Concrete Volute Pump Presentation,2015-08

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View Concrete Volute Pump Presentation,2015-08 as PDF for free.

More details

- Words: 1,599

- Pages: 56

Loading documents preview...

Product Presentation Concrete Volute Pump (CVP)

Agenda

Introduction Flowserve Concrete Volute Pump Comparison to VCT Benefits References Summary Installation movie

Flowserve

History The history of Flowserve goes back to the founding of Simpson & Dresser Pumps in 1790.

Flowserve •

Over 18000 employees

•

Operates in over 55 countries around the world

•

Serving customers in over 90 countries

Flowserve

Hengelo Founded in 1868 by Brothers Stork

Flowserve

Served Industries Petrochemical Refining Power Generation General Industry Irrigation & Drainage

Flowserve Hengelo Products

Service Contracts

Retrofits Replacements coping with existing boundary limits

History Flowserve Hengelo The Netherlands 1868

Founded as machine company Brothers Stork & Co. by C.T. Stork and C.C. Stork. Mainly manufacturing steam machines and boilers. Soon expanded with diesel engines, water turbines, pumps, etc.

1985

The several Stork departments became separate entities i.e. steam boilers, pumps, etc.

1997

Stork Engineered Pumps aquired by BW/IP International In June 1997 merging with Durco International. Company name is changed into

2000

Flowserve Corporation acquires Ingersoll-Dresser Pumps

Products

API diffuser pumps

OH2 (PHL)

OH3 (PVXM)

OH5 (PVML)

Horizontal, centerline-mounted, Vertical, in-line, single-stage Vertical Close-coupled, in-line, single-stage single-stage overhung pumps overhung pumps with overhung pumps separate bearing brackets

Products

VCT

AFV

CVP

Vertical Mixed Flow Circulating Pumps (VOA, VSO)

Axial Flow Vertical Pumps (VOP)

Concrete Volute Pumps (BSV, BCV, CVPS)

Background

Why CVP?

Background

Background

Total Area: 41,526 KM2 16,033 SQ ML Population: 16.926.367 people Density: 407.6/KM2 1,035,4/SQ ML Amsterdam

Hengelo NL

Hengelo

Background

26% of The Netherlands is below sea level 29% of The Netherlands is sensitive to river flood

Amsterdam

55% to manage

Hengelo NL

Hengelo

Background

This is were former “Stork Pompen” now came in. To keep the Netherlands dry

Amsterdam

Hengelo NL

Hengelo

Background

Dutch authorities demanded reliable and maintenance free pumps to secure the western part of the Netherlands from flooding Originated at Stork (Flowserve) in the Netherlands First installation 1929, Pumping Station Lely Currently over 275 pump installations worldwide

Concrete Volute Pump (CVP) Description

Introduction

Pump types CVPS Open impeller Head up to : 10 m

BSV Semi Enclosed Impeller Head up to: 15 m

BCV Enclosed impeller Head up to : 60 m

50 ft

33 ft Flow up to: 100.000 m3/h

Flow up to: 100.000 m3/h

440000 GPM

440000 GPM

197 ft Flow up to:

100.000 m3/h 440000 GPM

Introduction

Range chart

Design

CVP basic overview Electric motor

Gearbox Discharge pipe Pull out unit Concrete volute Concrete suction bell Formed suction intake

Design

Design features Pull-out unit Short, sturdy shaft Non clog impeller Easy inspection True pull-out design No intermediate shaft or bearing All bearings are anti-friction Maintenance free shaft seal

Design

Design features Pre-fabricated elements Simplified site installation No shuttering on site for pump volute and suction bell Reduced site installation time Guaranteed pump performance One civil contractor on site Formed suction intake with simple straight side walls

Comparison

VCT and CVP Vertical Circulator Deeper civil dig Higher speed Higher NPSHr Minimum submerge requirement

Pull out design is a considerable price adder Vibrations due to large motor support and long pump design

Concrete volute pump Minimum civil dig due to formed suction intake and civil integration Easy accessible for maintenance True pull out design Limited bearing span Concrete volute & Sturdy driver support eliminates vibrations issues

Comparison

VCT and CVP Vertical Circulator

Concrete volute pump

Maintenance interval 20.000 hrs

Maintenance interval 50.000 hrs

Spare part inventory required

No spare part inventory

High alloy steels in corrosive applications

Corrosion free concrete is main construction material Highest availability and reliability Responsibility from suction to discharge

