Six Sigma Green Belt Project Charter

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Six Sigma Green Belt Project Charter as PDF for free.

More details

- Words: 1,047

- Pages: 8

Loading documents preview...

Six Sigma Green Belt Project Charter

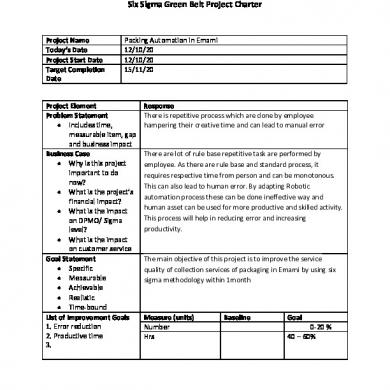

Project Name Today’s Date Project Start Date Target Completion Date

Packing Automation in Emami 12/10/20 12/10/20 15/11/20

Project Element Response Problem Statement There is repetitive process which are done by employee hampering their creative time and can lead to manual error Includes time, measurable item, gap and business impact Business Case There are lot of rule base repetitive task are performed by Why is this project employee. As there are rule base and standard process, it important to do requires respective time from person and can be monotonous. now? This can also lead to human error. By adapting Robotic What is the project’s automation process these can be done ineffective way and financial impact? human asset can be used for more productive and skilled activity. What is the impact This process will help in reducing error and increasing on DPMO/ Sigma productivity. level? What is the impact on customer service Goal Statement The main objective of this project is to improve the service Specific quality of collection services of packaging in Emami by using six Measurable sigma methodology within 1month Achievable Realistic Time-bound List of Improvement Goals Measure (units) Baseline Goal 1. Error reduction Number 0-20 % 2. Productive time Hrs 40 – 60% 3.

Six Sigma Green Belt Project Charter Process Describe the process in which the problem exists Project Scope What part of the process will be addressed? What are the boundaries of the project or process? What areas are inside or outside the team’s focus or authority? Attach a SIPOC diagram if necessary Team Project Sponsor Key Stakeholders Team Lead Team Members Process Owner Other Timeline by Project Stage

Currently data comes in form of email attachment file, which user must download and convert into excel manually. Post that he must enter same data in CRM system, generate report and mail to supervisor as attachment. The whole process is repeated again and again by person on regular basis Automating the entire process of data conversion from mail to sheet, entering in CRM system, generating report and mailing it to concern person. The boundary is already set process and rule which does not require human decision. The whole process is inside focused approach.

Member Name A. Agarwal M. Goyenka, R Agarwal S K Mandal T. Barman, K. Datta Joy Saha Milestone

Define Project Charter and kickoff Measure Define and collect data

Target Completion Date 12/10/2020 18/10/2020

Analysis Find causes

24/10/2020

Improve Fix causes

10/11/2020

Control Standardize the fix

14/11/2020

Team Charter Packaging Automation in Emami

Project Title

Expectation Attendance

Example Attendance is required at all team meetings.

Team Rule

Meeting should be attended by all member

Changes in meeting times must be made at least 24 hours ahead of time. Participation

Team members may not be substituted unless

All members must participate in the discussions

approved by team leader. Focus

We will stay on task and on topic, using the

Members should focus on the business problem.

Project Charter as our guide. A meeting agenda will be publishedat least one day in advance. Interruptions

Interruptions for emergencies only. Phones

No external interference ie. Alarm, Mobile etc

turned to silent. Preparation

All deliverables are expected to be completed

Each meeting will start with a published agenda.

in a timely manner. Each meeting will have a published agenda. Timeliness

Meetings will begin promptly as scheduled.

All members must present on time during meetings.

Team Charter Decisions

We will choose the best decision-making

Decisions made by team will be final.

method for each situation. We will support decisions made by the team. Data

We will rely on data to make decisions.

Quantitative support is required to approve final decision.

Conflict

We welcome honest disagreements, as long

All members should have mutual respect with

as everyone is treated with respect. A

other members argument and view. Identify the conflict and

facilitator will be used if conflict cannot be

Mitigate with communication. Accept right criticism and

resolved.

suggestion.

