and quantity (volume of liquid or mass of gas) of insulating material

–

l (gal) or kg (lb) (Note 2)

Contains fluid or gas

Y

Mass (including oil for oil-filled devices)

–

kg (lb) (Note 2)

Contains oil

Y

Serial number

–

–

X

Year of manufacture

–

–

X

In column (5):

Y X

Rated for fault making Greater than 1 mm and if type testing is required, see 7.110.2

Y Y

X = the marking of these values is mandatory; blanks indicate the value zero. Y = the marking of these values to the conditions in column (4).

NOTE 1—The abbreviation in column (2) may be used instead of the term in column (1). When the term in column (1) is used, the word “rated” is not required. NOTE 2—SI metric units are preferred; alternate units in parentheses ( ) are acceptable alternates.

11

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

6.11 Interlocking devices Subclause 5.11 of IEEE Std C37.100.1-2007 applies with the following addition. Interlocking devices may be specified for reasons of safety and/or convenience but are not covered by this standard.

6.12 Position/charge indicators 6.12.1 Position indicators Subclause 5.12 of IEEE Std C37.100.1-2007 applies with the following addition. If a position indicator is provided, the preferred colors are red to signify closed and green to signify open. If the words “OPEN” or “CLOSED” are included on the indicator, they should be in contrasting colors. 6.12.2 Stored energy mechanism charge indicator When indicators are used on stored energy operating mechanisms, the following colors are preferred subject to any local codes or indicator requirements: a)

Yellow background with the word “charged” in black letters for charged mechanism

b)

White background with the word “discharged” in black letters for discharged mechanism

As an alternative, red letters on a white background for both indicators may be used.

6.13 X-ray emission Subclause 5.19 of IEEE Std C37.100.1-2007 applies.

6.101 Counters If an operations counter is provided, it shall indicate the total number of tripping operations of the sectionalizer. The counter shall be visible from the normal operating position.

6.102 Instruction Instruction manuals for sectionalizers shall be supplied with the equipment. These may include directions for inspection, storage, unpacking, assembling, and testing the sectionalizer. Additional information may be contained in maintenance manuals and spare parts lists, which may be available from the manufacturer. Operating instructions shall include sufficient information to avoid potentially hazardous conditions if a sectionalizer is not rated for fault closing or load switching.

12

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

6.103 Conductor terminal For connection of bare conductors, bushing terminals shall accommodate conductors of a size adequate to conduct the rated continuous current of the sectionalizer without exceeding the appropriate temperature rise given in 5.5.2. For submersible sectionalizers, bushings shall accommodate cable terminations in accordance with IEEE Std 386TM or IEC 60502, unless specified by the user.

6.104 Tank construction 6.104.1 Tank construction—submersible and pad-mounted sectionalizers Tanks, cabinets, and all appurtenances shall be made of corrosion-resistant material or provided with an impact and corrosion-resistant finish. Equipment shall be suitable for storage in uncovered areas. No external portion of the equipment shall trap water. Lifting lugs shall be provided and positioned so that the equipment will remain level when lifted. The lugs shall be designed and located to avoid interference between lifting slings and any attachments, such as bushings and operating handles, and to avoid scratching or marring the finish during handling. 6.104.2 Tank construction—pad-mounted sectionalizers Pad-mounted enclosures shall meet the requirements of IEEE C57.12.28. Pad-mounted equipment shall be constructed so that it can be lifted into place on the pad without disturbing the entrance cables. Lifting provisions used on pad-mounted equipment shall be designed to not protrude above the top of the cabinet and shall be recessed so that no part of the lifting provision protrudes past the vertical plane. Any lifting provision not meeting the requirement listed above shall be removable after installation and reusable, should the equipment need to be moved, repositioned, or replaced. All cable terminating compartment access doors shall have padlocking provisions. Unless otherwise specified, these access doors shall also have pentahead bolt securing features as shown in IEEE C57.12.28. Compartment doors shall have a positive means of latching in the open position and to the extent practical should be large enough to facilitate working in the equipment. Pad-mounted equipment enclosure coating systems shall meet the requirements of IEEE C57.12.28. 6.104.3 Tank construction—submersible sectionalizers Submersible equipment shall meet the requirements of ANSI C57.12.32.

6.105 Manual operating provision Sectionalizers shall be provided with a manual operating means to both open and close the sectionalizer. If a fault-making rating is assigned, the manual closing shall be independent operation, that is, independent of operating personnel. If a fault-making rating is not assigned, the manual closing may be dependent operation. See 5.102. 13

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

Manual control is defined as control in which the main devices under control, whether manually or power operated, are controlled by an attendant. (Refer to IEEE Std C37.100.)