Comparison

VCT and CVP The surface area of the pump component in contact with water will have direct consequences for the pump price and maintenance High alloy steel materials are much more expensive than concrete materials

red = wetted parts of the pump

Comparison

VCT and CVP Difference in building volume 30% (m3)

At similar pump impeller size (1300 mm)

CVP have 50% reduction on crane capacity compared to VCT

Difference in digging volume 30% (m3)

Comparison

VCT and CVP

Concrete Volute Pumps

Comparison

Concrete Volute Pumps versus Vertical Metal pump

Summary, Cost Comparison Concrete Volute pump versus Vertical metal pump Limited suction pit depth Limited building height Limited Crane capacity for pump Reduced installation time if prefabricated concrete elements are applied High efficiency (up to 2%) Virtual no spares Very low maintenance cost Longer life time (many exceed 50 years service life) Only a few metal parts in contact with water, so minimum corrosion / erosion

Comparison

Cast on site and Pre-fab Concrete Cast on site by wooden shuttering Engineering, production, on-site placement and responsibility of: Shuttering Embedded parts Reinforcement Pouring of Concrete

Concrete curing time Shuttering removal

Prefabricated Elements Off- site prefab production Single day prefab installation No interference with job site schedule Single Flowserve responsibility, limited interfaces Embedded parts included and aligned Blast furnace slag cement Guaranteed quality and high accuracy shape & dimensions

Comparison

Cast on site and Pre-fab

56 days installation time

2 days installation time

Comparison

Cast in-situ and Pre-fab Simplified site installation (pre-fab) No shuttering on site for pump volute and suction bell Reduced site installation time Guaranteed pump performance One civil contractor on site Formed suction intake with simple straight side walls

Benefit summary INTAKE SIDE

- No vortices - No dead water areas

PUMP CASING

- No corrosion or erosion - No maintenance - No vibration

IMPELLER

- Wide operating area

PUMP SHAFT

- No contact with pumped medium - No line shaft couplings + bushings

Added value

Mechanical design validation Natural frequency analysis Stress + deformation analysis Torsional frequency analysis Model system using: Mass moment of inertia Torsional stiffness's

Added value

Computational Fluid Dynamics Impeller / volute / bowl design Cavitation prediction Performance calculation Intakes Prevent vortices No dead water areas Create uniform flow to impeller Retrofit performance prediction

Added value

System engineering Layout & calculations

Added value

Testing

Pump model test - Guaranteed performance, witnessed by customer Intake test - Optimization of dimensions and performance Site performance test

Added value

Testing • Growth of cavitation sheet by decreasing inlet pressure • R&D with Universities, Flowserve proprietary software

Added value

Testing Cavitation sheets at NPSH pressure drop

Sheet cavitation

Sheet cavitation

Concrete Volute Pumps

Hydraulic knowledge

Prediction of sheet cavitation Knowledge and control over performance characteristics Optimization of dimensions and performance Prediction of impeller / pump life

CVP v5.0 © flowserve

Concrete Volute Pumps

Total cost of ownership

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Energy Costs 90%

Maintenance 3%

Initial Investment 7%

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Initial investment Pumping station Reduced building height & pit depth

CVP 30% less

Reduced crane capacity

CVP 50% less

Pumps Less high alloy steel Reduced pump quantity

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Maintenance cost Less frequent overhaul No spare part inventory Virtually no wear Controlled bearing conditions Practically maintenance free seal

No corrosion No need to disconnect piping for pull-out pump No need to pull pump to inspect impeller

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Energy cost CVP higher efficiency due to Pump specific speed selection No losses in riser tube No losses in discharge bend

Average CVP: + 2%

Evaluate Life Cycle Cost

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Savings Initial investment savings CVP 20% less

Maintenance cost savings MTBM 5 to 10 years Spare part inventory virtually zero

Energy cost savings (project example) ∆η= 1.6%, 20 years, 4920 kW, €0.05/kWh CVP € 1,440,000.- less