Other

Team Member

S K Mandal Joy Saha T. Barman K. Datta

Role

Team lead Process Engineer Quality Business analyst

Signature

Team Charter

DATA COLLECTION PLAN Measure

Data type

How

Who

When

Quality test

Continuous

Compare with old data

Engineer

After project starts, every 10th unit

Update Costing

Continuous

Recalculate the

Project

After successful

amount per unit

Manager

completion of testing

Team Charter Customer Feedback

Discrete

Surveys, customer

Customer

Before start and

reviews

support

after end the project

Process Map Interview with user and data capture

Validate the Data

Map Process

Identify are to Automate

Identify Risk and Mitigate

Rollout

Team Charter NULL AND ALTERNATIVE HYPOTHESIS Before Improvement H0: q <= 3 HA: q > 3 (where q is customer rating given to the product quality, where 1 is lowest and 5 is highest) H0: p <= 3 HA: p > 3 (where p is customer rating given to the product price, where 1 is not good for price and 5 is good for price) After Improvement H0: q <= 3.5 HA: q > 3.5 (where q is customer rating given to the product quality, where 1 is lowest and 5 is highest) H0: p <= 3.5 HA: p > 3.5 (where p is customer rating given to the product price, where 1 is not good for price and 5 is good for price)

Team Charter The Capstone The six sigma green belt specialization is indeed a great course to learn. Especially for the ones who consider quality over everything. The lessons learned throughout the course are: Six Sigma is all about quality improvement effectively by removing the defects and it is highly customer focused. Lean is a process which is used to increase customer value while eliminating waste in the process. Six Sigma uses DMAIC methodology, which is Define, Measure, Analyze, Improve Phase, Control phase. There are different quality tools like flow charts and process map for collecting data, check sheets, histograms, Pareto Charts, Scatter diagrams to determine different aspects when dealing with quality. Team plays an important in quality improvement. The manager should value and give importance to each one of the team members and their point of view, the manager should involve them in the decision making process.

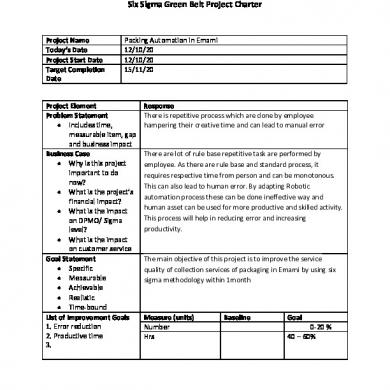

Project Name Today’s Date Project Start Date Target Completion Date

Packing Automation in Emami 12/10/20 12/10/20 15/11/20

Project Element Response Problem Statement There is repetitive process which are done by employee hampering their creative time and can lead to manual error Includes time, measurable item, gap and business impact Business Case There are lot of rule base repetitive task are performed by Why is this project employee. As there are rule base and standard process, it important to do requires respective time from person and can be monotonous. now? This can also lead to human error. By adapting Robotic What is the project’s automation process these can be done ineffective way and financial impact? human asset can be used for more productive and skilled activity. What is the impact This process will help in reducing error and increasing on DPMO/ Sigma productivity. level? What is the impact on customer service Goal Statement The main objective of this project is to improve the service Specific quality of collection services of packaging in Emami by using six Measurable sigma methodology within 1month Achievable Realistic Time-bound List of Improvement Goals Measure (units) Baseline Goal 1. Error reduction Number 0-20 % 2. Productive time Hrs 40 – 60% 3.

Six Sigma Green Belt Project Charter Process Describe the process in which the problem exists Project Scope What part of the process will be addressed? What are the boundaries of the project or process? What areas are inside or outside the team’s focus or authority? Attach a SIPOC diagram if necessary Team Project Sponsor Key Stakeholders Team Lead Team Members Process Owner Other Timeline by Project Stage

Currently data comes in form of email attachment file, which user must download and convert into excel manually. Post that he must enter same data in CRM system, generate report and mail to supervisor as attachment. The whole process is repeated again and again by person on regular basis Automating the entire process of data conversion from mail to sheet, entering in CRM system, generating report and mailing it to concern person. The boundary is already set process and rule which does not require human decision. The whole process is inside focused approach.