7. Design (type) tests

7.1 General conditions for tests Subclause 6.1 of IEEE Std C37.100.1-2007 does not apply. The design (type) tests are for the purpose of proving the characteristics of the sectionalizer, its operating device, and auxiliary equipment. 7.1.1 Grouping of tests Subclause 6.1 of IEEE Std C37.100.1-2007 does not apply. 7.1.2 Information for identification of specimens Subclause 6.1.1 of IEEE Std C37.100.1-2007 does not apply. When a manufacturer is requesting a certification or type test report, the manufacturer must submit to the testing laboratory drawings and other data containing sufficient information to unambiguously identify by type the essential details and parts of the automatic line sectionalizer presented for test. The definition of an automatic line sectionalizer includes its automatic control. The manufacturer shall include in the information provided to the testing laboratory sufficient information to identify the control used in the design tests. Where appropriate, this information shall include model number, serial number, firmware revision, software revision, and other appropriate control software information. The definition of a cutout type sectionalizer includes a fuse type support. This support is integral to the dielectric capability of the device. The manufacturer shall include in the information provided to the testing laboratory sufficient information to identify the mounting or support used in the design tests. Where appropriate, this information shall include make, model number, and rating. 7.1.3 Information to be included in design-test (type-test) reports Subclause 6.1.2 of IEEE Std C37.100.1-2007 does not apply. The results of all design (type-tests) shall be recorded in design-test (type-test) reports containing sufficient data to prove compliance with the ratings and the test clauses of the relevant standards and sufficient information shall be included so that the essential parts of the automatic line sectionalizer can be identified. The definition of an automatic line sectionalizer includes its automatic control. The control shall be considered an essential part of the automatic line sectionalizer in the test report, including its model number, serial number, firmware revision, software revision, and other appropriate control schemes. The definition of a cutout type sectionalizer includes a fuse type support. This mounting or support shall be considered an essential part of the cutout type sectionalizer and noted in the test report including its make, model number, and rating. 14

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

A cutout mounted sectionalizer may require the temporary attachment of an auxiliary device to perform the switching functions of a sectionalizer if such ratings are assigned. If such a device is required, it shall be considered an essential part of the switchgear and noted in the test report including its make, model number, and rating. 7.1.101 Test requirements Tests to verify the ratings and performance requirements of all sectionalizer shall be in accordance with Table 5. 7.1.102 Condition of device to be tested The sectionalizer shall be new and in good condition, and tests shall be applied before the device is put into commercial use. A resistance check shall be performed on the sectionalizer prior to any current or mechanical test, see 7.4. For cutout mounted sectionalizers, the resistance check shall be measured between the top and bottom conductor connectors of the cutout device. 7.1.103 Mounting of device The sectionalizer shall be mounted in a manner closely approximating the normal service conditions for which it is designed. Sectionalizers intended for pole or frame mounting may be mounted at any convenient height above ground. If the sectionalizer normally requires control apparatus, the control apparatus shall be connected during the tests observing the following minimum requirements: a)

The control shall be mounted on the sectionalizer as intended by the manufacturer’s design or positioned within 2 m of sectionalizer phase terminals under test, and

b)

The sectionalizer shall be connected to the control apparatus with the manufacturer’s approved cable whose length shall be the maximum allowed by the manufacturer except that it need not exceed 6 m.

If the control apparatus is intended by the manufacturer to always be integrally mounted to, or within, the sectionalizer structure, it shall be considered in compliance with a) and b) above with a zero length control cable.

15

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

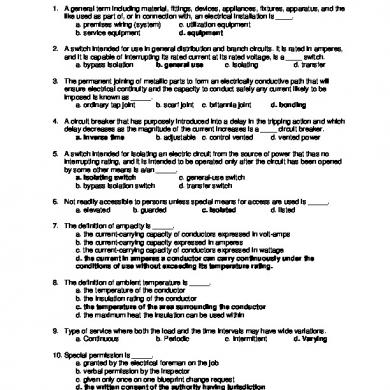

Table 5 —Test requirements for sectionalizers

a

Subclause no.

Type of test

Summary of test (see appropriate test specifications for details of each test)

7.1

General

General conditions for test

7.2

Dielectric

Insulation (dielectric) test

7.4

Resistance

Measurement of the resistance of circuits

7.5

Temperature rise

Temperature rise test

7.6

Short-time and peak withstand

Short-time withstand current and peak withstand current tests

7.8

Tightness

Tightness test

No tests required for air-filled devices at zero gauge pressure

7.11

X-radiation

X-radiation procedure for vacuum interrupters

For all devices using vacuum interrupters

7.101

Switching

Switching tests

Required only if a switching rating is assigned a

7.102

Fault making

Fault-making current tests

Required only if fault-making rating is assigned, see 7.102.1

7.104

Mechanical

Mechanical duty and cold temperature tests

7.105

Partial discharge

Partial discharge tests

Required only if the device uses a non-restoring dielectric as the primary insulation

7.106

Operating duty

Operating duty tests

See Table 8

7.107

Surge current

Surge current test—series coil sectionalizers

Required only for series coil sectionalizers

7.108

Control elements surge withstand

Control elements surge withstand capability tests

Not required for devices where the control elements are fully isolated from ground (earth)

7.109

Minimum actuating

Minimum actuating current tests

Exceptions or conditions

Switching ratings include any of the ratings in 5.1 h), i), j).