References

Customer voice

References

Reliability Pump Location Station 1 Barrowtown Pump Station

Country Canada

Number of Pumps 4

Years of Operation 29

Mechanical Pump Years of Failures Operation 0 116

2

Pump Station Westerkogge

The Netherlands

3

24

0

72

3 4 5

YC Harculo E6 Porvoo Works Neste of Finland

The Netherlands Finland Finland

2 1 1

32 26 23

0 0 0

64 26 23

6 7

Gemaal Wapenveld Oldersum

The Netherlands Finland

4 1

16 12

0 0

64 12

8 9

Emssperrwerk Borealis Polymers Oy

The Netherlands Finland

3 1

12 11

0 0

36 11

10

Gemaal Wortman

The Netherlands

4

60

0

240

11

Gemaal Lovink

The Netherlands

2

60

0

120

12

Gemaal Colijn

The Netherlands

3

60

0

180

13

Gemaal de Blocq van Kuffler The Netherlands

4

46

0

184

14

Gemaal Vissering

The Netherlands

1

23

0

23

15

Power Station Delesto II

The Netherlands

2

16

0

32

16

Essent Power Station Amer8 The Netherlands

3

35

0

105

17

Essent Power Station Amer9 The Netherlands Totals

2 41

21 506

1 1

42 1350

References

Projects Country: Project:

Germany Emssperrwerk

Scope: 3x BSV 225 3x BSV 260 total cap.: 100 m3/s at 3,6 m head In each pillar: Pump Coupling Gear unit E-motor

References

Projects Impression of dimensions

References

Projects

Conclusion

Summary True pull-out design with high efficiency and many references Smaller pumping station due to minimum civil dig and less crane height/capacity Prefabricated elements Off-site production, limited interfaces Single day installation Embedded parts included Guaranteed quality Lower Capex and Opex for seawater applications Flowserve can take responsibility from suction to discharge

Installation of CVP Movie

Example Plan View

CVP Pump Station Section Motor

Gear

Volute

FSI

CVP

Discharge

Thank you for your interest in our company

Agenda

Introduction Flowserve Concrete Volute Pump Comparison to VCT Benefits References Summary Installation movie

Flowserve

History The history of Flowserve goes back to the founding of Simpson & Dresser Pumps in 1790.

Flowserve •

Over 18000 employees

•

Operates in over 55 countries around the world

•

Serving customers in over 90 countries

Flowserve

Hengelo Founded in 1868 by Brothers Stork

Flowserve

Served Industries Petrochemical Refining Power Generation General Industry Irrigation & Drainage

Flowserve Hengelo Products

Service Contracts

Retrofits Replacements coping with existing boundary limits

History Flowserve Hengelo The Netherlands 1868

Founded as machine company Brothers Stork & Co. by C.T. Stork and C.C. Stork. Mainly manufacturing steam machines and boilers. Soon expanded with diesel engines, water turbines, pumps, etc.

1985

The several Stork departments became separate entities i.e. steam boilers, pumps, etc.

1997

Stork Engineered Pumps aquired by BW/IP International In June 1997 merging with Durco International. Company name is changed into

2000

Flowserve Corporation acquires Ingersoll-Dresser Pumps

Products

API diffuser pumps

OH2 (PHL)

OH3 (PVXM)

OH5 (PVML)

Horizontal, centerline-mounted, Vertical, in-line, single-stage Vertical Close-coupled, in-line, single-stage single-stage overhung pumps overhung pumps with overhung pumps separate bearing brackets

Products

VCT

AFV

CVP

Vertical Mixed Flow Circulating Pumps (VOA, VSO)

Axial Flow Vertical Pumps (VOP)

Concrete Volute Pumps (BSV, BCV, CVPS)

Background

Why CVP?

Background

Background

Total Area: 41,526 KM2 16,033 SQ ML Population: 16.926.367 people Density: 407.6/KM2 1,035,4/SQ ML Amsterdam

Hengelo NL

Hengelo

Background

26% of The Netherlands is below sea level 29% of The Netherlands is sensitive to river flood

Amsterdam

55% to manage

Hengelo NL

Hengelo

Background

This is were former “Stork Pompen” now came in. To keep the Netherlands dry

Amsterdam

Hengelo NL

Hengelo

Background

Dutch authorities demanded reliable and maintenance free pumps to secure the western part of the Netherlands from flooding Originated at Stork (Flowserve) in the Netherlands First installation 1929, Pumping Station Lely Currently over 275 pump installations worldwide

Concrete Volute Pump (CVP) Description

Introduction

Pump types CVPS Open impeller Head up to : 10 m

BSV Semi Enclosed Impeller Head up to: 15 m

BCV Enclosed impeller Head up to : 60 m

50 ft

33 ft Flow up to: 100.000 m3/h

Flow up to: 100.000 m3/h

440000 GPM

440000 GPM

197 ft Flow up to:

