Oil-su-01 Rev 0

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Oil-su-01 Rev 0 as PDF for free.

More details

- Words: 3,395

- Pages: 22

Loading documents preview...

OIL/SU/01 Oil Producer Well Start up Procedure. Table of Contents Action

Page 2 to 2 Pages 3 to 17

Symbols <> () []

Rev No. 0

Date Feb. 2004

Safety Action Verification Action

Prepared by PFI

Verified by G.Faber

Approved by P.L. d’Haussy

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

TABLE OF CONTENTS 1

INITIAL PLANT STATUS.......................................................................................3

2

PRELIMINARIES...................................................................................................3

3

LINE UP.................................................................................................................4 3.1 3.2

4

STARTING OF THE HYDRAULIC CONTROL PANEL........................................5 4.1 4.2

5

Corrosion inhibitor start up.....................................................................................12

ESDV PRESSURE EQUALIZATION...................................................................13 8.1 8.2 8.3 8.4 8.5

9

Opening the Wellhead choke valve........................................................................10 Opening more wells................................................................................................11

CHEMICAL INJECTION START-UP...................................................................12 7.1

8

Opening The Down Hole Safety valve (SCSSV)......................................................7 Opening the Surface safety valve (SSV)..................................................................7 Opening the manual master valve............................................................................8 Opening of the Wing valve.......................................................................................8 Threshold Flowrates in Production Lines..................................................................8

RECEIVING THE OIL..........................................................................................10 6.1 6.2

7

Wellhead control panel.............................................................................................5 ESDV Panel............................................................................................................. 5

START UP OF THE FIRST WELL........................................................................7 5.1 5.2 5.3 5.4 5.5

6

Wellhead and flow line instruments line up...............................................................4 Valves line up........................................................................................................... 4

Flowline ESDV pressure u/s higher than d/s..........................................................13 Flowline ESDV pressure u/s lower than d/s............................................................13 Production or test line ESDV pressure u/s higher than d/s.....................................14 Production line ESDV pressure u/s lower than d/s.................................................14 Test line ESDV pressure u/s lower than d/s............................................................15

FINAL STATUS....................................................................................................17

Page 2

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 3

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 4

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

INITIAL PLANT STATUS

The cluster has been properly commissioned and RFSU certificate issued Dor-3 oil plant is ready to receive Fire & Gas detection system in the Cluster is in operation. All fire extinguishers are placed in location Flare system is in operation at the plant. Turbo power generators running & power available. Sea water system running & Fresh water and boiler feed water units in operation Steam boiler is in operation & steam is available to use. Chemical injection skid ready for start up. Wellhead cluster manifold flow line /New plant manifold / equipments under nitrogen pressure. Wellhead control panels /safety shutdown system commissioned. All spectacle blinds are in normal operating condition. Tank farm area is ready to receive oil.

2

PRELIMINARIES <>

Inform Dor-3 CCR. (Central control room)

<>

Inform RSES if rig is present in the cluster

<>

Ensure all personnel have H2S detectors & Escape masks.

<>

Ensure that all F&G systems are in automatic.

<>

Any F&G or process Inhibitions are entered in the “RED BOOK”.

<>

Ensure proper tools are available at site.

Page 5

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 6

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

3 3.1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

LINE UP Wellhead and flow line instruments line up.

()

Ensure that the following gauges are installed and in service for each well head and flow line.

20” casing pressure gauge. (PG 1XX 5P)

133/8” casing pressure gauge. (PG 1XX 4P)

95/8” casing pressure gauge. (PG 1XX 3P)

Up stream wing valve pressure gauge on the wellhead instrument flange.(PG 1XX 0P)

Down stream choke valve pressure gauges.(PG 1XX2P & PG 1XX 1P)

Down stream choke valve temperature gauge.(TG 1XX 0P)

()

Ensure that PSHH 1XX 2P down stream choke is lined up.

()

Ensure that PSLL 1XX 3P down stream choke is lined up.

()

Ensure that the SSV & SCSSV are correctly lined up from the WHCP.

()

Ensure that the CC/CP are installed.(CC set with proper weight).

()

Ensure that the ESDV’s are correctly lined up from ESDV control panel.

3.2

Valves line up ()

Ensure the Swab valve is closed.

()

Ensure that the oil choke is closed.

()

Ensure that the lower manual master valve is closed.

()

Ensure that the 10” ball valve on the 18” production line is closed.