Member Name A. Agarwal M. Goyenka, R Agarwal S K Mandal T. Barman, K. Datta Joy Saha Milestone

Define Project Charter and kickoff Measure Define and collect data

Target Completion Date 12/10/2020 18/10/2020

Analysis Find causes

24/10/2020

Improve Fix causes

10/11/2020

Control Standardize the fix

14/11/2020

Team Charter Packaging Automation in Emami

Project Title

Expectation Attendance

Example Attendance is required at all team meetings.

Team Rule

Meeting should be attended by all member

Changes in meeting times must be made at least 24 hours ahead of time. Participation

Team members may not be substituted unless

All members must participate in the discussions

approved by team leader. Focus

We will stay on task and on topic, using the

Members should focus on the business problem.

Project Charter as our guide. A meeting agenda will be publishedat least one day in advance. Interruptions

Interruptions for emergencies only. Phones

No external interference ie. Alarm, Mobile etc

turned to silent. Preparation

All deliverables are expected to be completed

Each meeting will start with a published agenda.

in a timely manner. Each meeting will have a published agenda. Timeliness

Meetings will begin promptly as scheduled.

All members must present on time during meetings.

Team Charter Decisions

We will choose the best decision-making

Decisions made by team will be final.

method for each situation. We will support decisions made by the team. Data

We will rely on data to make decisions.

Quantitative support is required to approve final decision.

Conflict

We welcome honest disagreements, as long

All members should have mutual respect with

as everyone is treated with respect. A

other members argument and view. Identify the conflict and

facilitator will be used if conflict cannot be

Mitigate with communication. Accept right criticism and

resolved.

suggestion.

Other

Team Member

S K Mandal Joy Saha T. Barman K. Datta

Role

Team lead Process Engineer Quality Business analyst

Signature

Team Charter

DATA COLLECTION PLAN Measure

Data type

How

Who

When

Quality test

Continuous

Compare with old data

Engineer

After project starts, every 10th unit

Update Costing

Continuous

Recalculate the

Project

After successful

amount per unit

Manager

completion of testing

Team Charter Customer Feedback

Discrete

Surveys, customer

Customer

Before start and

reviews

support

after end the project

Process Map Interview with user and data capture

Validate the Data

Map Process

Identify are to Automate

Identify Risk and Mitigate

Rollout

Team Charter NULL AND ALTERNATIVE HYPOTHESIS Before Improvement H0: q <= 3 HA: q > 3 (where q is customer rating given to the product quality, where 1 is lowest and 5 is highest) H0: p <= 3 HA: p > 3 (where p is customer rating given to the product price, where 1 is not good for price and 5 is good for price) After Improvement H0: q <= 3.5 HA: q > 3.5 (where q is customer rating given to the product quality, where 1 is lowest and 5 is highest) H0: p <= 3.5 HA: p > 3.5 (where p is customer rating given to the product price, where 1 is not good for price and 5 is good for price)

Team Charter The Capstone The six sigma green belt specialization is indeed a great course to learn. Especially for the ones who consider quality over everything. The lessons learned throughout the course are: Six Sigma is all about quality improvement effectively by removing the defects and it is highly customer focused. Lean is a process which is used to increase customer value while eliminating waste in the process. Six Sigma uses DMAIC methodology, which is Define, Measure, Analyze, Improve Phase, Control phase. There are different quality tools like flow charts and process map for collecting data, check sheets, histograms, Pareto Charts, Scatter diagrams to determine different aspects when dealing with quality. Team plays an important in quality improvement. The manager should value and give importance to each one of the team members and their point of view, the manager should involve them in the decision making process.

Related Documents

Six Sigma Green Belt Project Charter

January 2021 3

Lean Six Sigma Green Belt

January 2021 1

Six Sigma Yellow Belt

February 2021 0

Six Sigma

January 2021 1

Lean Six Sigma Yellow Belt - Iassc

January 2021 1

The Certified Six Sigma Yellow Belt Handbook

January 2021 1More Documents from "Paul Brea"

Six Sigma Green Belt Project Charter

January 2021 3

Business Environment Project

January 2021 1

Penthouse Usa - January 2014

March 2021 0

Korean War

February 2021 1