100.000 m3/h 440000 GPM

Introduction

Range chart

Design

CVP basic overview Electric motor

Gearbox Discharge pipe Pull out unit Concrete volute Concrete suction bell Formed suction intake

Design

Design features Pull-out unit Short, sturdy shaft Non clog impeller Easy inspection True pull-out design No intermediate shaft or bearing All bearings are anti-friction Maintenance free shaft seal

Design

Design features Pre-fabricated elements Simplified site installation No shuttering on site for pump volute and suction bell Reduced site installation time Guaranteed pump performance One civil contractor on site Formed suction intake with simple straight side walls

Comparison

VCT and CVP Vertical Circulator Deeper civil dig Higher speed Higher NPSHr Minimum submerge requirement

Pull out design is a considerable price adder Vibrations due to large motor support and long pump design

Concrete volute pump Minimum civil dig due to formed suction intake and civil integration Easy accessible for maintenance True pull out design Limited bearing span Concrete volute & Sturdy driver support eliminates vibrations issues

Comparison

VCT and CVP Vertical Circulator

Concrete volute pump

Maintenance interval 20.000 hrs

Maintenance interval 50.000 hrs

Spare part inventory required

No spare part inventory

High alloy steels in corrosive applications

Corrosion free concrete is main construction material Highest availability and reliability Responsibility from suction to discharge

Comparison

VCT and CVP The surface area of the pump component in contact with water will have direct consequences for the pump price and maintenance High alloy steel materials are much more expensive than concrete materials

red = wetted parts of the pump

Comparison

VCT and CVP Difference in building volume 30% (m3)

At similar pump impeller size (1300 mm)

CVP have 50% reduction on crane capacity compared to VCT

Difference in digging volume 30% (m3)

Comparison

VCT and CVP

Concrete Volute Pumps

Comparison

Concrete Volute Pumps versus Vertical Metal pump

Summary, Cost Comparison Concrete Volute pump versus Vertical metal pump Limited suction pit depth Limited building height Limited Crane capacity for pump Reduced installation time if prefabricated concrete elements are applied High efficiency (up to 2%) Virtual no spares Very low maintenance cost Longer life time (many exceed 50 years service life) Only a few metal parts in contact with water, so minimum corrosion / erosion

Comparison

Cast on site and Pre-fab Concrete Cast on site by wooden shuttering Engineering, production, on-site placement and responsibility of: Shuttering Embedded parts Reinforcement Pouring of Concrete

Concrete curing time Shuttering removal

Prefabricated Elements Off- site prefab production Single day prefab installation No interference with job site schedule Single Flowserve responsibility, limited interfaces Embedded parts included and aligned Blast furnace slag cement Guaranteed quality and high accuracy shape & dimensions

Comparison

Cast on site and Pre-fab

56 days installation time

2 days installation time

Comparison

Cast in-situ and Pre-fab Simplified site installation (pre-fab) No shuttering on site for pump volute and suction bell Reduced site installation time Guaranteed pump performance One civil contractor on site Formed suction intake with simple straight side walls

Benefit summary INTAKE SIDE

- No vortices - No dead water areas

PUMP CASING

- No corrosion or erosion - No maintenance - No vibration

IMPELLER

- Wide operating area

PUMP SHAFT

- No contact with pumped medium - No line shaft couplings + bushings

Added value

Mechanical design validation Natural frequency analysis Stress + deformation analysis Torsional frequency analysis Model system using: Mass moment of inertia Torsional stiffness's

Added value

Computational Fluid Dynamics Impeller / volute / bowl design Cavitation prediction Performance calculation Intakes Prevent vortices No dead water areas Create uniform flow to impeller Retrofit performance prediction

Added value

System engineering Layout & calculations

Added value

Testing

Pump model test - Guaranteed performance, witnessed by customer Intake test - Optimization of dimensions and performance Site performance test

Added value

Testing • Growth of cavitation sheet by decreasing inlet pressure • R&D with Universities, Flowserve proprietary software

Added value

Testing Cavitation sheets at NPSH pressure drop

Sheet cavitation

Sheet cavitation

Concrete Volute Pumps

Hydraulic knowledge

Prediction of sheet cavitation Knowledge and control over performance characteristics Optimization of dimensions and performance Prediction of impeller / pump life