()

Ensure that the 10” ball valve on the 10” test line is closed.

Page 7

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

()

Ensure that the flow line ESDV u/s & d/s 2”&1” drain valves are closed.

()

Ensure that the 18” production & 10” test manifold 2” & 1” high & low point vent lines are closed.

()

Ensure that the production & test manifold future Methanol points are closed & blinded.

Page 8

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

4

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

STARTING OF THE HYDRAULIC CONTROL PANEL. Refer to Vendor P&ID for valve tags.

4.1

Wellhead control panel. ()

Ensure that the PetroControls system specialist is in attendance (in case of first start-up only)

()

Ensure that the WHCP is properly commissioned

()

Ensure that power is available to the cluster.

[]

Power up the hydraulic pump NN-1 in the WHCP.

[]

Select the hydraulic pump to auto

()

Ensure BBB-1 final valve for SCSSV & BBB-3 final valve for SSV valves are closed inside WHCP

()

Ensure that the BBB-2 valve for SCSSV from external wire line unit is closed

()

Ensure that the BBB-4 valve for SSV from external wire line unit is closed

()

Ensure that the SCSSV control line at the WH is isolated by the needle valve

[]

Charge the hydraulic circuit to the operating pressure.(refer to vendor package start-up)

[]

Push charge button G-1 on the front panel to charge the fusible loop.

()

Monitor the pressure (N-2) gauge mounted in the WHCP (fusible loop control pressure should be about 4 bar.)

4.2

[]

Pull to reset C-1 switch mounted on the WHCP to reset ESD-1

()

Ensure ESD-1 is healthy

ESDV Panel. ()

Ensure the valves for the ESDV control panel are correctly lined up.

()

Ensure that the hydraulic pumps are energized & selected in auto.

Page 9

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

()

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Ensure that the final valve(L-XX) for each ESDV is open inside the ESDV control panel

[]

Push G-1 switch mounted in front of the panel to charge the fusible loop and Rig ESD loop.

[]

Pull C-1 switch mounted in front of the panel to reset ESD-1

[]

Pull & engage the pin on C-2 switch mounted in front of the panel to reset ESD-2.

Once the PSLL is healthy & PSHH in the test & production manifolds is healthy C-2 pin will disengage automatically.

Page 10

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

5

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

START UP OF THE FIRST WELL.

Note: If the fusible loop is healthy Overriding HH-1 valve inside the WHCP can also open the SCSSV & SSV.

5.1

Opening The Down Hole Safety valve (SCSSV) ()

Ensure ESD-1 has been reset.

[]

Open BBB-1 final valve to SCSSV from WHCP

[]

Pull & engage the pin of D1 switch mounted in front of the WHCP

[]

Slowly open the control line isolation needle valve from the wellhead to the SCSSV

()

Ensure that the control line pressure is maintained automatically by the motorized pump at a regulated pressure of about 300 barg and that the pump stops automatically.

()

Once the control line is at the operating pressure D-1 will automatically disengage

5.2

Opening the Surface safety valve (SSV). Refer to vendor P&ID for some valve tag []

Open BBB-3 final valve to the SSV inside WHCP

[]

Pull & engage the pin of D2 switch mounted in front of the WHCP

[.]

Check the hydraulic pump starts automatically & the pressure is increasing at Q2 pressure gauge mounted in front of the WHCP (SSV regulated pressure is about 200barg)

()

Ensure the SSV has opened and the hydraulic control pressure is maintained at about 200barg and the pump has stopped.

Page 11

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

5.3

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Opening the manual master valve.

[]

Slowly open the manual lower master valve fully ( this valve should be either full open or fully close , not to use for controlling purposes.)

()

Monitor that the pressure increasing on wellhead pressure gauge PG 1XX OP u/s of wing valve.

()

Ensure that the SCSSV and SSV are well opened by verifying the required WHSIP

5.4

Opening of the Wing valve.

()

Ensure that the choke valve is closed.

()

Ensure 10” valves in production & test manifolds are closed

[]

Slowly open the manual wing valve

()

Monitor any pressure increase while opening wing valve at the flow line pressure gauges d/s of the oil choke to make sure choke is not passing.

