Ar-15 To Ar-180 Magazine Conversion

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Ar-15 To Ar-180 Magazine Conversion as PDF for free.

More details

- Words: 1,519

- Pages: 4

Loading documents preview...

This is a more detailed AR15/M16 to AR18/180 magazine conversion process to replace the one you have put at the bottom of the "PARTS" page. (Thank you by the way) This version is more detailed and will allow fellow 180's to do the conversion easier. Please replace the one on the board with this. (Thanks again).... To convert AR15/M16 magazines to fit the AR18/180 rifle you will need the following; Dremel tool with fiber-type cutting wheel, painters-type masking tape, #2 pencil, small hammer or similar tool, flat head screwdriver, adjustable pliers, safety glasses, and of course the AR18/180 and AR15/M16 magazines. You will want to wear down the cutting wheel to 1/2-inch diameter first. This can be done by turning it on high speed and grinding it down against a hard surface like stone or brick. Use light pressure so the wheel does not break. Once it has worn down to 1/2 inch or so check to be sure it is completely round. The 1/2-inch wheel will give you the best results. First use a magazine that is old and worn that you would not miss too much if you didn't get this right your first attempt. Place a strip of masking tape on the mag at the area the magazine catch will go. With the bolt closed, hold the magazine catch in, insert the magazine till you feel the follower connect with the bolt carrier and the lips at the top of the mag. Holding this in place, release the magazine catch and lightly tap on the foreword end with the hammer. Push the mag catch in again and remove the magazine. You will see an indention left by the magazine catch on the tape. With the pencil draw a line between the first two ribs in the mag at the indentation. Use the top of the mag to get your line level and straight. Now you are ready to cut. Take the Dremel with the 1/2-inch wheel and in the direction of the line cut SLIGHTLY into it going through the tape but not through the metal. Remove tape. Use the top of the magazine as a guide and work a small slit about

the width of the cutting wheel into the side of the mag going all the way through from rib to rib. Next, insert the mag into the rifle. You will feel one of two things. If the mag 'clicks' in without force, widen the slit from the bottom. This can be done by inserting the cutting wheel into the slit and slowly working it back and forth using the surface instead of the side to grind it down. Be careful not to widen it too much. The AR18/180 is designed for everything to fit loosely but too loose will cause functioning problems. The width of the finished slit is almost the width of two cutting wheels so have a light hand. If the magazine requires pressure before it 'clicks' you will need to widen from the TOP of your slit. The magazine should now fit. Once the mag is fitted to the rifle another slight modification should be done to allow flawless performance. The AR15/M16 magazine catches may have to be flattened slightly in order to let the magazine drop freely from the AR18/180. If the mags are govt. issue you will have to do this otherwise you will be pulling them out by hand. This is done with the flathead screwdriver and pliers. Open the pliers till they are about the same width as the magazine. Place the screwdriver flat against the AR15/M16 mag catch from the top side. With one jaw end of the pliers on the screwdriver head and the other on the back side of the magazine body (place near the edge and it is recommended that you cover that point of the mag with tape to avoid scratching the finish) squeeze lightly flattening the catch slightly. Start at the top and work your way down. Don’t crush or dent it, all you want to do is flatten it slightly. All you really need to flatten is about 1mm worth of the catch. If you have done this correctly the original catch should be about 1mm closer to and even with the mag body. It should also still work in AR15/M16 rifles like Daewoo’s, FNC’s. PART TWO MESSAGE: Webmaster, add this to my magazine conversion directions please. In my haste to get the instructions on converting cheaper govt. mags to work in AR18/180's I left out one important step. Perhaps it was the approaching thunderstorm or the lack of caffine either way I left out an important step. This is easy and the tools you need you should