7.1.104 Grounding of device All parts of the sectionalizer, and control apparatus where used, that are normally grounded shall be grounded by a lead attached to the ground terminal in a manner not to decrease the withstand voltage. 7.1.105 Power frequency The frequency of the power supply voltage shall be the rated value ± 5%, except that tests at either 50 Hz or 60 Hz may be used to qualify for both rated power frequencies. 7.1.106 Control voltage The sectionalizer shall perform satisfactorily over the full range of control voltages specified in 5.9. This requirement shall be met by performing the standard operating duty as specified in 7.106.3. This requirement does 16

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

not apply to tests that do not include open or close operating duties, for example, dielectric withstand and continuous current tests.

7.2 Insulation (dielectric) tests Subclause 6.2 of IEEE Std C37.100.1-2007 applies with the following additions. The tests shall be performed with the test voltages given in Table 1 or Table 2 using the line number specified by the manufacturer. Rated insulation levels for cutout mounted sectionalizers are based in part on the rating of the fuse support or base identified by the manufacturer in 7.1.2 and 7.1.3. Automatic line sectionalizer shall be capable of withstanding, without damage to the automatic line sectionalizer and associated control apparatus, if any, the test voltages of 7.2 when tested in accordance with 7.1. Insulation tests of automatic line sectionalizers shall be performed only when the automatic line sectionalizer is completely isolated from all system voltages. 7.2.1 Ambient air conditions during tests Subclause 6.2.1 of IEEE Std C37.100.1-2007 applies. 7.2.2 Wet test procedure Subclause 6.2.2 of IEEE Std C37.100.1-2007 applies with the additions given in 7.2.6.1 7.2.3 Conditions of sectionalizer during dielectric test Subclause 6.2.3 of IEEE Std C37.100.1-2007 applies with the following additions. a)

On overhead sectionalizer, electrical connections shall be made by means of bare wire, inserted in each terminal. These bare wires shall project in such a manner as not to decrease the withstand value. Any necessary bends may be made at the terminals. The test lead connections shall be made to the wires projecting from the terminals. Terminals shall be representative of those used in service.

b)

On pad-mounted, submersible, and dry-vault sectionalizers connections shall be made through a cable termination similar to that for which the sectionalizers was designed. If terminations capable of meeting the specified dielectric voltage are not available, other terminations (bushing or connectors, or both) may be substituted for the purpose of performing these tests. Breakdown of the termination interface used for the test connections does not constitute a failure of the entity. The termination interface may be replaced and testing continued.

7.2.4 Criteria to pass the test Subclause 6.2.4 of IEEE Std C37.100.1-2007 applies with the following addition. Refer also to IEEE Std C37.100.1-2007, subclause 6.2.6.2 for vacuum interrupter based sectionalizers. 7.2.5 Application of the test voltage and test conditions Subclause 6.2.5 of IEEE Std C37.100.1-2007 applies. 17

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

7.2.5.1 General case Subclause 6.2.5.1 of IEEE Std C37.100.1-2007 applies with the following addition. Single-phase sectionalizers shall be tested for conditions 1, 4, and 7 of Table 9 of IEEE Std C37.100.1-2007. The connections of the terminals for phases B and C are not applicable. 7.2.5.2 Special case There are no special cases included in this standard. 7.2.6 Tests of switchgear Subclause 6.2.6 of IEEE Std C37.100.1-2007 does not apply. The tests shall be performed with the test voltages given in Table 1 or Table 2. 7.2.6.1 Power-frequency withstand test voltage Subclause 6.2.6.1 of IEEE Std C37.100.1-2007 applies with the following addition. a)

Wet tests shall not apply to sectionalizers within weather-resistant enclosures or those utilizing submersible cables or terminations.

b)

IEEE values of rated maximum voltage, column 2 of Table 1 and Table 2 given in lines 1 through 4: Power-frequency withstand test voltages shall be applied in accordance with IEEE Std 4, with a peak value equal to 1.414 times the rated power-frequency withstand dry and wet test values given in columns 4 and 5 of Table 1 and Table 2. The test duration shall be 60 s for the dry test. The preferred method for wet tests shall be the “conventional procedure-practice in the US” of IEEE Std 4 with a test duration of 10 s. The “standard test procedure” of IEEE Std 4 is allowed as an alternate. NOTE—Future designs should standardize the wet test procedure by adopting the “standard test procedure” as defined in IEEE Std 4.