Page 12

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

5.5

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Threshold Flowrates in Production Lines. The 1st stage separator will be operated at varying flow rates depending on the wells being connected, turndown operations, ambient conditions and GOR of the produced crude. However, operation under very low flow rates can create unstable flow regimes in the production lines. Operating in unstable flow regime is not desirable and should be avoided. The production system and the process plant need to be looked at as a whole in order to define the operating boundary. The following threshold liquid rates are recommended for the production lines, from stable operation point of view for the individual lines. 10,000-15,000 bpd for the 18” NE and NW production lines; 5,000-15,000 bpd for the 18” South production line; The lower value of the thresholds is applicable to high GOR and/or low WC conditions, the higher value to low GOR and/or high WC conditions for all three production lines. When the production from individual clusters through production line falls below their recommended thresholds, it is suggested that the test line should be used, instead of production line, to minimize the terrain impact on liquid slugging. This will ensure stable flow to the oil section. Refer section 2.10 in this operating manual for the threshold limits of production line. Refer to section 2.8 in this operating manual for a detailed discussion on the Hydrate inhibition on production lines.

Page 13

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 14

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

6 6.1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

RECEIVING THE OIL Opening the Wellhead choke valve ()

Ensure that the Dor-3 plant is ready to receive the oil

()

Ensure that the line up from manifold to plant is ready. (Refer to OIL/SU/02 5. 5.3 / 4 / 5 /6)

()

Ensure that the differential pressure over the flowline ESDV is not more than 5 bar (check PG d/s choke and pressure in manifold). If not, equalize the pressure (refer section 8).

[]

Open the 10” well flow line ESDV by pulling the relevant switch mounted in front of the ESDV control panel

[]

Open the 10” isolation ball valve to the Production or test manifold

()

Ensure that the differential pressure over the departure line ESDV is not more than 5 bar. If not, equalize the pressure (refer section 8).

[]

Open the departure line ESDV by pulling the relevant switch in front of the ESDV control panel for the 10” test line or 18” production line

[]

Slowly open the choke valve to increase the pressure to normal in stages.

[]

Carry out a leak test for each step and make sure that the system is leak proof. In the event of a leak close the choke and depressurize through the plant and the residual pressure at the cluster side.

[]

Check

with

CCR

and

increase

the

production

according

to

requirements ()

Monitor the WHFP, WHFT and flow line pressure

()

Monitor the wellhead casing pressures. Ensure that they do not exceed the maximum allowable working pressure

Note: When the pressure at PG 1XXOP reaches above 10 barg, the PSLL-1XX 3P becomes healthy and disengaging the pin automatically resets D2 switch at WHCP override.

Page 15

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

6.2

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Opening more wells. []

If additional wells are required carry out the above procedure.

Page 16

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

7 7.1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

CHEMICAL INJECTION START-UP Corrosion inhibitor start up []

Line up all instruments and valves on the chemical injection Skid.

[]

Request an electrician to energize the pumps.

[]

Open all ¾” isolation valves to the 10” or 18” manifold.

[]

Open the ¾” ESDV on the injection line from ESDV control panel by pulling relevant switch mounted in front of the panel

[]

Open the pump suction & discharge valves.

()

Ensure that the pulsation damper is installed and the u/s isolation valve is open

()

Ensure that the PSV u/s valve is open.

()

Ensure that the flow meter is installed

[]

Adjust the flow rate adjustment screw according to the supplier curve in order to inject the required amount

[]

Start the selected pump.

[]

Perform a flow test with the calibration bottle to confirm the injection rate

Page 17

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

8

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

ESDV PRESSURE EQUALIZATION In this section procedures are given which shall be followed if there exists differential pressure over an ESDV that is to be opened.

8.1

Flowline ESDV pressure u/s higher than d/s The flowline u/s the ESDV shall be depressurized until a pressurize equal to the pressure d/s ESDV using the mobile burner. []

Connect the portable spools to the flowline vent point d/s the choke. Refer to section 3.2 in OIL/SD/06.

Note that the pressure in the flowline is high, unlike the situation described in section 3 of OIL/SD/06, where an initial depressurization via the test separator is performed prior to connecting the mobile burner. Hence extra care to be exercised in carrying out the procedure. []

Purge the drain system and light the pilot. Refer to section 3.3 in OIL/SD/06.

[]

Depressurize the flowline. Refer to section 3.4 in OIL/SD/06. Stop when the required pressure is reached.

[]

8.2

Disconnect the portable spool. Refer to section 3.5 in OIL/SD/06.