already have (Dremel with fiber-type cutting wheel) if you have done the conversion up to here. This involves modifying the follower to allow all 20, 30, or 40 rounds to feed, particularly the last round. (I overlooked this probably because I have modified the bolt hold device on my 180 to function with the previously mentioned process alone.) Anyway, this step takes about 5 minutes and once again I recommend using a cheap magazine to practice on first. Now, remove the floorplate of the magazine and remove the spring and follower. On the back end of the follower you will notice the block that protrudes through the back of the magazine body. This is what pushes the bolt device into the path of the bolt on AR-15 type rifles. For it to function properly in AR18/180's this must be cut down. It is best if you do this after "slitting" the magazine body as the plastic followers may gum up the cutting wheel and the metal ones may damage the wheel by shrinking it further. You may just want to use a new wheel. Measure 3mm (around 5/16") down from the top of the bolt catch block and mark it with a pencil. Draw a verticle line even with the top. I recommend useing a good pair of gloves for protection in case the wheel jumps and also if you are doing this to a metal follower as they tend to heat up badly. Also, you may want to use safety glasses about now. Hold firmly and cut along your line. You will want to cut down to the level even with the sides of the follower but not into it. After you have successfully done this cut from the top, level with the sides, into your mark. Basically you want to remove 3mm off the top of the follower and take that chunk out. Our AR18/180's are designed around loose tolerances so this doesn't have to be perfect or pretty, only functional, like the rifle itself. On your practice magazine try a 2mm cut and see if it works. It is better to cut too little than too much. If it still snags on the last round cut another 1mm off. Don't practice this with live ammo but if you dont have a blank or a dummy round then please be carefull. Always point the muzzle in a safe direction.

Method #2 This method comes from [email protected] Instead of using masking tape on the mag, and then hitting the mag release to mark the indent......INSTEAD use the liquid "White Out" correction fluid. With the mag out of the weapon, brush on some of this liquid on the inside of the mag catch. Insert the mag into the weapon while pushing down on the mag release. Allow the mag release to fall on the mag when the mag is properly inserted, all the way in. You now have a marking exactly on the mag, in the same contour as the mag catch. 2.Buy the Israeli AR15 "Orlite" 30 round mag for conversion. A little more expensive than old AR15 metal mags, but it has several advantages: A.It's easier to mill the slot in plastic than in metal. NOTE: take a LITTLE off at a time! You can always take a little more, and a little more, and a little more off, but you can't put it back once it's gone! B.The orlite mag fits in the AR180 mag well a little better AND, most importantly.............. C.Compare the feed lips of 20 round METAL AR15 mag to a 30 round METAL AR15 mag. The 20 round mags have FULL LENGTH lips, while 30 rounder feed lips only go half the length of the mag. Israeli 30 round Orlite mage are the only 30 round mag with FULL LENGTH lips. It has been my experience that the full length lip is the better design, especially so in the AR180, as it eliminates many of the failures to feed. John - Orlites are getting a little harder to find, but you might try the Pmag by Magpul (usually find them for around $12-14 http://www.44mag.com/category/pmag_magazines - free shipping) or the Lancer L5 mags. They are both plastic. I have used the Pmags in my other AR (Bushmaster AR-15) and like them a lot, but I have not yet tried to modify on for the AR-180.

the width of the cutting wheel into the side of the mag going all the way through from rib to rib. Next, insert the mag into the rifle. You will feel one of two things. If the mag 'clicks' in without force, widen the slit from the bottom. This can be done by inserting the cutting wheel into the slit and slowly working it back and forth using the surface instead of the side to grind it down. Be careful not to widen it too much. The AR18/180 is designed for everything to fit loosely but too loose will cause functioning problems. The width of the finished slit is almost the width of two cutting wheels so have a light hand. If the magazine requires pressure before it 'clicks' you will need to widen from the TOP of your slit. The magazine should now fit. Once the mag is fitted to the rifle another slight modification should be done to allow flawless performance. The AR15/M16 magazine catches may have to be flattened slightly in order to let the magazine drop freely from the AR18/180. If the mags are govt. issue you will have to do this otherwise you will be pulling them out by hand. This is done with the flathead screwdriver and pliers. Open the pliers till they are about the same width as the magazine. Place the screwdriver flat against the AR15/M16 mag catch from the top side. With one jaw end of the pliers on the screwdriver head and the other on the back side of the magazine body (place near the edge and it is recommended that you cover that point of the mag with tape to avoid scratching the finish) squeeze lightly flattening the catch slightly. Start at the top and work your way down. Don’t crush or dent it, all you want to do is flatten it slightly. All you really need to flatten is about 1mm worth of the catch. If you have done this correctly the original catch should be about 1mm closer to and even with the mag body. It should also still work in AR15/M16 rifles like Daewoo’s, FNC’s. PART TWO MESSAGE: Webmaster, add this to my magazine conversion directions please. In my haste to get the instructions on converting cheaper govt. mags to work in AR18/180's I left out one important step. Perhaps it was the approaching thunderstorm or the lack of caffine either way I left out an important step. This is easy and the tools you need you should