CVP v5.0 © flowserve

Concrete Volute Pumps

Total cost of ownership

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Energy Costs 90%

Maintenance 3%

Initial Investment 7%

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Initial investment Pumping station Reduced building height & pit depth

CVP 30% less

Reduced crane capacity

CVP 50% less

Pumps Less high alloy steel Reduced pump quantity

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Maintenance cost Less frequent overhaul No spare part inventory Virtually no wear Controlled bearing conditions Practically maintenance free seal

No corrosion No need to disconnect piping for pull-out pump No need to pull pump to inspect impeller

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Energy cost CVP higher efficiency due to Pump specific speed selection No losses in riser tube No losses in discharge bend

Average CVP: + 2%

Evaluate Life Cycle Cost

Concrete Volute Pumps •

20 year period

•

30.000 m3/h at 11 m

•

Seawater application

Evaluate Life Cycle Cost

Savings Initial investment savings CVP 20% less

Maintenance cost savings MTBM 5 to 10 years Spare part inventory virtually zero

Energy cost savings (project example) ∆η= 1.6%, 20 years, 4920 kW, €0.05/kWh CVP € 1,440,000.- less

References

Customer voice

References

Reliability Pump Location Station 1 Barrowtown Pump Station

Country Canada

Number of Pumps 4

Years of Operation 29

Mechanical Pump Years of Failures Operation 0 116

2

Pump Station Westerkogge

The Netherlands

3

24

0

72

3 4 5

YC Harculo E6 Porvoo Works Neste of Finland

The Netherlands Finland Finland

2 1 1

32 26 23

0 0 0

64 26 23

6 7

Gemaal Wapenveld Oldersum

The Netherlands Finland

4 1

16 12

0 0

64 12

8 9

Emssperrwerk Borealis Polymers Oy

The Netherlands Finland

3 1

12 11

0 0

36 11

10

Gemaal Wortman

The Netherlands

4

60

0

240

11

Gemaal Lovink

The Netherlands

2

60

0

120

12

Gemaal Colijn

The Netherlands

3

60

0

180

13

Gemaal de Blocq van Kuffler The Netherlands

4

46

0

184

14

Gemaal Vissering

The Netherlands

1

23

0

23

15

Power Station Delesto II

The Netherlands

2

16

0

32

16

Essent Power Station Amer8 The Netherlands

3

35

0

105

17

Essent Power Station Amer9 The Netherlands Totals

2 41

21 506

1 1

42 1350

References

Projects Country: Project:

Germany Emssperrwerk

Scope: 3x BSV 225 3x BSV 260 total cap.: 100 m3/s at 3,6 m head In each pillar: Pump Coupling Gear unit E-motor

References

Projects Impression of dimensions

References

Projects

Conclusion

Summary True pull-out design with high efficiency and many references Smaller pumping station due to minimum civil dig and less crane height/capacity Prefabricated elements Off-site production, limited interfaces Single day installation Embedded parts included Guaranteed quality Lower Capex and Opex for seawater applications Flowserve can take responsibility from suction to discharge

Installation of CVP Movie

Example Plan View

CVP Pump Station Section Motor

Gear

Volute

FSI

CVP

Discharge

Thank you for your interest in our company

Related Documents

Concrete Volute Pump Presentation,2015-08

January 2021 0

Cara Kerja Concrete Pump

March 2021 0

Concrete Durability

January 2021 1

Pump Maintenance

January 2021 2

Komatsu Pump

March 2021 0

Pump Fundamentals

March 2021 0More Documents from "kashifwarsi"

Concrete Volute Pump Presentation,2015-08

January 2021 0

Riscuri Climatice Extreme

January 2021 2

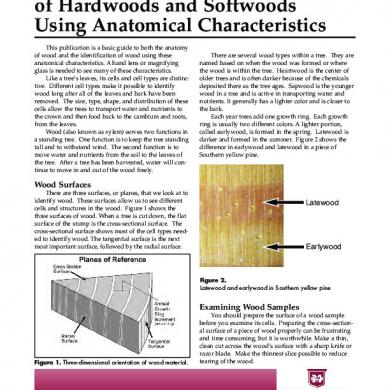

Basic Guide To Wood Id Of Soft And Hard Woods

January 2021 2

Pipeline Report S1198-01 Final 110303

February 2021 3

Surat Lamaran Kerja

January 2021 1