Flowline ESDV pressure u/s lower than d/s The pressure d/s the ESDV shall be let down to the same level of the pressure u/s. []

Line up the flow line to the cluster test manifold

[]

Depressurize the test manifold as per the procedure described in section 3.1 in OIL/SD/06. Stop when the required pressure is achieved.

Page 18

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

8.3

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Production or test line ESDV pressure u/s higher than d/s The cluster production/test manifold u/s the ESDV shall be depressurized until a pressurize equal to the pressure d/s ESDV using the mobile burner. []

Connect the portable spools to the manifold vent point. Refer to section 3.2 in OIL/SD/06.

Note that the pressure in the flowline is high, unlike the situation described in section 3 of OIL/SD/06, where an initial depressurization via the test separator is performed prior to connecting the mobile burner. Hence extra care to be exercised in carrying out the procedure. []

Purge the drain system and light the pilot. Refer to section 3.3 in OIL/SD/06.

[]

Depressurize the flowline. Refer to section 3.4 in OIL/SD/06. Stop when the required pressure is reached.

[]

8.4

Disconnect the portable spool. Refer to section 3.5 in OIL/SD/06.

Production line ESDV pressure u/s lower than d/s The pressure d/s the ESDV shall be let down to the same level of the pressure u/s. []

On Dorood-3, close the isolation valve in the concerned cluster production header to the production manifold.

[]

Override the PSLL on the concerned production header and enter in the “RED BOOK”.

()

Ensure that the liquid level in the HP Flare KO drum is at LLL.

[]

Open the 2” ball valve in the depressuring line on Dorood-3 from the concerned cluster production header.

[]

Slowly open the globe valve d/s this ball valve and start depressurizing the pipeline. Any liquid from the pipeline will be separated in the HP flare KO drum and pumped to the 2nd Stage Separater by the HP Flare Liquid Recovery Pump GX-200A/B.

[]

Carefully monitor the liquid level in the HP Flare KO drum. Page 19

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

[]

8.5

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Continue the depressurization until the required pressure is achieved.

Test line ESDV pressure u/s lower than d/s The pressure d/s the ESDV shall be let down to the same level of the pressure u/s. []

On Dorood-3, line-up the concerned cluster test header to the test manifold and isolate from the production manifold.

[]

Override the PSLL on the concerned test header and enter in the “RED BOOK”.

()

Ensure that other cluster test headers are isolated from Dorood-3 test manifold.

()

Ensure that the test header is lined up to the Test Separator.

[]

Lower the liquid level in the Test Separator to LLL by lowering the setting of LIC-3005.

[]

Depressurize the Test separator by lowering the set point of PIC/13003 to 0 barg step by step.

[]

When the pressure has dropped below 6 barg, close liquid outlet to the second stage.

[]

Carefully monitor the liquid level in the Test Separator. If depressurization is preformed slowly, the fluid velocity in the lines towards the test separator will be low and it is expected that no liquid will be carried into the test separator. However, in case during the depressurization liquid continues to flow into the Test Separator and the level approaches LSHH, the excess liquid shall be drained manually to the closed drain as per the following procedure: Stop the feed inlet by closing the inlet SDV 3000. Now open the control valve on the gas outlet line to flare to depressurize the separator. After the depressurization is over, drain the liquid to the closed drain drum. Once the level reaches LLL, stop the draining and again start the feed to the separator by opening SDV 3000. Repeat if required.

Page 20

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

[]

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Continue the depressurization and draining operation till the test line is is at the required pressure.

Page 21

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

9

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

FINAL STATUS The cluster oil wells are in production All fire extinguishers are placed in location Flare system is in operation at the plant. Turbo power generators are running and power is available. Sea water system running and fresh water and boiler feed water units are in operation The Steam boiler is in operation. Chemical injection is running at the optimum rate. Wellhead control panels / ESDV control panels / safety shutdown system are in automatic. All spectacle blinds are in the normal operating condition. Oil is exporting to tank farm.