already have (Dremel with fiber-type cutting wheel) if you have done the conversion up to here. This involves modifying the follower to allow all 20, 30, or 40 rounds to feed, particularly the last round. (I overlooked this probably because I have modified the bolt hold device on my 180 to function with the previously mentioned process alone.) Anyway, this step takes about 5 minutes and once again I recommend using a cheap magazine to practice on first. Now, remove the floorplate of the magazine and remove the spring and follower. On the back end of the follower you will notice the block that protrudes through the back of the magazine body. This is what pushes the bolt device into the path of the bolt on AR-15 type rifles. For it to function properly in AR18/180's this must be cut down. It is best if you do this after "slitting" the magazine body as the plastic followers may gum up the cutting wheel and the metal ones may damage the wheel by shrinking it further. You may just want to use a new wheel. Measure 3mm (around 5/16") down from the top of the bolt catch block and mark it with a pencil. Draw a verticle line even with the top. I recommend useing a good pair of gloves for protection in case the wheel jumps and also if you are doing this to a metal follower as they tend to heat up badly. Also, you may want to use safety glasses about now. Hold firmly and cut along your line. You will want to cut down to the level even with the sides of the follower but not into it. After you have successfully done this cut from the top, level with the sides, into your mark. Basically you want to remove 3mm off the top of the follower and take that chunk out. Our AR18/180's are designed around loose tolerances so this doesn't have to be perfect or pretty, only functional, like the rifle itself. On your practice magazine try a 2mm cut and see if it works. It is better to cut too little than too much. If it still snags on the last round cut another 1mm off. Don't practice this with live ammo but if you dont have a blank or a dummy round then please be carefull. Always point the muzzle in a safe direction.

Method #2 This method comes from [email protected] Instead of using masking tape on the mag, and then hitting the mag release to mark the indent......INSTEAD use the liquid "White Out" correction fluid. With the mag out of the weapon, brush on some of this liquid on the inside of the mag catch. Insert the mag into the weapon while pushing down on the mag release. Allow the mag release to fall on the mag when the mag is properly inserted, all the way in. You now have a marking exactly on the mag, in the same contour as the mag catch. 2.Buy the Israeli AR15 "Orlite" 30 round mag for conversion. A little more expensive than old AR15 metal mags, but it has several advantages: A.It's easier to mill the slot in plastic than in metal. NOTE: take a LITTLE off at a time! You can always take a little more, and a little more, and a little more off, but you can't put it back once it's gone! B.The orlite mag fits in the AR180 mag well a little better AND, most importantly.............. C.Compare the feed lips of 20 round METAL AR15 mag to a 30 round METAL AR15 mag. The 20 round mags have FULL LENGTH lips, while 30 rounder feed lips only go half the length of the mag. Israeli 30 round Orlite mage are the only 30 round mag with FULL LENGTH lips. It has been my experience that the full length lip is the better design, especially so in the AR180, as it eliminates many of the failures to feed. John - Orlites are getting a little harder to find, but you might try the Pmag by Magpul (usually find them for around $12-14 http://www.44mag.com/category/pmag_magazines - free shipping) or the Lancer L5 mags. They are both plastic. I have used the Pmags in my other AR (Bushmaster AR-15) and like them a lot, but I have not yet tried to modify on for the AR-180.

Related Documents

Ar-15 To Ar-180 Magazine Conversion

February 2021 0

Gage To Decimal Conversion

February 2021 0

Conversion

February 2021 0

The Conversion Marketers Guide To Landingpage Copywriting

February 2021 0

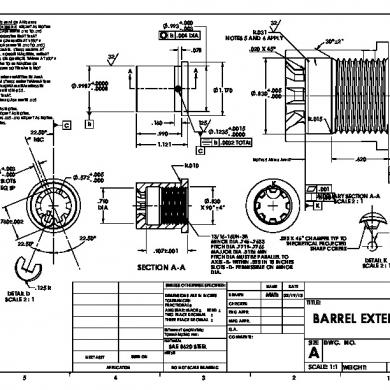

Ar15 Barrel Extension New

February 2021 0

The Conversion Marketers Guide To Landingpage Copywriting

January 2021 0More Documents from "aflorarte"

Ar-15 To Ar-180 Magazine Conversion

February 2021 0

Peon De Rey 52.pdf

January 2021 1

Peon De Rey 28.pdf

January 2021 1

Peon De Rey 49.pdf

January 2021 1

Peon De Rey 71.pdf

January 2021 1