c)

IEC values of rated maximum voltage, column 2 of Table 1 and Table 2 given in lines 11 through 14: Power-frequency withstand test voltages shall be applied in accordance with IEEE Std 4, with a peak value equal to 1.414 times the rated power-frequency withstand dry and wet test values given in columns 4 and 5 of Table 1 and Table 2. The test duration shall be 60 s for the dry test. For the IEC values of rated maximum voltage, the wet test method of test shall be the “standard test procedure” of IEEE Std 4 with a test duration of 60 s. WARNING

When performing tests involving open contacts in vacuum, adequate precautions such as shielding or distance should be used to protect test personnel against the possibility of X-radiation occurrences due, for example, to incorrect contact spacing or the application of voltages in excess of those specified. For appropriate shielding, distances, and exposure limits, refer to ANSI C37.85.

18

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

7.2.6.2 Lightning impulse withstand test voltage Subclause 6.2.6.2 of IEEE Std C37.100.1-2007 applies with the following addition. The voltage levels shall be equal to or greater than those that are specified. 7.2.6.101 DC withstand test voltage 7.2.6.101.1 Application A dc withstand voltage test is required on sectionalizers using pad-mounted, dry-vault, and submersible cable connectors. This test is in addition to the power-frequency withstand test in 6.2.6.1 of IEEE Std C37.100.1-2007. NOTE—A dc withstand voltage test is required as the design test on the sectionalizer. It is included to verify that the switchgear can withstand the same dc or very low frequency test voltages applied in the field to cables where the cables may still be connected to the switchgear.

7.2.6.101.2 Test procedure The test voltage applied shall be the value given in column 6 of Table 2. The test duration shall be 15 minutes. The dc power source for the dc withstand test shall be capable of supplying a minimum of 10 mA before tripping out on overload. The test shall be considered to have failed if there is: a)

A leakage current of more than 10 mA, or

b)

The test device is unable to withstand the voltage.

The test shall be considered to have passed if the test device withstands the test voltage with a leakage current that does not exceed 10 mA. Non-sustained disruptive discharges (NSDD) may occur and are allowed. NOTE—These test criteria recognize the likelihood that a small leakage current may pass through an insulating medium or across an insulating surface while still supporting the high dc voltage. This is particularly true of vacuum interrupters.

7.3 Radio influence voltage tests (RIV) RIV testing is not required by this standard.

7.4 Measurement of the resistance of circuits Subclause 6.4 of IEEE Std C37.100.1-2007 applies.

19

Copyright © 2013 IEEE. All rights reserved.

Authorized licensed use limited to: UCD Health Sciences Library. Downloaded on December 14,2014 at 18:57:06 UTC from IEEE Xplore. Restrictions apply.

IEEE Std C37.63-2013 IEEE Standard for Requirements for Overhead, Pad-Mounted, Dry-Vault, and Submersible Automatic Line Sectionalizers for Alternating Current Systems Up to 38 kV

7.5 Temperature rise test 7.5.1 Condition of the sectionalizer to be tested Subclause 6.5.1 of IEEE Std C37.100.1-2007 applies. 7.5.2 Arrangement of the equipment Subclause 6.5.2 of IEEE Std C37.100.1-2007 applies with the following addition. The following arrangement shall be allowed as an alternate to the arrangement of equipment specified in subclause 6.5.2 of IEEE Std C37.100.1-2007 in which case the 5 K difference of temperature rise between the terminals and the external connections shall not apply. The sectionalizer shall have a conductor connected to each terminal having a minimum length of 1.2 m. For sectionalizers with bushings designed for connection to bare copper conductors, use cables no larger than listed in Table 6. For aluminum cables use Table 7. For sectionalizers designed for use with submersible or insulated cables, the cables shall be chosen for the rated current and voltage of the sectionalizer. Refer to IEEE Std 386 for guidance. The connection shall be made to the ends of these conductors. Table 6 —Size of bare copper leads a Rated continuous (normal) current (A)

AWG

(kcmil)

mm2

Up to 50

#6 solid

26.2

14

70 to 100

#2/0 stranded

133

61

140 to 200

--

211

81

250 to 315

--

400

200

400

--

500

250

500

--

600

300

630

800

400

800

1 000

500

Size of leads

a Multiple (parallel) conductors of equivalent net cross section shall be permitted.

Table 7 —Size of bare aluminum leads a Rated continuous (normal) current (A)

Size of leads AWG

kcmil

mm2

200

#4/0 stranded

211

81

500

--

1 000

500

630

--

1 250

625