Page 22

Page 2 to 2 Pages 3 to 17

Symbols <> () []

Rev No. 0

Date Feb. 2004

Safety Action Verification Action

Prepared by PFI

Verified by G.Faber

Approved by P.L. d’Haussy

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

TABLE OF CONTENTS 1

INITIAL PLANT STATUS.......................................................................................3

2

PRELIMINARIES...................................................................................................3

3

LINE UP.................................................................................................................4 3.1 3.2

4

STARTING OF THE HYDRAULIC CONTROL PANEL........................................5 4.1 4.2

5

Corrosion inhibitor start up.....................................................................................12

ESDV PRESSURE EQUALIZATION...................................................................13 8.1 8.2 8.3 8.4 8.5

9

Opening the Wellhead choke valve........................................................................10 Opening more wells................................................................................................11

CHEMICAL INJECTION START-UP...................................................................12 7.1

8

Opening The Down Hole Safety valve (SCSSV)......................................................7 Opening the Surface safety valve (SSV)..................................................................7 Opening the manual master valve............................................................................8 Opening of the Wing valve.......................................................................................8 Threshold Flowrates in Production Lines..................................................................8

RECEIVING THE OIL..........................................................................................10 6.1 6.2

7

Wellhead control panel.............................................................................................5 ESDV Panel............................................................................................................. 5

START UP OF THE FIRST WELL........................................................................7 5.1 5.2 5.3 5.4 5.5

6

Wellhead and flow line instruments line up...............................................................4 Valves line up........................................................................................................... 4

Flowline ESDV pressure u/s higher than d/s..........................................................13 Flowline ESDV pressure u/s lower than d/s............................................................13 Production or test line ESDV pressure u/s higher than d/s.....................................14 Production line ESDV pressure u/s lower than d/s.................................................14 Test line ESDV pressure u/s lower than d/s............................................................15

FINAL STATUS....................................................................................................17

Page 2

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 3

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 4

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

INITIAL PLANT STATUS

The cluster has been properly commissioned and RFSU certificate issued Dor-3 oil plant is ready to receive Fire & Gas detection system in the Cluster is in operation. All fire extinguishers are placed in location Flare system is in operation at the plant. Turbo power generators running & power available. Sea water system running & Fresh water and boiler feed water units in operation Steam boiler is in operation & steam is available to use. Chemical injection skid ready for start up. Wellhead cluster manifold flow line /New plant manifold / equipments under nitrogen pressure. Wellhead control panels /safety shutdown system commissioned. All spectacle blinds are in normal operating condition. Tank farm area is ready to receive oil.

2

PRELIMINARIES <>

Inform Dor-3 CCR. (Central control room)

<>

Inform RSES if rig is present in the cluster

<>

Ensure all personnel have H2S detectors & Escape masks.

<>

Ensure that all F&G systems are in automatic.

<>

Any F&G or process Inhibitions are entered in the “RED BOOK”.

<>

Ensure proper tools are available at site.

Page 5

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 6

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

3 3.1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

LINE UP Wellhead and flow line instruments line up.

()

Ensure that the following gauges are installed and in service for each well head and flow line.

20” casing pressure gauge. (PG 1XX 5P)

133/8” casing pressure gauge. (PG 1XX 4P)

95/8” casing pressure gauge. (PG 1XX 3P)

Up stream wing valve pressure gauge on the wellhead instrument flange.(PG 1XX 0P)

Down stream choke valve pressure gauges.(PG 1XX2P & PG 1XX 1P)

Down stream choke valve temperature gauge.(TG 1XX 0P)

()

Ensure that PSHH 1XX 2P down stream choke is lined up.

()

Ensure that PSLL 1XX 3P down stream choke is lined up.

()

Ensure that the SSV & SCSSV are correctly lined up from the WHCP.

()

Ensure that the CC/CP are installed.(CC set with proper weight).

()

Ensure that the ESDV’s are correctly lined up from ESDV control panel.

3.2

Valves line up ()

Ensure the Swab valve is closed.

()

Ensure that the oil choke is closed.

()

Ensure that the lower manual master valve is closed.

()

Ensure that the 10” ball valve on the 18” production line is closed.

()

Ensure that the 10” ball valve on the 10” test line is closed.

Page 7

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

()

Ensure that the flow line ESDV u/s & d/s 2”&1” drain valves are closed.

()

Ensure that the 18” production & 10” test manifold 2” & 1” high & low point vent lines are closed.

()

Ensure that the production & test manifold future Methanol points are closed & blinded.

Page 8

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

4

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

STARTING OF THE HYDRAULIC CONTROL PANEL. Refer to Vendor P&ID for valve tags.

4.1

Wellhead control panel. ()

Ensure that the PetroControls system specialist is in attendance (in case of first start-up only)

()

Ensure that the WHCP is properly commissioned

()

Ensure that power is available to the cluster.

[]

Power up the hydraulic pump NN-1 in the WHCP.

[]

Select the hydraulic pump to auto

()

Ensure BBB-1 final valve for SCSSV & BBB-3 final valve for SSV valves are closed inside WHCP

()

Ensure that the BBB-2 valve for SCSSV from external wire line unit is closed

()

Ensure that the BBB-4 valve for SSV from external wire line unit is closed

()

Ensure that the SCSSV control line at the WH is isolated by the needle valve

[]

Charge the hydraulic circuit to the operating pressure.(refer to vendor package start-up)

[]

Push charge button G-1 on the front panel to charge the fusible loop.

()

Monitor the pressure (N-2) gauge mounted in the WHCP (fusible loop control pressure should be about 4 bar.)

4.2

[]

Pull to reset C-1 switch mounted on the WHCP to reset ESD-1

()

Ensure ESD-1 is healthy

ESDV Panel. ()

Ensure the valves for the ESDV control panel are correctly lined up.

()

Ensure that the hydraulic pumps are energized & selected in auto.

Page 9

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

()

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Ensure that the final valve(L-XX) for each ESDV is open inside the ESDV control panel

[]

Push G-1 switch mounted in front of the panel to charge the fusible loop and Rig ESD loop.

[]

Pull C-1 switch mounted in front of the panel to reset ESD-1

[]

Pull & engage the pin on C-2 switch mounted in front of the panel to reset ESD-2.

Once the PSLL is healthy & PSHH in the test & production manifolds is healthy C-2 pin will disengage automatically.

Page 10

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

5

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

START UP OF THE FIRST WELL.

Note: If the fusible loop is healthy Overriding HH-1 valve inside the WHCP can also open the SCSSV & SSV.

5.1

Opening The Down Hole Safety valve (SCSSV) ()

Ensure ESD-1 has been reset.

[]

Open BBB-1 final valve to SCSSV from WHCP

[]

Pull & engage the pin of D1 switch mounted in front of the WHCP

[]

Slowly open the control line isolation needle valve from the wellhead to the SCSSV

()

Ensure that the control line pressure is maintained automatically by the motorized pump at a regulated pressure of about 300 barg and that the pump stops automatically.

()

Once the control line is at the operating pressure D-1 will automatically disengage

5.2

Opening the Surface safety valve (SSV). Refer to vendor P&ID for some valve tag []

Open BBB-3 final valve to the SSV inside WHCP

[]

Pull & engage the pin of D2 switch mounted in front of the WHCP

[.]

Check the hydraulic pump starts automatically & the pressure is increasing at Q2 pressure gauge mounted in front of the WHCP (SSV regulated pressure is about 200barg)

()

Ensure the SSV has opened and the hydraulic control pressure is maintained at about 200barg and the pump has stopped.

Page 11

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

5.3

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Opening the manual master valve.

[]

Slowly open the manual lower master valve fully ( this valve should be either full open or fully close , not to use for controlling purposes.)

()

Monitor that the pressure increasing on wellhead pressure gauge PG 1XX OP u/s of wing valve.

()

Ensure that the SCSSV and SSV are well opened by verifying the required WHSIP

5.4

Opening of the Wing valve.

()

Ensure that the choke valve is closed.

()

Ensure 10” valves in production & test manifolds are closed

[]

Slowly open the manual wing valve

()

Monitor any pressure increase while opening wing valve at the flow line pressure gauges d/s of the oil choke to make sure choke is not passing.

Page 12

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

5.5

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Threshold Flowrates in Production Lines. The 1st stage separator will be operated at varying flow rates depending on the wells being connected, turndown operations, ambient conditions and GOR of the produced crude. However, operation under very low flow rates can create unstable flow regimes in the production lines. Operating in unstable flow regime is not desirable and should be avoided. The production system and the process plant need to be looked at as a whole in order to define the operating boundary. The following threshold liquid rates are recommended for the production lines, from stable operation point of view for the individual lines. 10,000-15,000 bpd for the 18” NE and NW production lines; 5,000-15,000 bpd for the 18” South production line; The lower value of the thresholds is applicable to high GOR and/or low WC conditions, the higher value to low GOR and/or high WC conditions for all three production lines. When the production from individual clusters through production line falls below their recommended thresholds, it is suggested that the test line should be used, instead of production line, to minimize the terrain impact on liquid slugging. This will ensure stable flow to the oil section. Refer section 2.10 in this operating manual for the threshold limits of production line. Refer to section 2.8 in this operating manual for a detailed discussion on the Hydrate inhibition on production lines.

Page 13

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

Page 14

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

6 6.1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

RECEIVING THE OIL Opening the Wellhead choke valve ()

Ensure that the Dor-3 plant is ready to receive the oil

()

Ensure that the line up from manifold to plant is ready. (Refer to OIL/SU/02 5. 5.3 / 4 / 5 /6)

()

Ensure that the differential pressure over the flowline ESDV is not more than 5 bar (check PG d/s choke and pressure in manifold). If not, equalize the pressure (refer section 8).

[]

Open the 10” well flow line ESDV by pulling the relevant switch mounted in front of the ESDV control panel

[]

Open the 10” isolation ball valve to the Production or test manifold

()

Ensure that the differential pressure over the departure line ESDV is not more than 5 bar. If not, equalize the pressure (refer section 8).

[]

Open the departure line ESDV by pulling the relevant switch in front of the ESDV control panel for the 10” test line or 18” production line

[]

Slowly open the choke valve to increase the pressure to normal in stages.

[]

Carry out a leak test for each step and make sure that the system is leak proof. In the event of a leak close the choke and depressurize through the plant and the residual pressure at the cluster side.

[]

Check

with

CCR

and

increase

the

production

according

to

requirements ()

Monitor the WHFP, WHFT and flow line pressure

()

Monitor the wellhead casing pressures. Ensure that they do not exceed the maximum allowable working pressure

Note: When the pressure at PG 1XXOP reaches above 10 barg, the PSLL-1XX 3P becomes healthy and disengaging the pin automatically resets D2 switch at WHCP override.

Page 15

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

6.2

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Opening more wells. []

If additional wells are required carry out the above procedure.

Page 16

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

7 7.1

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

CHEMICAL INJECTION START-UP Corrosion inhibitor start up []

Line up all instruments and valves on the chemical injection Skid.

[]

Request an electrician to energize the pumps.

[]

Open all ¾” isolation valves to the 10” or 18” manifold.

[]

Open the ¾” ESDV on the injection line from ESDV control panel by pulling relevant switch mounted in front of the panel

[]

Open the pump suction & discharge valves.

()

Ensure that the pulsation damper is installed and the u/s isolation valve is open

()

Ensure that the PSV u/s valve is open.

()

Ensure that the flow meter is installed

[]

Adjust the flow rate adjustment screw according to the supplier curve in order to inject the required amount

[]

Start the selected pump.

[]

Perform a flow test with the calibration bottle to confirm the injection rate

Page 17

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

8

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

ESDV PRESSURE EQUALIZATION In this section procedures are given which shall be followed if there exists differential pressure over an ESDV that is to be opened.

8.1

Flowline ESDV pressure u/s higher than d/s The flowline u/s the ESDV shall be depressurized until a pressurize equal to the pressure d/s ESDV using the mobile burner. []

Connect the portable spools to the flowline vent point d/s the choke. Refer to section 3.2 in OIL/SD/06.

Note that the pressure in the flowline is high, unlike the situation described in section 3 of OIL/SD/06, where an initial depressurization via the test separator is performed prior to connecting the mobile burner. Hence extra care to be exercised in carrying out the procedure. []

Purge the drain system and light the pilot. Refer to section 3.3 in OIL/SD/06.

[]

Depressurize the flowline. Refer to section 3.4 in OIL/SD/06. Stop when the required pressure is reached.

[]

8.2

Disconnect the portable spool. Refer to section 3.5 in OIL/SD/06.

Flowline ESDV pressure u/s lower than d/s The pressure d/s the ESDV shall be let down to the same level of the pressure u/s. []

Line up the flow line to the cluster test manifold

[]

Depressurize the test manifold as per the procedure described in section 3.1 in OIL/SD/06. Stop when the required pressure is achieved.

Page 18

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

8.3

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Production or test line ESDV pressure u/s higher than d/s The cluster production/test manifold u/s the ESDV shall be depressurized until a pressurize equal to the pressure d/s ESDV using the mobile burner. []

Connect the portable spools to the manifold vent point. Refer to section 3.2 in OIL/SD/06.

Note that the pressure in the flowline is high, unlike the situation described in section 3 of OIL/SD/06, where an initial depressurization via the test separator is performed prior to connecting the mobile burner. Hence extra care to be exercised in carrying out the procedure. []

Purge the drain system and light the pilot. Refer to section 3.3 in OIL/SD/06.

[]

Depressurize the flowline. Refer to section 3.4 in OIL/SD/06. Stop when the required pressure is reached.

[]

8.4

Disconnect the portable spool. Refer to section 3.5 in OIL/SD/06.

Production line ESDV pressure u/s lower than d/s The pressure d/s the ESDV shall be let down to the same level of the pressure u/s. []

On Dorood-3, close the isolation valve in the concerned cluster production header to the production manifold.

[]

Override the PSLL on the concerned production header and enter in the “RED BOOK”.

()

Ensure that the liquid level in the HP Flare KO drum is at LLL.

[]

Open the 2” ball valve in the depressuring line on Dorood-3 from the concerned cluster production header.

[]

Slowly open the globe valve d/s this ball valve and start depressurizing the pipeline. Any liquid from the pipeline will be separated in the HP flare KO drum and pumped to the 2nd Stage Separater by the HP Flare Liquid Recovery Pump GX-200A/B.

[]

Carefully monitor the liquid level in the HP Flare KO drum. Page 19

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

[]

8.5

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Continue the depressurization until the required pressure is achieved.

Test line ESDV pressure u/s lower than d/s The pressure d/s the ESDV shall be let down to the same level of the pressure u/s. []

On Dorood-3, line-up the concerned cluster test header to the test manifold and isolate from the production manifold.

[]

Override the PSLL on the concerned test header and enter in the “RED BOOK”.

()

Ensure that other cluster test headers are isolated from Dorood-3 test manifold.

()

Ensure that the test header is lined up to the Test Separator.

[]

Lower the liquid level in the Test Separator to LLL by lowering the setting of LIC-3005.

[]

Depressurize the Test separator by lowering the set point of PIC/13003 to 0 barg step by step.

[]

When the pressure has dropped below 6 barg, close liquid outlet to the second stage.

[]

Carefully monitor the liquid level in the Test Separator. If depressurization is preformed slowly, the fluid velocity in the lines towards the test separator will be low and it is expected that no liquid will be carried into the test separator. However, in case during the depressurization liquid continues to flow into the Test Separator and the level approaches LSHH, the excess liquid shall be drained manually to the closed drain as per the following procedure: Stop the feed inlet by closing the inlet SDV 3000. Now open the control valve on the gas outlet line to flare to depressurize the separator. After the depressurization is over, drain the liquid to the closed drain drum. Once the level reaches LLL, stop the draining and again start the feed to the separator by opening SDV 3000. Repeat if required.

Page 20

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

[]

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

Continue the depressurization and draining operation till the test line is is at the required pressure.

Page 21

Petrofac International Ltd. JI-163 Doc. No. OIL/SU/01 Rev 0

9

Elf Petroleum Iran Dorood Project Onshore Facilities & New Plant Oil Producer Start up Procedure

FINAL STATUS The cluster oil wells are in production All fire extinguishers are placed in location Flare system is in operation at the plant. Turbo power generators are running and power is available. Sea water system running and fresh water and boiler feed water units are in operation The Steam boiler is in operation. Chemical injection is running at the optimum rate. Wellhead control panels / ESDV control panels / safety shutdown system are in automatic. All spectacle blinds are in the normal operating condition. Oil is exporting to tank farm.

Page 22

Related Documents

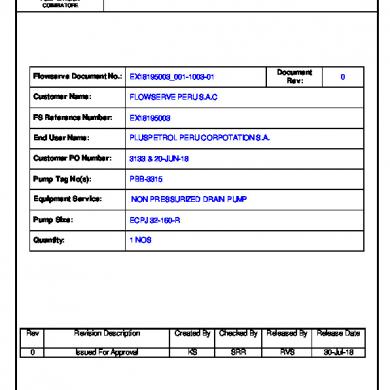

Ex18195003_001-1003-01 Rev.0

February 2021 1

Site Office Lighting Rev.0

January 2021 4

Oil-su-01 Rev 0

February 2021 0

Et-107-pemex-2019 Rev 0--rev De 30%

February 2021 0

Trigonometry - Review Questions Answers Rev 0

January 2021 0

217-1-pt-qsm1, Rev.0

January 2021 0More Documents from "Mudassir Mirza"